EUROPEAN COMMISSION

EUROPEAN COMMISSION

Brussels, 16.2.2016

SWD(2016) 24 final

COMMISSION STAFF WORKING DOCUMENT

Review of available information

Accompanying the document

Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions on an EU Strategy for Heating and Cooling

{COM(2016) 51 final}

Table of Contents

1.

Introduction: The role and share of heating and cooling in EU energy demand

2.

Primary and final energy consumption for heating and cooling

2.1. Buildings: current situation and trends in the residential sector

2.1.1.Total final energy used for heating in EU’s buildings in the residential sector

2.1.2.Total final energy used for cooling in EU’s buildings in the residential sector

2.1.3. Further distinctions concerning residential buildings performance and types

2.2. Industry: current situation and trends in the industrial sectors

2.3. Heating and cooling in the tertiary sector

3.

Fuel mix in heating and cooling

3.1. Fuel mix in buildings

3.2. Fuel mix in the industry and tertiary sector

4.

OVERVIEW OF HEATING AND COOLING TECHNOLOGIES

4.1. Technologies supplying heating and cooling in buildings

4.1.1. Affordability of heating and cooling

4.2. Heating and cooling technologies in industry

4.2.1 Heating technologies

4.2.2. Energy efficiency opportunities in industry and services

4.3. Overview of technologies based on renewable energy sources

4.3.1 The use of renewable energy sources in the building sector

4.3.2 The use of renewable energy sources in industry

4.3.3 Deployment of existing best available technologies

4.3.4 Technological innovation and R&D

5.

FOCUS ON SPECIFIC SOLUTIONS FOR HEATING AND COOLING

5.1. Linking buildings and industry: the use of waste heat

5.2. District heating

5.3. Linking Heating and Cooling with the Electricity System

5.3.1 Energy Storage

5.3.2 High-efficiency Cogeneration

5.3.3 Passive and active technologies to integrate and control heat and cool supply in buildings and industries

5.3.4 Smart thermal and electric networks

1.Introduction: The role and share of heating and cooling in EU energy demand

Heating and cooling in buildings, businesses and industry consume around half of the energy produced and used in the European Union. With 50% (546 Mtoe) of final energy consumption in 2012, it is the EU’s biggest energy sector. It is projected to remain the largest energy sector even in the long-term under both business-as-usual and decarbonisation scenarios by 2030 and 2050. Despite of its magnitude and importance in the European Union's energy markets, there is surprisingly little information about heating and cooling.

This is a sector composed of a large number and variety of actors and technologies. The bulk of heating and cooling is consumed in buildings and industry.

If we look at how this half of the EU’s final energy consumption that is used for heating and cooling, is distributed among the individual sectors, we see that the share of the residential sector is 45%, that of industry 37% and that of services is 18%. The exact sectoral and end-uses’ weights within the overall heating and cooling consumption change from Member State to Member State, depending on the economic structure (e.g. share of energy intensive industries) and other factors, such as climatic conditions, the efficiency of the building stock, etc.

Technologies for heat production range from small decentralised applications, such as gas and biomass boilers, micro and small cogeneration units, heat pumps and individual solar thermal panels, to large-scale industrial boilers and furnaces and large centralised generation units in district heating networks. Likewise, cooling can be produced in decentralised applications using technologies from small air-conditioning units to large chillers and heat pumps. The capacity used for thermal energy generation ranges from 1 kW or below to several hundred MW units.

Heat and cool cannot be transported economically on a long distance. Therefore, heating and cooling are produced and consumed locally. The heating or cooling market is fragmented and no single market has so far emerged either nationally or EU-wide. Instead, heat markets are local markets composed by many different technologies and economic players (vendors, installers and builders, engineering companies and energy advisors, energy utilities and energy service companies) selling the heat and cool as a commodity or service, often bundled with other services, such as facility management, water and sewage and waste treatment. Heating and cooling are closely linked with other energy markets, in particular fuel and electricity, but also with non-energy markets like, for example, water, waste, real estate and technology.

Due to their size and penetration, how heating and cooling are produced and consumed has a major impact on the EU economy and on whether the EU is able to achieve its climate and energy goals by 2020 and by 2050. The sector is key to the Europe’s competitiveness, supply security, international trade position, and the well-being of EU citizens. Heating and cooling are a major factor in social integration, the spending power and the poverty level of EU citizens.

A comprehensive assessment of how energy efficiency and decarbonisation can be achieved in the heating and cooling sector is lacking. The options to reduce heat demand vary greatly across the sectors using heating and cooling. A first set of possibilities is to improve the building envelope in the residential sector, and several options exist to ensure that at different costs. In industry heat demand can be reduced by making heating and cooling processes more efficient through technologies or by recovering waste heat. However, after the heat demand is reduced, then energy efficiency needs to focus on the supply of heat, both in terms of the fuels and renewable resources consumed and the efficiency of conversion technology that is used to produce it.

In view of the strategic objectives set under the EU Energy Union framework for the EU to become a world leader on renewable energy and to apply the "energy efficiency first" principle, there is the need for the EU to fully harness the potential of the heating and cooling sector.

The EU has a number of policies and legislation affecting heating and cooling directly or indirectly. A number of Member States developed – or are in the process of developing – specific strategies addressing heating and cooling in the context of their national climate and energy policies. However, there is an insufficient understanding, as this sector has so far not been subject to a dedicated EU level assessment as a whole. This Staff Working Document is a first step to review the available information on this sector. Preliminary extracts of this review were summarized in five thematic 'Issues Papers' which have benefitted from the comments of stakeholders and Member States representatives. A dedicated Consultation Forum was convened in Brussels on 9 September 2015 and the minutes are included in Annex I.

2.Primary and final energy consumption for heating and cooling

Heating and cooling are understood in this document as thermal energy that is produced (including from electricity) and consumed for space heating, space cooling, cooking and hot water in buildings, and for processes in industry.

Unlike electrical energy, thermal energy is used in many qualities and temperatures, depending on the purpose and the technology. Thermal energy typically is carried through water and steam, but other materials, such as air and chemicals, can also be used as carrier. Thermal energy cannot be economically transported on longer distances (beyond 40 km) and therefore is produced and used locally.

The heating and cooling sector comprises a great variety of technologies and users. Thermal energy can be produced from conventional and renewable energy sources and through chemical processes. Thermal energy can also be produced from electricity; and electricity can, on the other hand, be produced from thermal energy. Thermal energy can be also a secondary product recovered and reused for heating and cooling purposes (e.g. residual heat from industry or even from big malls/supermarkets/retailers, which can be used for heating residential buildings).

Providing a picture of the heating and cooling sector and the uses of heat and cool across sectors is an exercise subject to the limitations of the current statistical data in this area. There is no comprehensive statistical data readily available for heating and cooling demand by end-use sectors (useful heat). Primary and/or final energy consumption for heating and cooling in Eurostat only cover derived heat sold on the market, which represents however only a portion of the total supply. Primary and final energy consumption for heating and cooling, therefore, have to be derived from primary and final energy and fuel consumption in the residential, service and industrial sectors.

The availability and reliability of data in the building sector is expected to improve in the future, thanks to The EU Building Stock Observatory, which will further improve the quality of data on energy uses in the residential sector, and to the forthcoming activities from Eurostat on residential energy uses and energy efficiency.

There are also a number of methodological issues relating to the way the contribution of certain energy sources to total energy use for heat are calculated. The proportion of energy consumed for heating and cooling has to be approximated by subtracting the part of primary and final consumption used for electricity or transport; however, a considerable amount of electricity is used for space heating in buildings. Moreover, cooling data is not reported as a separate use in official statistics and consumption for cooling is included generally in final electricity consumption data, as most cooling in residential and services sectors today is provided by individual electric air-conditioning and ventilation units or large electric absorption chillers (heat pumps).

Similarly, at global level official statistics of the International Energy Agency (IEA) acknowledge limitations and shortcomings, and identify additional specific difficulties that particularly affects heat from renewable sources. Data availability and consistency, in particular with regards to biomass use, but also related to other fuels, is recognised as a limiting factor. Such limitations of comprehensive statistical data about heating and cooling have also an impact on the forecasting of future heating and cooling needs, and on scenario modelling exercises. In this Staff Working Document, the data on heating and cooling come from the ongoing study “Mapping and analyses of the current and future (2020 - 2030) heating/cooling fuel deployment”, if not specified differently. This study makes use of several statistical sources, including Eurostat, and of its own elaboration.

The total demand for heating and cooling in 2012 amounted to 546 Mtoe and represented half of the total final energy consumption in the EU (1102 Mtoe). Heating and cooling are consumed in three main sectors, namely residential, tertiary and industry, with the residential (mainly households buildings) representing the highest share. The residential sector accounted for 45% (248 Mtoe) of final energy heating and cooling consumption in 2012, followed by industry's share of 37% (202 Mtoe) and services’ of 18% (96 Mtoe).

Figure 2-1: Heating and cooling final energy consumption share per sector (2012)

The sectorial weight changes from country to country, depending on the economic structure and other factors, like for instance climatic conditions. The variability could be substantial. For instance, the share of industry in total heat consumption is above 45% in Spain, Finland, Portugal, Slovakia, Austria and Sweden.

If the different uses of heating and cooling across sectors are considered, it is possible to distinguish six categories: space heating, space cooling, water heating, process heating, process cooling and others, which includes cooking. The figure 2-2 provides a breakdown of the total heat consumption per use. Space heating provides for the biggest share (52%) and can be considered as a basic necessity in climates where temperatures descend below certain levels. Most of the EU belongs to such climates, although the length of time when heating is needed varies considerably, ranging from yearlong heating seasons to a few days a year. Space cooling counts for only 2% and it is often considered a comfort service, but in warm climates it is a necessity. If some negative effects of climate change happen, cooling may become a more wide-spread necessity or be perceived more and more as such. Process cooling (3%) is a service required in many industrial and service sectors too, e.g. the food and beverage sectors, pharmaceutical, food retail, and data centers.

Space cooling in buildings and process cooling are amongst the most dynamically growing energy uses and the provision of cooling has in fact become a vital service to modern EU society. Without cooling, the supply of seafood, dairy, meat and poultry and all frozen foods would break down, along with significant proportion of medicines, flowers, beverages and confectionery; internet data services would fail; not only comfort but economic productivity would be adversely affected in summer for people in most of southern Europe. Cooling is therefore crucial to food security and many parts of the manufacturing sector. In particular, its contribution to reduction of food waste protects also the water, chemical, processing and transportation resources invested in that food throughout its supply chain.

The German Association for International Cooperation (Deutsche Gesellschaft für Internationale Zusammenarbeit) GIZ Proklima estimates in its Green Cooling Initiative publication (GIZ ProKlima 2014a) that globally the refrigeration and air conditioning sectors are responsible for just over 7% of global greenhouse gas (GHG) emissions when direct emission of refrigerants is combined with indirect emissions due to energy consumption. This will rise to around 13% of global emissions by 2030, with almost exponential growth of demand for space cooling in some parts of the world. One detailed model projected that global residential energy demand for cooling will exceed that for heating by 2060 (NEAA 2008).

The vast majority of cooling is provided by electrically driven plant, with only very limited use of heat driven (absorption cooling) plant. Hence, refrigeration and air conditioning accounts for about 17% of global electricity use (IIR 2014). Direct impacts on carbon emissions are through release of refrigerants (CFCs, HCFCs, HFCs) which are potent greenhouse gases when released into the atmosphere. Climate change will reduce energy demand for heating and increase energy demand for cooling in the residential and commercial sectors, as confirmed and quantified by the Intergovernmental Panel on Climate Change in 2014. Refrigeration demands are also projected to increase - thus refrigeration and air conditioning will have an increasingly important influence on the EU energy system, particularly due to its demand being almost entirely electrical.

Space cooling supplies present specific challenges as they are seldom measured and electricity used as input to cooling devices is not measured or reported separately. The exceptions are district cooling systems, where cold deliveries are measured for billing purposes. Electricity supply for cooling is normally just a part of all electricity delivered to a building.

The table below summarises the estimates calculated in different studies, some of which also produced forecasts or assessment of cooling demand potentials. Current demand estimates for both space cooling and refrigeration in 2009-2012 vary from 16 to 24 Mtoe per year. The range of the potential demand goes from 100 to 174 Mtoe, demonstrating the high expected increase but, at the same time, the uncertainty attributed to the future cooling demand. Kemna (2014) estimates that the potential space cooling demand is 42.1 Mtoe, less than half of which is fulfilled. In 2020 the mainly tertiary central air conditioners would cover a load of 17.9 Mtoe (a growth of 27%) and residential room air conditioner load would almost double at 8.2 Mtoe, bringing the total cooling supply to 26.2 Mtoe (a growth of 38%). Reportedly, the tertiary sector demand would then more or less stagnate, whereas –albeit at a slower pace—residential space cooling demand would continue to increase. In 2030 the total EU space cooling load would be 30.3 Mtoe (a growth of 15% versus 2020).

Table 2-1: Estimates of cooling demand (Mtoe)

|

Source

|

Cooling demand

(space and process cooling)

|

Cooling demand “potential”

|

Space cooling demand in residential

|

Cooling demand potential in residential

|

Space cooling demand in services

|

Cooling demand potential in services

|

Cooling demand in industry

|

|

Service contract (2015)

|

26.5 (2012)

|

n.a.

|

1.5

|

n.a.

|

16.7

|

n.a

|

5.4

|

|

RESCUE (2015)

|

24

(2010)

|

105

|

4

|

61

|

20

|

44

|

n.a

|

|

Stratego (2015)

|

16

(2010)

|

100

|

n.a.

|

4

|

12

|

n.a.

|

n.a

|

|

Eurac (2014)

|

22

|

174

|

5

|

117

|

17

|

57

|

n.a

|

|

Kemna (2014)

|

10.8 (2010)

|

42.1

|

4.8

|

30.3

|

14

|

n.a

|

n.a

|

Process heating represents the second largest share (31%) and represent an essential inputs to several industrial processes. Hot water (9%) is used both in the residential, service and industrial sectors.

Figure 2-2: Heating and cooling end-uses in 2012 (Mtoe, %)

Also in this case, structural and climatic differences across countries result in different shares across the uses of heating and cooling. The graph below illustrates that in combination with the absolute levels of the final energy demand for heating and cooling. Included are EU28 Member States plus Norway, Switzerland and Iceland.

A comparison of final energy demand for heating and cooling by end-use reveals substantial differences across countries. For instance, the share of process heating varies from about 15% in Estonia to 56% in Portugal. Although space cooling shows clear peaks in Mediterranean countries, its share arrives at a maximum of 9% (Greece) of total final energy demand for H&C - excluding Malta and Cyprus where space cooling makes up 19% and 33%, respectively. Process cooling, on the other hand, is more evenly distributed across countries as it does not so much depend on the outdoor temperature, especially in very low temperature applications in the chemical sector such as air fractioning. Despite these differences, the general pattern is still comparable: space heating and process heating account for the major share in most countries and all end-uses are represented in each country.

Figure 2-3: Final energy demand for heating and cooling per end-uses (2012)

2.1.Buildings: current situation and trends in the residential sector

Space cooling and heating are energy services required for securing a proper indoor thermal comfort. The need for heating and cooling in residential buildings is influenced by three main factors: the efficiency of the building's shell, the efficiency of the heating and cooling supply equipment and the behavior of the occupants. The climate and local weather conditions, i.e. outdoor temperature, have a major impact on the energy consumption of buildings and exercised a major influence on how the buildings are constructed and supplied with heat and cool, leading to widely diverging construction traditions and buildings’ characteristics in the various Member States. Each factor can affect buildings’ consumption significantly. For example too low and too high temperature increase the need for heating or cooling, while the demand decrease with the increase of the energy performance of the building shell or if heating and cooling is supplied through efficient technology and equipment.

2.1.1.Total final energy used for heating in EU’s buildings in the residential sector

The demand for heating and cooling in the residential sector amounted to 248 Mtoe in 2012, and represented the 85% of the total final energy consumption in this sector. Therefore, only around 15% of the total energy consumed in our houses is used for non – heating and cooling uses.

Heat is used in houses to provide warmth and hot water, and to cook the food. To satisfy space heating (and hot water) requirements, supply temperatures below 100°C are sufficient (or below 120° C in conventional district heating).

Building heat demand for space heating and hot water preparation in the residential and service sectors is not directly measured and reported in EU energy statistics. It has to be calculated by using a combination of EU, international and national energy statistics, conversion efficiencies for fuels used in final consumption, and estimating how much electricity (mainly resistance heaters and heat pumps), is used for heating purposes. Increasingly, energy is used also to cool buildings, relying mostly on air conditioning and mechanical ventilation to maintain comfortable temperatures.

Such estimation has to take into account a number of factors: the heated floor area, the building thermal integrity, its size and type, climatic conditions (heating or cooling degree days), usage patterns, the number of inhabitants (m2/person), their activity patterns and the age, of the building. Heat demand is linked to the quality of the building envelope as well as the outside temperature, with northern cities usually having a much higher level of insulation than southern cities. The final energy used for heating purposes depends strongly also on consumers' behaviour and end-users preferences, and whether proper control instruments, such as meters, meter displays and thermostatic valves allow the rational regulation of space heating and cooling comfort levels.

Different studies have estimated the total EU floor area, which is a key parameter to estimate heating and cooling demand. Europe’s total useful floor area in the residential and services sector was calculated to be 25 billion m2, of which 75% or 18.75 billion m2 was estimated to be in the residential sector (based on 2009 data), the rest, i.e. 6.25 billion m2 in the services sector BPIE (2011). Another study calculated the total heated floor area is much higher if industrial buildings are included (Kemna 2014). A further study estimated the total floor at 25.7 billion m2, out of which 19.7 billion m2 in the residential sector and 6 billion m2 in the services sector (Stratego 2015).

Table 2-2: Estimate of EU28 useful floor areas (billion m2)

|

Source

|

Total floor area

|

Residential

|

Service sector

|

Industrial sector

|

|

BPIE (2011)

|

25.0

|

18.7

|

6.2

|

n.a

|

|

Kemna (2014)

|

32.8

|

21.2

|

8.1

|

3.5

|

|

Stratego (2015)

|

25.7

|

19.7

|

6

|

n.a

|

Buildings differ greatly in their annual energy consumption. For single family buildings, the reported range extends from 585 kWh/m2 (UK, pre-1920, detached house) to 34 kWh/ m2 (Slovenia, post-2005). 40% of the EU’s building stock was built before 1960, when there were few or no requirements for energy efficiency, and only a small proportion of these have undergone major energy retrofits. The average annual energy consumption of residential buildings is 168 kWh/m2. In another assessment, Odysee-Mure (2015) estimates that after adjustment to the EU average climate, Luxembourg and Belgium turn out to have the highest consumption, at around 2 toe/dwelling (i.e. 23000 kWh), compared to 0.8 toe (9300 kWh) in Portugal and Bulgaria. The differences are still quite large and due to a combination of actors, among which efficiency of dwellings and appliances, lifestyles (size of dwellings, appliance ownership), etc.

These values are expected to be influenced by the progressive uptake of energy performance requirements set by legislation. The Energy Performance of Buildings Directive (2010/31/EU) (EPBD), together with the Energy Efficiency Directive (EED) and the Renewable Energy Directive (RED), set out a package of measures that create the conditions for significant and long term improvements in the energy performance of Europe's building stock.

The EPBD introduced the obligation to set minimum energy performance requirements with the view to achieving cost-optimal levels. In consideration of the diversity of climate conditions, the setting of a single level of requirements across the EU could not be envisaged. Instead, the use of cost-optimal methodology was included in the EPBD in order to facilitate the setting of similar ambition levels in Member States. ‘Cost-optimality’ describes the level of energy performance that leads to the lowest cost during the estimated lifecycle. The calculation includes investment costs, maintenance and operating costs, energy costs, earnings from energy produced and disposal costs (costs for deconstruction at the end of life). The objective is also that national provisions do not target specific technologies only, but instead address building systems while taking into consideration the building as a whole. The EPBD also foresees for new buildings the high-efficient alternative systems, which include district heating and combined heat and power (CHP) with renewables. The cost-optimal methodology should also help Member States to set the ambition for nearly-zero energy building (NZEB) energy performance, as this should be equal or better than the cost-optimal level in 2020.

Based on national reports on progress towards NZEBs under the EPBD, the range of values goes from targets beyond NZEB requirements (such positive energy buildings) up to 270 kWh/m2/y. Energy performance indicators can vary remarkably from 20 kWh/m2/y to 180 kWh/m2/y in residential buildings, but usually targets aim at 45 kWh/m2/y or 50 kWh/m2/y. Values from 25 kWh/m2/y to 270 kWh/m2/y are reported for non-residential buildings with higher values given for hospitals.

Regarding renewable energy in buildings, the Renewable Energy Directive requires integrating renewable energy use in all new or renovated buildings and the EPBD states that the very low amount of energy in a NZEB should be covered to a very significant extent by energy from renewable sources, including energy from renewable sources produced on-site or nearby.

Space heating

In the residential sector space heating constitutes the biggest share of energy consumption amounting to 78% of total final energy use. This average masks considerable differences depending on climate, the building type, thermal integrity, activity, etc. While the share of space heating is above 80% in colder climates, in warmer climates it is lower, around 50%. Figure 2-5 presents the amount of energy consumed in 2012 in EU28 only for space heating in the residential sector.

Figure 2-4: Thermal energy consumption per use in the residential sector (2012)

Figure 2-5: Space heating in the residential sector, 2012 (TWh, EU28 + Norway, Iceland and Switzerland)

As regards the trends over time, Odyssee-Mure estimated that since 2000 energy consumption for space heating declined by 12% and the efficiency of household space heating, measured in kWh or GJ/m2 improved steadily, by around 2.3% per year at EU level. The reasons were the deployment of more efficient new buildings and heating appliances and the renovation of existing dwellings. Energy use per square metre has decreased steadily in most countries since 2000, but energy efficiency improvement was partially offset by an increase in dwelling size.

Water heating

The share of hot water use in buildings is 16% of total heating and cooling demand in the residential sector (and 14% in tertiary sector). A decrease in hot water use is projected under EU decarbonisation scenarios, but other studies project on the contrary that hot water consumption would remain stable around the same levels as today .

Cooking

Cooking consumes around 5% of heating and cooling in the residential sector.

2.1.2.Total final energy used for cooling in EU’s buildings in the residential sector

Space cooling demand is estimated to be 1,6 Mtoe the EU residential sector and it is a fairly small share of total buildings’ energy consumption in the European Union, but is growing fast. Several studies indicate that this is likely to increase significantly in the future mainly to satisfy unmet demand for thermal comfort and partly because of more extreme weather types with warmer summers, driven by climate change. Projections even indicate ‘exponential’ growth in cooling under current trends.

It is nevertheless to be noted that the future development of the cooling sector is much more uncertain than the heating sector, also because the cooling demand and use is not measured; instead, cooling demand is usually included in the electricity demand of a building. Furthermore, studies have shown that the cooling demand in a building is not as stable as the heating demand, because there is great variability across households’ behaviour and preferences, and people tend to be less predictable about the level of cooling they implement. New building codes with stricter requirements for the tightness of building envelopes also introduce significant cooling demands in summer.

Cooling supplies are seldom measured and electricity used as input to cooling devices is not measured or reported separately. The exceptions are district cooling systems, where cold deliveries are measured for billing purposes. Therefore, the electricity supply for cooling is normally just a part of all electricity delivered to a building when cooling is applied. Unlike heating, cooling is today not considered a necessity throughout Europe, but only a comfort factor in some Member States. Therefore, cooling supplies are almost always lower than full cooling demands, since all cooling demands are not met and, in some Member States, most consumers accept higher indoor temperatures during warm summers.

Figure 2-6: Cooling demand in 2012, EU28 (Twh)

Also in the case of cooling, the picture is varied across countries depending from their climatic conditions and economic structure. As it can be seen from the figure above, Italy is by far the country with the highest consumption, followed by Spain, Bulgaria, France and Germany.

According to the EU Intelligent Energy Europe project

RESCUE

, in 2010 around 40% of service building sector floor area and 7% of residential sector in Europe were equipped with some type of active cooling systems. In the residential sector the share of cooling in energy consumption is around 1%, while in the tertiary sector this share can be as much as 30% (BPIE; 2011).

At a more detailed level for five EU countries, the EU Intelligent Energy Europe project STRATEGO has estimated that annual space cooling demands for Italy are currently 13% of concurrent heat demand in primary energy terms but could rise to 70% of heat demands by 2050, after heat efficiency measures take effect and all currently foreseen space cooling demands are met (referred to as the STRATEGO maximum potential cooling demand) (STRATEGO 2015). The space cooling demands for the UK would rise from 1% today to 29% in 2050; those for Romania rise more steeply from 2% now to 63% of the heat demand in 2050. The demand figures are shown in the Figure below. These figures do not include any refrigeration demands.

Figure 2-7: Current and future potential cooling (air conditioning) demand in the five STRATEGO project countries for both residential and services (TWh, primary energy).

CZ = Czech Republic, HR = Croatia, IT = Italy, RO = Romania, UK = United Kingdom. Source: STRATEGO 2015. The HR 2050 is the heat roadmap 2050 scenario that includes energy savings.

2.1.3.Further distinctions concerning residential buildings performance and types

Type of dwelling

Heating and cooling demand in buildings also depends on the building type (single family house, multi-apartment buildings) and region types (urban, non-urban). In 2013, 41 % of the EU-28 population lived in flats, just over one third (34 %) in detached houses and 24 % in semi-detached houses. The share of persons living in flats was highest across the EU Member States in Spain (65 %), Latvia (65 %) and Estonia (64 %). The share of people living in detached houses peaked in Croatia (71 %), Slovenia (67 %), Hungary (64 %), Romania (60 %) and Denmark (56 %). The highest propensities to live in semi-detached houses were reported in the Netherlands (61 %), the United Kingdom (60 %) and Ireland (58 %).

Figure 2-8: Distribution of population by dwelling type, 2013 (% of population)

The heating and cooling energy demand of all single family houses is more than twice as high as that of all multi-family houses. The regional disaggregation reveals that more than half of the heating and cooling demand is consumed in single family houses in non-urban areas. Heating and cooling demand in urban areas is equally distributed among single and multi-family houses.

Figure 2-9: Final energy demand for heating and cooling per buildings type (TWh, 2012)

Tenure status

In 2013 over one quarter (28%) of the EU-28 population lived in an owner-occupied home for which there was an outstanding loan or mortgage, while more than two fifths (43%) of the population lived in an owner-occupied home without a loan or mortgage. As such, seven out of every 10 (70%) persons in the EU28 lived in owner-occupied dwellings, while 19% were tenants with a market price rent, and 11% tenants in reduced-rent or free accommodation (social housing).

More than half of the population in each EU Member State lived in owner-occupied dwellings in 2013, ranging from 53 % in Germany up to 96% in Romania. In Sweden (62 %) and the Netherlands (60 %) more than half of the population lived in owner-occupied dwellings with an outstanding loan or mortgage.

The share of persons living in rented dwellings with a market price rent in 2013 was less than 10 % in ten of the EU Member States. By contrast, close to two fifths of the population in Germany and Denmark lived in rented dwellings with a market price rent, as did close to one third of the population in the Netherlands, more than one quarter in Sweden and Austria, and more than one fifth in Luxembourg. The share of the population living in a dwelling with a reduced price rent or occupying a dwelling free of charge was less than 20 % in all EU Member States.

Figure 2-10: Population by tenure status, 2013 (% of population)

Source: Eurostat

2.2.Industry: current situation and trends in the industrial sectors

Industry accounts for one fourth of the EU's total final energy consumption in 2012, of which the majority (73%, amounting to 202 Mtoe) is used for heating and cooling. The 27% of final energy demand not used for heating and cooling is mainly used for mechanical applications driven by electricity.

Like the residential sector, industry's heating and cooling (heat) consumption is not directly reported in Eurostat energy statistics. Industry’s primary, final and useful heat consumption must be derived from overall primary (conventional and renewable energy sources) and final consumption (fuels, derived heat, renewable energies, electricity) in the various industrial sectors and estimated taking into account the efficiencies of specific conversion technologies and industrial processes, as well as organisational and behavioural patterns in industrial companies. The challenge in establishing useful heat consumption, i.e. actual heat used in industrial processes and industrial buildings, is even more significant, because actual delivered heat is rarely measured (except for a few district heating systems). The calculation of final, primary and useful energy requires the knowledge of the cross-cutting technologies used in most industrial sectors, and of the efficiency of specific processes which differ sector by sector, even sub-sector by sub-sector, and down to the plant level. Examples of cross-cutting heat technologies are steam systems (large boilers) generating process steam in a wide range of industrial processes such as drying, fractionation, component separation or heating, e.g. in the pulp and paper, the chemical food and beverage and refinery sectors.

Industry is very diverse. Processes are specific to sectors and even sub-sectors and require different temperatures ranging up to 2000°C and above. Process heating can be divided into low, medium and high temperatures. The definition of low, medium and high temperature is specific to each sector and different thresholds are used

. A possible distinction is of temperatures below 200° C, between 200°C and 500°C and above 500°C

. A large number of processes in industry uses heat at medium and low temperatures like, for example, the production of plastics (temperature 180 – 290°C) and drying technologies (160 – 180°C). At lower temperatures, heating and drying processes are used in many industries such as dairy, breweries, chemicals, food industry, slaughterhouses, production of paint, textile industry and the mineral oil industry.

Temperature levels are one important variable when assessing the potentials for substitution of fossil fuels with renewable sources for heat supply in industry, since not all renewable energy sources are capable of reaching temperatures above 200°C, and this constitutes a technical limit to the decarbonisation of heating through renewable sources.

Process cooling qualities again have sector specific definitions. One distribution distinguishes between temperatures below –30°C, between –30°C and 0°C and between 0°C and 15°C. Industrial process cooling is produced from electrical refrigeration. Cooling is needed in the industrial processes for the production of food and for process cooling. Process cooling also covers a wide range of industries where the materials first have to be heated and then cooled.

Overall, it has been estimated that, in 2012, out of the total thermal energy use, 60% of industry's energy consumption is for high temperature process heat (over 500°C), while medium or low temperature (below 500°C) represents 39% of heat demand. Heat demand above 500°C is provided by industrial furnaces, while heat demands below 500°C are mostly provided by steam boilers and CHP units. Space heating is 14% and 4% is used for process cooling, of which half is used for temperatures between 0 and 15°C. In total, industry consumed 37% of the total heating and cooling demand in Europe.

Figure 2-11: EU28 final energy consumption in industry per end-use (2012)

Figure 2-12: EU28 final heating and cooling consumption in industry per end-use (2012)

The share of energy consumed in the form of thermal energy varies sector-by sector. In some sectors, thermal energy needs constitute more than two thirds of overall energy consumed, e.g. in non-metallic minerals, while in others on the contrary electricity driven processes and motors dominate, such as in non-ferrous metals and machinery, as shown in Figure 2-14.

The figure below represents the sectoral breakdown of heating and cooling consumption in energy intensive industries.

Figure 2-13: EU 28 heating and cooling consumption in industry per sector (2012)

The following figure combines the two sets of information and illustrates the demand disaggregated per end-uses across the different industrial sectors.

Figure 2-14: Final energy demand in industry in EU28 by end-uses (TWh, 2012)

High temperature process heating is mostly needed in the iron and steel, the chemical and the non-metallic minerals (cement and glass) industries. Also non-ferrous metals (main demand in aluminium) has a high share of process heat >500°C, although in lower total numbers. Process heat in the form of steam between 100 and 200°C is mostly needed in the pulp and paper industry and the “others” sub-sectors, but to some extent in all sub-sectors. Space heating has high shares in the light industries (machinery, food and tobacco and others). Process cooling is mainly used in the chemicals industry (mostly for air fractioning at very low temperatures) and in the food industry.

Another study (ICF 2015) has calculated the specific share of process heat, process cooling and electricity in energy intensive industries. According to this study, the highest share of process heat is registered in refineries, while it is the food and beverage industry which consumes the highest share of cooling.

Table 2-3: Energy consumption in energy intensive sectors broken down to process heat, process cool and electricity

|

|

Final energy consumption in 2013 [ktoe]

|

Process heat [%]

|

Process cooling [%]

|

Electricity [%]

|

|

Chemical and Pharmaceutical

|

51,485

|

58%

|

0.6%

|

30%

|

|

Iron & Steel

|

50,815

|

75%

|

0.4%

|

19%

|

|

Refineries

|

44,657

|

84%

|

0.6%

|

7%

|

|

Pulp & Paper

|

34,265

|

59%

|

0.3%

|

31%

|

|

Non-metallic Mineral

|

34,249

|

74%

|

0.2%

|

17%

|

|

Food & Beverage

|

28,353

|

62%

|

10.0%

|

34%

|

|

Machinery

|

19,282

|

40%

|

1.0%

|

53%

|

|

Non-ferrous Metal

|

9,381

|

36%

|

-

|

57%

|

Source: ICF, 2015

For what concerns cooling and refrigeration in specific, the estimated electricity demand for process cooling amounted to 7 Mtoe in 2012. The top six countries with higher cooling use are Germany (19%), Italy (15%), France (12%), Spain (10%), UK (7%), and the Netherlands (6%).These countries represent 68% of total process and space cooling in the EU28+3 countries.

Figure 2-15: Final energy demand in industry in EU28 by country (TWh, 2012)

Process cooling between 0°C and 15°C amounts to 53% of the total process cooling demand in Europe and this highlights the importance of the industrial food cool supply along its supply chain. Additional requirements for the food industry with respect to freshness, reduction or complete avoidance of the use of additives, sustainability, increased quality, and hygiene increase the importance of process cooling technologies in the processing of foodstuffs. The cooling processes in this industry, mostly for high temperature cooling (>0°C) and deep freezing temperature levels, are found in industrial producing plants, creameries and dairy production, breweries, milk production and slaughter-houses. The storage of products before production and after production of foodstuffs in cold storage houses is central for process cooling. Centralised cooling technologies for storage are found across Europe with relevant capacity sizes.

The demand for process cooling between 0°C and -30°C is employed for processes of deep cooling in different food processes (see above) and chemical industries. The use of cooling is very diverse in the chemical industry and includes the cooling down of different types of fluids as well as gases, and the direct cooling of processes. At this temperature level different cooling machines are used in auxiliary processes or in integrated cooling machines in laboratories. In addition, freeze-drying processes require deep freeze temperatures relevant for pharmaceuticals and medicine production. This is particularly needed for the storage of final products and climate chambers also relevant in bio-technology.

Process cooling at very low temperatures below -30°C down to about -190°C is only needed for the refrigeration in some processes and for certain products of the chemical industry (air fractioning, gas liquefaction in basic chemicals). A small proportion is also used in research and development processes or military uses.

Figure 2-16: Final energy demand for cooling in industry by country and temperature level (EU28, TWh, 2012)

2.3.Heating and cooling in the tertiary sector

The tertiary sector is also very diverse, with markedly different structures of energy consumption depending on the subsector. Compared to residential buildings in the tertiary sector lighting, ventilation, air-conditioning and process cooling often constitute important end-energy uses and therefore electricity consumption share in non-residential buildings is higher than in the residential sector . However space heating and hot water still generally remain the biggest end-uses.

It is estimated that the average annual energy consumption in the non-residential (tertiary and industry) sector buildings is 280kWh/m2 (covering all end-uses), and around 52% or 145 kWh/m2 of this is used for heating. This is at least 40% larger than the equivalent value for the residential buildings (BPIE 2011).

Overall, the service sector consumed in 2012 152 Mtoe of final energy, out of which 63% (96 Mtoe) was used for heating and cooling. As for the different end-uses, space heating makes still the biggest share (62%), while cooling needs altogether consume 19% of the overall heating and cooling needs.

Figure 2-17: Thermal energy consumption per use in the tertiary sector (2012)

The service sector contributes significantly to the EU’s economic activity. Key service sectors and their associated sub-sectors are listed in the table below.

Table 2-4: Service sector grouping and sub-sectors

|

|

EUROSTAT Sector grouping

|

NACE Code

|

Sub-sector components

|

|

1

|

Wholesale and retail sale

|

G46-47

|

Wholesale and retail sale of textiles and clothing, food, beverages and tobacco, households goods

|

|

2

|

Information and communications

|

J62-63

|

Computer programming, data processing, data hosting and related activities

|

|

3

|

Financial and insurance activities

|

K64-65

|

Financial services, insurance, reinsurance and pension funds

|

|

4

|

Accommodation and Food service activities

|

I55-56

|

Hotels, holiday accommodation, restaurant and other food serving activities

|

Source: ICF

If we look at the final energy consumed for heating and cooling across the tertiary sub-sectors, it becomes evident that overall the biggest consumer is the wholesale and retail trade sector, which makes 25% of consumption.

Figure 2-18: EU 28 heating and cooling consumption in services per sector (2012)

As for the ‘traffic and data transmission’ sector, another study has estimated that the electricity consumed in data centres accounts for between 25% and 60% of operating costs, and up to 30% of turnover (Intellect 2013a) with cooling accounting for an average of between 35% and 40% of the electricity bill.

Within the EU, non-residential buildings (which includes the sectors presented in the table above) accounts for 25% of the total European building stock. Buildings in the retail and wholesale space comprise 28% of the non-residential stock, while office buildings (which include financial and insurance) are the second biggest category, with 23%. The accommodation and food service sector (Horeca) accounts for 11% of EU non-residential building stock.

Figure 2-19: Services share in the buildings stock in m2 - % (2009)

Source: BPIE; 2011

Hospitals are, on average, the most energy intensive buildings with continuous occupancy, but since their share is only 7% of non-residential buildings, their total consumption is small. This is also the case for hotels and restaurants, which are equally energy intensive, but constitute only 11% of non-residential buildings. While these two categories represent the highest energy intensive type in specific terms, offices (23% of total), wholesale and retail trade buildings (28% of total), on the other hand, represent more than 50% of energy use. Education (17% of total) and sports facilities (4% of total) account for a further 18% of the energy use while other buildings account for some 6%.

In the biggest sector (wholesale and retail), the average share of energy consumption for a food retailer is largely driven by refrigeration – which accounts for 50% of the energy use. Stringent European food regulations coupled with consumer demand for convenience and fresh products are key contributing factors. Additionally, these stores require refrigeration for fresh and frozen products 365 days a year for 24 hours a day to ensure product quality. Lighting is the second largest energy consumer accounting for 25% in an average store followed by HVAC (20%) and electrical appliances and other internal processes (5%).

For non-food retailers, energy consumption is unclear, since energy use depends on the products being sold in the store. Heating and air-conditioning remains however a significant contributor since comfortable temperatures for consumers are maintained by retailers to ensure a ‘pleasant shopping atmosphere’, and this varies both regionally and seasonally across the EU. In warehouses, energy consumption can vary significantly according to the types of goods stored as well as the climate of the region they are located in. An analysis in the UK showed that heating represents almost 60% of the energy consumed (ICF; 2015).

Office buildings are the second largest consumers of energy among non-residential buildings in Europe. Due to tightly packed areas, such as trading floors, the financial and insurance sector occupies office space at high densities.

In terms of cross-country comparison, the following figure shows that the highest amount of energy for heating and cooling in the service sector is consumed in Germany, France, Italy, UK and Spain.

Figure 2-20: Final energy demand for heating cooling in the tertiary by country (EU28, TWh, 2012)

3.Fuel mix in heating and cooling

Europe’s energy system is dominated by fossil fuels. The heating and cooling sector represented 50% of the overall final energy demand in EU28 in 2012. In terms of final energy demand, direct fossil fuels use represented 68%.

Figure 3-1: Final energy consumption for heating and cooling per energy carrier, 2012 (%)

Natural gas was the largest energy source for heating and cooling in 2012, with a share of 43%. Overall, the direct use of natural gas for heating and cooling represented 59% of the total gas onsumption in Europe in 2012. It was followed by electricity (13%), fuel oil (12%), biomass (11%), coal (9%) and district heat (7%). The figure below represents the share of the different energy carriers across EU28 in 2012.

Figure 3-2: Final energy consumption for heating and cooling per energy carrier per country, 2012 (%)

If the energy carrier used to produce electricity and district heating is taken into account, the total (direct and indirect) share of fossil fuels employed for heating and cooling is higher, and this can be seen from the primary energy data presented below.

Figure 3-3: Primary energy for heating and cooling per energy carrier, 2012 (%)

About 684 Mtoe of primary energy demand were used for heating and cooling purposes in the EU28. Thereof, 46% was natural gas, which is the individual most important energy carrier for the supply of heating and cooling in the EU28. It is followed by coal (about 15%), biomass (about 11%), fuel oil (10%), nuclear energy (7%) and some renewable energy sources (wind, PV and hydro, about 5%). Other renewables like solar (thermal) energy, ambient heat and geothermal energy in sum accounted for 1.5%. Across all energy carriers, renewables accounted for 18% of primary energy supply for heating and cooling, whereas fossil fuels accounted for the major share of 75%. The share of heat sources in the EU is similar to what happens at global level. In fact, according to IEA statistics, three‐quarters of global energy use for heat is currently met with fossil fuels.

While the penetration of renewable energy has gone the farthest in the electricity sector (26% of electricity production), in the heating and cooling sector it reaches only 18% of primary energy.

Figure 3-4: Primary energy demand in EU-28SIN in 2012

Renewable energy is growing due to the EU renewable energy target for 2020 and the policies to reach it. Its share was estimated to have reached 16.6 % of final energy in 2014 overall in the European Union. As regards heating and cooling, biomass is the leading renewable energy carrier representing around 90%, while other renewable energy sources, such as geothermal, solar thermal and biogas remained below 1%.

Figure 3-5: Technology-specific RES deployment for heating and cooling at EU level (Mtoe)

As regards future potentials for renewables in the heating and cooling sector, Member States plan to generate nearly 21 % of their heating needs from renewables by 2020. Biomass is the source for which the highest increase is foreseen, with an additional 140 TWh (12 Mtoe) to be employed by 2020. The second largest increase is attributed to heat pumps, which are expected to provide an additional 65 TWh (5,6 Mtoe) of renewable heating and cooling in 2020 (Figure 3-5).

The share of biogas was estimated to reach 3% of all renewable heat sources and below 1% of the whole heating and cooling sector in 2014. According to the Progress Reports, only Germany and Cyprus were slightly above 1%. As for heat pumps, their share is estimated to reach 10% of all renewable heat sources and 1.6% of the whole heating and cooling sector in 2014. According to the 2012 Progress Reports, heat pumps covered a substantial share of heating demand in Sweden (8.4%), Italy (4.6%) and Malta (3.4%). Solar thermal energy was estimated to reach around 3% of all renewable heating and cooling sources and below 1% of the whole heating and cooling sector in 2014.

At EU level, the share of geothermal energy was estimated to reach 1% of all renewable energy sources and below 1% of the whole heating and cooling sector in 2014. Geothermal heat reaches noticeable heat market shares only in a few Member States (e.g. Bulgaria, Hungary, and Slovenia), while the largest volumes are found in France.

The averages values for the EU mask, however, considerable variations in Member States. All Member States have adopted a sector specific renewable energy target for heating and cooling in their National Renewable Energy Action Plans. Most Member States are on track to achieve their 2020 target; some are switching faster than planned. This trend is particularly visible in the Baltic and Nordic Member States, where the share of renewable energy in heat consumption is also highest among all Member States (ranging from 67% in Sweden to 43% in Estonia). These are also the Member States where the use of district heating and CHP, including based on renewables, is the highest.

Table 3-1: Share of renewable energy in heating and cooling (%)

|

|

2004

|

2005

|

2006

|

2007

|

2008

|

2009

|

2010

|

2011

|

2012

|

2013

|

|

EU28

|

9.9

|

10.3

|

10.9

|

11.9

|

12.0

|

13.7

|

14.1

|

15.0

|

16.1

|

16.5

|

|

Belgium

|

2.8

|

3.4

|

3.7

|

4.5

|

5.0

|

6.2

|

6.1

|

6.3

|

7.7

|

8.1

|

|

Bulgaria

|

14.1

|

14.3

|

14.8

|

13.9

|

17.3

|

21.7

|

24.4

|

24.9

|

27.5

|

29.2

|

|

Czech Republic

|

8.4

|

9.1

|

9.6

|

11.4

|

11.1

|

11.8

|

12.6

|

13.2

|

14.1

|

15.3

|

|

Denmark

|

19.9

|

22.1

|

23.0

|

27.0

|

28.1

|

29.5

|

30.7

|

32.0

|

33.5

|

34.8

|

|

Germany

|

6.3

|

6.8

|

6.9

|

8.3

|

7.4

|

9.2

|

9.7

|

10.4

|

10.4

|

10.6

|

|

Estonia

|

33.2

|

32.2

|

30.7

|

32.7

|

35.5

|

41.8

|

43.3

|

44.1

|

43.1

|

43.1

|

|

Ireland

|

2.9

|

3.5

|

3.6

|

3.9

|

3.6

|

4.3

|

4.5

|

5.1

|

5.4

|

5.7

|

|

Greece

|

12.8

|

12.8

|

12.5

|

14.4

|

14.3

|

16.4

|

17.8

|

19.4

|

23.4

|

26.5

|

|

Spain

|

9.5

|

9.4

|

11.4

|

11.3

|

11.7

|

13.3

|

12.6

|

13.6

|

14.1

|

14.9

|

|

France

|

12.3

|

12.4

|

12.1

|

12.9

|

13.4

|

15.2

|

16.4

|

16.3

|

17.3

|

18.3

|

|

Croatia

|

11.7

|

10.8

|

11.4

|

10.5

|

10.4

|

11.6

|

13.0

|

15.6

|

18.3

|

18.1

|

|

Italy

|

4.3

|

4.6

|

5.8

|

5.9

|

6.4

|

8.7

|

10.4

|

12.2

|

16.9

|

18.0

|

|

Cyprus

|

9.3

|

10.0

|

10.4

|

13.1

|

14.5

|

16.3

|

18.2

|

19.2

|

20.7

|

21.7

|

|

Latvia

|

42.5

|

42.7

|

42.6

|

42.4

|

42.9

|

47.9

|

40.7

|

44.8

|

47.4

|

49.7

|

|

Lithuania

|

30.4

|

30.1

|

29.7

|

29.8

|

32.8

|

34.4

|

33.2

|

33.7

|

35.5

|

37.7

|

|

Luxembourg

|

1.8

|

3.6

|

3.6

|

4.4

|

4.6

|

4.7

|

4.8

|

4.8

|

5.0

|

5.6

|

|

Hungary

|

6.5

|

6.0

|

7.5

|

8.9

|

8.3

|

10.5

|

11.0

|

12.3

|

13.4

|

13.5

|

|

Malta

|

1.1

|

2.2

|

2.6

|

3.2

|

3.6

|

1.8

|

8.4

|

8.1

|

16.7

|

23.7

|

|

Netherlands

|

1.9

|

2.1

|

2.4

|

2.5

|

2.6

|

3.0

|

2.7

|

3.2

|

3.4

|

3.6

|

|

Austria

|

20.2

|

22.6

|

23.5

|

26.2

|

26.8

|

28.6

|

30.5

|

30.7

|

32.4

|

33.5

|

|

Poland

|

10.2

|

10.1

|

10.2

|

10.4

|

10.9

|

11.6

|

11.7

|

13.0

|

13.3

|

13.9

|

|

Portugal

|

32.5

|

32.1

|

34.2

|

35.0

|

37.5

|

38.0

|

33.9

|

35.2

|

34.0

|

34.5

|

|

Romania

|

17.6

|

18.0

|

17.6

|

19.4

|

23.2

|

26.4

|

27.2

|

24.3

|

25.7

|

26.2

|

|

Slovenia

|

18.4

|

18.9

|

18.6

|

20.4

|

19.2

|

25.0

|

25.7

|

28.4

|

30.2

|

31.7

|

|

Slovakia

|

5.0

|

5.0

|

4.4

|

6.2

|

6.1

|

8.1

|

7.8

|

9.1

|

8.7

|

7.5

|

|

Finland

|

39.5

|

39.2

|

41.4

|

41.6

|

43.4

|

43.5

|

44.4

|

46.2

|

48.4

|

50.9

|

|

Sweden

|

46.6

|

51.8

|

56.2

|

58.6

|

60.9

|

63.5

|

60.9

|

62.5

|

65.7

|

67.2

|

|

United Kingdom

|

0.8

|

0.8

|

0.9

|

1.1

|

1.3

|

1.6

|

1.8

|

2.2

|

2.3

|

2.6

|

|

Norway

|

25.7

|

29.0

|

28.6

|

29.5

|

31.1

|

32.1

|

32.6

|

34.2

|

33.8

|

31.8

|

Source: Eurostat

The increased use of renewable energy will be accelerated, in particular in Central and Eastern Europe, also with the support of the €6 billion from the European Structural and Investment Funds allocated to renewable energy over the 2014-2020 period.

Additional use of renewable energy in 2013 compared to the level in 2005 enabled the EU to cut its demand for fossil fuels by 116 Mtoe. The electricity sector accounted for 71% of this, while the heating and cooling sector contributed 19%. Most of the replaced fuel was coal (47%) and natural gas (30%). Avoided imported fuel costs due to increased use of renewable energy are more than €30 billion per year.

3.1.Fuel mix in buildings

Like energy consumption, the fuels used for heating of buildings are not reported, but must be derived from primary and final energy statistics, processed using a number of factors.

Natural gas is the dominant fuel for heating and cooling. Its overall share is 43% in the residential sector and is followed by oil products and electricity with 13% and 11% respectively. The share of coal and coal products is 4%, which raises concerns about the pollution and consequent negative health effects especially in urban and dense areas. Biomass represents 17%, while solar is 1% and geothermal is around 0.1%. The share of district heating is 9%.

These overall averages cover large differences in regional and national fuel mixes. In the residential sector, gas is the most common fuel in all EU regions – with the exceptions of few countries like Bulgaria, where it represents only 3% and the main energy carriers for heating and cooling is biomass, followed by electricity and coal. Similarly, in Estonia, natural gas represents only 6% and heat is supplied mainly through district heating and biomass. The highest use of coal in the residential sector is found in Central and Eastern Europe, with Poland supplying 44% of heating from coal, and also in Ireland (19%). As for renewable energy sources, solar heat reaches the highest share in the southern countries, like in Cyprus (26,1%), Greece (4,3%) and Spain (1,6%).

Figure 3-6: Heating and cooling fuel mix in the residential sector, 2012

District heating supplies about half of the national heat consumption of the residential sector in some northern Member States (42,2% in Sweden, 41,9% in Denmark, 36.7% in Lithuania, 36.2% in Estonia and, 32.7% in Finland), and accounts for a significant national heat market share in most of the countries in Eastern Europe.

3.2.Fuel mix in the industry and tertiary sector

The energy dense fossil fuels and related technologies dominate the supply of medium and high temperature heat for industries, which seek supply solutions adapted to provide high quality steam at large quantities with a high degree of reliability and at commercially competitive costs.

Among renewable energies, biomass is the most used in industry. It has similar characteristics allowing it to replace fossil fuels in many applications. The role of the other renewable energies is marginal, as most renewable technologies are not yet sufficiently developed to generate high temperature heat or steam, or, at least, are not perceived sufficiently scaled, reliable or of reasonable cost. Heat pumps, solar thermal and geothermal can supply heat up to around 200°C. Pilot projects are testing solar energy and industrial heat pump technologies that can provide medium temperature heat above 200°C. There is currently no or limited technology solution to directly replace fossil fuels for very high temperature process heat, e.g. in the steel and chemical sectors or in cement production.

Overall, fossil fuel supplied heat in 2012 represent 75% of the final energy consumed for heating and cooling in industry, to which the share of fossils fuels in electricity and district heating should also be added. Coal with 17% still plays an important role in industrial heating. Renewables (biomass) accounts for 9% of the total supply, while the other renewable sources are negligible (below 1%).

Figure 3-7: Heating and cooling fuel mix in the industry sector (2012)

In the tertiary sector, it can be noted that overall-across-sectors renewable energy is still low. The dominant sources is by far natural gas with a share of 49%, with electricity in the second place (28%) and fuel oil (15%) in the third place. The share of renewables is 3%, and is almost entirely provided by biomass.

Figure 3-8: EU28 heating and cooling fuel mix in the service sector (2012)

4.OVERVIEW OF HEATING AND COOLING TECHNOLOGIES

4.1.Technologies supplying heating and cooling in buildings

A wide range of technologies can be used to supply heat and cooling for buildings. Boilers are the most commonly used technology. They can be operated on natural gas, oil, coal and bioenergy. Boilers can be of different efficiencies. The currently most widely used standard boilers have an efficiency of 40-80%, while modern condensing boilers can reach efficiencies above 100% and are typically more than 90% efficient. Individual stoves fueled by gas, oil, coal and biomass and furnaces using coal, biomass and waste are also an important technology. Direct electric heating is also widely used in some Member States. Cogeneration technologies constitute an important family of heating technologies, which include combined cycle and steam turbines and engines operated on gas, coal or biomass, internal combustion engines using gas, and emerging technologies, such as fuel cells, Stirling engines and Organic Rankine Cycle. While cogeneration is usually applied in large capacities up to 150 MW and above, micro-CHP is emerging in the residential sector supplying individual buildings and even apartments. Out of the renewable technologies, not based on biomass or biofuels, heat pumps are the next big family of heating and cooling technologies. They can be of many types, such as air source heat pumps operating on electricity or gas, ground source and water source heat pumps using again either electricity or gas. Solar thermal heating and cooling technologies have been increasingly gaining ground. They can be either with flat plate or vacuum tube collectors. Geothermal energy technologies also provide heat and cool, but they can be applied only if there is a piping system to convey the thermal energy from the depth of around 200 meter or more to consumers and are usually applied in larger district heating systems.

Most of the heating technologies, such as cogeneration, heat pumps, solar thermal and boilers can be applied in larger capacities in district heating system supplying groups of buildings in districts or cities.

To assess the best heating and cooling technology for a particular application, different criteria have to be considered. The most relevant ones are the annual thermal load profile for water and/or space heating, the annual cooling profile, the relative timing of thermal and electric loads, space constraints, emission regulations, fuel availability and of course the cost of the technology itself and that of the utility prices for electricity and other fuel prices. Costs and performance vary widely among heating and cooling technologies and also for each individual technology because of differences in equipment prices, installation and running costs, different end-use applications, climate, technology specification, user requirements and building occupation profiles.

Various classifications of individual heating supply technologies employed in the residential sectors exist. The figure below (Fraunhofer 2015) includes the most common categories, which can be distinguished not only for the technology employed, but also for the energy carriers used, being fossil fuels and renewable energies, or secondary energy carriers, such as electricity and district heating. The various individual heating solutions compete with each other.

Figure 4-1: Categories of heating supply technologies

Source: Fraunhofer et al.; 2015

A number of new technologies, e.g. fuel cells, are emerging to complete the existing established heat technology families, while alternative fuels, such as biogases, synthetic gases and hydrogen or recovered waste heat, widen the range of available energy carriers and sources for heating.

Modern heating systems include other technologies, which complement boilers and are often used to provide more comfort to the users, depending on specific needs: heat storage and domestic hot water; intelligent thermal control and communication instruments; radiators and heat exchangers; surface (floor) heating and cooling; passive heating and cooling elements, smart metering and smart homes integrating heating (and cooling) with the wider technical systems of buildings.

European Heating Industry (EHI) statistics provide an overview of the stock and the annual sales for the different heating categories. According to these statistics, in 2010 89% of the installed stock of central space heaters was composed of inefficient low temperature gas and oil boilers (in future to be labelled in the appliance market with C and D energy labels). The more efficient condensing boilers represented only 10% of the stock, while the residual 1% consisted of heat pumps and mini-micro-combined heat and power (CHP) devices (less than 0.1%). EHI also calculated that in EU25 in 2012, 64% of the installed space heating systems were non-condensing boilers, while condensing boilers represented 26%. The residual shares were represented by biomass boilers (6%), heat pumps, and other technologies (e.g. micro-CHP).

Most of the existing heating equipment stock is old, installed before 1992, and it is thus at the end of their lifetime. Almost one quarter (22%) of individual gas boilers, a third of direct electric heaters (34%), almost half (47%) of oil boilers and more than half (58%) of coal boilers are older than their technical lifetime (Fraunhofer 2015). These data show that the level of efficiency of the installed stock is low, around 60%, below the nominal efficiencies of these appliances of between 78% and 85%, as operational performance deteriorate over time, and even more so, if regular maintenance is not followed up. The modernisation of heating and cooling systems even only to condensing boiler levels could bring significant energy efficiency gains. The gas industry estimated that replacing of the current non-condensing gas boilers with the available condensing types would increase efficiency of gas heating by around 20% in the currently non-condensing gas appliance stock, which constituted 88% of the gas appliances in 2014. These savings would be further increased by around 10% if programmable radiator thermostats are also installed.

Significant differences exist across countries. In the UK, for example, the share of condensing boilers is much higher than the average, thanks to regulatory pull and incentives towards condensing boilers. In Sweden, heat pumps are the most diffused technology and reach 46% of the installed capacity.

Table 4-1: Space heaters in EU25, 2012

|

|

EU25 (Thousands)

|

Italy

|

UK

|

Germany

|

France

|

Sweden

|

|

Non-condensing boilers

|

(75.784) 64%

|

87%

|

44%

|

71%

|

80%

|

12%

|

|

Condensing boilers

|

(31.092) 26%

|

12%

|

56%

|

22%

|

12%

|

1%

|

|

Biomass boilers

|

(7.030) 6%

|

1%

|

<1%

|

4%

|

3%

|

18%

|

|

Heat pumps

|

(2.712) 2%

|

<1%

|

<1%

|

3%

|

5%

|

46%

|

|

Other

|

(1.083) 2%

|

<1%

|

<1%

|

1%

|

1%

|

22%

|

Source: EHI

The cooling sector is heterogeneous regarding its technologies and actors. Cooling shows a strong interlinkage with the electricity sector because, on the one hand, electricity is used as secondary energy in order to produce cooling (e.g. compression methods) or to satisfy the heat demand (e.g. heat pumps). On the other hand, there is an interaction of cooling with heating. One example of this is when heat is used to drive heat driven chillers for the generation of cooling e.g. tri-generation applications, or when cooling is produced from the waste heat generated in electricity production or industrial processes. Moreover, it is also possible to recover the heat rejected in compression chillers for instance for the pre-heating of hot water.

Cooling is mostly supplied from electric devices removing heat / moisture from air, using individual ventilation and air conditioning units (i.e. room air-conditioners and central air-conditioning units (chiller evaporators). The European market is therefore dominated by electric cooling machines. Thermal cooling machines operated with district heating and cooling or waste heat are also present to a limited extent in the high performance, large-scale classes.

Conventional cooling technologies include electrical air conditioners and chillers based on a vapour compression refrigeration cycle. High-efficiency absorption chillers, which use mixtures of water and ammonia (or lithium bromide) with natural gas or cogenerated heat sources, could replace traditional electric chillers in buildings with a high demand for cooling and/or heating and air conditioning.

District cooling allows using locally available sources. Often district cooling use the direct thermal energy converting heat into cool using waste heat from industry and waste incineration (often via tri-generation) to produce cooling with heat driven sorption chillers and heat pumps. Electric compression chillers are also large portion of many of the existing systems. A new emerging application is the so-called free cooling, whereby cold from rivers, lakes and seas is transported directly or enhanced with heat pumps through pipes to the end-users, mainly service sector and public buildings. Free cooling is best established in Finland, France, Sweden and Spain.

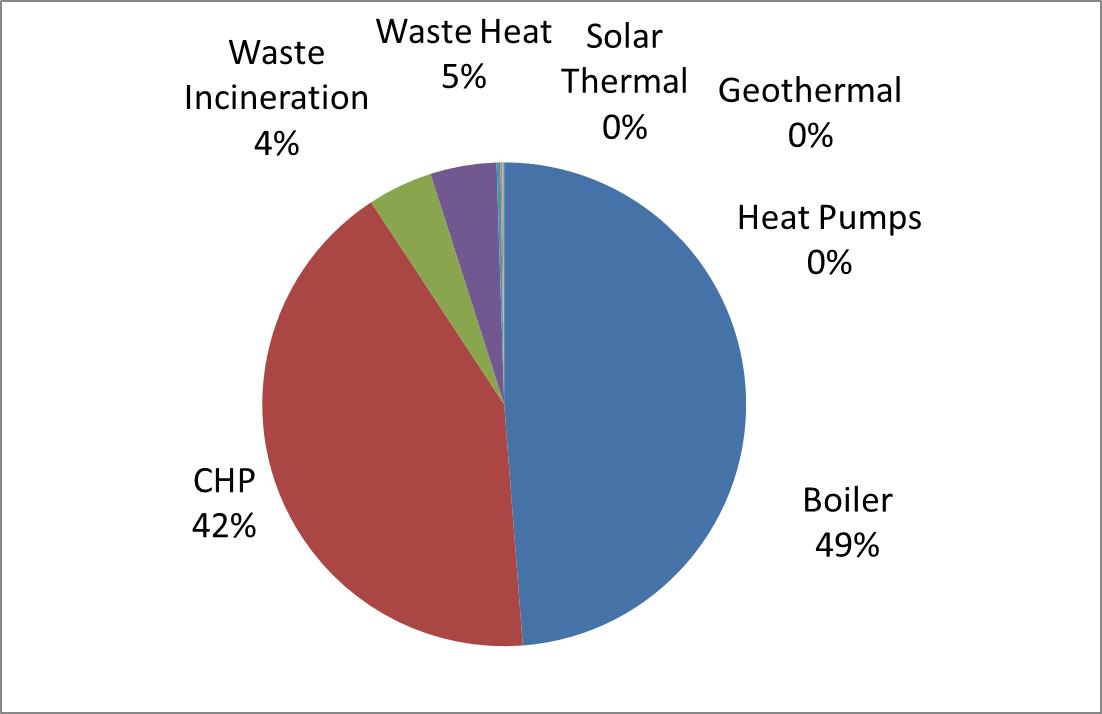

District cooling is still a small portion with a total installed capacity of only 2.4 GW, which is less than 1% of the installed district heating capacity of 301.5 GW in EU28 (Fraunhofer, 2015). The largest district cooling capacities are in France (669 MW), Sweden (650 MW), Spain (317 MW), Finland (247 MW), Italy (172 MW) and Germany (168 MW). Austria (55 MW), Poland (35 MW), Denmark (34 MW) and Hungary (7 MW) also have district cooling systems. According to RESCUE, in 2011 two thirds of the cooling delivered by these systems took place in France and Sweden. In the case of Sweden, the district cooling market developed from 71 GWh in 1996 up to 888 GWh in 2011. Utility companies distribute cooling in 32 cities in Sweden. This significant development has been largely due to the phasing out of refrigerants chlorofluorocarbons (CFCs) and hydro chlorofluorocarbons (HCFC) in 1996 and 2002.