ISSN 1725-5104

doi:10.3000/17255104.L_2011.144.mlt

Il-Ġurnal Uffiċjali

tal-Unjoni Ewropea

L 144

Edizzjoni bil-Malti

Leġiżlazzjoni

Volum 54

31 ta' Mejju 2011

|

ISSN 1725-5104 doi:10.3000/17255104.L_2011.144.mlt |

||

|

Il-Ġurnal Uffiċjali tal-Unjoni Ewropea |

L 144 |

|

|

||

|

Edizzjoni bil-Malti |

Leġiżlazzjoni |

Volum 54 |

|

Werrej |

|

II Atti mhux leġiżlattivi |

Paġna |

|

|

|

DEĊIŻJONIJIET |

|

|

|

|

2011/314/UE |

|

|

|

* |

Deċiżjoni tal-Kummissjoni tat-12 ta’ Mejju 2011 dwar l-ispeċifikazzjoni teknika għall-interoperabbiltà relatata mas-subsistema ta' l-operat u l-immaniġġjar tat-traffiku tas-sistema ferrovjarja konvenzjonali trans-Ewropea (notifikata bid-dokument numru C(2011) 3099) ( 1 ) |

|

|

|

|

|

(1) Test b’relevanza għaż-ŻEE |

|

MT |

L-Atti li t-titoli tagħhom huma stampati b'tipa ċara huma dawk li għandhom x'jaqsmu mal-maniġment ta' kuljum ta' materji agrikoli, u li ġeneralment huma validi għal perijodu limitat. It-titoli ta'l-atti l-oħra kollha huma stampati b'tipa skura u mmarkati b'asterisk quddiemhom. |

II Atti mhux leġiżlattivi

DEĊIŻJONIJIET

|

31.5.2011 |

MT EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN |

Il-Ġurnal Uffiċjali tal-Unjoni Ewropea |

L 144/1 |

DEĊIŻJONI TAL-KUMMISSJONI

tat-12 ta’ Mejju 2011

dwar l-ispeċifikazzjoni teknika għall-interoperabbiltà relatata mas-subsistema ta' “l-operat u l-immaniġġjar tat-traffiku” tas-sistema ferrovjarja konvenzjonali trans-Ewropea

(notifikata bid-dokument numru C(2011) 3099)

(Test b’relevanza għaż-ŻEE)

(2011/314/UE)

IL-KUMMISSJONI EWROPEA,

Wara li kkunsidrat it-Trattat dwar il-Funzjonament tal-Unjoni Ewropea,

Wara li kkunsidrat id-Direttiva 2008/57/KE tal-Parlament Ewropew u tal-Kunsill tas-17 ta' Ġunju 2008 dwar l-interoperabbiltà tas-sistema ferrovjarja fil-Komunità (1), u b’mod partikolari l-Artikolu 6(1) tagħha,

Billi:

|

(1) |

L-Artikolu 12 tar-Regolament (KE) Nru 881/2004 tal-Parlament Ewropew u tal-Kunsill tad-29 ta' April 2004 li jistabbilixxi Aġenzija Ewropea tal-Ferroviji [Aġenzija Ferrovjarja Ewropea] (2) jeħtieġ li l-Aġenzija Ferrovjarja Ewropea (minn hawn ‘il quddiem, “l-Aġenzija”) għandha tiżgura illi l-ispeċifikazzjonijiet tekniċi għall-interoperabbiltà (minn hawn ‘il quddiem, “TSIs”) jiġu addattati għall-progress tekniku u x-xejriet tas-suq u għall-ħtiġijiet soċjali u illi tipproponi lill-Kummissjoni l-emendi għat-TSIs li tikkunsidra meħtieġa. |

|

(2) |

Bid-Deċiżjoni C(2007) 3371 tat-13 ta' Lulju 2007, il-Kummissjoni tat mandat ta' qafas lill-Aġenzija biex twettaq ċerti attivitajiet taħt id-Direttiva tal-Kunsill 96/48/KE tat-23 ta' Lulju 1996 fuq l-interoperabbiltà tas-sistema ferrovjarja trans-Ewropea ta' veloċità għolja (3) u d-Direttiva 2001/16/KE tal-Parlament Ewropew u tal-Kunsill tad-19 ta' Marzu 2001 dwar l-interoperabbiltà tas-sistema ferrovjarja konvenzjonali trans-Ewropea (4). Skont it-termini tal-mandat ta’ qafas, l-Aġenzija ntalbet tirrevedi t-TSI adottata permezz tad-Deċiżjoni tal-Kummissjoni 2006/920/KE tal-11 ta' Awwissu 2006 dwar l-ispeċifikazzjoni teknika tal-interoperabbiltà relatata mas-subsistema ta' “l-Operat u l-Immaniġġjar tat-Traffiku” tas-sistema ferrovjarja konvenzjonali trans-Ewropea (5). |

|

(3) |

Fis-17 ta' Lulju 2009, l-Aġenzija ppubblikat erba' rakkomandazzjonijiet dwar, rispettivament, ir-regoli operattivi tas-Sistema Ewropea tal-Ġestjoni tat-Traffiku Ferrovjarju (ERTMS) (ERA/REC/2009-02/INT), ir-reviżjoni tal-Anness P għat-TSIs relatati mal-operat u l-immaniġġjar tat-traffiku (ERA/REC/2009-03/INT), ir-reviżjoni tal-Anness T għat-TSIs relatati mal-operat u l-immaniġġjar tat-traffiku tas-sistema ferrovjarja konvenzjonali (ERA/REC/2009-04/INT), u l-konsistenza mad-Direttiva 2007/59/KE fir-rigward tal-kompetenzi tas-sewwieqa tal-ferroviji (ERA/REC/2009-05/INT). Dawn l-erba' rakkomandazzjonijiet wasslu għall-abbozz ta' Deċiżjoni tal-Kummissjoni li temenda d-Deċiżjonijiet 2006/920/KE u 2008/231/KE fir-rigward tat-TSIs relatati mal-operat u l-immaniġġjar tat-traffiku. Fil-25 ta' Frar 2010, il-Kumitat stabbilit skont l-Artikolu 29(1) tad-Direttiva 2008/57/KE iddikjara opinjoni favur dan l-abbozz ta' Deċiżjoni tal-Kummissjoni. |

|

(4) |

Ir-rakkomandazzjoni tal-Aġenzija tas-7 ta' Mejju 2010 (ERA/REC/03-2010/INT) tipproponi aktar emendi għat-TSI relatata mal-operat u l-immaniġġjar tat-traffiku tas-sistema ferrovjarja konvenzjonali, fir-rigward ta', fost l-oħrajn, il-viżibbiltà tal-ferroviji (in-naħa ta' wara tal-ferrovija), l-identifikazzjoni tal-ferroviji, u l-konsistenza mad-Direttiva 2004/49/KE tal-Parlament Ewropew u tal-Kunsill tad-29 ta' April 2004 fuq is-sigurtà tal-linji tal-ferrovija tal-Komunità u li temenda d-Direttiva tal-Kunsill 95/18/KE fuq l-għoti tal-liċenzji tal-impriżi tal-linji tal-ferrovija u d-Direttiva 2001/14/KE dwar l-allokazzjoni ta' kapaċità ta' infrastruttura tal-ferroviji u t-tqegħid ta' piżijiet għall-użu ta' infrastruttura tal-ferroviji u ċertifikazzjoni tas-sigurtà (6). |

|

(5) |

Għal raġunijiet ta' ċareżża u sempliċità, ikun xieraq li d-Deċiżjoni 2006/920/KE tiġi ssostitwita. |

|

(6) |

It-TSI stipulata fl-Anness ma għandhiex tirrikjedi l-użu ta' teknoloġiji jew soluzzjonijiet tekniċi speċifiċi għajr fejn dan ikun strettament meħtieġ għall-interoperabbiltà tas-sistema ferrovjarja trans-Ewropea konvenzjonali. |

|

(7) |

L-implimentazzjoni tat-TSI stipulata fl-Anness u ż-żamma ta' konformità mal-punti rilevanti ta' dik it-TSI għandhom jiġu ddeterminati skont pjan ta' implimentazzjoni li kull Stat Membru għandu jżomm aġġornat fir-rigward tal-linji li jkun responsabbli għalihom. |

|

(8) |

Attwalment, it-traffiku ferrovjarju jopera skont ftehimiet eżistenti ta' natura nazzjonali, bilaterali, multinazzjonali jew internazzjonali. Huwa importanti li dawk il-ftehimiet ma jtellfux il-progress kurrenti u futur lejn l-interoperabbiltà. Għal dan il-għan, jeħtieġ li l-Kummissjoni teżamina dawk il-ftehimiet biex tiddetermina jekk it-TSI stipulata fl-Anness jeħtiġilhiex tiġi riveduta skont dan. |

|

(9) |

Il-miżuri previsti f'din id-Direttiva huma skont l-opinjoni tal-Kumitat stabbilit skont l-Artikolu 29(1) tad-Direttiva 2008/57/KE, |

ADOTTAT DIN ID-DEĊIŻJONI:

Artikolu 1

1. L-ispeċifikazzjoni teknika għall-interoperabbiltà (TSI) relatata mas-subsistema ta' “l-operat u l-immaniġġjar tat-traffiku” tas-sistema ferrovjarja konvenzjonali trans-Ewropea, kif stipulata fl-Anness, hija adottata.

2. It-TSI stipulata fl-Anness għal din id-Deċiżjoni għandha tkun applikabbli għas-subsistema ta' “l-operat u l-immaniġġjar tat-traffiku” kif deskritt fil-punt 2.4 tal-Anness II għad-Direttiva 2008/57/KE.

Artikolu 2

1. L-Aġenzija għandha tippubblika l-elenki tal-kodiċi msemmija fil-parti 9, 10, 11, 12 u 13 tal-Appendiċi Pa fuq is-sit elettroniku tagħha.

2. L-Aġenzija għandha żżomm l-elenki tal-kodiċi msemmija fil-paragrafu 1 aġġornati u tinforma lill-Kummissjoni dwar l–iżvilupp tagħhom.

Il-Kummissjoni għandha tinforma lill-Istati Membri dwar l-iżvilupp ta' dawn il-kodiċi, permezz tal-Kumitat stabbilit skont l-Artikolu 29 tad-Direttiva 2008/57/KE.

Artikolu 3

Sal-31 ta' Diċembru 2013, f'każ li vettura, kif definita fl-Artikolu 2(c) tad-Direttiva 2008/57/KE, tiġi mibjugħa jew mikrija għal perjodu kontinwu ta' aktar minn sitt xhur u jekk il-karatteristiċi tekniċi kollha li bihom tkun ġiet awtorizzata għat-tqegħid fis-servizz ma jinbidlux, in-Numru Ewropew tal-Vettura (minn hawn 'il quddiem, “EVN”) jista' jiġi mibdul permezz ta' reġistrazzjoni mill-ġdid tal-vettura u bl-irtirar tal-ewwel reġistrazzjoni.

F'każ li dik ir-reġistrazzjoni mill-ġdid tkun tikkonċerna Stat Membru li jkun differenti minn dak tal-ewwel reġistrazzjoni, l-entità ta' reġistrazzjoni responsabbli għar-reġstrazzjoni mill-ġdid tal-vettura tista' titlob għal kopja tad-dokumentazzjoni relatata mar-reġistrazzjoni ta' qabel.

F'dak li jirrigwardja il-proċeduri tal-awtorizzazzjoni, dan it-tibdil tal-EVN huwa bla preġudizzju għall-applikazzjoni tal-Artikoli 21 sa 26 tad-Direttiva 2008/57/KE.

L-ispejjeż amministrattivi li jsiru minħabba t-tibdil tal-EVN għandhom jitħallsu mill-applikant li jitlob għat-tibdil tal-EVN.

Artikolu 4

Fi żmien sitt xhur mid-dħul fis-seħħ tat-TSI stipulata fl-Anness, l-Istati Membri għandhom jinnotifikaw lill-Kummissjoni dwar dawn it-tipi ta' ftehimiet, sakemm dawn il-ftehimiet ma jkunux diġà ġew notifikati fl-ambitu tad-Deċiżjoni 2006/920/KE:

|

(1) |

ftehimiet nazzjonali bejn l-Istati Membri u impriżi ferrovjarji jew amministraturi tal-infrastruttura, maqbula fuq bażi permanenti jew temporanja u meħtieġa minħabba n-natura speċifika ħafna jew lokali tas-servizz ferrovjarju maħsub; |

|

(2) |

ftehimiet bilaterali jew multilaterali bejn impriżi ferrovjarji, amministraturi tal-infrastruttura jew awtoritajiet tas-sikurezza li jrendu livelli sinifikanti ta' interoperabbiltà lokali jew reġjonali; |

|

(3) |

ftehimiet internazzjonali bejn wieħed jew aktar mill-Istati Membri u talanqas pajjiż terz wieħed, jew bejn impriżi ferrovjarji jew amministraturi tal-infrastruttura tal-Istati Membri u talanqas impriża ferrovjarja waħda jew amministratur tal-infrastruttura wieħed ta' pajjiż terz, li jrendu livelli sinifikanti ta' interoperabbiltà lokali jew reġjonali. |

Artikolu 5

Kull Stat Membru għandu jaġġorna l-pjan nazzjonali ta' implimentazzjoni tat-TSI li stabbilixxa skont l-Artikolu 4 tad-Deċiżjoni 2006/920/KE. It-tfassil tal-pjan ta' implimentazzjoni aġġornat għandu jsir skont il-Kapitolu 7 tal-Anness għal din id-Deċiżjoni.

Kull Stat Membru għandu jressaq l-pjan ta' implimentazzjoni aġġornat lill-Istati Membri l-oħra u lill-Kummissjoni sa mhux aktar tard mill-31 ta' Diċembru 2012.

Artikolu 6

Id-Deċiżjoni tal-Kummissjoni 2006/920/KE hi revokata b'effett mill-1 ta' Jannar 2012.

Artikolu 7

Din id-Deċiżjoni għandha tkun applikabbli mill-1 ta’ Jannar 2012.

Iżda,

|

(1) |

L-Appendiċi P għandu jkun applikabbli mill-1 ta’ Jannar 2012 sal-31 ta’ Diċembru 2013, |

|

(2) |

L-Appendiċi Pa għandu jkun applikabbli mill-1 ta’ Jannar 2014. |

Artikolu 8

Din id-Deċiżjoni hija indirizzata lill-Istati Membri.

Magħmul fi Brussell, it-12 ta’ Mejju 2011.

Għall-Kummissjoni

Siim KALLAS

Viċi-President

(1) ĠU L 191, 18.7.2008, p. 1.

(2) ĠU L 164, 30.4.2004, p. 1.

(3) ĠU L 235, 17.9.1996, p. 6.

(4) ĠU L 110, 20.4.2001, p. 1.

(5) ĠU L 359, 18.12.2006, p. 1.

(6) ĠU L 164, 30.4.2004, p. 44.

ANNEX

TECHNICAL SPECIFICATION FOR INTEROPERABILITY FOR THE ‘OPERATION AND TRAFFIC MANAGEMENT’ SUBSYTEM

TABLE OF CONTENTS

|

1. |

INTRODUCTION | 9 |

|

1.1. |

Technical scope | 9 |

|

1.2. |

Geographical scope | 9 |

|

1.3. |

Content of this TSI | 9 |

|

2. |

DESCRIPTION OF SUBSYSTEM/SCOPE | 9 |

|

2.1. |

Subsystem | 9 |

|

2.2. |

Scope | 9 |

|

2.2.1. |

Staff and trains | 9 |

|

2.2.2. |

Principles | 10 |

|

2.2.3. |

Applicability to existing vehicles and infrastructure | 10 |

|

3. |

ESSENTIAL REQUIREMENTS | 10 |

|

3.1. |

Compliance with the essential requirements | 10 |

|

3.2. |

Essential requirements — overview | 11 |

|

4. |

CHARACTERISTICS OF THE SUBSYSTEM | 15 |

|

4.1. |

Introduction | 15 |

|

4.2. |

Functional and technical specifications of the subsystem | 15 |

|

4.2.1. |

Specifications relating to staff | 15 |

|

4.2.1.1. |

General requirements | 15 |

|

4.2.1.2. |

Documentation for drivers | 15 |

|

4.2.1.2.1. |

Driver’s Rule Book | 15 |

|

4.2.1.2.2. |

Description of the line and the relevant line-side equipment associated with the lines worked over | 16 |

|

4.2.1.2.2.1. |

Preparation of the Route Book | 16 |

|

4.2.1.2.2.2. |

Modifications to information contained within the Route Book | 17 |

|

4.2.1.2.2.3. |

Informing the driver in real time | 17 |

|

4.2.1.2.3. |

Timetables | 17 |

|

4.2.1.2.4. |

Rolling stock | 17 |

|

4.2.1.3. |

Documentation for railway undertaking staff other than drivers | 17 |

|

4.2.1.4. |

Documentation for infrastructure manager’s staff authorising train movements | 17 |

|

4.2.1.5. |

Safety-related communications between train crew, other railway undertaking staff and staff authorising train movements | 18 |

|

4.2.2. |

Specifications relating to trains | 18 |

|

4.2.2.1. |

Train visibility | 18 |

|

4.2.2.1.1. |

General requirement | 18 |

|

4.2.2.1.2. |

Front end | 18 |

|

4.2.2.1.3. |

Rear end | 19 |

|

4.2.2.2. |

Train audibility | 20 |

|

4.2.2.2.1. |

General requirement | 20 |

|

4.2.2.2.2. |

Control | 20 |

|

4.2.2.3. |

Vehicle identification | 20 |

|

4.2.2.4. |

Safety of passengers and load | 20 |

|

4.2.2.4.1. |

Safety of load | 20 |

|

4.2.2.4.2. |

Safety of passengers | 20 |

|

4.2.2.5. |

Train composition | 20 |

|

4.2.2.6. |

Train braking | 21 |

|

4.2.2.6.1. |

Minimum requirements of the braking system | 21 |

|

4.2.2.6.2. |

Braking performance | 21 |

|

4.2.2.7. |

Ensuring that the train is in running order | 21 |

|

4.2.2.7.1. |

General requirement | 21 |

|

4.2.2.7.2. |

Data required | 21 |

|

4.2.2.8. |

Requirements for signal and lineside marker sighting | 21 |

|

4.2.2.9. |

Driver vigilance | 22 |

|

4.2.3. |

Specifications relating to train operations | 22 |

|

4.2.3.1. |

Train planning | 22 |

|

4.2.3.2. |

Identification of trains | 22 |

|

4.2.3.2.1. |

Format of train running number | 22 |

|

4.2.3.3. |

Train departure | 22 |

|

4.2.3.3.1. |

Checks and tests before departure | 22 |

|

4.2.3.3.2. |

Informing the infrastructure manager of the train's operational status | 22 |

|

4.2.3.4. |

Traffic management | 22 |

|

4.2.3.4.1. |

General requirements | 22 |

|

4.2.3.4.2. |

Train reporting | 22 |

|

4.2.3.4.2.1. |

Data required for train position reporting | 22 |

|

4.2.3.4.2.2. |

Predicted hand over time | 23 |

|

4.2.3.4.3. |

Dangerous goods | 23 |

|

4.2.3.4.4. |

Operational quality | 23 |

|

4.2.3.5. |

Data recording | 23 |

|

4.2.3.5.1. |

Recording of supervision data outside the train | 24 |

|

4.2.3.5.2. |

Recording of supervision data on-board the train | 24 |

|

4.2.3.6. |

Degraded operation | 24 |

|

4.2.3.6.1. |

Advice to other users | 24 |

|

4.2.3.6.2. |

Advice to train drivers | 24 |

|

4.2.3.6.3. |

Contingency arrangements | 24 |

|

4.2.3.7. |

Managing an emergency situation | 25 |

|

4.2.3.8. |

Aid to train crew in the event of an incident or of a major rolling stock malfunction | 25 |

|

4.3. |

Functional and technical specifications of the interfaces | 25 |

|

4.3.1. |

Interfaces with the infrastructure TSI | 25 |

|

4.3.2. |

Interfaces with the control-command and signalling TSI | 26 |

|

4.3.3. |

Interfaces with the rolling stock TSI | 26 |

|

4.3.3.1. |

Interfaces with TSI on locomotives and passenger rolling stock TSI | 26 |

|

4.3.3.2. |

Interfaces with TSI on freight wagons | 26 |

|

4.3.4. |

Interfaces with the Energy TSI | 27 |

|

4.4. |

Operating rules | 27 |

|

4.5. |

Maintenance rules | 27 |

|

4.6. |

Professional qualifications | 27 |

|

4.6.1. |

Professional competency | 27 |

|

4.6.1.1. |

Professional knowledge | 27 |

|

4.6.1.2. |

Ability to put this knowledge into practice | 28 |

|

4.6.2. |

Linguistic competency | 28 |

|

4.6.2.1. |

Principles | 28 |

|

4.6.2.2. |

Level of knowledge | 28 |

|

4.6.3. |

Initial and ongoing assessment of staff | 28 |

|

4.6.3.1. |

Basic elements | 28 |

|

4.6.3.2. |

Analysis of training needs | 29 |

|

4.6.3.2.1. |

Development of the analysis of training needs | 29 |

|

4.6.3.2.2. |

Updating the analysis of training needs | 29 |

|

4.6.3.2.3. |

Specific elements for train crew and auxiliary staff | 29 |

|

4.6.3.2.3.1. |

Infrastructure knowledge | 29 |

|

4.6.3.2.3.2. |

Knowledge of rolling stock | 29 |

|

4.6.3.2.3.3. |

Auxiliary staff | 30 |

|

4.7. |

Health and safety conditions | 30 |

|

4.7.1. |

Introduction | 30 |

|

4.7.2. |

Deleted | 30 |

|

4.7.3. |

Deleted | 30 |

|

4.7.4. |

Medical examinations and psychological assessments | 30 |

|

4.7.4.1. |

Before appointment | 30 |

|

4.7.4.1.1. |

Minimum content of the medical examination | 30 |

|

4.7.4.1.2. |

Psychological assessment | 30 |

|

4.7.4.2. |

After appointment | 31 |

|

4.7.4.2.1. |

Periodicity of periodic medical examinations | 31 |

|

4.7.4.2.2. |

Minimum content of the periodic medical examination | 31 |

|

4.7.4.2.3. |

Additional medical examinations and/or psychological assessments | 31 |

|

4.7.5. |

Medical requirements | 31 |

|

4.7.5.1. |

General requirements | 31 |

|

4.7.5.2. |

Vision requirements | 31 |

|

4.7.5.3. |

Hearing requirements | 32 |

|

4.8. |

Registers of infrastructure and vehicles | 32 |

|

4.8.1. |

Infrastructure | 32 |

|

4.8.2. |

Rolling stock | 32 |

|

5. |

INTEROPERABILITY CONSTITUENTS | 32 |

|

5.1. |

Definition | 32 |

|

5.2. |

List of constituents | 32 |

|

6. |

ASSESSMENT OF CONFORMITY AND/OR SUITABILITY FOR USE OF THE CONSTITUENTS AND VERIFICATION OF THE SUBSYSTEM | 32 |

|

6.1. |

Interoperability constituents | 32 |

|

6.2. |

Operation and traffic management subsystem | 32 |

|

6.2.1. |

Principles | 32 |

|

7. |

IMPLEMENTATION | 33 |

|

7.1. |

Principles | 33 |

|

7.2. |

Implementation guidelines | 33 |

|

7.3. |

Specific cases | 33 |

|

7.3.1. |

Introduction | 33 |

|

7.3.2. |

List of specific cases | 34 |

|

7.3.2.1. |

Temporary specific case (T1) Estonia, Latvia and Lithuania | 34 |

|

7.3.2.2. |

Temporary specific case (T2) Ireland and United Kingdom | 34 |

|

Appendix A: |

ERTMS/ETCS operating rules | 35 |

|

Appendix B: |

Other rules enabling a coherent operation | 36 |

|

Appendix C: |

Safety related communications methodology | 37 |

|

Appendix D: |

Information to which the Railway Undertaking must have access in connection with the route(s) over which he intends to operate | 47 |

|

Appendix E: |

Language and communication level | 51 |

|

Appendix F: |

|

52 |

|

Appendix G: |

|

52 |

|

Appendix H: |

|

52 |

|

Appendix I: |

|

52 |

|

Appendix J: |

Minimum elements relevant to professional qualification for the tasks associated with ‘accompanying trains’ | 53 |

|

Appendix K: |

|

55 |

|

Appendix L: |

Minimum elements relevant to professional qualification for the task of preparing trains | 56 |

|

Appendix M: |

|

58 |

|

Appendix N: |

|

58 |

|

Appendix O: |

|

58 |

|

Appendix P: |

|

59 |

|

Appendix Pa: |

|

97 |

|

Appendix Q: |

|

107 |

|

Appendix R: |

|

107 |

|

Appendix S: |

|

107 |

|

Appendix T: |

Braking performance | 108 |

|

Appendix U: |

List of open points | 109 |

|

Appendix V: |

|

109 |

|

Appendix W: |

Glossary | 110 |

1. INTRODUCTION

1.1. Technical scope

This Technical Specification for Interoperability (hereinafter referred to as ‘TSI’) concerns the ‘operation and traffic management’ subsystem shown in the list contained in point 1 of Annex II to Directive 2008/57/EC. Further information on this subsystem is provided in Chapter 2.

1.2. Geographical scope

The geographical scope of this TSI is the trans-European conventional rail system as described in Annex I to Directive 2008/57/EC.

1.3. Content of this TSI

In accordance with Article 5(3) of Directive 2008/57/EC, this TSI:

|

(a) |

indicates its intended scope for the ‘operation and traffic management’ subsystem — Chapter 2; |

|

(b) |

lays down essential requirements for the subsystem concerned and its interfaces vis-à-vis other subsystems — Chapter 3; |

|

(c) |

establishes the functional and technical specifications to be met by the target subsystem and its interfaces vis-à-vis other subsystems. If necessary, these specifications may vary according to the use of the subsystem, for example according to the categories of line, hub and/or rolling stock provided for in Annex I to Directive 2008/57/EC — Chapter 4; |

|

(d) |

determines the interoperability constituents and interfaces covered by European specifications, including European standards, which are necessary to achieve interoperability within the trans-European conventional rail system — Chapter 5; |

|

(e) |

states, in each case under consideration, which procedures are to be used in order to assess the conformity or suitability for use of the interoperability constituents — Chapter 6; |

|

(f) |

indicates the strategy for implementing the TSI. In particular, it is necessary to specify the stages to be completed and the elements that can be applied in order to make a gradual transition from the existing situation to the final situation in which compliance with the TSI must be the norm — Chapter 7; |

|

(g) |

indicates, for the staff concerned, the professional qualifications and health and safety conditions at work required for the operation and maintenance of the subsystem concerned, as well as for the implementation of the TSI — Chapter 4. |

Moreover, in accordance with Article 5(5) of Directive 2008/57/EC, provision may be made for specific cases for each TSI. These are indicated in Chapter 7.

This TSI also comprises, in Chapter 4, the operating and maintenance rules specific to the scope indicated in points 1.1 and 1.2 of this Annex.

2. DESCRIPTION OF SUBSYSTEM/SCOPE

2.1. Subsystem

The ‘operation and traffic management’ subsystem is described in point 2.4. of Annex II to Directive 2008/57/EC as:

‘The procedures and related equipment enabling a coherent operation of the different structural subsystems, both during normal and degraded operation, including in particular training and train driving, traffic planning and management.

The professional qualifications which may be required for carrying out cross-border services’.

2.2. Scope

This TSI applies to the ‘operation and traffic management’ subsystem of infrastructure managers (hereinafter referred to as ‘IM’) and railway undertakings (hereinafter referred to as ‘RU’) related to the operation of trains on the conventional rail TEN lines.

The specifications laid down in the TSI on operation and traffic management may be used as a reference document for the operation of trains even if they are not covered by the scope of this TSI.

2.2.1. Staff and trains

Points 4.6 and 4.7 apply to those staff undertaking the safety-critical tasks of accompanying a train, when this involves crossing a border(s) between states and working beyond any location(s) designated as the ‘frontier’ in the network statement of an infrastructure manager and included in his safety authorisation.

Point 4.6.2 also applies to train drivers as stipulated by point 8 of Annex VI to Directive 2007/59/EC. A staff member will not be considered as crossing a border if the activity only involves working as far as any ‘frontier’ locations as described in the first paragraph of this point.

For those staff undertaking the safety-critical tasks of despatching trains and authorising train movements, mutual recognition of professional qualifications and health and safety conditions between Member States will apply.

For those staff undertaking the safety-critical tasks associated with the last preparation of a train before it is scheduled to cross a border(s) and work beyond any ‘frontier’ location(s) as described in the first paragraph of this point, point 4.6 will apply with mutual recognition between Member States of health and safety conditions. A train will not be considered to be a cross border service, if all the vehicles of the train crossing the state border cross it only to the ‘frontier’ location(s) as described in the first paragraph of this point.

This can be summarised in the tables below:

Staff involved with the working of trains that will cross-state borders and proceed beyond the frontier location

|

Task |

Professional Qualifications |

Medical Requirements |

|

Accompanying a Train |

4.6 |

4.7 |

|

Authorising Train movements |

Mutual recognition |

Mutual recognition |

|

Train Preparation |

4.6 |

Mutual recognition |

|

Train Despatch |

Mutual recognition |

Mutual recognition |

Staff working trains that do not cross state borders or do so as far as frontier locations

|

Task |

Professional Qualifications |

Medical Requirements |

|

Accompanying a Train |

Mutual recognition |

Mutual recognition |

|

Authorising Train movements |

Mutual recognition |

Mutual recognition |

|

Train Preparation |

Mutual recognition |

Mutual recognition |

|

Train Despatch |

Mutual recognition |

Mutual recognition |

2.2.2. Principles

This TSI covers those elements (as set out in Chapter 4) of the conventional rail ‘operation and traffic management’ subsystem, where principally there are operational interfaces between RU and IM and where there is a particular benefit to interoperability.

RU and IM must ensure that all requirements concerning rules and procedures as well as documentation are met by the establishment of the appropriate processes. The set up of these processes is a relevant part of RU’s and IM’s safety management system (hereinafter referred to as ‘SMS’) as required by Directive 2004/49/EC. The SMS itself is assessed by the relevant national safety authority (hereinafter referred to as ‘NSA’) before granting safety certificate/authorisation.

2.2.3. Applicability to existing vehicles and infrastructure

While the majority of the requirements contained in this TSI relate to processes and procedures, a number also relate to physical elements, trains and vehicles which are important for operation.

The design criteria for these elements are described in the TSIs covering other subsystems such as rolling stock. In the context of this TSI it is their operational function that is considered.

3. ESSENTIAL REQUIREMENTS

3.1. Compliance with the essential requirements

In accordance with Article 4(1) of Directive 2008/57/EC, the trans-European conventional rail system, its subsystems and their interoperability constituents must meet the essential requirements set out in general terms in Annex III to the Directive.

3.2. Essential requirements — overview

The essential requirements cover:

|

— |

safety, |

|

— |

reliability and availability, |

|

— |

health, |

|

— |

environmental protection, |

|

— |

technical compatibility. |

According to Directive 2008/57/EC, the essential requirements may be generally applicable to the whole trans-European conventional rail system or be specific to each subsystem and its constituents.

The following table summarises the correspondence between the essential requirements set out in Annex III to Directive 2008/57/EC and the present TSI.

|

Clause |

Clause Title |

Safety |

Reliability & Availability |

Health |

Environmental protection |

Technical compatibility |

Essential requirements specific to operation and traffic management |

|||||||||||

|

1.1.1 |

1.1.2 |

1.1.3 |

1.1.4 |

1.1.5 |

1.2 |

1.3.1 |

1.3.2 |

1.4.1 |

1.4.2 |

1.4.3 |

1.4.4 |

1.4.5 |

1.5 |

2.6.1 |

2.6.2 |

2.6.3 |

||

|

4.2.1.2 |

Documentation for drivers |

|

|

|

|

|

X |

|

|

|

|

|

|

|

|

X |

|

X |

|

4.2.1.2.1 |

Rule book |

|

|

|

|

|

|

|

|

|

|

|

X |

|

|

X |

|

X |

|

4.2.1.2.2 |

Route book |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

|

X |

|

4.2.1.2.2.1 |

Preparation of the Route book |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

|

|

|

4.2.1.2.2.2 |

Modification to Information contained within the route book |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

|

X |

|

4.2.1.2.2.3 |

Informing the driver in real time |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

X |

X |

|

4.2.1.2.3 |

Time tables |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

X |

X |

|

4.2.1.2.4 |

Rolling stock |

|

|

|

|

|

X |

|

|

|

|

|

|

|

|

X |

|

X |

|

4.2.1.3 |

Documentation for railway undertaking staff other than drivers |

|

|

|

|

|

X |

|

|

|

|

|

|

|

|

X |

|

X |

|

4.2.1.4 |

Documentation for infrastructure manager’s staff authorising train movements |

|

|

|

|

|

X |

|

|

|

|

|

|

|

|

X |

X |

|

|

4.2.1.5 |

Safety-related communications between train crew, other railway undertaking staff and staff authorising train movements |

|

|

|

|

|

X |

|

|

|

|

|

|

|

|

X |

X |

X |

|

4.2.2.1 |

Train visibility |

X |

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

|

X |

|

4.2.2.1.1 |

General requirement |

X |

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

|

X |

|

4.2.2.1.2 |

Front end |

X |

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

|

X |

|

4.2.2.1.3 |

Rear end |

X |

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

|

X |

|

4.2.2.2 |

Train audibility |

X |

|

|

|

|

|

|

|

|

|

|

X |

|

|

X |

|

X |

|

4.2.2.2.1 |

General requirement |

X |

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

|

X |

|

4.2.2.2.2 |

Control |

X |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

|

4.2.2.3 |

Vehicle identification |

|

|

|

|

|

X |

|

|

|

|

|

|

|

|

X |

|

X |

|

4.2.2.4 |

Safety of passengers and load |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

|

|

|

4.2.2.5 |

Train composition |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

|

|

|

4.2.2.6 |

Train braking |

|

X |

|

|

|

|

|

|

|

|

|

|

|

|

X |

|

X |

|

4.2.2.6.1 |

Minimum requirements of the braking system |

|

X |

|

|

|

|

|

|

|

|

|

|

|

|

X |

|

X |

|

4.2.2.6.2 |

Braking performance |

|

X |

|

|

|

|

|

|

|

|

|

|

|

|

X |

|

X |

|

4.2.2.7 |

Ensuring that the train is in running order |

|

X |

|

|

|

|

|

|

|

|

|

|

|

|

X |

|

X |

|

4.2.2.7.1 |

General requirement |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

|

X |

|

4.2.2.7.2 |

Data required |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

|

X |

|

4.2.2.8 |

Requirements for Signal and lineside marker sighting |

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

X |

|

|

|

4.2.2.9 |

Driver vigilance |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

|

|

|

4.2.3.1 |

Train planning |

|

X |

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

X |

|

4.2.3.2 |

Identification of trains |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

X |

X |

|

4.2.3.3 |

Train departure |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

|

X |

|

4.2.3.3.1 |

Checks and tests before departure |

|

X |

|

|

|

X |

|

|

|

|

|

|

|

|

X |

|

X |

|

4.2.3.3.2 |

Informing the Infrastructure Manager of the train's operational status |

|

X |

|

|

|

X |

|

|

|

|

|

|

|

|

|

X |

X |

|

4.2.3.4 |

Traffic management |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

X |

X |

|

4.2.3.4.1 |

General requirements |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

X |

X |

|

4.2.3.4.2 |

Train reporting |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

X |

X |

|

4.2.3.4.2.1 |

Data required for train position reporting |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

|

X |

|

4.2.3.4.2.2 |

Predicted hand over time |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

|

X |

|

4.2.3.4.3 |

Dangerous goods |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

X |

|

|

4.2.3.4.4 |

Operational quality |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

X |

|

4.2.3.5 |

Data recording |

|

|

|

|

|

X |

|

|

|

|

|

|

|

|

|

X |

|

|

4.2.3.5.1 |

Recording of supervision data outside the train |

|

|

|

|

|

X |

|

|

|

|

|

|

|

|

|

X |

|

|

4.2.3.5.2 |

Recording of supervision data on-board the train |

|

|

|

|

|

X |

|

|

|

|

|

|

|

|

|

X |

|

|

4.2.3.6 |

Degraded operation |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

X |

X |

|

4.2.3.6.1 |

Advice to other users |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

|

X |

|

4.2.3.6.2 |

Advice to train drivers |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

|

|

|

4.2.3.6.3 |

Contingency arrangements |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

X |

X |

|

4.2.3.7 |

Managing an emergency situation |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

X |

X |

|

4.2.3.8 |

Aid to train crew in the event of an incident or of a major rolling stock malfunction |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

|

4.4 |

ERTMS operating rules |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

X |

|

|

4.6 |

Professional qualifications |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

X |

X |

|

4.7 |

Health and safety conditions |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

|

|

4. CHARACTERISTICS OF THE SUBSYSTEM

4.1. Introduction

Taking into account all the relevant essential requirements, the ‘operation and traffic management’ subsystem, as described in point 2.2, covers only the elements specified in this Chapter.

In conformity with Directive 2001/14/EC, it is the overall responsibility of the infrastructure manager to provide all the appropriate requirements which must be met by trains permitted to run on his network, taking into account the geographic particularities of individual lines and the functional or technical specifications set out in this Chapter.

4.2. Functional and technical specifications of the subsystem

The functional and technical specifications of the ‘operation and traffic management’ subsystem comprise of the following:

|

— |

specifications relating to staff, |

|

— |

specifications relating to trains, |

|

— |

specifications relating to train operations. |

4.2.1. Specifications relating to staff

4.2.1.1.

This point deals with staff who contributes to the operation of the subsystem by performing safety-critical tasks involving a direct interface between a railway undertaking and an infrastructure manager.

|

1. |

Railway undertaking staff:

|

|

2. |

Infrastructure manager’s staff undertaking the task of authorising the movement of trains |

The areas covered are:

|

— |

Documentation |

|

— |

Communication |

In addition, for the staff as defined in point 2.2.1., this TSI sets out requirements on:

|

— |

Qualifications (see point 4.6. and Appendix L) |

|

— |

Health and safety conditions (see point 4.7) |

4.2.1.2.

The railway undertaking operating the train must supply the driver with all the necessary information and documentation required to carry out his duties.

This information must take into account the necessary elements for operation in normal, degraded and emergency situations for the routes to be worked over and the rolling stock used on those routes.

4.2.1.2.1. Driver’s Rule Book

All the necessary procedures for the driver must be included in a document or a computer medium called the ‘Driver’s Rule Book’.

The Driver's Rule Book must state the requirements for all the routes worked and the rolling stock used on those routes according to the situations of normal operation, degraded operation and in emergency situations which the driver may encounter.

The Driver’s Rule Book must cover two distinct aspects:

|

— |

one which describes the set of common rules and procedures valid across the TEN (taking into account the contents of Appendices A, B and C), |

|

— |

another which sets out any necessary rules and procedures specific to each infrastructure manager. |

It must include procedures covering, as a minimum, the following aspects:

|

— |

Staff safety and security, |

|

— |

Signalling and control command, |

|

— |

Train operation including degraded mode, |

|

— |

Traction and rolling stock, |

|

— |

Incidents and accidents. |

The railway undertaking is responsible for compiling the Driver’s Rule Book.

The railway undertaking must present the Driver's Rule Book in the same format for the entire infrastructure over which their drivers will work.

The railway undertaking must compile the Driver’s Rule Book in such a way that the driver’s application of all operational rules is enabled.

It must have two appendices:

|

— |

Appendix 1: Manual of communication procedures; |

|

— |

Appendix 2: Book of Forms. |

Messages and forms must remain in the ‘operating’ language of infrastructure manager(s).

The process for preparing and updating the Driver's Rule Book must include the following steps:

|

— |

the infrastructure manager (or the organisation responsible for the preparation of the operating rules) must provide the railway undertaking with the appropriate information in the infrastructure manager’s operating language, |

|

— |

the railway undertaking must draw up the initial or updated document; |

|

— |

if the language chosen by the railway undertaking for the Driver’s Rule Book is not the language in which the appropriate information was originally supplied, it is the responsibility of the railway undertaking to arrange for any necessary translation and/or provide explanatory notes in another language. |

The infrastructure manager must ensure that the content of the documentation provided to the railway undertaking(s) is complete and accurate.

The railway undertaking must ensure that the content of the Driver’s Rule Book is complete and accurate.

4.2.1.2.2. Description of the line and the relevant line-side equipment associated with the lines worked over

Drivers must be provided with a description of the lines and the associated line-side equipment for the lines over which they will operate and relevant to the driving task. Such information must be set out in a single document called the ‘Route Book’ (which can either be a traditional document or computer based).

The following is a list of information which must, as a minimum, be provided:

|

— |

the general operating characteristics, |

|

— |

indication of rising and falling gradients, |

|

— |

detailed line diagram. |

4.2.1.2.2.1. Preparation of the route book

The format of the Route Book must be prepared in the same manner for all the infrastructures worked over by the trains of an individual railway undertaking.

The railway undertaking is responsible for the competent and correct compilation of the Route book (for example, arranging for any necessary translation and/or providing explanatory notes), using the information supplied by the infrastructure manager(s).

The following information must be included (this list is not exhaustive):

|

(a) |

the general operating characteristics:

|

|

(b) |

indication of rising and falling gradients with their gradient values and location; |

|

(c) |

detailed line diagram:

|

The infrastructure manager must ensure that the content of the documentation provided to the railway undertaking(s) is complete and accurate.

The railway undertaking must ensure that the content of the Route Book is complete and accurate.

4.2.1.2.2.2. Modifications to information contained within the route book

The infrastructure manager must advise the railway undertaking of any permanent or temporary modifications to information supplied in accordance with point 4.2.1.2.2.1.

These changes must be grouped by the railway undertaking into a dedicated document or computer medium whose format must be the same for all the infrastructures worked over by the trains of an individual railway undertaking.

The infrastructure manager must ensure that the content of the documentation provided to the railway undertaking(s) is complete and accurate.

The railway undertaking must ensure that the content of the document grouping the modifications to information contained within the Route book is complete and accurate.

4.2.1.2.2.3. Informing the driver in real time

The infrastructure manager must inform drivers of any changes to the line or relevant lineside equipment that have not been advised as modifications to information for the Route Book as set out in point 4.2.1.2.2.2.

4.2.1.2.3. Timetables

The provision of train schedule information facilitates the punctual running of trains and assists in service performance.

The railway undertaking must provide drivers with the information necessary for the normal running of the train and as a minimum include:

|

— |

the train identification; |

|

— |

the train running days (if necessary); |

|

— |

the stopping points and the activities associated with them |

|

— |

other timing points; |

|

— |

the arrival/departure/passing times at each of those points. |

Such train running information, which must be based on information supplied by the infrastructure manager, may be provided either electronically or in a paper format.

Presentation to the driver must be consistent across all the lines over which the railway undertaking operates.

4.2.1.2.4. Rolling stock

The railway undertaking must provide the driver with all information relevant to the working of the rolling stock during degraded situations (such as trains requiring assistance). Such documentation must also focus on the specific interface with the infrastructure manager’s staff in these cases.

4.2.1.3.

The railway undertaking must provide all members of his staff (whether on train or otherwise) who undertake safety-critical tasks involving a direct interface with the staff, equipment or systems of the infrastructure manager with the rules, procedures, rolling stock and route specific information it deems appropriate to such tasks. Such information shall be applicable in both normal and degraded operation.

For staff on-board trains, the structure, format, content and process for preparation and updating of such information must be based on the specification set out in Subsection 4.2.1.2 of this TSI.

4.2.1.4.

All the information necessary to ensure safety-related communication between staff authorising the movement of trains and train crews must be set out in:

|

— |

documents describing the Communications Principles (Appendix C); |

|

— |

the document entitled Book of forms. |

The infrastructure manager must draw up these documents in his operating language.

4.2.1.5.

The language used for safety-related communication between train crew, other railway undertaking staff (as defined in Appendix L) and the staff authorising train movements is the operating language (see glossary) used by the infrastructure manager on the route concerned.

The principles for safety-related communication between train crew and staff responsible for authorising the movement of trains are to be found in Appendix C.

In conformity with Directive 2001/14/EC, the infrastructure manager is responsible for publishing the ‘operating’ language used by his personnel in daily operational use.

Where, however, local practice requires that a second language is also provided for, it is the responsibility of the infrastructure manager to determine the geographic boundaries for its use.

4.2.2. Specifications relating to trains

4.2.2.1.

4.2.2.1.1. General requirement

The railway undertaking must ensure that trains are fitted with means of indicating the front and rear of the train.

4.2.2.1.2. Front end

The railway undertaking must ensure that an approaching train is clearly visible and recognisable as such, by the presence and layout of its lit white front-end lights.

The forward facing front-end of the leading vehicle of a train must be fitted with three lights in an isosceles triangle, as shown below. These lights must always be lit when the train is being driven from that end.

The front lights must optimise train detectability (for example, to track workers and those using public crossings) (marker lights), provide sufficient visibility for the train driver (illumination of the line ahead, lineside information markers/boards, etc.) (head lights) by night and during low light conditions and must not dazzle the drivers of oncoming trains.

The spacing, the height above rails, the diameter, the intensity of the lights, the dimensions and shape of the emitted beam in both day and night time operation are defined in the rolling stock TSI(hereinafter referred to as ‘RST TSI’).

4.2.2.1.3. Rear end

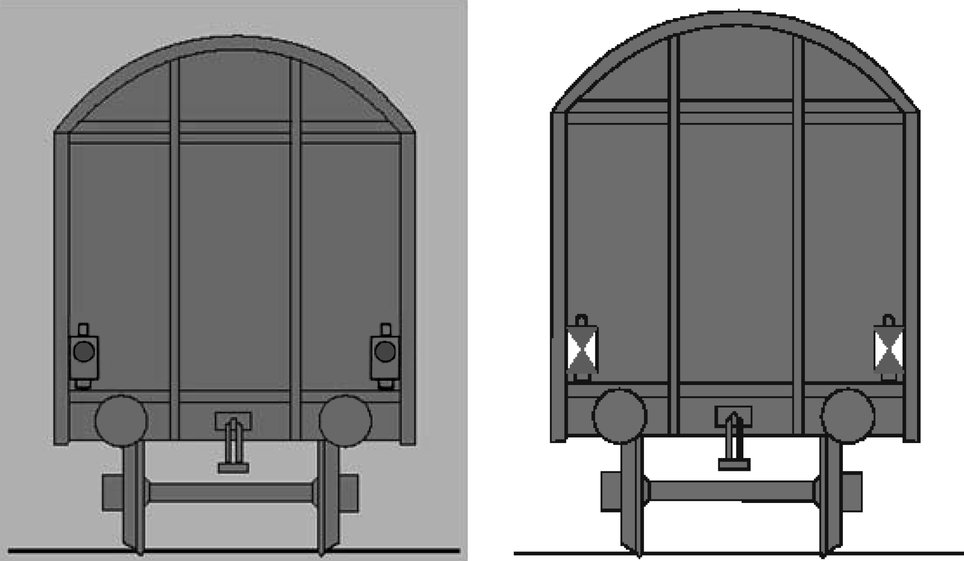

The railway undertaking must provide the required means of indicating the rear of a train. The rear end signal must only be exhibited on the rear of the last vehicle of the train. It must be displayed as shown below.

4.2.2.1.3.1. Passenger trains

The rear end indication of a passenger train must consist of 2 steady red lights at the same height above buffer on the transversal axis.

4.2.2.1.3.2. Freight trains in international traffic

The Member State must notify which of the following requirements will apply on the network of its Member State for trains that cross a border between Member States:

Either

|

— |

2 steady red lights, or |

|

— |

2 reflective plates of the following shape with white side triangles and red top and bottom triangle:

|

The lamps or plates must be on the same height above buffer on the transversal axis. Member States that require 2 reflective plates must also accept 2 steady red lights as train rear end indication.

4.2.2.1.3.3. Freight trains not crossing a border between member states

For freight trains not crossing a border between Member States the train rear end indication is an open point (see Appendix U).

4.2.2.2.

4.2.2.2.1. General requirement

The railway undertaking must ensure that trains are fitted with an audible warning device to indicate the approach of a train.

4.2.2.2.2. Control

The activation of the audible warning device must be possible from all driving positions.

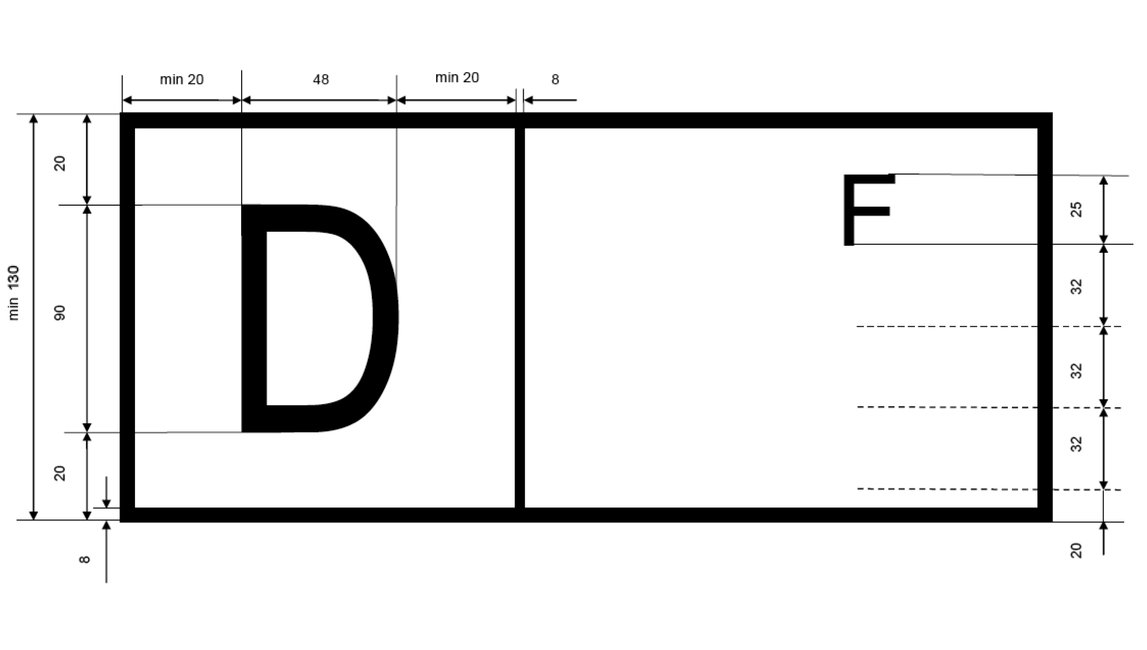

4.2.2.3.

Each vehicle must have a number to uniquely identify it from any other rail vehicle. This number must be prominently displayed at least on each longitudinal side of the vehicle.

It must also be possible to identify operational restrictions applicable to the vehicle.

Further requirements are specified in Appendix P.

4.2.2.4.

4.2.2.4.1. Safety of load

The railway undertaking must make sure that freight vehicles are safely and securely loaded and remain so throughout the journey.

4.2.2.4.2. Safety of passengers

The railway undertaking must ensure that passenger transport is undertaken safely at the departure and during the journey.

4.2.2.5.

The railway undertaking must define the rules and procedures to be followed by his staff so as to ensure that the train is in compliance with the allocated path.

Train composition requirements must take into account the following elements:

|

(a) |

the vehicles

|

|

(b) |

the train

|

|

(c) |

the weight and axle load

|

|

(d) |

the maximum speed of the train

|

|

(e) |

the kinematic envelope

|

Additional constraints may be required or imposed due to the type of braking regime or traction type on a particular train.

4.2.2.6.

4.2.2.6.1. Minimum requirements of the braking system

All vehicles in a train must be connected to the continuous automatic braking system as defined in the RST TSI.

The first and last vehicles (including any traction units) in any train must have the automatic brake operative.

In the case of a train becoming accidentally divided into two parts, both sets of detached vehicles must come automatically to a stand as a result of a maximum application of the brake.

4.2.2.6.2. Braking performance

The infrastructure manager must provide the railway undertaking with the actual performance required. This data shall include, if necessary, conditions of use of braking systems possibly affecting the infrastructure such as magnetic, regenerative and eddy-current brake.

The railway undertaking is responsible for ensuring that the train has sufficient braking performance by providing braking rules for its staff to be followed.

The rules concerning braking performance have to be managed within the infrastructure manager’s and railway undertaking’s safety management system.

Further requirements are specified in Appendix T.

4.2.2.7.

4.2.2.7.1. General requirement

The railway undertaking must define the process to ensure that all safety-related on-train equipment is in a fully functional state and that the train is safe to run.

The railway undertaking must inform the infrastructure manager of any modification to the characteristics of the train affecting its performance or any modification that might affect the ability to accommodate the train in its allocated path.

The infrastructure manager and the railway undertaking must define and keep up to date conditions and procedures for train running in degraded mode.

4.2.2.7.2. Data required

The data required for safe and efficient operation and the process by which this data must be forwarded must comprise:

|

— |

the train identification |

|

— |

the identity of the railway undertaking responsible for the train |

|

— |

the actual length of the train |

|

— |

if a train carries passengers or animals when it is not scheduled to do so |

|

— |

any operational restrictions with an indication of the vehicle(s) concerned (gauge, speed restrictions, etc.) |

|

— |

information the infrastructure manager requires for the transport of dangerous goods. |

The railway undertaking must ensure that this data is made available to the infrastructure manager(s) prior to the departure of the train.

The railway undertaking must advise the infrastructure manager(s) if a train will not occupy its allocated path or is cancelled.

4.2.2.8.

The driver must be able to observe signals and lineside markers, and they must be observable by the driver. The same applies for other types of lineside signs if they are safety related.

Therefore, signals, lineside markers, signs and information boards must be designed and positioned in such a consistent way to facilitate this. Issues that must be taken into account include:

|

— |

that they are suitably sited so that train headlights allow the driver to read the information, |

|

— |

suitability and intensity of lighting, where required to illuminate the information, |

|

— |

where retro-reflectivity is employed, the reflective properties of the material used are in compliance with appropriate specifications and the signs are fabricated so that train headlights easily allow the driver to read the information. |

Driving cabs must be designed in such a consistent way that the driver is able to easily see the information displayed to him.

4.2.2.9.

A means of onboard monitoring of driver vigilance is necessary. This shall intervene to bring the train to a stand if the driver does not react within a certain time; the time range is specified in the rolling stock TSI.

4.2.3. Specifications relating to train operations

4.2.3.1.

In accordance with Directive 2001/14/EC the infrastructure manager must advise what data is required when a train path is requested.

4.2.3.2.

Each train must be identified by a train running number. The train running number is given by the infrastructure manager when allocating a train path and must be known by the railway undertaking and all infrastructure managers operating the train. The train running number must be unique per network. Changes of train running number during a train journey should be avoided.

4.2.3.2.1. Format of train running number

The train running number format is defined in the control-command and signalling TSI (hereinafter referred to as ‘CCS TSI’)

4.2.3.3.

4.2.3.3.1. Checks and tests before departure

The railway undertaking must define the checks and tests to ensure that any departure is undertaken safely (e.g. doors, load, brakes).

4.2.3.3.2. Informing the infrastructure manager of the train's operational status

The railway undertaking shall inform the infrastructure manager when a train is ready for access to the network.

The railway undertaking must inform the infrastructure manager of any anomaly affecting the train or its operation having possible repercussions on the train's running prior to departure and during the journey.

4.2.3.4.

4.2.3.4.1. General requirements

Traffic management must ensure the safe, efficient and punctual operation of the railway, including effective recovery from service disruption.

The infrastructure manager must determine procedures and means for:

|

— |

the real time management of trains, |

|

— |

operational measures to maintain the highest possible performance of the infrastructure in case of delays or incidents, whether actual or anticipated, and |

|

— |

the provision of information to the railway undertaking(s) in such cases. |

Any additional processes required by the railway undertaking and which affect the interface with the infrastructure manager(s) can be introduced after being agreed with the infrastructure manager.

4.2.3.4.2. Train reporting

4.2.3.4.2.1. Data required for train position reporting

The infrastructure manager must:

|

(a) |

provide a means of real time recording of the times at which trains depart from, arrive at or pass appropriate pre-defined reporting points on their networks and the delta-time value; |

|

(b) |

provide the specific data required in relation to train position reporting. Such information must include:

|

4.2.3.4.2.2. Predicted hand over time

The infrastructure manager must have a process, which enables an indication of the estimated number of minutes of deviation from the scheduled time a train is scheduled to be handed over from one infrastructure manager to another.

This must include information on service disruption (description and location of problem).

4.2.3.4.3. Dangerous goods

The railway undertaking must define the procedures to supervise the transport of dangerous goods.

These procedures must include:

|

— |

the provisions as specified in Directive 2008/68/EC of the European Parliament and of the Council (1) |

|

— |

advice to the driver of the presence and position of dangerous goods on the train |

|

— |

information the infrastructure manager requires for transport of dangerous goods |

|

— |

determination, in conjunction with the infrastructure manager, of lines of communication and planning of specific measures in case of emergency situations involving the goods. |

4.2.3.4.4. Operational quality

The infrastructure manager and the railway undertaking must have processes in place to monitor the efficient operation of the all the services concerned.

Monitoring processes must be designed to analyse data and detect underlying trends, both in terms of human error and system error. The results of this analysis must be used to generate improvement actions, designed to eliminate or mitigate against events which could compromise the efficient operation of the network.

Where such improvement actions would have network-wide benefits, involving other infrastructure managers and railway undertakings, they must, subject to commercial confidentiality, be communicated accordingly.

Events that have significantly disrupted operations must be analysed as soon as possible by the infrastructure manager. Where appropriate, and in particular where one of their staff is concerned, the infrastructure manager must invite those railway undertaking(s) involved in the event concerned to participate in the analysis. Where the result of such analysis leads to network improvement recommendations designed to eliminate or mitigate against causes of accidents/incidents, these must be communicated to all relevant infrastructure managers and railway undertakings concerned.

These processes shall be documented and subject to internal audit.

4.2.3.5.

Data pertaining to the running of a train must be recorded and retained for the purposes of:

|

— |

Supporting systematic safety monitoring as a means of preventing incidents and accidents. |

|

— |

Identifying driver, train and infrastructure performance in the period leading up to and (if appropriate) immediately after an incident or accident, to enable the identification of causes related to train driving or train equipment, and supporting the case for new or changed measures to prevent recurrence. |

|

— |

To record information relating to the performance of both the locomotive/traction unit and the person driving. |

It must be possible to match recorded data to:

|

— |

the date and time of the recording |

|

— |

the precise geographic location of the event being recorded (distance in kilometres from a recognisable location) |

|

— |

the train identification |

|

— |

the identity of the driver |

Requirements with regard to storage, periodic evaluation of and access to this data are specified in relevant national laws of the Member State:

|

— |

in which the railway undertaking is licensed (with regard to on-board recorded data), or |

|

— |

of the Member State in which the infrastructure is located (with regard to data recorded outside the train). |

4.2.3.5.1. Recording of supervision data outside the train

As a minimum, the infrastructure manager must record the following data:

|

— |

the failure of line-side equipment associated with the movement of trains (signalling, points etc.); |

|

— |

the detection of an overheating axle bearing, where this equipment is provided; |

|

— |

communication between the train driver and infrastructure manager’s staff authorising train movements. |

4.2.3.5.2. Recording of supervision data on-board the train

As a minimum, the railway undertaking must record the following data:

|

— |

the passing of signals at danger or ‘end of movement authority’ without authority |

|

— |

application of the emergency brake |

|

— |

speed at which the train is running |

|

— |

any isolation or overriding of the on-board train control (signalling) systems |

|

— |

operation of the audible warning device (horn) |

|

— |

operation of door controls (release, closure) |

|

— |

detection by on-board hot axle box detectors, if fitted |

|

— |

identity of the cab for which data is being recorded to be checked. |

4.2.3.6.

4.2.3.6.1. Advice to other users

The infrastructure manager in conjunction with the railway undertaking(s) must define a process to immediately inform each other of any situation that impedes the safety, performance and/or the availability of the rail network or rolling stock.

4.2.3.6.2. Advice to train drivers

In any case of degraded operation associated with the infrastructure manager’s area of responsibility, the infrastructure manager must give formal instructions to drivers on what measures to take in order to safely overcome the degradation.

4.2.3.6.3. Contingency arrangements

The infrastructure manager in conjunction with all the railway undertakings operating over his infrastructure, and neighbouring infrastructure managers as appropriate, must define, publish and make available appropriate contingency measures and assign responsibilities based on the requirement to reduce any negative impact as a result of degraded operation.

The planning requirements and the response to such events must be proportional to the nature and potential severity of the degradation.

These measures, which must as a minimum include plans for recovering the network to ‘normal’ status, may also address:

|

— |

rolling stock failures (for example, those which could result in substantial traffic disruption, the procedures for rescuing failed trains); |

|

— |

infrastructure failures (for example, when there has been a failure of the electric power or the conditions under which trains may be diverted from the booked route); |

|

— |

extreme weather conditions. |

The infrastructure manager must establish and keep updated contact information for key infrastructure manager and railway undertaking staff who may be contacted in the event of service disruption leading to degraded operation. This information must include contact details both during and outside office hours.

The railway undertaking must submit this information to the infrastructure manager and advise the infrastructure manager of any changes to these contact details.

The infrastructure manager must advise all the railway undertaking(s) of any changes to his details.

4.2.3.7.

The infrastructure manager must, in consultation with:

|

— |

all railway undertakings operating over his infrastructure, or, where appropriate, representative bodies of railway undertakings operating over his infrastructure, |

|

— |

neighbouring infrastructure managers, as appropriate, |

|

— |

local authorities, representative bodies of the emergency services (including fire fighting and rescue) at either local or national level, as appropriate. |

define, publish and make available appropriate measures to manage emergency situations and restore the line to normal operation.

Such measures shall typically cover:

|

— |

collisions, |

|

— |

fires on train, |

|

— |

evacuation of trains, |

|

— |

accidents in tunnels, |

|

— |

incidents involving dangerous goods |

|

— |

derailments |

The railway undertaking must provide the infrastructure manager with any specific information in respect to these circumstances, especially in respect to the recovery or re-railing of their trains.

Additionally, the railway undertaking must have processes to inform passengers about onboard emergency and safety procedures.

4.2.3.8.

The railway undertaking must define appropriate procedures to assist the train crew in degraded situations in order to avoid or decrease delays caused by technical or other failures of the rolling stock (for example, lines of communication, measures to be taken in case of evacuation of a train).

4.3. Functional and technical specifications of the interfaces

In the light of the essential requirements set out in Chapter 3, the functional and technical specifications of the interfaces are as follows:

4.3.1. Interfaces with the infrastructure TSI

|

Reference conventional rail operation TSI |

|

Reference conventional rail infrastructure TSI |

|

|

Parameter |

Point |

Parameter |

Point |

|

Braking performance |

4.2.2.6.2 |

Longitudinal track resistance |

4.2.7.2 |

|

Modifications to information contained in the route book |

4.1.2.2.2 |

Operating rules |

4.4 |

|

Degraded operation |

4.2.3.6 |

4.3.2. Interfaces with the control-command and signalling TSI

|

Reference conventional rail operation TSI |

|

Reference conventional rail CCS draft TSI |

|

|

Parameter |

Point |

Parameter |

Point |

|

Rule book |

4.2.1.2.1 |

|

|

|

Operating rules |

4.4 |

Operating rules |

4.4 |

|

Signal and lineside marker sighting |

4.2.2.8 |

Visibility of track-side control-command objects |

4.2.16 |

|

Braking performance |

4.2.2.6 |

Train braking performance and characteristics |

4.3.2.3 |

|

Rule Book |

4.2.1.2.1 |

Use of sanding equipment |

4.2.10 |

|

Train running number |

4.2.3.2.1 |

ETCS DMI |

4.2.12 |

|

|

GSM-R DMI |

4.2.13 |

|

|

Data recording onboard |

4.2.3.5 |

Interface to data recording for regulatory purposes |

4.2.15 |

4.3.3. Interfaces with the rolling stock TSI

4.3.3.1.

|

Reference conventional rail operation TSI |

|

Reference conventional rail locom. and pass. TSI |

|

|

Parameter |

Point |

Parameter |

Point |

|

Contingency arrangements |

4.2.3.6.3 |

Rescue coupling |

4.2.2.2.4 |

|

Train composition |

4.2.2.5 |

Interface with infrastructure: axle load parameter |

4.2.3.2 |

|

Minimum requirements of the braking system |

4.2.2.6.1 |

Braking performance |

4.2.4.5 |

|

Train visibility |

4.2.2.1 |

External front and rear lights |

4.2.7.1 |

|

Train audibility |

4.2.2.2 |

Horn |

4.2.7.2 |

|

Signal sighting |

4.2.2.8 |

External visibility |

4.2.9.1.3 |

|

Optical characteristics of the windscreen |

4.2.9.2.2 |

||

|

Internal lighting |

4.2.9.1.8 |

||

|

Driver vigilance |

4.2.2.9 |

Driver's activity control function |

4.2.9.3.1 |

|

Data recording |

4.2.3.5.2 |

Recording device |

4.2.9.5 |

4.3.3.2.

|

Reference conventional rail operation TSI |

|

Reference conventional freight wagon draft TSI |

|

|

Parameter |

Point |

Parameter |

Point |

|

Rear end |

4.2.2.1.3.2 |

Attachment devices for rear-end signal |

4.2.6.3 |

|

Rear end |

4.2.2.1.3.2 |

Rear-end signal |

Annex E |

|

Train composition |

4.2.2.5 |

Gauging |

4.2.3.1 |

|

Train composition |

4.2.2.5 |

Axle load parameter |

4.2.3.3.2 |

|

Contingency arrangements |

4.2.3.6.3 |

Lifting and jacking |

4.2.2.2 |

|

Train braking |

4.2.2.6 |

Brake |

4.2.4 |

4.3.4. Interfaces with the Energy TSI

|

Reference conventional rail operation TSI |

|

Reference conventional rail energy TSI |

|

|

Parameter |

Point |

Parameter |

Point |

|

Description of the line and the relevant line side equipment associated with the lines worked over |

4.2.1.2.2 |

Management of power supply |

4.4.2 |

|

Informing the driver in real time |

4.2.1.2.2.3 |

|

|

|

Modifications to information contained within the route book |

4.2.1.2.2.2 |

Execution of works |

4.4.3 |

4.4. Operating rules

The rules and procedures enabling coherent operation of new and different structural subsystems intended to be used in the TEN, and in particular those that are linked directly to the operation of a new train control and signalling system, must be identical where identical situations exist.

To this end, the operating rules for the European Rail Traffic Management System (ERTMS/ETCS) and for ERTMS/GSM-R radio system are specified in Appendix A.

Other operating rules, which are able to be standardised across the TEN, will be specified in Appendix B.

4.5. Maintenance rules

Not applicable

4.6. Professional qualifications

In accordance with point 2.2.1 of this TSI, this point deals with professional and linguistic competency and the assessment process required for staff to attain this competency.

4.6.1. Professional competency

Staff (including contractors) of the railway undertaking and the infrastructure manager must have attained appropriate professional competency to undertake all necessary safety-related duties in normal, degraded and emergency situations. Such competency comprises professional knowledge and the ability to put this knowledge into practice.

Minimum elements relevant to professional qualification for individual tasks can be found in Appendices J and L.

4.6.1.1.