This document is an excerpt from the EUR-Lex website

Document 01991R1538-20060323

Commission Regulation (EEC) No 1538/91 of 5 June 1991 introducing detailed rules for implementing Regulation (EEC) No 1906/90 on certain marketing standards for poultrymeat

Consolidated text: Commission Regulation (EEC) No 1538/91 of 5 June 1991 introducing detailed rules for implementing Regulation (EEC) No 1906/90 on certain marketing standards for poultrymeat

Commission Regulation (EEC) No 1538/91 of 5 June 1991 introducing detailed rules for implementing Regulation (EEC) No 1906/90 on certain marketing standards for poultrymeat

No longer in force

No longer in force

- Date of document:

- 23/03/2006

- Date of effect:

- 23/03/2006

- Author:

- Европейска комисия

- Form:

- Консолидиран текст

- Additional information:

- LASTMODIN 32006R0433

- Link

- Link

- Link

- Select all documents mentioning this document

- Consolidation: basic act:

- 31991R1538

1991R1538 — EN — 23.03.2006 — 007.001

This document is meant purely as a documentation tool and the institutions do not assume any liability for its contents

|

COMMISSION REGULATION (EEC) No 1538/91 of 5 June 1991 introducing detailed rules for implementing Regulation (EEC) No 1906/90 on certain ►C1 marketing standards for poultrymeat ◄ (OJ L 143, 7.6.1991, p.11) |

Amended by:

|

|

|

Official Journal |

||

|

No |

page |

date |

||

|

L 284 |

26 |

12.10.1991 |

||

|

L 34 |

23 |

11.2.1992 |

||

|

L 198 |

31 |

17.7.1992 |

||

|

L 263 |

12 |

22.10.1993 |

||

|

L 112 |

32 |

3.5.1994 |

||

|

L 338 |

48 |

28.12.1994 |

||

|

L 244 |

60 |

12.10.1995 |

||

|

L 27 |

6 |

3.2.1996 |

||

|

L 134 |

9 |

5.6.1996 |

||

|

L 119 |

21 |

20.5.2000 |

||

|

L 194 |

17 |

23.7.2002 |

||

|

L 231 |

3 |

30.6.2004 |

||

|

L 14 |

8 |

19.1.2006 |

||

|

L 79 |

16 |

16.3.2006 |

||

Corrected by:

|

NB: This consolidated version contains references to the European unit of accout and/or the ecu, which from 1 January 1999 should be understood as references to the euro — Council Regulation (EEC) No 3308/80 (OJ L 345, 20.12.1980, p. 1) and Coundil Regulation (EC) No 1103/97 (OJ L 162, 19.6.1997, p. 1). |

COMMISSION REGULATION (EEC) No 1538/91

of 5 June 1991

introducing detailed rules for implementing Regulation (EEC) No 1906/90 on certain ►C1 marketing standards for poultrymeat ◄

THE COMMISSION OF THE EUROPEAN COMMUNITIES,

Having regard to the Treaty establishing the European Economic Community,

Having regard to Council Regulation (EEC) No 1906/90 of 26 June 1990 on certain ►C1 marketing standards for poultrymeat ◄ ( 1 ), and in particular Article 9 thereof,

Whereas Regulation (EEC) No 1906/90 enacted certain ►C1 marketing standards for poultrymeat ◄ , the application of which requires the adoption of provisions concerning in particular the list of those poultry carcases, parts thereof and offals to which the said Regulation applies, classification by conformation, appearance an weight, types of presentation, the indication of the name under which the products in question are to be sold, the optional use of indications concerning chilling methods and the type of farming, conditions for storage and transport of certain types of poultrymeat and the supervision of these provisions in order to ensure their uniform application throughout the Community;

Whereas, in order to provide for the marketing of poultry in different classes according to conformation and appearance, it is necessary to lay down definitions relating to species, age and presentation in the case of carcases, and anatomical conformation and content in the case of poultry cuts; whereas in the case of the product known as ‘Foie gras’ the high value and consequent risk of fraudulent practices make it necessary to lay down especially precise minimum marketing standards;

Whereas it is not necessary for these standards to be applied to certain products and presentations which are of local or otherwise limited importance; whereas, however, names under which such products are sold should not be likely to mislead the consumer to a material degree by causing him to confuse these products with products which are subject to these provisions; whereas, similarly, additional descriptive terms used to qualify the names of such products should also be subject to this provision;

Whereas storage and handling temperature is of crucial importance to the maintenance of high standards of quality; whereas, therefore, it is appropriate to lay down a minimum temperature at which forzen poultrymeat products are to be kept;

Whereas the provisions of this Regulation and in particular those relating to surveillance and enforcement must be applied uniformly throughout the Community; whereas detailed rules adopted to those ends must also be uniform; whereas it is therefore necessary to lay down common measures in the matter of sampling procedures and tolerances;

Whereas it is necessary, both in order that the consumer be provided with sufficient, unequivocal and objective information concerning such products offered for sale, and in order to secure the free movement of such products throughout the Community, to ensure that poultrymeat marketing standards take into account as far as is paracticable (SIC! practicable) the provisions of Council Directive 76/211/EEC of 20 January 1976 on the approximation of the laws of the Member States relating to the making-up by weight or by volume of certain prepackaged products ( 2 ), as amended by Directive 78/891/EEC ( 3 );

Whereas among the indications which may optionally be ued on the labelling are those concerning the method of chilling and particular types of farming; whereas the use of the latter, in the interest of consumer protection, needs to be subordinated to the respect of closely-defined criteria concerning both husbandry conditions and quantity thresholds for stating certain criteria such as age at slaughter or length of fattening period and content of certain foodstuff ingredients;

Whereas it is appropriate for the Commission to exercise permanent surveillance of the compatibility with Community law, including the marketing standards, in particular of any national measures adopted in pursuance of these provisions; whereas particular provision should also be made for the registration and regular inspection of undertakings authorized to use terms referring to particular types of farming; whereas such undertakings must therefore be obliged to maintain regular and detailed records for this purpose;

Whereas, in view of the specialized nature of these inspections, responsibility for them may be delegated by the competent authorities of the Member State concerned, subject to the appropriate supervision and safeguards, to properly qualified and duly licensed outside bodies;

Whereas operators in third countries may wish to make use of optional indications concerning chilling methods and types of farming; whereas provision should be made for them to do so, subject to appropriate certification by the competent authority of the third country concerned, and which appears on a list established by the Commission;

Whereas the measures provided for in this Regulation are in accordance with the opinion of the Management Committe for Poultrymeat and Eggs,

HAS ADOPTED THIS REGULATION:

Article 1

The products referred to in Article 1 (2) of Regulation (EEC) No 1906/90 are hereby defined as follows:

1. Poultry carcases

(a) DOMESTIC FOWL (Gallus domesticus)

— chicken, broiler: fowl in which the tip of the sternum is flexible (not ossified),

— cock, hen, casserole or boiling fowl: fowl in which the tip of the sternum is rigid (ossified),

— capon: male fowl castrated surgically before reaching sexual maturity and slaughtered at a minimum age of 140 days: after castration the capons must be fattened for at least 77 days,

— poussin, coquelet: chicken of less than 650 g carcase weight (expressed without giblets, head and feet), chicken of 650 g to 750 g may be called ‘poussin’ if the age at slaughter does not exceed 28 days. Member States may apply Article 11 for the checking of this slaughter age;

— young cock: male chicken of laying strains in which the tip of sternum is rigid but not completely ossified and for which the age at slaughter is at least 90 days;

(b) TURKEYS (Meleagris gallopavo dom.)

— (young) turkey: bird in which the tip of the sternum is flexible (not ossified),

— turkey: bird in which the tip of the sternum is rigid (ossified);

(c) DUCKS (Anas platyrhynchos dom., cairina muschata), Mulard ducks (c.m.x.a.p.),

— young duck or duckling, (young) Muscovy duck, (young) Mulard duck: bird in which the tip of the sternum is flexible (not ossified),

— duck, Muscovy duck, Mulard duck: bird in which the tip of the sternum is rigid (ossified);

(d) GEESE (Anser anser dom.)

— (young) goose or gosling: bird in which the tip of the sternum is flexible (not ossified). The fat layer all over the carcase is thin or moderate; the fat of the young goose may have a colour indicative of a special diet,

— goose: bird in which the tip of the sternum is rigid (ossified); a moderate to thick fat layer is present all over the carcase;

(e) GUINEA FOWL (Numida meleagris domesticus)

— (young) guinea fowl: bird in which the tip of the sternum is flexible (not ossified),

— guinea fowl: bird in which the tip of the sternum is rigid (ossified).

For the purpose of this Regulation, variants of the above terms relating to sex shall be construed as equivalent.

2. Poultry cuts

(a) Half: half of the carcase, obtrained by a longitudinal cut in a plane along the sternum and the backbone;

(b) Quarter: leg quarter or breast quarter, obtained by a transversal cut of a half;

(c) Unseparated leg quarters: both leg quarters united by a portion of the back, with or without the rump;

(d) Breast: the sternum and the ribs, or part thereof, distributed on both sides of its, together with the surrounding musculature. The breast may be presented as a whole or a half;

(e) Leg: the femur, tibia and fibula together with the surrounding musculature. The two cuts shall be made at the joints;

(f) Chicken leg with a portion of the back: the weight of the back does not exceed 25 % of that of the whole cut;

(g) Thigh: the femur together with the surrounding muscultature. The two cuts shall be made at the joints;

(h) Drumstick: the tibia and fibula together with the surrounding musculature. The two cuts shall be made at the joints;

(i) Wing: the humerus, radius, and ulna, together with the surrounding musculature. In the case of turkey wings, humerus or radius/ulna together with the surrounding musculature may be presented separately. The tip, including the carpal bones, may or may not have been removed. The cuts shall be made at the joints;

(j) Unseparated wings: both wings united by a portion of the back, where the weight of the latter does not exceed 45 % of that of the whole cut;

(k) Breast fillet: the whole or half of the breast deboned, i.e. without sternum and ribs. In the case of turkey breast, the fillet may comprise the deep pectoral muscle only;

(l) Breast fillet with wishbone: the breast fillet without skin with the clavicle and the cartilagenous point of the sternum only, the weight of clavicle and cartilage not to exceed 3 % of that of the cut;

(m) Magret, maigret: breast fillet of ducks and geese referred to in 3 comprising skin and sub-cutan fat covering the breast muscle, without the deep pectoral muscle;

(n) Deboned turkey leg meat: turkey thighs and/or drumsticks, deboned, i.e. without femur, tibia and fibula, whole, diced or cut into strips.

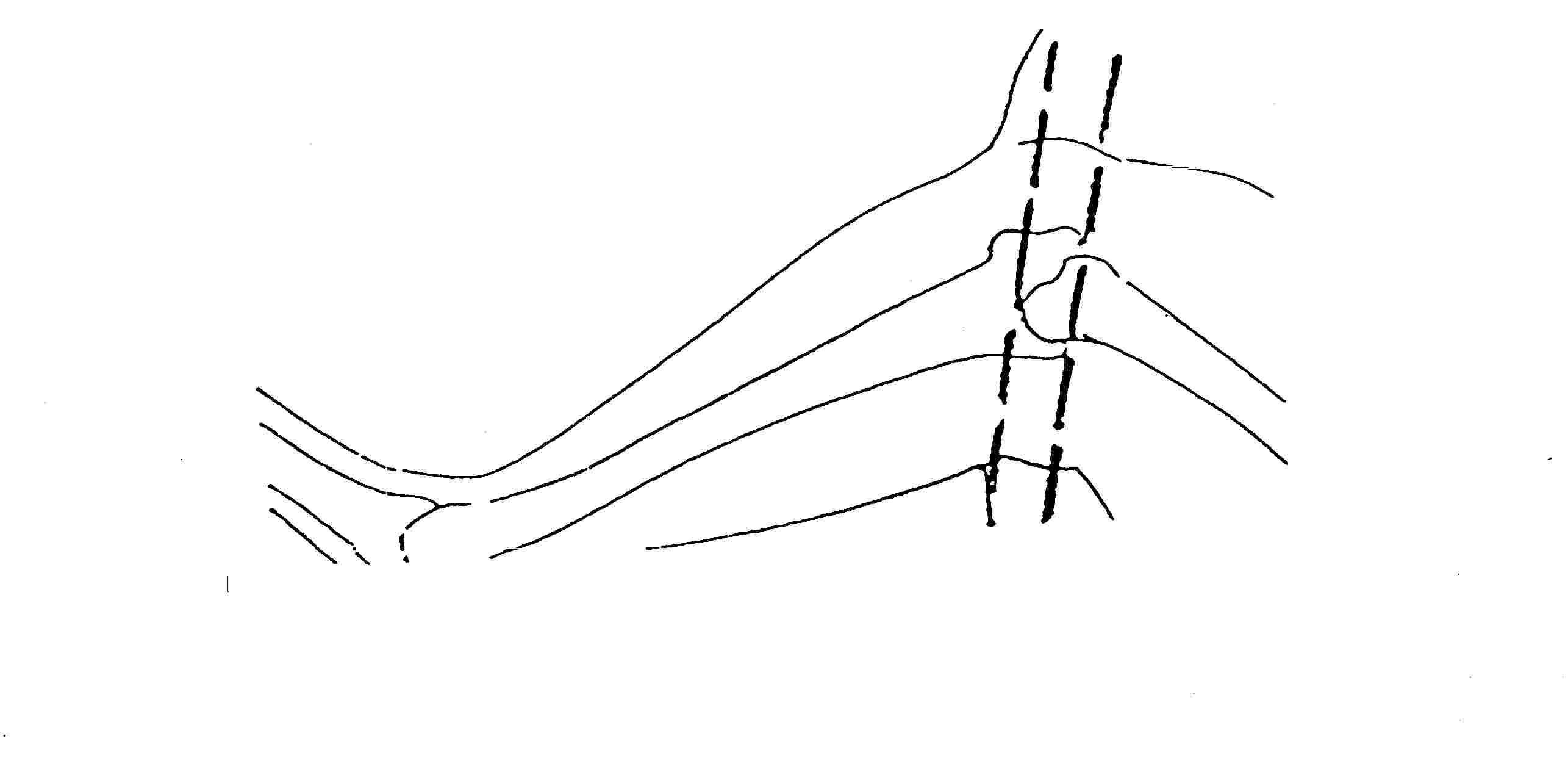

For the products listed under (e), (g) and (h) the wording ‘cuts shall be made at the joints’ is to mean cuts made within the two lines deliminating the joints as shown in the graphical presentation in Annex Ia.

Until 31 December 1991, in the case of products listed under (e), (g) and (h) the two cuts may be made near the joints.

Products listed under (d) to (k) may be presented with or without skin. The absence of the skin in the case of products listed under (d) to (j) or the presence of the skin in the case of the product listed under (k) shall be mentioned on the labelling within the meaning of Article 1 (3) (a) of Council ►M12 Directive 2000/13/EC ◄ ( 4 ).

3. Foie gras:

the livers of geese, or of ducks of the species cairina muschata or c.m. × Anas platyrachos which have been fed in such a way as to produce hepatic fatty cellular hypertrophy.

The birds from which such livers are removed shall have been completely bled, and the livers be of a uniform colour.

The livers shall be of the following weight:

— duck livers shall weigh at least 300 g net,

— goose livers shall weigh at least 400 g net.

Article 1 a

For the purposes of this Regulation:

‘marketing’ means holding or displaying for sale, offering for sale, selling, delivery or any other form of marketing;

‘batch’ means poultrymeat of the same species and type, the same class, the same production run, from the same slaughterhouse or cutting plant, situated in the same place, which are to be inspected. For the purposes of Article 8 and Annexes V and VI, a batch shall only comprise prepackages of the same nominal weight category.

Article 2

1. Poultry carcases shall, in order to be marketed in accordance with this Regulation, be presented for sale in one of the following forms:

— partially eviscerated (‘effilé’, ‘roped’),

— with giblets,

— without giblets.

The word ‘eviscerated’ may be added.

2. Partially eviscerated carcases are carcases from which the heart, liver, lungs, gizzard, crop, and kidneys have not been removed.

3. For all carcase presentations, if the head is not removed, trachea, oesophagus and crop may remain in the carcase.

4. Giblets shall comprise only the following:

The heart, neck, gizzard and liver, and all other parts considered as edible by the market on which the product is intended for final consumption. Livers shall be without gall bladders. The gizzard shall be without the horned membrane, and the contents of the gizzard shall have been removed. The heart may be with or without the pericardial sac. If the neck remains attached to the carcase, it is not considered as one of the giblets.

Where one of these four organs is customarily not included with the carcase for sale, its absence shall be mentioned on the labelling.

Article 3

1. The names under which the products covered by this Regulation are sold, within the meaning of Article 3 (1) (1) of Directive 79/112/EEC, shall be those enumerated in Article 1 and the corresponding terms in the other Community languages listed in Annex I qualified in the case

— of whole carcases by reference to one of the forms of presentation as laid down in Article 2 (1),

— of poultry cuts, by reference to the respective species.

2. The names defined in Article 1 (1) and (2) may be supplemented by other terms provided that the latter do not mislead the consumer to a material degree and in particular such as would lead to confusion with other products listed in Article 1 (1) and (2) or with indications provided for in Article 10.

Article 4

Products other than those defined in Article 1 may be marketed in the Community only under names which do not mislead the consumer to a material degree by allowing confusion with those referred to in Article 1 or with indications provided for in Article 10.

Article 5

The following additional provisions shall apply to frozen poultrymeat as defined in Article 2 (6) of Regulation (EEC) No 1906/90:

The temperature of frozen poultrymeat concerned by this Regulation must be stable and maintained, at all points in the product, at −12 °C or lower, with possibly brief upward fluctuations of no more than 3 °C. These tolerances in the temperature of the product shall be permitted in accordance with good storage and sitribution practice during local distribution and in retail display cabinets.

Article 6

1. Poultry carcases and cuts covered by this Regulation shall meet the following minimum requirements in order to be graded into classes A and B:

— intact, taking into account the presentation,

— clean, free from any visible foreign matter, dirt or blood,

— free of any foreign smell,

— free of visible bloodstains except those which are small and unobtrusive,

— free of produtruding broken bones,

— free of severe contusions.

In the case of fresh poultry, there shall be no traces of prior freezing.

2. In order to be graded as class A, poultry carcases and cuts shall in addition satisfy the following criteria:

— they shall be of good conformation. The flesh shall be plump; the breast well developed, broad, long and fleshy, and the legs shall be fleshy. On chickens, young ducks or ducklings and turkeys there shall be a thin regular layer of fat on the breast, back und thighs. On cocks, hens, ducks and young geese a thicker layer of fat is permissible. On geese a moderate to thick fat layer shall be present all over the carcass,

— a few small feathers, stubs (quill ends) and hairs (filoplumes) may be present on the breast, legs, rump, footjoints and wing tips. In the case of boiling fowl, ducks, turkeys and geese a few may also be present on other parts,

— some damage, contusion and discoloration is permitted provided that it is small and unobtrusive, and not present on the breast or legs. The wing tip may be missing. A slight redness is permissible in wing tips and follicies,

— in the case of frozen or quick-frozen poultry there shall be no traces of freezer-burn ( 5 ) except those that are indidental, small and unobtrusive and not present on the breast or legs.

Article 7

1. Decisions arising from failure to comply with Articles 1, 2 and 6 may only be taken for the whole of the batch which has been checked in accordance with the provisions of this Article.

▼M4 —————

3. A sample consisting of the following numbers of individual products as defined in Article 1 shall be drawn at random from each batch to be inspected in slaughterhouses, cutting plants, wholesale and retail warehouses or in the case of imports from third countries at the time of customs clearance:

|

Batch size |

Sample size |

Tolerable number of defective units |

|

|

Total |

For Article 1 (1), 3, and 6 (1) |

||

|

1 |

2 |

3 |

4 |

|

100 - 500 |

30 |

5 |

2 |

|

501 - 3 200 |

50 |

7 |

3 |

|

> 3 200 |

80 |

10 |

4 |

|

(1) Tolerance within each species, not from one species to another. |

|||

4. In the checking of a batch of class A poultrymeat, the total tolerable number of detective units referred to in column 3 of the table of paragraph 3 is allowed. These defective units may also comprise, in the case of breast fillet, fillets with up to 2 % in weight of cartilage (flexible tip of sternum).

However, the number of defective units not complying with the provisions of points 1 and 3 of provisions of Article 1 (1) and (3) as well as Article 6 (1) shall not exceed the figures shown in column 4 of the table contained in paragraph 3.

As regards point 3 of Article 1 (3), any defective unit shall not be considered tolerable unless it be of a weight of at least 240 g in the case of duck livers and of at least 385 g in the case of goose livers.

5. In the checking of a batch of class B poultrymeat, the tolerable number of defective units shall be doubled.

6. Where the checked batch is not deemed to comply, the supervising agency shall prohibit its marketing or import if the batch comes from a third country, unless and until proof is forthcoming that it has been made to comply with Articles 1 and 6.

Article 8

1. Prepackaged frozen or quick frozen poultrymeat may be classified by weight category in accordance with Article 3 (3) of Regulation (EEC) No 1906/90 in prepackages within the meaning of Article 2 of Directive 76/211/EEC.

These prepackages may be:

— prepackages containing one poultry carcase, or

— prepackages containing one or several poultry cuts of the same type and species,

as defined in Article 1.

2. All prepackages shall in accordance with paragraphs 3 and 4 bear an indication of the weight of the product known as ‘nominal weight’ which they are required to contain.

3. Prepackages of frozen or quick-frozen poultrymeat may by classified by categories of nominal weights as follows:

— carcases:

—— <1 100 g: classes of 50 g (1 050 — 1 000 — 950 etc.),

— 1 100- < 2 400 g: classes of 100 g (1 100 - 1 200 - 1 300 etc. ),

— ≥ 2 400 g: classes of 200 g (2 400 - 2 600 - 2 800 etc.),

— cuts:

—— <1 100 g: classes of 50 g (1 050 - 1 000 - 950 etc.),

— ≥ 1 100 g: classes of 100 g (1 100 - 1 200 - 1 300 etc.).

4. Prepackages referred to in paragraph 1 shall be made up in such a way that they satisfy the following requirements:

— the actual contents shall not be less, on average, than the nominal weight,

— the proportion of prepackages having a negative error greater than the tolerable negative error laid down in paragraph 9 shall be sufficiently small for batches of prepackages to satisfy the requirements of the tests specified in paragraph 10,

— no prepackage having a negative error greater than twice the tolerable negative error given in paragraph 9 shall be marketed.

The definitions of nominal weight, actual content and negative error laid down in Annex I to Directive 76/211/EEC shall apply to this Regulation.

5. Regarding responsibility of the packer or importer of frozen or quick-frozen poultrymeat and checks to be carried out by competent authorities, points 4,5 and 6 of Annex I to Directive 76/211/EEC apply mutatis mutandis.

6. The checking of prepackages shall be carried out by sampling and shall be in two parts:

— a check covering the actual content of each prepackage in the sample,

— a check on the average actual contents of the prepackages in the sample.

A batch of prepackages shall be considered acceptable if the results of both these checks satisfy the acceptance criteria referred to in paragraphs 10 and 11.

7. A batch shall be made up of all the prepackages of the same nominal weight, the same type and the same production rund, packed in the same place, which are to be inspected.

The batch size shall be limited to the quantities laid down below:

— when prepackages are checked at the end of the packing line, the number in each batch shall be equal to the maximum hourly output of the packing line, without any restriction as to batch size,

— in other cases the batch size shall be limited to 10 000.

8. A sample consisting of the following numbers of prepackages shall be drawn at random from each batch to be inspected:

|

Batch size |

Sample size |

|

100 to 500 |

30 |

|

501 to 3 200 |

50 |

|

> 3 200 |

80 |

For batches of fewer than 100 prepackages, the non-destructive test, within the meaning of Annex II to Directive 76/211/EEC, where carried out, shall be 100 %.

9. In the case of prepackaged poultrymeat the following tolerable negative errors are permitted:

|

(g) |

||||

|

Nominal weight, g |

Tolerable negative error, g |

|||

|

carcases |

cuts |

|||

|

< less than 1 000 |

25 |

25 |

||

|

1 100 < 2 400 |

50 |

|

||

|

2 400 and more |

100 |

|||

10. For the checking of the actual content of each prepackage in the sample, the minimum acceptable content shall be calculated by subtracting the tolerable negative error for the contents concerned from the nominal weight of the prepackage.

The prepackages in the sample whose actual contents are less than the minimum acceptable content shall be considered defective.

The batch of prepackages, checked shall be considered acceptable or rejected, if the number of defective units found in the sample is less than or equal to the acceptance criterion or equal to or greater than the criterion for rejection shown below:

|

Number in sample |

Number of defective units |

|

|

Acceptance criterion |

Rejection criterion |

|

|

30 |

2 |

3 |

|

50 |

3 |

4 |

|

80 |

5 |

6 |

11. For the checking of the average actual contents, a batch of prepackages shall be considered acceptable, if the average actual content of the prepackages forming the sample is greater than the acceptance criterion shown below:

|

Sample size |

Acceptance criterion for average actual content |

|

30 |

|

|

50 |

|

|

80 |

|

![]()

= average actual content of prepackages,

Qn = nominal quantity of the prepackage,

s = standard deviation of the actual contents of the prepackages in the batch.

The standard deviation shall be estimated as set out under point 2.3.2.2. of Annex II to Directive 76/211/EEC.

12. For so long as Directive 80/181/EEC authorizes the use of supplementary indications, the indication of the nominal weight of prepackages to which this Article applies may be accompanied by a supplementary indication.

13. As an alternative to making use of the provisions of paragraphs 2 to 12, operators may market in the United Kingdom until 31 December 1994 prepackages referred to in this Article which are lawfully marked in accordance with national legislation with the nominal weights expressed in imperial units.

In respect of poultrymeat coming into the United Kingdom from other Member States and complying with the provisions of the preceding subparagraph, checks shall be carried out on a random basis and shall not be made at the border.

Article 9

An indication of the use of one of the methods of chilling defined hereafter and the corresponding terms in the other Community languages listed in Annex II may appear on the labelling within the meaning of Article 1 (3) (a) of ►M12 Directive 2000/13/EC ◄ :

|

—air chilling: |

chilling of poultry carcases in cold air, |

|

air-spray chilling: |

chilling of poultry carcases in cold air interspersed with waterhaze or fine water spray, |

|

immersion chilling: |

chilling of poultry carcases in tanks of water or of ice and water, in accordance with the counterflow process as defined in Council Directive 71/118/EEC ( 6 )., Annex I, Chapter V, points 28 (a) and (b). |

Article 10

1. In order to indicate types of farming with the exception of organic or biological farming, no other terms except those set out hereunder and the corresponding terms in the other Community languages listed in Annex III may appear on the labelling within the meaning of Article 1 (3) (a) of ►M12 Directive 2000/13/EC ◄ , and in any case they may appear only if the relevant conditions specified in Annex IV are fulfilled:

(a) ‘Fed with … % of …’

(b) ‘Extensive indoor’ (‘Barn reared’)

(c) ‘Free range’

(d) ‘Traditional free range’

(e) ‘Free range — total freedom’.

These terms may be supplemented by indications referring to the particular characteristics of the respective types of farming.

When free-range production (points c, d and e) is indicated on the label for meat coming from ducks and geese kept for the production of ‘foie gras’, the term ‘from foie gras production’ shall also be indicated.

2. Mention of the age at slaughter of length of fattening period shall be permitted only when use is made of one of the terms referred to in paragraph 1 and for an age of not less than that indicated in Annex IV (b), (c) or (d). However, this provisions does not apply in the case of animals falling within the fourth indent of point 1 (a) of Article 1.

3. These provisions shall apply without prejudice to national technical measures going beyond the minimum requirements given in Annex IV, which are applicable only to producers of the Member State concerned, provided that they are compatible with Community law and are in conformity with the common marketing standards for poultrymeat.

4. The national measures referred to in paragraph 3 shall be communicated to the Commission.

5. At any time and at the request of the Commission, Member States shall provide all the information necessary for assessing the compatibility of the measures reffered to in this Article with Community law and their conformity with the common marketing standards for poultrymeat.

Article 11

1. Slaughterhouses authorized to use the terms reffered (SIC! referred) to in Article 10 shall be subject to special registration. They shall keep a separate record, by type of farming:

— of the names and addresses of the producers of such birds, who shall be registered following an inspection by the competent authority of the Member State,

— at the request of this authority the number of birds kept by each producer per turnround,

— of the number and total live or carcasse weight of such birds delivered and processed,

— of details of sales including names and addresses of purchasers for a minimum of 6 months following dispatch.

2. The said producers shall subsequently be inspected regularly. They shall keep current records, for a minimum of six months following dispatch, of the number of birds by type of poultry system showing also the number of birds sold and the names and addresses of the purchasers and quantities and source of feed supply.

In addition producers using free-range systems shall also keep records of the date when birds were first given access to range.

2a. Feed manufacturers and suppliers shall keep records for at least six months after dispatch showing that the composition of the feed supplied to the producers referred to in Article 10(1)(a) complies with the indications given about feeding.

2b. Hatcheries shall keep records of birds of the strains recognised as slow growing supplied to the producers referred to in Article 10(1)(d) and (e) for at least six months after dispatch.

3. Regular inspections regarding compliance with Articles 10 and 11 shall be carried out at the

— farm: at least once per turnround,

— feed manufacturer and supplier: at least once a year,

— slaughterhouse: at least four times per year,

— hatchery: at least once per year for the types of farming referred to in Article 10 (1) (d) and (e).

4. Each Member State shall provide the other Member States and the Commission before 1 July 1991 with a list of the approved slaughterhouse registered according to paragraph 1, showing the name and address and the number allotted to each of them. Any alteration of that list shall be communicated at the beginning of each quarter of the calender year to the other Member States and the Commission.

Article 12

In the case of supervision of the indication of the type of farming used as referred to in Article 5 (6), second paragraph of Regulation (EEC) No 1906/90 bodies designated by the Member States shall comply with the criteria set out in European Norm No En/45011 of 26 June 1989, and as such shall be licensed and supervised by the competent authorities of the Member State concerned.

Article 13

Poultrymeat imported from third countries may bear one or more of the optional indications provided for in Articles 9 or 10 if it is accompanied by a certificate issued by the competent authority of the country of origin attesting to the compliance of the products in question with the relevant provisions of this Regulation.

On request from a third country to the Commission, a list of such authorities shall be established by the Commission.

▼M12 —————

Article 14a

1. Without prejudice to paragraphs 6 and 10, frozen and quick-frozen chickens may be marketed by way of business or trade within the Community only if the water content does not exceed the technically unavoidable values determined by the method of analysis described in Annex V (drip method) or that in VI (chemical method).

2. The competent authorities designated by each Member State shall ensure that the slaughterhouses adopt all measures necessary to comply with the provisions of paragraph 1 and in particular that:

— samples for monitoring water absorption during chilling and water content of frozen and quick-frozen chickens are taken,

— results of the checks are recorded and kept for a period of one year,

— each batch is marked in such a way that its date of production can be identified; this batch mark must appear on the production record.

3. Regular checks in accordance with Annex VII on the water absorbed or checks in accordance with Annex V shall be carried out in the slaughterhouses at least once each working period of ►M11 eight ◄ hours.

Where these checks reveal that the amount of water absorbed is greater than the total water content permitted under the terms of this Regulation, account being taken of the water absorbed by the carcases during the stages of processing which are not subject to checking, and where, in any case, the amount of water absorbed is greater than the levels referred to in point 9 of Annex VII, or in point 7 of Annex V, the necessary technical adjustments shall be made immediately by the slaughterhouse to the process.

4. In all cases referred to in the second subparagraph of paragraph 3 and in any case at least once ►M8 every two months, ◄ checks on water content referred to in paragraph 1 shall be carried out, by sampling, on frozen and quick frozen chickens from each slaughterhouse according to Annexes V or VI, to be chosen by the competent authority of the Member State. These checks shall not be conducted for carcases in respect of which proof is provided to the satisfaction of the competent authority that they are intended exclusively for export.

5. The checks referred to in paragraphs 3 and 4 shall be carried out by or under the responsibility of the competent authorities. The competent authorities may, in specific cases, apply the provisions of paragraph 3, and in particular of points 1 and 9 of Annex VII, and of paragraph 4 more stringently in respect of a given slaughterhouse, where this proves necessary to ensure compliance with the total water content permitted under this Regulation.

They shall in all cases, where a batch of frozen or quick-frozen chickens was deemed not to comply with this Regulation, resume testing at the minimum frequency of checks referred to in paragraph 4 only after three successive checks according to Annexes V or VI, to be carried out by sampling from three different days of production within a maximum of four weeks, have shown negative results. The costs for these check shall be paid by the slaughterhouse concerned.

5a. Where, in the case of air chilling, the results of checks referred to in paragraphs 3 and 4 show compliance with the criteria laid down in Annexes V to VII during a period of six months, the frequency of the checks referred to in paragraph 3 may be reduced to once every month. Any failure to comply with the criteria laid down in these Annexes shall result in reinstatement of checks as referred to in paragraph 3.

6. If the result of the checks referred to in paragraph 4 is in excess of the admissible limits, the batch concerned shall be deemed not to comply with this Regulation. In that event, however, the slaughterhouse concerned may request that a counter-analysis be carried out in the reference laboratory of the Member State, using a method to be chosen by the competent authority of the Member State. The costs of this counter-analysis shall be borne by the holder of the batch.

7. Where, if necessary after such counter-analysis, the batch in question is deemed not to comply with this Regulation, the competent authority shall take the appropriate measures aimed at allowing such a batch to be marketed within the Community only on condition such a batch to be marketed within the Community only on condition that both individual and bulk packaging of the carcases concerned shall be marked by the slaughterhouse under the supervision of the competent authority with a tape or label bearing at least one of the following forms of wording in red capital letters:

— Contenido en agua superior al límite CEE

— Obsah vody překračuje limit EHS

— Vandindhold overstiger EØF-Normen

— Wassergehalt über dem EWG-Höchstwert

— Veesisaldus ületab EMÜ normi

— Περιεκτικότητα σε νερό ανώτερη του ορίου ΕΟΚ

— Water content exceeds EEC limit

— Teneur en eau supérieure à la limite CEE

— Tenore d'acqua superiore al limite CEE

— Ūdens saturs pārsniedz EEK noteikto normu

— Vandens kiekis viršija EEB nustatytą ribą

— Víztartalom meghaladja az EGK által előírt határértéket

— Il-kontenut ta’ l-ilma superjuri għal-limitu KEE

— Watergehalte hoger danhet EEG-maximum

— Zawartość wody przekracza normę EWG

— Teor de água superior ao limite CEE

— Cudzia voda v hydinovom mäse EEC limit

— Vsebnost vode presega EES omejitev

— Vesipitoisuus ylittää ETY-normin

— Vattenhalten överstiger den halt som är tillåten inom EEG.

The batch referred to in the first subparagraph shall remain under the supervision of the competent authority until it is dealt with in accordance with the paragraph or otherwise disposed of. If it is certified to the competent authority that the batch referred to in the first subparagraph is to be exported, the competent authority shall take all necessary measures to prevent the batch in question from being marketed within the Community. The forms of wording provided for in the first subparagraph shall be marked in a conspicuous place in such a way as to be easily visible, clearly legible and indelible. They shall not in any way be hidden, obscured or interrupted by other written or pictorial matter. The latters shall be at least 1 cm high on the individual packaging and 2 cm on bulk packaging.

8. The Member State of destination may, where there are serious ground for suspecting irregularities, carry out non-discriminatory random checks of frozen or quick-frozen chickens in order to verify that a consignment meets the requirements of this Article.

9. The checks referred to in paragraph 8 shall be carried out at the place of destination of the goods or at another suitable place, provided that in the latter case the choice of the places is not at the border and interferes as little as possible with the routing of the goods and that the goods may proceed normally to their destination once the appropriate sample has been taken. However the products concerned shall not be sold to the final consumer until the result of the check is available.

Such checks shall be carried out as soon as possible so as not unduly to delay their placing on the market, or cause delays which might impair their quality.

Results of these checks and any subsequent decisions and the grounds for taking them shall be notified at the latest two working days after sampling to the consignor, the consignee or their representative. Decisions taken by the competent authority of the Member State of destination and the reasons for such decisions shall be notified to the competent authority of the Member State of dispatch.

If the consignor or his representative so requests, the said decisions and reasons shall be forwarded to him in writing with details of the rights of appeal which are available to him under the law in force in the Member State of destination and of the procedure and time limits applicable.

10. If the result of the checks referred to in paragraph 8 is in excess of the admissible limits, the holder of the batch concerned may request that a counter-analysis be carried out in one of the reference laboratories listed in Annex VIII, using the same method as for the initial test. The expenses occasioned by this counter-analysis shall be borne by the holder of the batch. Tasks and competencies of reference laboratories are provided for in Annex IX.

11. If, after a check carried out in accordance with paragraphs 8 and 9 and, if requested, after a counter-analysis, it is found that the frozen or quick-frozen chickens do not comply with this Article, the competent authority of the Member State of destination shall apply the procedures provided for in paragraph 7.

12. In the cases provided for in paragraphs 10 and 11, the competent authority of the Member State of destination shall contact the competent authorities of the Member State of dispatch without delay. The latter authorities shall take all necessary measures and notify the competent authority of the first Member State of the nature of the checks carried out, the decisions taken and the reasons for such decisions.

Where the checks referred to in paragraphs 8 and 10 show repeated irregularities, or where such checks, in the view of the Member State or dispatch, are being carried out without sufficient justification, the competent authorities of the Member States concerned shall inform the Commission.

The Commission, to the extent necessary to ensure uniform application of this Regulation or at the request of the competent authority of the Member State of destination, and taking into account the nature of the infringements may:

— send a mission of experts to the establishment concerned, and in conjunction with the competent national authorities, carry out on-the-spot inspections, or

— request the competent authority of the Member State of dispatch to intensify its sampling of the products of the establishment concerned and if necessary to apply sanctions in accordance with Article 10 of Regulation (EEC) No 1906/90.

The Commission shall inform the Member States of its findings. Member States in whose territory an inspection is carried out shall give the experts all the assistance necessary for the performance of their tasks.

Pending the Commission's findings, the Member State of dispatch must, at the request of the Member State of destination, intensify checks on products coming from the establishment in question.

Where these measures are taken to deal with repeated irregularities on the part of an establishment, the Commission shall charge any expenses occasioned by the application of the indents of the third subparagraph to the establishment involved.

12a. The competent authorities of the Member States shall inform the respective national reference laboratory without delay about the results of the checks carried out by them or under their responsibility.

The national reference laboratories shall forward these data to the board of experts referred to in paragraph 14 for further evaluation and discussion with national reference laboratories before 1 July each year. The findings shall be presented to the Management Committee for consideration in accordance with Article 18 of Regulation (EEC) No 2777/75.

13. The Member States shall adopt the practical measures for the checks provided for in this Article at all stages of marketing including checks of imports from third countries at the time of customs clearance in accordance with Annexes V and VI. They shall inform the other Member States and the Commission before 1 September 2000 of these measures. Any relevant changes shall be communicated immediately to the other Member States and to the Commission.

14. A board of experts in monitoring water content in poultrymeat shall act as a coordinating body for testing activities of national reference laboratories. It shall consist of representatives of the Commission and national reference laboratories. Tasks of the board and of national reference laboratories, as well as the organisational structure of the board are provided for in Annex IX.

Article 14b

1. The following fresh, frozen and quick-frozen poultry cuts may be marketed by way of business or trade within the Community only if the water content does not exceed the technically unavoidable values determined by the method of analysis described in Annex VIa (chemical method):

(a) chicken breast fillet, with or without wishbone, without skin;

(b) chicken breast, with skin;

(c) chicken thighs, drumsticks, legs, legs with a portion of the back, leg-quarters, with skin;

(d) turkey breast fillet, without skin;

(e) turkey breast, with skin;

(f) turkey thighs, drumsticks, legs, with skin;

(g) deboned turkey leg meat, without skin.

2. The competent authorities designated by each Member State shall ensure that the slaughterhouses and cutting plants whether or not attached to slaughterhouses adopt all measures necessary to comply with the provisions of paragraph 1 and in particular that:

— regular checks on water absorbed are carried out in the slaughterhouses in accordance with Article 14a(3) also for chicken and turkey carcasses intended for the production of the fresh, frozen and quick-frozen cuts listed in paragraph 1. These checks shall be carried out at least once each working period of eight hours. However, in case of air chilling of turkey carcasses, regular checks on water absorbed need not to be carried out. The limit values fixed in Annex VII(9) shall also apply for turkey carcasses,

— results of the checks are recorded and kept for a period of one year,

— each batch is marked in such a way that its date of production can be identified; this batch mark must appear on the production record.

Where, in the case of air chilling of chickens, the results of checks referred to in the first indent and in paragraph 3 show compliance with the criteria laid down in Annexes V to VII during a period of six months, the frequency of the checks referred to in the first indent may be reduced to once every month. Any failure to comply with the criteria laid down in Annexes V to VII shall result in reinstatement of checks as referred to in the first indent.

3. At least once every three months checks on the water content referred to in paragraph 1 shall be carried out, by sampling, on frozen and quick-frozen poultry cuts from each cutting-plant producing such cuts, according to Annex VIa. These checks shall not be conducted for poultry cuts in respect of which proof is provided to the satisfaction of the competent authority that they are intended exclusively for export.

After one year of compliance with the criteria laid down in Annex VIa in a particular cutting plant, the frequency of tests shall be reduced to once every six months. Any failure to comply with these criteria shall result in reinstatement of checks as referred to in the first subparagraph.

4. Paragraphs 5 to 13 of Article 14a shall apply, mutatis mutandis, for poultry cuts referred to in paragraph 1.

Article 15

This Regulation shall enter into force on 20 June 1991.

It shall apply from 1 July 1991.

Article 8 shall apply from 1 March 1992 in the case of imports from third countries.

However, until ►M2 31 March 1992 ◄ operators may pack products covered by this Regulation in packing material bearing indications provided for in Community or national legislation applicable before the entry into force of this Regulation. These products may then be marketed until 31 December 1992.

This Regulation shall be binding in its entirety and directly applicable in all Member States.

ANNEX I

ARTICLE 1(1) – NAMES OF POULTRY CARCASES

|

es |

cs |

da |

de |

et |

el |

en |

fr |

it |

lv |

|

|

1. |

Pollo (de carne) |

Kuře, brojler |

Kylling, slagtekylling |

Hähnchen Masthuhn |

Tibud, broiler |

Κοτόπουλο Πετεινοί και κότες (κρεατοπαραγωγής) |

Chicken, broiler |

Poulet (de chair) |

Pollo, ‘Broiler’ |

Cālis, broilers |

|

2. |

Gallo, gallina |

Kohout, slepice, drůbež na pečení, nebo vaření |

Hane, høne, suppehøne |

Suppenhuhn |

Kuked, kanad, hautamiseks või keetmiseks mõeldud kodulinnud |

Πετεινοί και κότες (για βράσιμο) |

Cock, hen, casserole, or boiling fowl |

Coq, poule (à bouillir) |

Gallo, gallina Pollame da brodo |

Gailis, vista, sautēta vai vārīta mājputnu gaļa |

|

3. |

Capón |

Kapoun |

Kapun |

Kapaun |

Kohikukk |

Καπόνια |

Capon |

Chapon |

Cappone |

Kapauns |

|

4. |

Polluelo |

Kuřátko, Kohoutek |

Poussin, Coquelet |

Stubenküken |

Kana- ja kukepojad |

Νεοσσός, πετεινάρι |

Poussin, Coquelet |

Poussin, coquelet |

Galletto |

Cālītis |

|

5. |

Gallo joven |

Mladý kohout |

Unghane |

Junger Hahn |

Noor kukk |

Πετεινάρι |

Young cock |

Jeune coq |

Giovane gallo |

Jauns gailis |

|

1. |

Pavo (joven) |

(Mladá) krůta |

(Mini) kalkun |

(Junge) Pute, (Junger) Truthahn |

(Noor) kalkun |

(Νεαροί) γάλοι και γαλοπούλες |

(Young) turkey |

Dindonneau, (jeune) dinde |

(Giovane) tacchino |

(Jauns) tītars |

|

2. |

Pavo |

Krůta |

Avlskalkun |

Pute, Truthahn |

Kalkun |

Γάλοι και γαλοπούλες |

Turkey |

Dinde (à bouillir) |

Tacchino/a |

Tītars |

|

1. |

Pato (joven o anadino), pato de Berberia (joven), Pato cruzado (joven) |

(Mladá) kachna, kachně, (Mladá) Pižmová kachna, (Mladá) Kachna Mulard |

(Ung) and (Ung) berberand (Ung) mulardand |

Frühmastente, Jungente, (Junge) Barbarieente (Junge) Mulardente |

(Noor) part, pardipoeg, (noor) muskuspart, (noor), (noor) mullard |

(Νεαρές) πάπιες ή παπάκια, (νεαρές) πάπιες βαρβαρίας, (νεαρές) πάπιες mulard |

(Young) duck, duckling, (Young) Muscovy duck (Young) Mulard duck |

(Jeune) canard, caneton, (jeune) canard de barbarie, (jeune) canard mulard |

(Giovane) anatra (Giovane) Anatra muta (Giovane) Anatra ‘mulard’ |

(Jauna) pīle, pīlēns, (Jauna) Muskuss pīle, (Jauna) Mullard pīle |

|

2. |

Pato, pato de Berbería Pato cruzado |

Kachna, Pižmová kachna, Kachna Mulard |

Avlsand Berberand Mulardand |

Ente, Barbarieente Mulardente |

Part, muskuspart, mullard |

Πάπιες, πάπιες βαρβαρίας πάπιες mulard |

Duck, Muscovy duck, Mulard duck |

Canard, canard de Barbarie (à bouillir), canard mulard (à bouillir) |

Anatra Anatra muta Anatra ‘mulard’ |

Pīle, Muskuss pīle, Mullard pīle |

|

1. |

Oca (joven), ansarón |

Mladá husa, house |

(Ung) gås |

Frühmastgans, (Junge) Gans, Jungmastgans |

(Noor) hani, hanepoeg |

(Νεαρές) χήνες ή χηνάκια |

(Young) goose, gosling |

(Jeune) oie ou oison |

(Giovane) oca |

(Jauna) zoss, zoslēns |

|

2. |

Oca |

Husa |

Avlsgås |

Gans |

Hani |

Χήνες |

Goose |

Oie |

Oca |

Zoss |

|

1. |

Pintada (joven) |

Mladá perlička |

(Ung) perlehøne |

(Junges) Perlhuhn |

(Noor) pärlkana |

(Νεαρές) φραγκόκοτες |

(Young) guinea fowl |

(Jeune) pintade Pintadeau |

(Giovane) faraona |

(Jauna) pērļu vistiņa |

|

2. |

Pintada |

Perlička |

Avlsperlehøne |

Perlhuhn |

Pärlkana |

Φραγκόκοτες |

Guinea fowl |

Pintade |

Faraona |

Pērļu vistiņa |

|

lt |

hu |

mt |

nl |

pl |

pt |

sk |

sl |

fi |

sv |

|

|

1. |

Viščiukas broileris |

Brojler csirke, pecsenyecsirke |

Fellus, brojler |

Kuiken, braadkuiken |

Kurczę, broiler |

Frango |

Kurča, brojler |

Pitovni piščanec-brojler |

Broileri |

Kyckling, slaktkyckling (broiler) |

|

2. |

Gaidys, višta, skirti troškinti arba virti |

Kakas és tyúk (főznivaló baromfi) |

Serduk, tiġieġa (tal-brodu) |

Haan, hen, soep- of stoofkip |

Kura rosołowa |

Galo, galinha |

Kohút, sliepka |

Petelin, kokoš, perutnina za pečenje ali kuhanje |

Kukko, kana |

Tupp, höna, gryt- eller kokhöna |

|

3. |

Kaplūnas |

Kappan |

Ħasi |

Kapoen |

Kapłon |

Capão |

Kapún |

Kopun |

Chapon (syöttökukko) |

Kapun |

|

4. |

Viščiukas |

Minicsirke |

Għattuqa, coquelet |

Piepkuiken |

Kurczątko |

Franguitos |

Kuriatko |

Mlad piščanec, mlad petelin (kokelet) |

Kananpoika, kukonpoika |

Poussin, Coquelet |

|

5. |

Gaidžiukas |

Fiatal kakas |

Serduk żgħir fl-eta |

Jonge han |

Młody kogut |

Galo jovem |

Mladý kohút |

Mlad petelin |

Nuori kukko |

Ung tupp |

|

1. |

Kalakučiukas |

Pecsenyepulyka, gigantpulyka, növendék pulyka |

Dundjan (żgħir fl-eta) |

(Jonge) kalkoen |

(Młody) indyk |

Peru |

Mladá morka |

(Mlada) pura |

(Nuori) kalkkuna |

(Ung) kalkon |

|

2. |

Kalakutas |

Pulyka |

Dundjan |

Kalkoen |

Indyk |

Peru adulto |

Morka |

Pura |

Kalkkuna |

Kalkon |

|

1. |

Ančiukai, Muskusinės anties ančiukai, Mulardinės anties ančiukai |

Pecsenyekacsa, Pecsenye pézsmakacsa, Pecsenye mulard -kacsa |

Papra (żgħira fl-eta), papra żgħira (fellus ta’ papra), papra muskovy (żgħira fl-eta), papra mulard |

(Jonge) eend, (Jonge) Barbarijse eend (Jonge) ‘Mulard’-eend |

(Młoda) kaczka tuczona, (Młoda) kaczka piżmowa, (Młoda) kaczka mulard |

Pato, Pato Barbary, Pato Mulard |

(Mladá kačica), kačiatko, (Mladá) pyžmová kačica, (Mladý) mulard |

(Mlada) raca, račka, (Mlada) muškatna raca, (Mlada) mulard raca |

(Nuori) ankka, (Nuori) myskiankka |

(Ung) anka, ankunge, (ung) mulardand (ung) myskand |

|

2. |

Antis, Muskusinė antis, Mulardinė antis |

Kacsa, Pézsma kacsa, Mulard kacsa |

Papra, papra muscovy, papra mulard |

Eend Barbarijse eend ‘Mulard’-eend |

Kaczka, Kaczka piżmowa, Kaczka mulard |

Pato adulto, pato adulto Barbary, pato adulto Mulard |

Kačica, Pyžmová kačica, Mulard |

Raca, Muškatna raca, Mulard raca |

Ankka, myskiankka |

Anka, mulardand, myskand |

|

1. |

Žąsiukas |

Fiatal liba, pecsenye liba |

Wiżża (żgħira fl-eta), fellusa ta’ wiżża |

(Jonge) gans |

Młoda gęś |

Ganso |

(Mladá) hus, húsatko |

(Mlada) gos, goska |

(Nuori) hanhi |

(Ung) gås, gåsunge |

|

2. |

Žąsis |

Liba |

Wiżża |

Gans |

Gęś |

Ganso adulto |

Hus |

Gos |

Hanhi |

Gås |

|

1. |

Perlinių vištų viščiukai |

Pecsenyegyöngyös |

Fargħuna (żgħira fl-eta) |

(Jonge) parelhoen |

(Młoda) perliczka |

Pintada |

(Mladá) perlička |

(Mlada) pegatka |

(Nuori) helmikana |

(Ung) pärlhöna |

|

2. |

Perlinės vištos |

Gyöngytyúk |

Fargħuna |

Parelhoen |

Perlica |

Pintada adulta |

Perlička |

Pegatka |

Helmikana |

Pärlhöna |

ARTICLE 1(2) – NAMES OF POULTRY PARTS

|

es |

cs |

da |

de |

et |

el |

en |

fr |

it |

lv |

|

|

a) |

Medio |

Půlka |

Halvt |

Hälfte oder Halbes |

Pool |

Μισά |

Half |

Demi ou moitié |

Metà |

Puse |

|

b) |

Charto |

Čtvrtka |

Kvart |

(Vorder-, Hinter-) Viertel |

Veerand |

Τεταρτημόριο |

Quarter |

Quart |

Quarto |

Ceturdaļa |

|

c) |

Cuartos traseros unidos |

Neoddělená zadní čtvrtka |

Sammenhængende lårstykker |

Hinterviertel am Stück |

Lahtilõikamata koivad |

Αδιαχώριστα τεταρτημόρια ποδιών |

Unseparated leg quarters |

Quarts postérieurs non séparés |

Cosciotto |

Nesadalītas kāju ceturdaļas |

|

d) |

Pechuga |

Prsa |

Bryst |

Brust, halbe Brust, halbierte Brust |

Rind |

Στήθος |

Breast |

Poitrine, blanc ou filet sur os |

Petto con osso |

Krūtiņa |

|

e) |

Muslo y contramuslo |

Stehno |

Helt lår |

Schenkel, Keule |

Koib |

Πόδι |

Leg |

Cuisse |

Coscia |

Kāja |

|

f) |

Charto trasero de pollo |

Stehno kuřete s částí zad |

Kyllingelår med en del af ryggen |

Hähnchenschenkel mit Rückenstück, Hühnerkeule mit Rückenstück |

Koib koos seljaosaga |

Πόδι από κοτόπουλο με ένα κομμάτι της ράχης |

Chicken leg with a portion of the back |

Cuisse de poulet avec une portion du dos |

Coscetta |

Cāļa kāja ar muguras daļu |

|

g) |

Contramuslo |

Horní stehno |

Overlår |

Oberschenkel, Oberkeule |

Reis |

Μηρός (μπούτι) |

Thigh |

Haut de cuisse |

Sovraccoscia |

Šķiņkis |

|

h) |

Muslo |

Dolní stehno (Palička) |

Underlår |

Unterschenkel, Unterkeule |

Sääretükk |

Κνήμη |

Drumstick |

Pilon |

Fuso |

Stilbs |

|

i) |

Ala |

Křídlo |

Vinge |

Flügel |

Tiib |

Φτερούγα |

Wing |

Aile |

Ala |

Spārns |

|

j) |

Alas unidas |

Neoddělená křídla |

Sammenhængende vinger |

Beide Flügel, ungetrennt |

Lahtilõikamata tiivad |

Αδιαχώριστες φτερούγες |

Unseparated wings |

Ailes non séparées |

Ali non separate |

Nesadalīti spārni |

|

k) |

Filete de pechuga |

Prsní řízek |

Brystfilet |

Brustfilet, Filet aus der Brust, Filet |

Rinnafilee |

Φιλέτο στήθους |

Breast fillet |

Filet de poitrine, blanc, filet, noix |

Filetto, fesa (tacchino) |

Krūtiņas fileja |

|

l) |

Filete de pechuga con clavícula |

Filety z prsou (Klíční kost s chrupavkou prsní kosti včetně svaloviny v přirozené souvislosti, klíč. kost a chrupavka max.3 % z cel.hmotnosti) |

Brystfilet med ønskeben |

Brustfilet mit Schlüsselbein |

Rinnafilee koos harkluuga |

Φιλέτο στήθους με κλειδοκόκαλο |

Breast fillet with wishbone |

Filet de poitrine avec clavicule |

Petto (con forcella), fesa (con forcella) |

Krūtiņas fileja ar krūšukaulu |

|

m) |

Magret, maigret |

Magret, maigret (Filety z prsou kachen a hus s kůží a podkožním tukem pokrývajícím prsní sval, bez hlubokého svalu prsního) |

Magret, maigret |

Magret, Maigret |

Rinnaliha (‘magret’ või ‘maigret’) |

Maigret, magret |

Magret, maigret |

Magret, maigret |

Magret, maigret |

Pīles krūtiņa |

|

lt |

hu |

mt |

nl |

pl |

pt |

sk |

sl |

fi |

sv |

|

|

a) |

Pusė |

Fél baromfi |

Nofs |

Helft |

Połówka |

Metade |

Polená hydina |

Polovica |

Puolikas |

Halva |

|

b) |

Ketvirtis |

Negyed baromfi |

Kwart |

Kwart |

Ćwiartka |

Quarto |

Štvrťka hydiny |

Četrt |

Neljännes |

Kvart |

|

c) |

Neatskirti kojų ketvirčiai |

Összefüggő (egész) combnegyedek |

Il-kwarti ta’ wara tas-saqajn, mhux separati |

Niet-gescheiden achterkwarten |

Ćwiartka tylna w całości |

Quartos de coxa não separados |

Neoddelené hydinové stehná |

Neločene četrti nog |

Takaneljännes |

Bakdelspart |

|

d) |

Krūtinėlė |

Mell |

Sidra |

Borst |

Pierś, połówka piersi |

Peito |

Prsia |

Prsi |

Rinta |

Bröst |

|

e) |

Koja |

Comb |

Koxxa |

Hele poot, hele dij |

Noga |

Perna inteira |

Hydinové stehno |

Bedro |

Koipireisi |

Klubba |

|

f) |

Viščiuko koja su neatskirta nugaros dalimi |

Csirkecomb a hát egy részével |

Koxxa tat-tiġieġa b’porzjon tad-dahar |

Poot/dij met rugdeel (bout) |

Noga kurczęca z częścią grzbietu |

Perna inteira de frango com uma porção do dorso |

Kuracie stehno s panvou |

Piščančja bedra z delom hrbta |

Koipireisi, jossa selkäosa |

Kycklingklubba med del av ryggben |

|

g) |

Šlaunelė |

Felsőcomb |

Il-biċċa ta’ fuq tal-koxxa |

Bovenpoot, bovendij |

Udo |

Coxa |

Horné hydinové stehno |

Stegno |

Reisi |

Lår |

|

h) |

Blauzdelė |

Alsócomb |

Il-biċċa t’isfel tal-koxxa (drumstick) |

Onderpoot, onderdij (Drumstick) |

Podudzie |

Perna |

Dolné hydinové stehno |

Krača |

Koipi |

Ben |

|

i) |

Sparnas |

Szárny |

Ġewnaħ |

Vleugel |

Skrzydło |

Asa |

Hydinové krídelko |

Peruti |

Siipi |

Vinge |

|

j) |

Neatskirti sparnai |

Összefüggő (egész) szárnyak |

Ġwienaħ mhux separati |

Niet-gescheiden vleugels |

Skrzydła w całości |

Asas não separadas |

Neoddelené hydinové krídla |

Neločene peruti |

Siivet kiini toisissaan |

Sammanhängande vingar |

|

k) |

Krūtinėlės filė |

Mellfilé |

Flett tas-sidra |

Borstfilet |

Filet z piersi |

Carne de peito |

Hydinový rezeň |

Prsni file |

Rintafile' |

Bröstfilé |

|

l) |

Krūtinėlės filė su raktikauliu ir krūtinkauliu |

Mellfilé szegycsonttal |

Flett tas-sidra bil-wishbone |

Borstfilet met vorkbeen |

Filet z piersi z obojczykiem |

Carne de peito com fúrcula |

Hydinový rezeň s kosťou |

Prsni file s prsno kostjo |

Rintafile' solisluineen |

Bröstfilé med nyckelben |

|

m) |

Krūtinėlės filė be kiliojo raumens (magret) |

Bőrös libamell-filé, (maigret) |

Magret, maigret |

Magret |

Magret |

Magret, maigret |

Magret |

Magret |

Magret, maigret |

Magret, maigret |

ANNEX I A

Cut separating thigh/leg and back

— delimination of hip joint —

—

Cut separating thigh and drumstick

— delimination of knee joint —

—

ANNEX II

ARTICLE 9 – CHILLING METHODS

|

es |

cs |

da |

de |

et |

el |

en |

fr |

it |

lv |

|

|

1. |

Refrigeración por aire |

Vzduchem (Chlazení vzduchem) |

Luftkøling |

Luftkühlung |

Õhkjahutus |

Ψύξη με αέρα |

Air chilling |

Refroidissement à l'air |

Raffreddamento ad aria |

Dzesēšana ar gaisu |

|

2. |

Refrigeración por aspersión ventilada |

Vychlazeným proudem vzduchu s postřikem |

Luftspraykøling |

Luft-Sprühkühlung |

Õhkpiserdusjahutus |

Ψύξη με ψεκασμό |

Air spray chilling |

Refroidissement par aspersion ventilée |

Raffreddamento per aspersione e ventilazione |

Dzesēšana ar izsmidzinātu gaisu |

|

3. |

Refrigeración por immersión |

Ve vodní lázni ponořením |

Neddypningskøling |

Gegenstrom-Tauchkühlung |

Sukeljahutus |

Ψύξη με βύθιση |

Immersion chilling |

Refroidissement par immersion |

Raffreddamento per immersione |

Dzesēšana iegremdējot |

|

lt |

hu |

mt |

nl |

pl |

pt |

sk |

sl |

fi |

sv |

|

|

1. |

Atšaldymas ore |

Levegős hűtés |

Tkessiħ bl-arja |

Luchtkoeling |

Owiewowa |

Refrigeração por ventilação |

Chladené vzduchom |

Zračno hlajenje |

Ilmajähdytys |

Luftkylning |

|

2. |

Atšaldymas pučiant orą |

Permetezéses hűtés |

Tkessiħ b’air spray |

Lucht-sproeikoeling |

Owiewowo-natryskowa |

Refrigeração por aspersão e ventilação |

Chladené sprejovaním |

Hlajenje s pršenjem |

Ilmasprayjäähdytys |

Evaporativ kylning |

|

3. |

Atšaldymas panardinant |

Bemerítéses hűtés |

Tkessiħ b’immersjoni |

Dompelkoeling |

Zanurzeniowa |

Refrigeração por imersão |

Chladené vo vode |

Hlajenje s potapljanjem |

Vesijähdytys |

Vattenkylning |

ANNEX III

ARTICLE 10(1) – TYPES OF FARMING

|

es |

cs |

da |

de |

et |

el |

en |

fr |

it |

lv |

|

|

a) |

Alimentado con… %Oca engordada con avena |

Krmena (čím)…%(čeho)…Husa krmená ovsem |

Fodret med… % …Havrefodret gås |

Mast mit… % …Hafermastgans |

Söödetud…, mis sisaldab…% …Kaeraga toidetud hani |

Έχει τραφεί με… % …Χήνα που παχαίνεται με βρώμη |

Fed with… % of …Oats fed goose |

Alimenté avec… % de …Oie nourrie à l'avoine |

Alimentato con il… % di …Oca ingrassata con avena |

Barība ar… % …ar auzām barotas zosis |

|

b) |

Sistema extensivo en gallinero |

Extenzivní v hale |

Ekstensivt staldopdræt (skrabe…) |

Extensive Bodenhaltung |

Ekstensiivne seespidamine (lindlas pidamine) |

Εκτατικής εκτροφής |

Extensive indoor (barnreared) |

Élevé à l'intérieur: système extensif |

Estensivo al coperto |

Turēšana galvenokārt telpās (‘Audzēti kūtī’) |

|

c) |

Gallinero con salida libre |

Volný výběh |

Fritgående |

Auslaufhaltung |

Vabapidamine |

Ελεύθερης βοσκής |

Free range |

Sortant à l'extérieur |

All'aperto |

Brīvā turēšana |

|

d) |

Granja al aire libre |

Tradiční volný výběh |

Frilands … |

Bäuerliche Auslaufhaltung |

Traditsiooniline vabapidamine |

Πτηνοτροφείο παραδοσιακά ελεύθερης βοσκής |

Traditional free range |

Fermier-élevé en plein air |

Rurale all'aperto |

Tradicionālā brīvā turēšana |

|

e) |

Granja de cría en libertad |

Volný výběh – úplná volnost |

Frilands… opdrættet i fuld frihed |

Bäuerliche Freilandhaltung |

Täieliku liikumisvabadusega traditsiooniline vabapidamine |

Πτηνοτροφείο απεριόριστης τροφής |

Free-range — total freedom |

Fermier-élevé en liberté |

Rurale in libertà |

Pilnīgā brīvība |

|

lt |

hu |

mt |

nl |

pl |

pt |

sk |

sl |

fi |

sv |

|

|

a) |

Lesinta…%…Avižomis penėtos žąsys |

…%-ban…..-val etetettZabbal etetett liba |

Mitmugħa b’… % ta’ …Wiżża mitmugħa bil-ħafur |

Gevoed met… % …Met haver vetgemeste gans |

Żywione z udziałem…%…tucz owsiany (gęsi) |

Alimentado com… % de …Ganso engordado com aveia |

Kŕmené…% …husi kŕmené ovsom |

Krmljeno s/z…….%gos krmljena z ovsem |

Ruokittu… % …Kauralla ruokittu hanhi |

Utfodrad med… % …Havreutfodrad gås |

|

b) |

Patalpose laisvai auginti paukščiai (Auginti tvartuose) |

Istállóban külterjesen tartott |

Mrobbija ġewwa: sistema estensiva |

Scharrel… binnengehouden |

Ekstensywny chów ściółkowy |

Produção extensiva em interior |

Extenzívne v halách |

Ekstenzivna zaprta reja |

Laajaperäinen siskasvatus |

Extensivt uppfödd inomhus |

|

c) |

Laisvai laikomi paukščiai |

Szabadtartás |

Barra (free range) |

Scharrel… met uitloop |

Chów wybiegowy |

Produção em semiliberdade |

Chované vo voľnom výbehu |

Prosta reja |

Ulkoilumahdollisuus |

Tillgång till utomhusvistelse |

|

d) |

Tradiciškai laisvai laikomi paukščiai |

Hagyományos szabadtartás |

Barra (free range) tradizzjonali |

Boerenscharrel… met uitloopHoeve… met uitloop |

Tradycyjny chów wybiegowy |

Produção ao ar livre |

Chované tradičným spôsobom v halách |

Tradicionalna prosta reja |

Ulkoiluvapaus |

Traditionell utomhusvistelse |

|

e) |

Visiškoje laisvėje laikomi paukščiai |

Teljes szabadtartás |

Barra (free range) – liberta totali |

Boerenscharrel… met vrije uitloopHoeve… met vrije uitloop |

Chów wybiegowy bez ograniczeń |

Produção em liberdade |

Chované na paši |

Prosta reja – neomejen izpust |

Vapaa kasvatus |

Uppfödd i full frihet |

ANNEX IV

The conditions referred to in Article 10 are as follows:

(a) Fed with … % of …

Reference to the following particular feed ingredients may only be made where:

— in the case of cereals, they account for at least 65 % in weight of the feed formula givne (SIC! given) during the greater part of the fattening period, which may include not more than 15 % of cereal by-products; however, where reference is made to one specific cereal, it shall account for at least 35 % of the feed formula used, and for at least 50 % in the case of maize,

— in the case of pulses or green vegetables they account for at least 5 % in weight of the feed formula given during most of the fattening period,

— in the case of dairy products, they account for at least 5 % in weight of the feed formula given during the finishing stage.

The term ‘Oats fed goose’ may however be used where the geese are fed during the finishing stage of three weeks not less than 500 g of oats per day.

(b) ‘Extensive indoor’ (‘barn reared’)

This term may only be used where:

— the stocking rate per m2 floor space does not exceed in the case of

—— chickens, young cocks, capons: 15 birds but not more than 25 kg liveweight,

— ducks, guinea fowl, turkeys: 25 kg liveweight,

— geese: 15 kg liveweight,

— the birds are slaughtered in the case of:

—— chickens at 56 days or later,

— turkeys at 70 days or later,

— geese at 112 days or later,

— peking ducks: 49 days or later,

— Muscovy ducks: 70 days or later for females, 84 days or later for males,

— female mulard ducks: 65 days or later,

— guinea fowl: 82 days or later,

— young geese (goslings): 60 days or later,

— young cocks: 90 days or later,

— capons: 140 days or later.

(c) Free range

This term may only be used where:

— the stocking rate in the house and the age of slaughter are in accordance with the limits fixed under (b), except for chickens, for which the stocking rate may be increased to 13, but not more than 27,5 kg liveweight per m2 and for capons, for which the stocking rate shall not exceed 7,5 m2, and not more than 27,5 kg liveweight per m2,

— the birds have had during at least half their lifetime continuous daytime access to open-air runs comprising an area mainly covered by vegetation of not less than:

—— 1 m2 per chicken or guinea fowl

— 2 m2 per duck or per capon

— 4 m2 per turkey or goose.

— In the chase (SIC! case) of guinea fowls, open-air runs may be replaced by a perchery having a floor surface of at least that of the house and a height of at least 2 m. Perches of at least 10 cm length are available per bird in total (house and perchery),

— the feed formula used in the fattening stage contains at least 70 % of cereals,

— the poultryhouse is provided with popholes of a combined length at least equal to 4 m per 100 m2 surface of the house.

(d) Traditional free range

This term may only be used where:

— the indoor stocking rate per m2 does not exceed in the case of:

—— chickens: 12 but not more than 25 kg liveweight; however, in the case of mobile houses not exceeding 150 m2 floor space and which remain open at night, the stocking rate may be increased to 20, but not more than 40 kg liveweight per m2,

— capons: 6,25 (up to 91 days of age: 12) but not more than 35 kg liveweight,

— Muscovy and Peking ducks: 8 males but not more than 35 kg liveweight, 10 females but not more than 25 kg liveweight,

— Mulard ducks: 8 but not more than 35 kg liveweight,

— guinea fowl: 13 but not more than 25 kg liveweight,

— turkeys: 6,25 (up to seven weeks of age: 10) but not more than 35 kg liveweight,

— geese: 5 (up to six weeks of age: 10), 3 during last three weeks of fattening if kept in claustration, but not more than 30 kg liveweight,

— the total usable area of poultryhouses at any single production site does not exceed 1 600 m2,

— each poultryhouse does not contain more than:

—— 4 800 chickens,

— 5 200 guinea flow, (SIC! fowl,)

— 4 000 female Muscovy or Peking ducks or 3 200 male Muscovy or Peking ducks or 3 200 Mulard ducks,

— 2 500 capons, geese and turkeys,

— the poultryhouse is provided with propholes of a combined length at least equal to 4 m per 100 m2 surface of the house,

— there is continuous day-time access to open-air runs at least as from the age of

—— six weeks in the case of chickens, and capons,

— eight weeks in the case of ducks, geese, guinea fowl and turkeys,

— open-air runs comprise an area mainly covered by vegetation amounting to at least:

—— 2 m2 per chicken or Muscovy or Peking duck or guinea fowl,

— 3 m2 per Mulard duck,

— 4 m2 per capon, as from 92 days (2 m2 up to 91st day),

— 6 m2 per turkey,

— 10 m2 per goose.

— In the case of guinea fowls, open-air runs may be replaced by a perchery having a floor surface of at least double that of the house and a height of at least 2 m. Perches of at least 10 cm length are available per bird in total (house and perchery),

— the birds fattened are of a strain recognized as being slow growing,

— the feed formula used in the fattening stage contains at least 70 % of cereals,

— the minimum age at slaughter is:

—— 81 days for chickens,

— 150 days for capons,

— 49 days for Peking ducks,

— 70 days for female Muscovy ducks,

— 84 days for male Muscovy ducks,

— 92 days for Mulard ducks,

— 94 days for guinea fowl,

— 140 days for turkeys and geese marketed whole for roasting,

— 98 days for female turkeys intended for cutting up,

— 126 days for male turkeys intended for cutting up,

— 95 days for geese intended for the production of foie gras and ‘magret’,

— 60 days for young geese (goslings),

(e) Free-rang (SIC! Free-range) — total freedom

The use of this term shall require conformity with the criteria set out under (d), except that the birds shall have continuous day-time access to open-air runs of unlimited area.

In the event of restrictions, including veterinary restrictions adopted under Community law to protect public and animal health, having the effect of restricting the access of poultry to open-air runs, poultry reared in accordance with the production methods described in points (c), (d) and (e) of the first subparagraph, with the exception of guinea fowls reared in percheries, may continue to be marketed with a special reference to the method of rearing for the duration of the restriction but under no circumstances for more than 12 weeks.

ANNEX V

DETERMINATION OF THAW LOSS

(Drip test)

1. Object and scope

This method shall be used to determine the amount of water lost from frozen or quick-frozen chickens during thawing. If this drip loss, expressed as a percentage by weight of the carcase (including all the edible offal contained in the pack) exceeds the limit value laid down in paragraph 7, it is considered that excess water has been absorbed during processing. ►C2 ◄

2. Definition

Drip loss determined by this method shall be expressed as a percentage of the total weight of the frozen or quick-frozen carcase, including edible offal.

3. Principle

The frozen or quick-frozen carcase, including edible offal present, shall be allowed to thaw under controlled conditions which allow the weight of water lost to be calculated.

4. Apparatus

4.1. Scales capable of weighing up to 5 kg with an accuracy better than approximately 1 g.

4.2. Plastic bags large enough to hold the carcase and having a secure means of fixing the bag.

4.3. Thermostatically controlled water-bath with equipment capable of holding the carcases as described in 5.5 and 5.6. The water-bath shall contain a volume of water not less than eight times that of the poultry to be checked and shall be capable of maintaining the water at a temperature of 42 plus or minus 2 °C.

4.4. Filter paper or other absorbent paper towels.

5. Technique