ISSN 1977-0677

doi:10.3000/19770677.L_2012.254.eng

Official Journal

of the European Union

L 254

English edition

Legislation

Volume 55

20 September 2012

|

ISSN 1977-0677 doi:10.3000/19770677.L_2012.254.eng |

||

|

Official Journal of the European Union |

L 254 |

|

|

||

|

English edition |

Legislation |

Volume 55 |

|

Contents |

|

II Non-legislative acts |

page |

|

|

|

ACTS ADOPTED BY BODIES CREATED BY INTERNATIONAL AGREEMENTS |

|

|

|

* |

||

|

|

* |

|

EN |

Acts whose titles are printed in light type are those relating to day-to-day management of agricultural matters, and are generally valid for a limited period. The titles of all other Acts are printed in bold type and preceded by an asterisk. |

II Non-legislative acts

ACTS ADOPTED BY BODIES CREATED BY INTERNATIONAL AGREEMENTS

|

20.9.2012 |

EN |

Official Journal of the European Union |

L 254/1 |

Only the original UN/ECE texts have legal effect under international public law. The status and date of entry into force of this Regulation should be checked in the latest version of the UN/ECE status document TRANS/WP.29/343, available at:

http://www.unece.org/trans/main/wp29/wp29wgs/wp29gen/wp29fdocstts.html

Regulation No 10 of the Economic Commission for Europe of the United Nations (UN/ECE) — Uniform provisions concerning the approval of vehicles with regard to electromagnetic compatibility

Incorporating all valid text up to:

04 series of amendments — Date of entry into force: 28 October 2011

Corrigendum 1 to the Revision 4 — Date of entry into force: 28 October 2011

Supplement 1 to the 04 series of amendments — Date of entry into force: 26 July 2012

CONTENTS

|

1. |

Scope |

|

2. |

Definitions |

|

3. |

Application for approval |

|

4. |

Approval |

|

5. |

Markings |

|

6. |

Specification in configurations other than ‘RESS charging mode coupled to the power grid’ |

|

7. |

Additional specifications in the configuration ‘RESS charging mode coupled to the power grid’ |

|

8. |

Amendment or extension of a vehicle type-approval following electrical/electronic sub assembly (ESA) addition or substitution |

|

9. |

Conformity of production |

|

10. |

Penalties for non-conformity of production |

|

11. |

Production definitively discontinued |

|

12. |

Modification and extension of type-approval of a vehicle or ESA |

|

13. |

Transitional provisions |

|

14. |

Names and addresses of Technical Services conducting approval tests, and of Type Approval Authorities |

APPENDICES

|

1 |

List of standards referred to in this Regulation |

|

2 |

Vehicle broadband reference limits |

|

3 |

Vehicle broadband reference limits |

|

4 |

Vehicle narrowband reference limits |

|

5 |

Vehicle narrowband reference limits |

|

6 |

Electrical/electronic sub-assembly |

|

7 |

Electrical/electronic sub-assembly |

ANNEXES

|

1 |

Examples of approval marks |

|

2A |

Information document for type-approval of a vehicle with respect to electromagnetic compatibility |

|

2B |

Information document for type-approval of an electric/electronic sub-assembly with respect to electromagnetic compatibility |

|

3A |

Communication concerning the approval or extension or refusal or withdrawal of approval or production definitely discontinued of a type of vehicle/component/separate technical unit with regard to Regulation No 10 |

|

3B |

Communication concerning the approval or extension or refusal or withdrawal of approval or production definitely discontinued of a type of electrical/electronic sub-assembly with regard to Regulation No 10 |

|

4 |

Method of measurement of radiated broadband electromagnetic emissions from vehicles |

|

5 |

Method of measurement of radiated narrowband electromagnetic emissions from vehicles |

|

6 |

Method of testing for immunity of vehicles to electromagnetic radiation |

|

7 |

Method of measurement of radiated broadband electromagnetic emissions from electrical/electronic sub-assemblies |

|

8 |

Method of measurement of radiated narrowband electromagnetic emissions from electrical/electronic sub-assemblies |

|

9 |

Method(s) of testing for immunity of electrical/electronic sub-assemblies to electromagnetic radiation |

|

10 |

Method(s) of testing for immunity to and emission of transients of electrical/electronic sub-assemblies |

|

11 |

Method(s) of testing for emission of harmonics generated on AC power lines from vehicle |

|

12 |

Method(s) of testing for emission of voltage changes, voltage fluctuations and flicker on AC power lines from vehicle |

|

13 |

Method(s) of testing for emission of radiofrequency conducted disturbances on AC or DC power lines from vehicle |

|

14 |

Method(s) of testing for emission of radiofrequency conducted disturbances on network and telecommunication access from vehicle |

|

15 |

Method(s) of testing for immunity of vehicles to electrical fast transient/ burst disturbances conducted along AC and DC power lines |

|

16 |

Method(s) of testing for immunity of vehicles to surges conducted along AC and DC power lines |

1. SCOPE

This Regulation applies to:

|

1.1. |

Vehicles of categories L, M, N and O (1) with regard to electromagnetic compatibility. |

|

1.2. |

Components and separate technical units intended to be fitted in these vehicles with the limitation given in paragraph 3.2.1 with regard to electromagnetic compatibility. |

|

1.3. |

It covers:

|

2. DEFINITIONS

For the purposes of this Regulation:

|

2.1. |

‘Electromagnetic compatibility’ means the ability of a vehicle or component(s) or separate technical unit(s) to function satisfactorily in its electromagnetic environment without introducing intolerable electromagnetic disturbances to anything in that environment. |

|

2.2. |

‘Electromagnetic disturbance’ means any electromagnetic phenomenon which may degrade the performance of a vehicle or component(s) or separate technical unit(s), or of any other device, unit of equipment or system operated in vicinity of a vehicle. An electromagnetic disturbance may be electromagnetic noise, an unwanted signal or a change in the propagation medium itself. |

|

2.3. |

‘Electromagnetic immunity’ means the ability of a vehicle or component(s) or separate technical unit(s) to operate without degradation of performance in the presence of (specified) electromagnetic disturbances which includes wanted radio frequency signals from radio transmitters or radiated in-band emissions of industrial-scientific-medical (ISM) apparatus, internal or external to the vehicle. |

|

2.4. |

‘Electromagnetic environment’ means the totality of electromagnetic phenomena existing at a given location. |

|

2.5. |

‘Broadband emission’ means an emission, which has a bandwidth greater than that of a particular measuring apparatus or receiver (International Special Committee on Radio Interference (CISPR) 25, second edition 2002 and Corrigendum 2004). |

|

2.6. |

‘Narrowband emission’ means an emission which has a bandwidth less than that of a particular measuring apparatus or receiver (CISPR 25, second edition 2002 and Corrigendum 2004). |

|

2.7. |

‘Electrical/electronic system’ means (an) electrical and/or electronic device(s) or set(s) of devices together with any associated electrical connections which form part of a vehicle but which are not intended to be type-approved separately from the vehicle. Both RESS and Coupling system for charging the RESS are considered electrical/electronic systems. |

|

2.8. |

‘Electrical/electronic sub-assembly’ (ESA) means an electrical and/or electronic device or set(s) of devices intended to be part of a vehicle, together with any associated electrical connections and wiring, which performs one or more specialised functions. An ESA may be approved at the request of a manufacturer or his authorised representative as either a ‘component’ or a ‘separate technical unit (STU)’. |

|

2.9. |

‘Vehicle type’ in relation to electromagnetic compatibility includes all vehicles, which do not differ essentially in such respects as:

|

|

2.10. |

An ‘ESA type’ in relation to electromagnetic compatibility means ESAs, which do not differ in such essential respects as:

|

|

2.11. |

‘Vehicle wiring harness’ means supply voltage, bus system (e.g. CAN), signal or active antenna cables, which are installed by the vehicle manufacturer. |

|

2.12. |

‘Immunity related functions’ are:

|

|

2.13. |

‘RESS’ means the rechargeable energy storage system that provides electric energy for electric propulsion of the vehicle. |

|

2.14. |

‘Coupling system for charging the RESS’ means the electrical circuit installed in the vehicle used for charging the RESS. |

3. APPLICATION FOR APPROVAL

3.1. Approval of a vehicle type

|

3.1.1. |

The application for approval of a vehicle type, with regard to its electromagnetic compatibility, shall be submitted by the vehicle manufacturer. |

|

3.1.2. |

A model of information document is shown in Annex 2A. |

|

3.1.3. |

The vehicle manufacturer shall draw up a schedule describing all relevant vehicle electrical/electronic systems or ESAs, body styles, variations in body material, general wiring arrangements, engine variations, left-hand/right-hand drive versions and wheelbase versions. Relevant vehicle electrical/electronic systems or ESAs are those which may emit significant broadband or narrowband radiation and/or those which are involved in immunity related functions of the vehicle (see paragraph 2.12) and those which provide coupling systems for charging the RESS. |

|

3.1.4. |

A vehicle representative of the type to be approved shall be selected from this schedule by mutual agreement between the manufacturer and the Competent Authority. The choice of vehicle shall be based on the electrical/electronic systems offered by the manufacturer. One or more vehicles may be selected from this schedule if it is considered by mutual agreement between the manufacturer and the Competent Authority that different electrical/electronic systems are included which are likely to have a significant effect on the vehicle’s electromagnetic compatibility compared with the first representative vehicle. |

|

3.1.5. |

The choice of the vehicle(s) in conformity with paragraph 3.1.4 above shall be limited to vehicle/electrical/electronic system combinations intended for actual production. |

|

3.1.6. |

The manufacturer may supplement the application with a report on tests which have been carried out. Any such data provided may be used by the approval authority for the purpose of drawing up the communication form for type-approval. |

|

3.1.7. |

If the Technical Service responsible for the type-approval test carries out the test itself, then a vehicle representative of the type to be approved according to paragraph 3.1.4 shall be provided. |

|

3.1.8. |

For vehicles of categories M, N, and O the vehicle manufacturer must provide a statement of frequency bands, power levels, antenna positions and installation provisions for the installation of radio frequency transmitters (RF-transmitters), even if the vehicle is not equipped with an RF transmitter at time of type-approval. This should cover all mobile radio services normally used in vehicles. This information must be made publicly available following the type-approval. Vehicle manufacturers must provide evidence that vehicle performance is not adversely affected by such transmitter installations. |

|

3.1.9. |

Vehicle type-approval shall be applied for both RESS and Coupling system for charging the RESS as they are considered as electrical/electronic systems. |

3.2. ESA type-approval

|

3.2.1. |

Applicability of this Regulation to ESA:

|

|

3.2.2. |

The application for approval of a type of ESA with regard to its electromagnetic compatibility shall be submitted by the vehicle manufacturer or by the manufacturer of the ESA. |

|

3.2.3. |

A model of information document is shown in Annex 2B. |

|

3.2.4. |

The manufacturer may supplement the application with a report on tests which have been carried out. Any such data provided may be used by the approval authority for the purpose of drawing up the communication form for type-approval. |

|

3.2.5. |

If the Technical Service responsible for the type-approval test carries out the test itself, then a sample of the ESA system representative of the type to be approved shall be provided, if necessary, after discussion with the manufacturer on, e.g. possible variations in the layout, number of components, number of sensors. If the Technical Service deems it necessary, it may select a further sample. |

|

3.2.6. |

The sample(s) must be clearly and indelibly marked with the manufacturer’s trade name or mark and the type designation. |

|

3.2.7. |

Where applicable, any restrictions on use should be identified. Any such restrictions should be included in Annexes 2B and/or 3B. |

|

3.2.8. |

ESA which are brought to the market as spare parts need no type-approval if they are obviously marked as a spare part by an identification number and if they are identical and from the same manufacturer as the corresponding original equipment manufacturer (OEM) part for an already type-approved vehicle. |

|

3.2.9. |

Components sold as aftermarket equipment and intended for the installation in motor vehicles need no type-approval if they are not related to immunity related functions (see paragraph 2.12). In this case a declaration must be issued by the manufacturer that the ESA fulfils the requirements of this Regulation and in particular the limits defined in paragraphs 6.5, 6.6, 6.8 and 6.9. |

4. APPROVAL

4.1. Type-approval procedures

4.1.1. Type-approval of a vehicle

The following alternative procedures for vehicle type-approval may be used at the discretion of the vehicle manufacturer.

4.1.1.1. Approval of a vehicle installation

A vehicle installation may be type-approved directly by following the provisions laid down in paragraph 6 of this Regulation. If this procedure is chosen by a vehicle manufacturer, no separate testing of electrical/electronic systems or ESAs is required.

4.1.1.2. Approval of vehicle type by testing of individual ESAs

A vehicle manufacturer may obtain approval for the vehicle by demonstrating to the approval authority that all the relevant (see paragraph 3.1.3 of this Regulation) electrical/electronic systems or ESAs have been approved in accordance with this Regulation and have been installed in accordance with any conditions attached thereto.

4.1.1.3. A manufacturer may obtain approval according to this Regulation if the vehicle has no equipment of the type, which is subject to immunity or emission tests. Such approvals do not require testing.

4.1.2. Type-approval of an ESA

Type-approval may be granted to an ESA to be fitted either to any vehicle type (component approval) or to a specific vehicle type or types requested by the ESA manufacturer (separate technical unit approval).

4.1.3. ESAs, which are intentional RF transmitters, which have not received type-approval in conjunction with a vehicle manufacturer, must be supplied with suitable installation guidelines.

4.2. Granting of type-approval

4.2.1. Vehicle

4.2.1.1. If the representative vehicle fulfils the requirements of paragraph 6 of this Regulation, type-approval shall be granted.

4.2.1.2. A model of communication form for type-approval is contained in Annex 3A.

4.2.2. ESA

4.2.2.1. If the representative ESA system(s) fulfil(s) the requirements of paragraph 6 of this Regulation, type-approval shall be granted.

4.2.2.2. A model of communication form for type-approval is contained in Annex 3B.

4.2.3. In order to draw up the communication forms referred to in paragraph 4.2.1.2 or 4.2.2.2 above, the Competent Authority of the Contracting Party granting the approval may use a report prepared or approved by a recognised laboratory or in accordance with the provisions of this Regulation.

4.3. Approval, or refusal of approval, of a type of vehicle or ESA in accordance with this Regulation shall be notified to the Parties to the Agreement applying this Regulation on a form conforming to the model in Annex 3A or 3B of this Regulation, accompanied by photographs and/or diagrams or drawings on an appropriate scale supplied by the applicant in a format not larger than A4 (210 × 297 mm) or folded to those dimensions.

5. MARKINGS

5.1. An approval number shall be assigned to each vehicle or ESA type-approved. The first two digits of this number shall indicate the series of amendments corresponding to the most recent essential technical amendments made to the Regulation at the date of approval. A Contracting Party may not assign the same approval number to another type of vehicle or ESA.

5.2. Presence of markings

5.2.1. Vehicle

An approval mark described in paragraph 5.3 below shall be affixed to every vehicle conforming to a type-approved under this Regulation.

5.2.2. Sub-assembly

An approval mark described in paragraph 5.3 below shall be affixed to every ESA conforming to a type-approved under this Regulation.

No marking is required for electrical/electronic systems built into vehicles which are approved as units.

5.3. An international approval mark must be affixed, in a conspicuous and easily accessible place specified on the approval communication form, on each vehicle conforming to the type-approved under this Regulation. This mark shall comprise:

5.3.1. A circle containing the letter ‘E’, followed by the distinguishing number of the country granting the approval (2).

5.3.2. The number of this Regulation, followed by the letter ‘R’, a dash and the approval number to the right of the circle specified in paragraph 5.3.1.

5.4. An example of the type-approval mark is shown in Annex 1 to this Regulation.

5.5. Markings on ESAs in conformity with paragraph 5.3 above need not be visible when the ESA is installed in the vehicle.

6. SPECIFICATIONS IN CONFIGURATIONS OTHER THAN ‘RESS CHARGING MODE COUPLED TO THE POWER GRID’

6.1. General specifications

6.1.1. A vehicle and its electrical/electronic system(s) or ESA(s) shall be so designed, constructed and fitted as to enable the vehicle, in normal conditions of use, to comply with the requirements of this Regulation.

|

6.1.1.1. |

A vehicle shall be tested for radiated emissions and for immunity to radiated disturbances. No tests for conducted emissions or immunity to conducted disturbances are required for vehicle type-approval. |

|

6.1.1.2. |

ESA(s) shall be tested for radiated and conducted emissions, for immunity to radiated and conducted disturbances. |

6.1.2. Before testing the Technical Service has to prepare a test plan in conjunction with the manufacturer, which contains at least mode of operation, stimulated function(s), monitored function(s), pass/fail criterion(criteria) and intended emissions.

6.2. Specifications concerning broadband electromagnetic radiation from vehicles

6.2.1. Method of measurement

The electromagnetic radiation generated by the vehicle representative of its type shall be measured using the method described in Annex 4. The method of measurement shall be defined by the vehicle manufacturer in accordance with the Technical Service.

6.2.2. Vehicle broadband type-approval limits

|

6.2.2.1. |

If measurements are made using the method described in Annex 4 using a vehicle-to-antenna spacing of 10,0 ± 0,2 m, the limits shall be 32 dB microvolts/m in the 30 to 75 MHz frequency band and 32 to 43 dB microvolts/m in the 75 to 400 MHz frequency band, this limit increasing logarithmically with frequencies above 75 MHz as shown in Appendix 2. In the 400 to 1 000 MHz frequency band the limit remains constant at 43 dB microvolts/m. |

|

6.2.2.2. |

If measurements are made using the method described in Annex 4 using a vehicle-to-antenna spacing of 3,0 ± 0,05 m, the limits shall be 42 dB microvolts/m in the 30 to 75 MHz frequency band and 42 to 53 dB microvolts/m in the 75 to 400 MHz frequency band, this limit increasing logarithmically with frequencies above 75 MHz as shown in Appendix 3. In the 400 to 1 000 MHz frequency band the limit remains constant at 53 dB microvolts/m. |

|

6.2.2.3. |

On the vehicle representative of its type, the measured values, expressed in dB microvolts/m shall be below the type-approval limits. |

6.3. Specifications concerning narrowband electromagnetic radiation from vehicles

6.3.1. Method of measurement

The electromagnetic radiation generated by the vehicle representative of its type shall be measured using the method described in Annex 5. These shall be defined by the vehicle manufacturer in accordance with the Technical Service.

6.3.2. Vehicle narrowband type-approval limits

|

6.3.2.1. |

If measurements are made using the method described in Annex 5 using a vehicle-to-antenna spacing of 10,0 ± 0,2 m, the limits shall be 22 dB microvolts/m in the 30 to 75 MHz frequency band and 22 to 33 dB microvolts/m in the 75 to 400 MHz frequency band, this limit increasing logarithmically with frequencies above 75 MHz as shown in Appendix 4. In the 400 to 1 000 MHz frequency band the limit remains constant at 33 dB microvolts/m. |

|

6.3.2.2. |

If measurements are made using the method described in Annex 5 using a vehicle-to-antenna spacing of 3,0 ± 0,05 m, the limit shall be 32 dB microvolts/m in the 30 to 75 MHz frequency band and 32 to 43 dB microvolts/m in the 75 to 400 MHz frequency band, this limit increasing logarithmically with frequencies above 75 MHz as shown in Appendix 5. In the 400 to 1 000 MHz frequency band the limit remains constant at 43 dB microvolts/m. |

|

6.3.2.3. |

On the vehicle representative of its type, the measured values, expressed in dB microvolts/m, shall be below the type-approval limit. |

|

6.3.2.4. |

Notwithstanding the limits defined in paragraphs 6.3.2.1, 6.3.2.2 and 6.3.2.3 of this Regulation, if, during the initial step described in paragraph 1.3 of Annex 5, the signal strength measured at the vehicle broadcast radio antenna is less than 20 dB microvolts over the frequency range 76 to 108 MHz measured with an average detector, then the vehicle shall be deemed to comply with the limits for narrowband emissions and no further testing will be required. |

6.4. Specifications concerning immunity of vehicles to electromagnetic radiation

6.4.1. Method of testing

The immunity to electromagnetic radiation of the vehicle representative of its type shall be tested by the method described in Annex 6.

6.4.2. Vehicle immunity type-approval limits

|

6.4.2.1. |

If tests are made using the method described in Annex 6, the field strength shall be 30 volts/m rms (root mean squared) in over 90 per cent of the 20 to 2 000 MHz frequency band and a minimum of 25 volts/m rms over the whole 20 to 2 000 MHz frequency band. |

|

6.4.2.2. |

The vehicle representative of its type shall be considered as complying with immunity requirements if, during the tests performed in accordance with Annex 6, there shall be no degradation of performance of ‘immunity related functions’, according to paragraph 2.1 of Annex 6. |

6.5. Specification concerning broadband electromagnetic interference generated by ESAs.

6.5.1. Method of measurement

The electromagnetic radiation generated by the ESA representative of its type shall be measured by the method described in Annex 7.

6.5.2. ESA broadband type-approval limits

|

6.5.2.1. |

If measurements are made using the method described in Annex 7, the limits shall be 62 to 52 dB microvolts/m in the 30 to 75 MHz frequency band, this limit decreasing logarithmically with frequencies above 30 MHz, and 52 to 63 dB microvolts/m in the 75 to 400 MHz band, this limit increasing logarithmically with frequencies above 75 MHz as shown in Appendix 6. In the 400 to 1 000 MHz frequency band the limit remains constant at 63 dB microvolts/m. |

|

6.5.2.2. |

On the ESA representative of its type, the measured values, expressed in dB microvolts/m, shall be below the type-approval limits. |

6.6. Specifications concerning narrowband electromagnetic interference generated by ESAs.

6.6.1. Method of measurement

The electromagnetic radiation generated by the ESA representative of its type shall be measured by the method described in Annex 8.

6.6.2. ESA narrowband type-approval limits

|

6.6.2.1. |

If measurements are made using the method described in Annex 8, the limits shall be 52 to 42 dB microvolts/m in the 30 to 75 MHz frequency band, this limit decreasing logarithmically with frequencies above 30 MHz, and 42 to 53 dB microvolts/m in the 75 to 400 MHz band, this limit increasing logarithmically with frequencies above 75 MHz as shown in Appendix 7. In the 400 to 1 000 MHz frequency band the limit remains constant at 53 dB microvolts/m. |

|

6.6.2.2. |

On the ESA representative of its type, the measured value, expressed in dB microvolts/m shall be below the type-approval limits. |

6.7. Specifications concerning immunity of ESAs to electromagnetic radiation

6.7.1. Method(s) of testing

The immunity to electromagnetic radiation of the ESA representative of its type shall be tested by the method(s) chosen from those described in Annex 9.

6.7.2. ESA immunity type-approval limits

|

6.7.2.1. |

If tests are made using the methods described in Annex 9, the immunity test levels shall be 60 volts/m root-mean-square (rms) for the 150 mm stripline testing method, 15 volts/m rms for the 800 mm stripline testing method, 75 volts/m rms for the Transverse Electromagnetic Mode (TEM) cell testing method, 60 mA rms for the bulk current injection (BCI) testing method and 30 volts/m rms for the free field testing method in over 90 per cent of the 20 to 2 000 MHz frequency band, and to a minimum of 50 volts/m rms for the 150 mm stripline testing method, 12,5 volts/m rms for the 800 mm stripline testing method, 62,5 volts/m rms, for the TEM cell testing method, 50 mA rms for the bulk current injection (BCI) testing method and 25 volts/m rms for the free field testing method over the whole 20 to 2 000 MHz frequency band. |

|

6.7.2.2. |

The ESA representative of its type shall be considered as complying with immunity requirements if, during the tests performed in accordance with Annex 9, there shall be no degradation of performance of ‘immunity related functions’. |

6.8. Specifications concerning the immunity of ESAs to transient disturbances conducted along supply lines.

6.8.1. Method of testing

The immunity of ESA representative of its type shall be tested by the method(s) according to ISO 7637-2 (second edition 2004) as described in Annex 10 with the test levels given in Table 1.

Table 1

Immunity of ESA

|

Test pulse number |

Immunity test level |

Functional status for systems: |

|

|

Related to immunity related functions |

Not related to immunity related functions |

||

|

1 |

III |

C |

D |

|

2a |

III |

B |

D |

|

2b |

III |

C |

D |

|

3a/3b |

III |

A |

D |

|

4 |

III |

B (for ESA which must be operational during engine start phases) C (for other ESA) |

D |

6.9. Specifications concerning the emission of transient conducted disturbances generated by ESAs on supply lines.

6.9.1. Method of testing

The emission of ESA representative of its type shall be tested by the method(s) according to ISO 7637-2 (second edition 2004) as described in Annex 10 for the levels given in Table 2.

Table 2

Maximum allowed pulse amplitude

|

Maximum allowed pulse amplitude for |

||

|

Polarity of pulse amplitude |

Vehicles with 12 V systems |

Vehicles with 24 V systems |

|

Positive |

+75 |

+ 150 |

|

Negative |

– 100 |

– 450 |

6.10. Exceptions

6.10.1. Where a vehicle or electrical/electronic system or ESA does not include an electronic oscillator with an operating frequency greater than 9 kHz, it shall be deemed to comply with paragraph 6.3.2 or 6.6.2 and with Annexes 5 and 8.

6.10.2. Vehicles which do not have electrical/electronic systems with ‘immunity related functions’ need not be tested for immunity to radiated disturbances and shall be deemed to comply with paragraph 6.4 and with Annex 6 to this Regulation.

6.10.3. ESAs with no immunity related functions need not be tested for immunity to radiated disturbances and shall be deemed to comply with paragraph 6.7 and with Annex 9 to this Regulation.

6.10.4. Electrostatic discharge

For vehicles fitted with tyres, the vehicle body/chassis can be considered to be an electrically isolated structure. Significant electrostatic forces in relation to the vehicle’s external environment only occur at the moment of occupant entry into or exit from the vehicle. As the vehicle is stationary at these moments, no type-approval test for electrostatic discharge is deemed necessary.

6.10.5. Emission of transient conducted disturbances generated by ESAs on supply lines.

ESAs that are not switched, contain no switches or do not include inductive loads need not be tested for transient conducted emission and shall be deemed to comply with paragraph 6.9.

6.10.6. The loss of function of receivers during the immunity test, when the test signal is within the receiver bandwidth (RF exclusion band) as specified for the specific radio service/product in the harmonised international EMC standard, does not necessarily lead to fail criteria.

6.10.7. RF transmitters shall be tested in the transmit mode. Wanted emissions (e.g. from RF transmitting systems) within the necessary bandwidth and out of band emissions are disregarded for the purpose of this Regulation. Spurious emissions are subject to this Regulation.

|

6.10.7.1. |

‘Necessary Bandwidth’: for a given class of emission, the width of the frequency band which is just sufficient to ensure the transmission of information at the rate and with the quality required under specified conditions (Article 1, No 1.152 of the International Telecommunication Union (ITU) Radio Regulations). |

|

6.10.7.2. |

‘Out-of-band Emissions’: emission on a frequency or frequencies immediately outside the necessary bandwidth which results from the modulation process, but excluding spurious emissions (Article 1, No 1.144 of the ITU Radio Regulations). |

|

6.10.7.3. |

‘Spurious Emission’: in every modulation process additional undesired signals exist. They are summarised under the expression ‘spurious emissions’. Spurious emissions are emissions on a frequency or frequencies, which are outside the necessary bandwidth and the level of which may be reduced without affecting the corresponding transmission of information. Spurious emissions include harmonic emissions, parasitic emissions, intermodulation products and frequency conversion products, but exclude out-of-band emissions (Article 1, No 1.145 of the ITU Radio Regulations). |

7. ADDITIONAL SPECIFICATIONS IN THE CONFIGURATION ‘RESS CHARGING MODE COUPLED TO THE POWER GRID’

7.1. General specifications

7.1.1. A vehicle and its electrical/electronic system(s) shall be so designed, constructed and fitted as to enable the vehicle, in configuration ‘RESS charging mode coupled to the power grid’, to comply with the requirements of this Regulation.

7.1.2. A vehicle in configuration ‘RESS charging mode coupled to the power grid’ shall be tested for radiated emissions, immunity to radiated disturbances, conducted emissions and immunity to conducted disturbances.

7.1.3. Before testing the Technical Service has to prepare a test plan in conjunction with the manufacturer, for the configuration ‘RESS charging mode coupled to the power grid’ configuration which contains at least mode of operation, stimulated function(s), monitored function(s), pass/fail criterion (criteria) and intended emissions.

7.2. Specifications concerning broadband electromagnetic radiation from vehicles

7.2.1. Method of measurement

The electromagnetic radiation generated by the vehicle representative of its type shall be measured using the method described in Annex 4. The method of measurement shall be defined by the vehicle manufacturer in accordance with the Technical Service.

7.2.2. Vehicle broadband type-approval limits

|

7.2.2.1. |

If measurements are made using the method described in Annex 4 using a vehicle-to-antenna spacing of 10,0 ± 0,2 m, the limits shall be 32 dB microvolts/m in the 30 to 75 MHz frequency band and 32 to 43 dB microvolts/m in the 75 to 400 MHz frequency band, this limit increasing logarithmically with frequencies above 75 MHz as shown in Appendix 2. In the 400 to 1 000 MHz frequency band the limit remains constant at 43 dB microvolts/m. |

|

7.2.2.2. |

If measurements are made using the method described in Annex 4 using a vehicle-to-antenna spacing of 3,0 ± 0,05 m, the limits shall be 42 dB microvolts/m in the 30 to 75 MHz frequency band and 42 to 53 dB microvolts/m in the 75 to 400 MHz frequency band, this limit increasing logarithmically with frequencies above 75 MHz as shown in Appendix 3. In the 400 to 1 000 MHz frequency band the limit remains constant at 53 dB microvolts/m. On the vehicle representative of its type, the measured values, expressed in dB microvolts/m shall be below the type-approval limits. |

7.3. Specifications concerning emission of harmonics on AC power lines from vehicles

7.3.1. Method of measurement

The harmonics emission on AC power lines generated by the vehicle representative of its type shall be measured using the method described in Annex 11. The method of measurement shall be defined by the vehicle manufacturer in accordance with the Technical Service.

7.3.2. Vehicle type-approval limit

|

7.3.2.1. |

If measurements are made using the method described in Annex 11, the limits for input current ≤ 16 A per phase are those defined in IEC 61000-3-2 (edition 3.2 - 2005 + Amd1: 2008 + Amd2: 2009) and given in Table 3. Table 3 Maximum allowed harmonics (input current ≤ 16 A per phase)

|

||||||||||||||||||||||||||||

|

7.3.2.2. |

If measurements are made using the method described in Annex 11, the limits for input current > 16 A and ≤ 75 A per phase are those defined in IEC 61000-3-12 (edition 1.0 - 2004) and given in Tables 4, 5 and 6. Table 4 Maximum allowed harmonics (input current > 16 A and ≤ 75 A per phase) for equipment other than balanced three-phase equipment

Table 5 Maximum allowed harmonics (input current > 16 A and ≤ 75 A per phase) for balanced three-phase equipment

Table 6 Maximum allowed harmonics (input current > 16 A and ≤ 75 A per phase) for balanced three-phase equipment under specific conditions

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

7.4. Specifications concerning emission of voltage changes, voltage fluctuations and flicker on AC power lines from vehicles.

7.4.1. Method of measurement

The emission of voltage changes, voltage fluctuations and flicker on AC power lines generated by the vehicle representative of its type shall be measured using the method described in Annex 12. The method of measurement shall be defined by the vehicle manufacturer in accordance with the Technical Service.

7.4.2. Vehicle type-approval limit

|

7.4.2.1. |

If measurements are made using the method described in Annex 12, the limits for rated current ≤ 16 A per phase and not subjected to conditional connection are those defined in IEC 61000-3-3 (edition 2.0 - 2008) and given in Table 7. Table 7 Maximum allowed voltage changes, voltage fluctuations and flicker (rated current ≤ 16 A per phase and not subjected to conditional connection) Limits Values given in 61000-3-3 clause 5 |

|

7.4.2.2. |

If measurements are made using the method described in Annex 12, the limits for rated current > 16 A and ≤ 75 A per phase and subjected to conditional connection are those defined in IEC 61000-3-11 (edition 1.0 - 2000) and given in Table 8. Table 8 Maximum allowed voltage changes, voltage fluctuations and flicker (rated current > 16 A and ≤ 75 A per phase and subjected to conditional connection) Limits Values given in IEC 61000-3-11 (edition 1.0 - 2000), clause 5 |

7.5. Specifications concerning emission of radiofrequency conducted disturbances on AC or DC power lines from vehicles

7.5.1. Method of measurement

The emission of radiofrequency conducted disturbances on AC or DC power lines generated by the vehicle representative of its type shall be measured using the method described in Annex 13. The method of measurement shall be defined by the vehicle manufacturer in accordance with the Technical Service.

7.5.2. Vehicle type-approval limit

|

7.5.2.1. |

If measurements are made using the method described in Annex 13, the limits on AC power lines are those defined in IEC 61000-6-3 (edition 2.0 - 2006) and given in Table 9. Table 9 Maximum allowed radiofrequency conducted disturbances on AC power lines

|

|

7.5.2.2. |

If measurements are made using the method described in Annex 13, the limits on DC power lines are those defined in IEC 61000-6-3 (edition 2.0 - 2006) and given in Table 10. Table 10 Maximum allowed radiofrequency conducted disturbances on DC power lines

|

7.6. Specifications concerning emission of radiofrequency conducted disturbances on network and telecommunication access from vehicles

7.6.1. Method of measurement

The emission of radiofrequency conducted disturbances on network and telecommunication access generated by the vehicle representative of its type shall be measured using the method described in Annex 14. The method of measurement shall be defined by the vehicle manufacturer in accordance with the Technical Service.

7.6.2. Vehicle type-approval limit

|

7.6.2.1. |

If measurements are made using the method described in Annex 14, the limits on network and telecommunication access are those defined in IEC 61000-6-3 (edition 2.0 - 2006) and given in Table 11. Table 11 Maximum allowed radiofrequency conducted disturbances on network and telecommunication access

|

|||||||||

7.7. Specifications concerning immunity of vehicles to electromagnetic radiation

7.7.1. Method of testing

The immunity to electromagnetic radiation of the vehicle representative of its type shall be tested by the method described in Annex 6.

7.7.2. Vehicle immunity type-approval limits

|

7.7.2.1. |

If tests are made using the method described in Annex 6, the field strength shall be 30 volts/m rms (root mean squared) in over 90 per cent of the 20 to 2 000 MHz frequency band and a minimum of 25 volts/m rms over the whole 20 to 2 000 MHz frequency band. |

|

7.7.2.2. |

The vehicle representative of its type shall be considered as complying with immunity requirements if, during the tests performed in accordance with Annex 6, there shall be no degradation of performance of ‘immunity related functions’, according to paragraph 2.2 of Annex 6. |

7.8. Specifications concerning the immunity of vehicles to electrical fast transient/burst disturbances conducted along AC and DC power lines.

7.8.1. Method of testing

|

7.8.1.1. |

The immunity to electrical fast transient/burst disturbances conducted along AC and DC power lines of the vehicle representative of its type shall be tested by the method described in Annex 15. |

7.8.2. Vehicle immunity type-approval limits

|

7.8.2.1. |

If tests are made using the methods described in Annex 15, the immunity test levels, for AC or DC power lines, shall be: ± 2 kV test voltage in open circuit, with a rise time (Tr) of 5 ns, and a hold time (Th) of 50 ns and a repetition rate of 5 kHz for at least 1 minute. |

|

7.8.2.2. |

The vehicle representative of its type shall be considered as complying with immunity requirements if, during the tests performed in accordance with Annex 15, there shall be no degradation of performance of ‘immunity related functions’, according to paragraph 2.2 of Annex 6. |

7.9. Specifications concerning the immunity of vehicles to surge conducted along AC or DC power lines.

7.9.1. Method of testing

|

7.9.1.1. |

The immunity to surge conducted along AC/DC power lines of the vehicle representative of its type shall be tested by the method described in Annex 16. |

7.9.2. Vehicle immunity type-approval limits

|

7.9.2.1. |

If tests are made using the methods described in Annex 16, the immunity test levels shall be:

|

|

7.9.2.2. |

The vehicle representative of its type shall be considered as complying with immunity requirements if, during the tests performed in accordance with Annex 16, there shall be no degradation of performance of ‘immunity related functions’, according to paragraph 2.2 of Annex 6. |

7.10. Exceptions

7.10.1. When network and telecommunication access of the vehicle uses power line Transmission (PLT) on its AC/DC power lines, Annex 14 shall not be applied.

8. AMENDMENT OR EXTENSION OF A VEHICLE TYPE-APPROVAL FOLLOWING ELECTRICAL/ELECTRONIC SUB-ASSEMBLY (ESA) ADDITION OR SUBSTITUTION

|

8.1. |

Where a vehicle manufacturer has obtained type-approval for a vehicle installation and wishes to fit an additional or substitutional electrical/electronic system or ESA which has already received approval under this Regulation, and which will be installed in accordance with any conditions attached thereto, the vehicle approval may be extended without further testing. The additional or substitutional electrical/electronic system or ESA shall be considered as part of the vehicle for conformity of production purposes. |

|

8.2. |

Where the additional or substitutional part(s) has (have) not received approval pursuant to this Regulation, and if testing is considered necessary, the whole vehicle shall be deemed to conform if the new or revised part(s) can be shown to conform to the relevant requirements of paragraph 6 or if, in a comparative test, the new part can be shown not to be likely to adversely affect the conformity of the vehicle type. |

|

8.3. |

The addition by a vehicle manufacturer to an approved vehicle of standard domestic or business equipment, other than mobile communication equipment, which conforms to other regulations, and the installation, substitution or removal of which is according to the recommendations of the equipment and vehicle manufacturers, shall not invalidate the vehicle approval. This shall not preclude vehicle manufacturers fitting communication equipment in accordance with suitable installation guidelines developed by the vehicle manufacturer and/or manufacturer(s) of such communication equipment. The vehicle manufacturer shall provide evidence (if requested by the test authority) that vehicle performance is not adversely affected by such transmitters. This can be a statement that the power levels and installation are such that the immunity levels of this Regulation offer sufficient protection when subject to transmission alone, i.e. excluding transmission in conjunction with the tests specified in paragraph 6. This Regulation does not authorise the use of a communication transmitter when other requirements on such equipment or its use apply. |

9. CONFORMITY OF PRODUCTION

The conformity of production procedures shall comply with those set out in the Agreement, Appendix 2 (E/ECE/324-E/ECE/TRANS/505/Rev.2), with the following requirements:

|

9.1. |

Vehicles or components or ESAs approved under this Regulation shall be so manufactured as to conform to the type-approved by meeting the requirements set forth in paragraph 6 above. |

|

9.2. |

Conformity of production of the vehicle or component or separate technical unit shall be checked on the basis of the data contained in the communication form(s) for type-approval set out in Annexes 3A and/or 3B to this Regulation. |

|

9.3. |

If the Competent Authority is not satisfied with the checking procedure of the manufacturer, then paragraphs 8.3.1 and 8.3.2 below shall apply. |

|

9.3.1. |

When the conformity of a vehicle, component or ESA taken from the series is being verified, production shall be deemed to conform to the requirements of this Regulation in relation to broadband electromagnetic disturbances and narrowband electromagnetic disturbances if the levels measured do not exceed by more the 2 dB (25 per cent) the reference limits prescribed in paragraphs 6.2.2.1, 6.2.2.2, 6.3.2.1, 6.3.2.2, 7.2.2.1 and 7.2.2.2 (as appropriate). |

|

9.3.2. |

When the conformity of a vehicle, component or ESA taken from the series is being verified, production shall be deemed to conform to the requirements of this Regulation in relation to immunity to electromagnetic radiation if the vehicle ESA does not exhibit any degradation relating to the direct control of the vehicle which could be observed by the driver or other road user when the vehicle is in the state defined in Annex 6, paragraph 4, and is subjected to a field strength, expressed in volts/m, up to 80 per cent of the reference limits prescribed in paragraphs 6.4.2.1 and 7.7.2.1 above. |

|

9.3.3. |

If the conformity of a component, or Separate Technical Unit (STU) taken from the series is being verified, production shall be deemed to conform to the requirements of this Regulation in relation to immunity to conducted disturbances and emission if the component or STU shows no degradation of performance of ‘immunity related functions’ up to levels given in paragraph 6.8.1 and does not exceed the levels given in paragraph 6.9.1. |

10. PENALTIES FOR NON-CONFORMITY OF PRODUCTION

|

10.1. |

The approval granted in respect of a type of vehicle, component or separate technical unit pursuant to this Regulation may be withdrawn if the requirements laid down in paragraph 6 above are not complied with or if the selected vehicles fail to pass the tests provided for in paragraph 6 above. |

|

10.2. |

If a Party to the Agreement which applies this Regulation withdraws an approval it has previously granted, it shall forthwith notify the other Contracting Parties applying this Regulation thereof by means of a communication form conforming to the model in Annexes 3A and 3B to this Regulation. |

11. PRODUCTION DEFINITIVELY DISCONTINUED

If the holder of an approval permanently ceases to manufacture a type of vehicle or ESA approved in accordance with this Regulation, he shall so inform the authority which granted the approval, which shall in turn notify the other Parties to the 1958 Agreement which apply this Regulation, by means of a communication form conforming to the model in Annexes 3A and 3B to this Regulation.

12. MODIFICATION AND EXTENSION OF TYPE-APPROVAL OF A VEHICLE OR ESA

|

12.1. |

Every modification of the vehicle or ESA type shall be notified to the Type Approval Authority which granted approval of the vehicle type. This department may then either:

|

|

12.2. |

Notice of conformation of approval or of refusal of approval, accompanied by particulars of the modifications, shall be communicated by the procedure indicated in paragraph 4 above to the Parties to the Agreement applying this Regulation. |

|

12.3. |

The Competent Authority granting the approval extension shall assign a serial number to the extension and so notify the other Parties to the 1958 Agreement applying this Regulation by means of a communication form conforming to the models in Annexes 3A and 3B to this Regulation. |

13. TRANSITIONAL PROVISIONS

|

13.1. |

As from the official date of entry into force of the 03 series of amendments, no Contracting Party applying this Regulation shall refuse to grant ECE approval under this Regulation as amended by the 03 series of amendments. |

|

13.2. |

As from 12 months after the date of entry into force of this Regulation, as amended by the 03 series of amendments, Contracting Parties applying this Regulation shall grant approvals only if the vehicle type, component or separate technical unit to be approved meets the requirements of this Regulation as amended by the 03 series of amendments. |

|

13.3. |

Contracting Parties applying this Regulation shall not refuse to grant extensions of approval to the preceding series of amendments to this Regulation. |

|

13.4. |

Starting 48 months after the entry into force of the 03 series of amendments to this Regulation, Contracting Parties applying this Regulation may refuse first national registration (first entry into service) of a vehicle, component or separate technical unit which does not meet the requirements of the 03 series of amendments to this Regulation. |

|

13.5. |

As from 36 months after the official date of entry into force of this Regulation, as amended by the 04 series of amendments, Contracting Parties applying this Regulation shall grant approvals only if the vehicle type to be approved meets the requirements of this Regulation as amended by the 04 series of amendments. |

|

13.6. |

Until 36 months after the date of entry into force of the 04 series of amendments, no Contracting Parties shall refuse national or regional approval of a vehicle approved to the preceding series of amendments to this Regulation. |

|

13.7. |

As from 60 months after the date of entry into force of the 04 series of amendments, Contracting Parties may refuse first registration of a new vehicle which does not meet the requirements of the 04 series of amendments to this Regulation. |

|

13.8. |

Notwithstanding paragraphs 13.6 and 13.7 approvals of vehicle granted to the preceding series of amendments to the Regulation, which are not affected by the 04 series of amendments, shall remain valid and Contracting Parties applying the Regulation shall continue to accept them. |

14. NAMES AND ADDRESSES OF TECHNICAL SERVICES CONDUCTING APPROVAL TESTS AND OF TYPE APPROVAL AUTHORITIES

The Parties to the 1958 Agreement applying this Regulation shall communicate to the United Nations Secretariat the names and addresses of the Technical Services conducting approval tests and of the Type Approval Authorities which grant approvals and to which forms certifying approval or extension, refusal or withdrawal of approval, issued in other countries, are to be sent.

(1) As defined in the Consolidated Resolution on the Construction of Vehicles (R.E.3), document ECE/TRANS/WP.29/78/Rev.2, paragraph 2.

(2) The distinguishing numbers of the Contracting Parties to the 1958 Agreement are reproduced in Annex 3 to Consolidated Resolution on the Construction of Vehicles (R.E.3), document ECE/TRANS/WP.29/78/Rev.2/Amend.1.

Appendix 1

List of standards referred to in this Regulation

|

1. |

CISPR 12 ‘Vehicles’, motorboats’ and spark-ignited engine-driven devices’ radio disturbance characteristics — Limits and methods of measurement’, fifth edition 2001 and Amd1: 2005. |

|

2. |

CISPR 16-1-4 ‘Specifications for radio disturbance and immunity measuring apparatus and methods — Part 1: Radio disturbance and immunity measuring apparatus — Antennas and test sites for radiated disturbances measurements’, third edition 2010. |

|

3. |

CISPR 25 ‘Limits and methods of measurement of radio disturbance characteristics for the protection of receivers used on board vehicles’, second edition 2002 and Corrigendum 2004. |

|

4. |

ISO 7637-1 ‘Road vehicles — Electrical disturbance from conduction and coupling — Part 1: Definitions and general considerations’, second edition 2002. |

|

5. |

ISO 7637-2 ‘Road vehicles — Electrical disturbance from conduction and coupling — Part 2: Electrical transient conduction along supply lines only on vehicles with nominal 12 V or 24 V supply voltage’, second edition 2004. |

|

6. |

ISO-EN 17025 ‘General requirements for the competence of testing and calibration laboratories’, second edition 2005 and Corrigendum: 2006. |

|

7. |

ISO 11451 ‘Road vehicles — Electrical disturbances by narrowband radiated electromagnetic energy — Vehicle test methods’:

|

|

8. |

ISO 11452 ‘Road vehicles — Electrical disturbances by narrowband radiated electromagnetic energy — Component test methods’:

|

|

9. |

ITU Radio Regulations, edition 2008. |

|

10. |

IEC 61000-3-2 ‘Electromagnetic Compatibility (EMC) — Part 3-2 — Limits for harmonic current emissions (equipment input current ≤ 16 A per phase)’, edition 3.2 - 2005 + A1: 2008 + A2: 2009. |

|

11. |

IEC 61000-3-3 ‘Electromagnetic Compatibility (EMC) — Part 3-3 — Limits — Limitation of voltage changes, voltage fluctuations and flicker in public low-voltage systems for equipment with rated current ≤ 16 A per phase and not subjected to conditional connection’, edition 2.0 - 2008. |

|

12. |

IEC 61000-3-11 ‘Electromagnetic Compatibility (EMC) — Part 3-11 — Limits — Limitation of voltage changes, voltage fluctuations and flicker in public low-voltage systems — Equipment with rated current ≤ 75 A per phase and subjected to conditional connection’, edition 1.0 - 2000. |

|

13. |

IEC 61000-3-12 ‘Electromagnetic Compatibility (EMC) — Part 3-12 — Limits for harmonic current emissions produced by equipment connected to public low-voltage systems with input current > 16 A and ≤ 75 A per phase’, edition 1.0 - 2004. |

|

14. |

IEC 61000-4-4 ‘Electromagnetic Compatibility (EMC) — Part 4-4 — Testing and measurement techniques — Electrical fast transients/burst immunity test’, edition 2.0 - 2004. |

|

15. |

IEC 61000-4-5 ‘Electromagnetic Compatibility (EMC) — Part 4-5 — Testing and measurement techniques — Surge immunity test’, edition 2.0 - 2005. |

|

16. |

IEC 61000-6-2 ‘Electromagnetic Compatibility (EMC) — Part 6-2 — Generic standards Immunity for industrial environments’, edition 2.0 - 2005. |

|

17. |

IEC 61000-6-3 ‘Electromagnetic Compatibility (EMC) — Part 6-3 — Generic standards Emission standard for residential, commercial and light-industrial environments’, edition 2.0 - 2006. |

|

18. |

CISPR 16-2-1 ‘Specification for radio disturbances and immunity measuring apparatus and methods — Part 2-1 — Methods of measurement of disturbances and immunity — Conducted disturbances measurement’, edition 2.0 - 2008. |

|

19. |

CISPR 22 ‘Information Technology Equipment — Radio disturbances characteristics — Limits and methods of measurement’, edition 6.0 - 2008. |

|

20. |

CISPR 16-1-2 ‘Specification for radio disturbance and immunity measuring apparatus and methods — Part 1-2: Radio disturbance and immunity measuring apparatus — Ancillary equipment — Conducted disturbances’, edition 1.2: 2006. |

Appendix 2

Vehicle broadband reference limits

Antenna-vehicle separation: 10 m

|

Limit E (dBμV/m) at frequency F (MHz) |

||

|

30 - 75 MHz |

75 - 400 MHz |

400 - 1 000 MHz |

|

E = 32 |

E = 32 + 15,13 log (F/75) |

E = 43 |

Appendix 3

Vehicle broadband reference limits

Antenna-vehicle separation: 3 m

|

Limit E (dBμV/m) at frequency F (MHz) |

||

|

30-75 MHz |

75-400 MHz |

400-1 000 MHz |

|

E = 42 |

E = 42 + 15,13 log (F/75) |

E = 53 |

Appendix 4

Vehicle narrowband reference limits

Antenna-vehicle separation: 10 m

|

Limit E (dBμV/m) at frequency F (MHz) |

||

|

30 - 75 MHz |

75 - 400 MHz |

400 - 1 000 MHz |

|

E = 22 |

E = 22 + 15,13 log (F/75) |

E = 33 |

Appendix 5

Vehicle narrowband reference limits

Antenna-vehicle separation: 3 m

|

Limit E (dBμV/m) at frequency F (MHz) |

||

|

30-75 MHz |

75-400 MHz |

400-1 000 MHz |

|

E = 32 |

E = 32 + 15,13 log (F/75) |

E = 43 |

Appendix 6

Electrical/electronic sub-assembly

Broadband reference limits

|

Limit E (dBμV/m) at frequency F (MHz) |

||

|

30-75 MHz |

75-400 MHz |

400-1 000 MHz |

|

E = 62 – 25,13 log (F/30) |

E = 52 + 15,13 log (F/75) |

E = 63 |

Appendix 7

Electrical/electronic sub-assembly

Narrowband reference limits

|

Limit E (dBμV/m) at frequency F (MHz) |

||

|

30-75 MHz |

75-400 MHz |

400-1 000 MHz |

|

E = 52 – 25,13 log (F/30) |

E = 42 + 15,13 log (F/75) |

E = 53 |

ANNEX 1

EXAMPLES OF APPROVAL MARKS

Model A

(See paragraph 5.2 of this Regulation)

The above approval mark affixed to a vehicle or ESA shows that the vehicle type concerned has, with regard to electromagnetic compatibility, been approved in the Netherlands (E4) pursuant to Regulation No 10 under approval No 042439. The approval number indicates that the approval was granted according to the requirements of Regulation No 10 as amended by the 04 series of amendments.

Model B

(See paragraph 5.2 of this Regulation)

The above approval mark affixed to a vehicle or ESA shows that the vehicle type concerned has, with regard to electromagnetic compatibility, been approved in the Netherlands (E4) pursuant to Regulations Nos 10 and 33 (1).

The approval numbers indicate that, at the date when the respective approvals were given, Regulation No 10 included the 04 series of amendments and Regulation No 33 was still in its original form.

(1) The second number is given merely as an example.

ANNEX 2A

Information document for type-approval of a vehicle with respect to electromagnetic compatibility

The following information shall be supplied in triplicate and shall include a list of contents.

Any drawings shall be supplied in appropriate scale and in sufficient detail on size A4 or in a folder of A4 format.

Photographs, if any, shall show sufficient detail.

If the systems, components or separate technical units have electronic controls, information concerning their performance shall be supplied.

GENERAL

|

1. |

Make (trade name of manufacturer): … |

|

2. |

Type: … |

|

3. |

Category of vehicle: … |

|

4. |

Name and address of manufacturer: … Name and address of authorised representative, if any: … |

|

5. |

Address(es) of assembly plant(s): … |

GENERAL CONSTRUCTION CHARACTERISTICS OF THE VEHICLE

|

6. |

Photograph(s) and/or drawing(s) of a representative vehicle: … |

|

7. |

Position and arrangement of the engine: … |

POWER PLANT

|

8. |

Manufacturer: … |

|

9. |

Manufacturer’s engine code as marked on the engine: … |

|

10. |

Internal combustion engine: … |

|

11. |

Working principle: positive ignition/compression ignition, four-stroke/two-stroke (1) |

|

12. |

Number and arrangement of cylinders: … |

|

13. |

Fuel feed: … |

|

14. |

By fuel injection (compression ignition only): yes/no (1). |

|

15. |

Electronic control unit: … |

|

16. |

Make(s): … |

|

17. |

Description of the system: … |

|

18. |

By fuel injection (positive ignition only): yes/no (1). |

|

19. |

Electrical system: … |

|

20. |

Rated voltage: … V, positive/negative ground (1) |

|

21. |

Generator: … |

|

22. |

Type: … |

|

23. |

Ignition: … |

|

24. |

Make(s): … |

|

25. |

Type(s): … |

|

26. |

Working principle: … |

|

27. |

LPG fuelling system: yes/no (1). |

|

28. |

Electronic engine management control unit for LPG fuelling: … |

|

29. |

Make(s): … |

|

30. |

Type(s): … |

|

31. |

NG fuelling system: yes/no (1). |

|

32. |

Electronic engine management control unit for NG fuelling: … |

|

33. |

Make(s): … |

|

34. |

Type(s): … |

|

35. |

Electric motor: … |

|

36. |

Type (winding, excitation): … |

|

37. |

Operating voltage: … |

GAS FUELLED ENGINES (IN THE CASE OF SYSTEMS LAID-OUT IN A DIFFERENT MANNER, SUPPLY EQUIVALENT INFORMATION)

|

38. |

Electronic control unit (ECU): |

|

39. |

Make(s): … |

|

40. |

Type(s): … |

TRANSMISSION

|

41. |

Type (mechanical, hydraulic, electric, etc.): … |

|

42. |

A brief description of the electrical/electronic components (if any): … |

SUSPENSION

|

43. |

A brief description of the electrical/electronic components (if any): … |

STEERING

|

44. |

A brief description of the electrical/electronic components (if any): … |

BRAKES

|

45. |

Anti-lock braking system: yes/no/optional (1) |

|

46. |

For vehicles with anti-lock systems, description of system operation (including any electronic parts), electric block diagram, hydraulic or pneumatic circuit plan: … |

BODYWORK

|

47. |

Type of bodywork: … |

|

48. |

Materials used and methods of construction: … |

|

49. |

Windscreen and other windows: |

|

50. |

A brief description of the electrical/electronic components (if any) of the window lifting mechanism: … |

|

51. |

Rear-view mirrors (state for each mirror): … |

|

52. |

A brief description of the electronic components (if any) of the adjustment system: … |

|

53. |

Safety belts and/or other restraint systems: … |

|

54. |

A brief description of the electrical/electronic components (if any): … |

|

55. |

Suppression of radio interference: |

|

56. |

Description and drawings/photographs of the shapes and constituent materials of the part of the body forming the engine compartment and the part of the passenger compartment nearest to it: … |

|

57. |

Drawings or photographs of the position of the metal components housed in the engine compartment (e.g. heating appliances, spare wheel, air filter, steering mechanism, etc.): … |

|

58. |

Table and drawing of radio interference control equipment: … |

|

59. |

Particulars of the nominal value of the direct current resistance and, in the case of resistive ignition cables, of their nominal resistance per metre: … |

LIGHTING AND LIGHT SIGNALLING DEVICES

|

60. |

A brief description of electrical/electronic components other than lamps (if any): … |

MISCELLANEOUS

|

61. |

Devices to prevent unauthorised use of the vehicle: … |

|

62. |

A brief description of the electrical/electronic components (if any): … |

|

63. |

Table of installation and use of RF transmitters in the vehicle(s), if applicable (see paragraph 3.1.8 of this Regulation): …

|

|

64. |

Vehicle equipped with 24 GHz short-range radar equipment: yes/no/optional (1). The applicant for type-approval must also supply, where appropriate:

|

|

65. |

Charger: onboard/external/without (1) … |

|

66. |

Charging current: direct current/alternating current (number of phases/frequency) (1): … |

|

67. |

Maximal nominal current (in each mode if necessary): |

|

68. |

Nominal charging voltage: … |

|

69. |

Basic vehicle interface functions: e.g. L1/L2/L3/N/E/control pilot: … |

(1) Strike out what does not apply.

ANNEX 2B

Information document for type-approval of an electric/electronic sub-assembly with respect to electromagnetic compatibility

The following information, if applicable, shall be supplied in triplicate and must include a list of contents. Any drawings shall be supplied in appropriate scale and in sufficient detail on size A4 or on a folder of A4 format. Photographs, if any, shall show sufficient detail.

If the systems, components or separate technical units have electronic controls, information concerning their performance shall be supplied.

|

1. |

Make (trade name of manufacturer): … |

|

2. |

Type: … |

|

3. |

Means of identification of type, if marked on the component/separate technical unit (1): |

|

3.1. |

Location of that marking: … |

|

4. |

Name and address of manufacturer: … Name and address of authorised representative, if any: … |

|

5. |

In the case of components and separate technical units, location and method of affixing of the approval mark: … |

|

6. |

Address(es) of assembly plant(s): … |

|

7. |

This ESA shall be approved as a component/STU (1) |

|

8. |

Any restrictions of use and conditions for fitting: … |

|

9. |

Electrical system rated voltage: … V, positive/negative (2) ground. … |

Appendix 1: description of the ESA chosen to represent the type (electronic block diagram and list of main component constituting the ESA (e.g. make and type of microprocessor, crystal, etc.)).

Appendix 2: relevant test report(s) supplied by the manufacturer from a test laboratory accredited to ISO 17025 and recognised by the Approval Authority for the purpose of drawing up the type-approval certificate.

(1) If the means of identification of type contains characters not relevant to describe the component or separate technical unit types covered by this information document, such characters shall be represented in the documentation by the symbol ‘?’ (e.g. ABC??123??).

(2) Delete where not applicable.

ANNEX 3A

COMMUNICATION

(Maximum format: A4 (210 × 297 mm))

ANNEX 3B

COMMUNICATION

(Maximum format: A4 (210 × 297 mm))

ANNEX 4

Method of measurement of radiated broadband electromagnetic emissions from vehicles

1. GENERAL

1.1. The test method described in this annex shall only be applied to vehicles.

This method concerns both configurations of the vehicle:

|

(a) |

Other than ‘RESS in charging mode coupled to the power grid’; |

|

(b) |

‘RESS in charging mode coupled to the power grid’. |

1.2. Test method

This test is intended to measure the broadband emissions generated by electrical or electronic systems fitted to the vehicle (e.g. ignition system or electric motors).

If not otherwise stated in this annex the test shall be performed according to CISPR 12 (fifth edition 2001 and Amd1: 2005).

2. VEHICLE STATE DURING TESTS

2.1. Vehicle in configuration other than ‘RESS in charging mode coupled to the power grid.’

2.1.1. Engine

The engine shall be in operation according to CISPR 12 (fifth edition 2001 and Amd1: 2005)

2.1.2. Other vehicle systems

All equipment capable of generating broadband emissions which can be switched on permanently by the driver or passenger should be in operation in maximum load, e.g. wiper motors or fans. The horn and electric window motors are excluded because they are not used continuously.

2.2. Vehicle in configuration ‘RESS in charging mode coupled to the power grid’.

This vehicle shall be in battery charging mode at rated power until the AC or DC current reached at least 80 per cent of its initial value. The test set-up for the connection of the vehicle in configuration ‘RESS in charging mode coupled to the power grid’ is shown in Figure 3 of the appendix to this annex.

3. MEASURING LOCATION

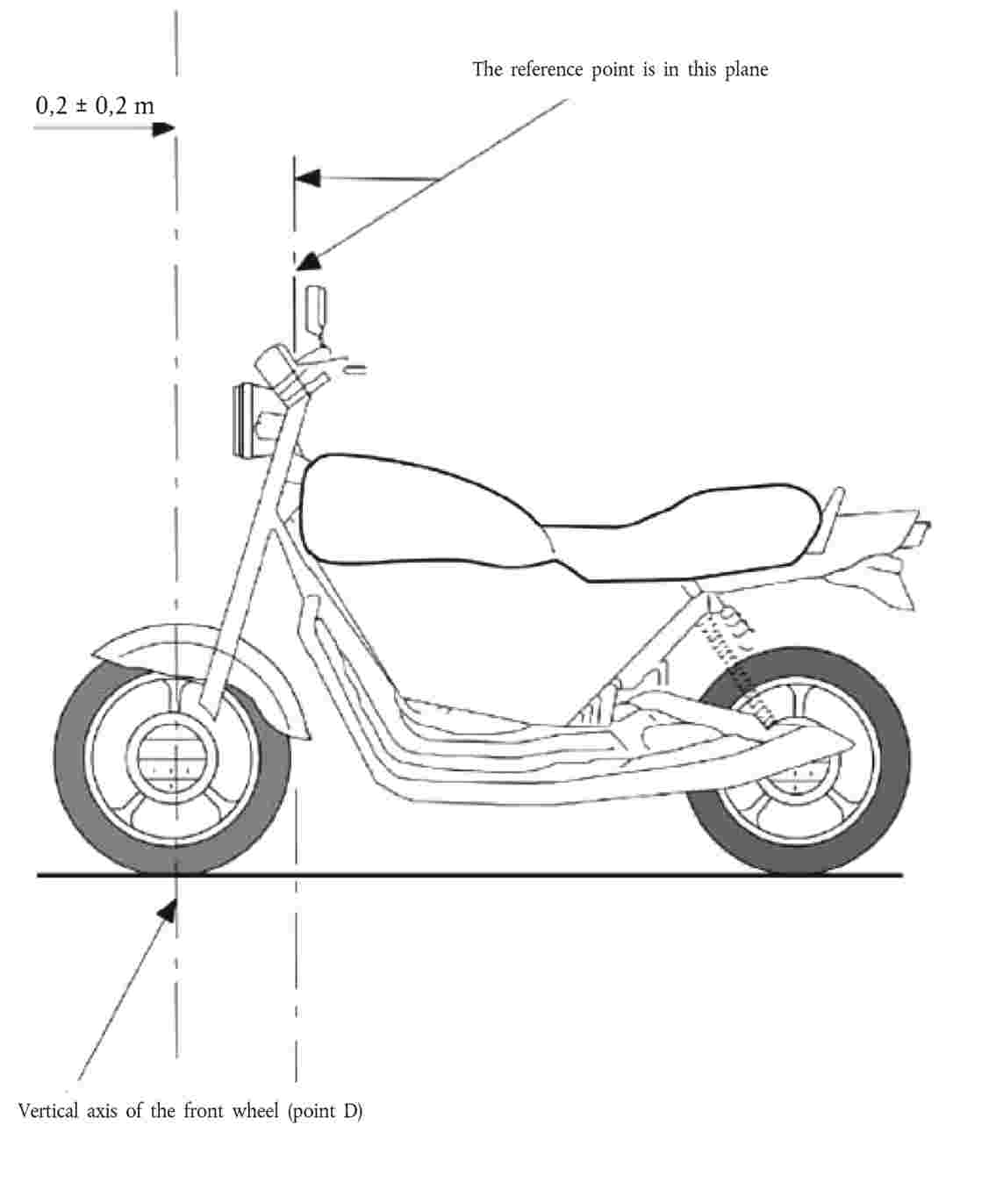

3.1. As an alternative to the requirements of CISPR 12 (fifth edition 2001 and Amd1: 2005) for vehicles of category L the test surface may be any location that fulfils the conditions shown in Figure 1 of the appendix to this annex. In this case the measuring equipment must lie outside the part shown in Figure 1 of the appendix to this annex.

3.2. Enclosed test facilities may be used if correlation can be shown between the results obtained in the enclosed test facility and those obtained at an outdoor site. Enclosed test facilities do not need to meet the dimensional requirements of the outdoor site other than the distance from the antenna to the vehicle and the height of the antenna.

4. TEST REQUIREMENTS

4.1. The limits apply throughout the frequency range 30 to 1 000 MHz for measurements performed in a semi anechoic chamber or an outdoor test site.

4.2. Measurements can be performed with either quasi-peak or peak detectors. The limits given in paragraphs 6.2 and 6.5 of this Regulation are for quasi-peak detectors. If peak detectors are used a correction factor of 20 dB as defined in CISPR 12 (fifth edition 2001 and Amd1: 2005) shall be applied.

4.3. Measurements

The Technical Service shall perform the test at the intervals specified in the CISPR 12 (fifth edition 2001 and Amd1: 2005) standard throughout the frequency range 30 to 1 000 MHz.

Alternatively, if the manufacturer provides measurement data for the whole frequency band from a test laboratory accredited to the applicable parts of ISO 17025 (second edition 2005 and Corrigendum: 2006) and recognised by the Approval Authority, the Technical Service may divide the frequency range in 14 frequency bands — 30-34, 34-45, 45-60, 60-80, 80-100, 100-130, 130-170, 170-225, 225-300, 300-400, 400-525, 525-700, 700-850, 850-1 000 MHz — and perform tests at the 14 frequencies giving the highest emission levels within each band to confirm that the vehicle meets the requirements of this annex.

In the event that the limit is exceeded during the test, investigations shall be made to ensure that this is due to the vehicle and not to background radiation.

4.4. Readings

The maximum of the readings relative to the limit (horizontal and vertical polarisation and antenna location on the left and right-hand sides of the vehicle) in each of the 14 frequency bands shall be taken as the characteristic reading at the frequency at which the measurements were made.

Appendix

Figure 1

Clear horizontal surface free of electromagnetic reflection delimitation of the surface defined by an ellipse

Figure 2

Position of antenna in relation to the vehicle

Dipole antenna in position to measure the vertical radiation components

Dipole antenna in position to measure the horizontal radiation components

Figure 3

Vehicle in configuration ‘RESS charging mode’ coupled to the power grid

Elevation

ANNEX 5

Method of measurement of radiated narrowband electromagnetic emissions from vehicles

1. GENERAL

1.1. The test method described in this annex shall only be applied to vehicles.

This method concerns only the configuration of the vehicle other than ‘RESS in charging mode coupled to the power grid’.

1.2. Test method

This test is intended to measure the narrowband electromagnetic emissions such as might emanate from microprocessor-based systems or other narrowband source.

If not otherwise stated in this annex the test shall be performed according to CISPR 12 (fifth edition 2001 and Amd1: 2005) or to CISPR 25 (and Corrigendum: 2004).

1.3. As an initial step the levels of emissions in the Frequency Modulation (FM) band (76 to 108 MHz) shall be measured at the vehicle broadcast radio antenna with an average detector. If the level specified in paragraph 6.3.2.4 of this Regulation is not exceeded, then the vehicle shall be deemed to comply with the requirements of this annex in respect of that frequency band and the full test shall not be carried out.

1.4. As an alternative for vehicles of category L the measurement location can be chosen according to Annex 4, paragraphs 3.1 and 3.2.

2. VEHICLE STATE DURING TESTS

2.1. The ignition switch shall be switched on. The engine shall not be operating.

2.2. The vehicle’s electronic systems shall all be in normal operating mode with the vehicle stationary.

2.3. All equipment which can be switched on permanently by the driver or passenger with internal oscillators > 9 kHz or repetitive signals should be in normal operation.

3. TEST REQUIREMENTS

3.1. The limits apply throughout the frequency range 30 to 1 000 MHz for measurements performed in a semi anechoic chamber or an outdoor test site.

3.2. Measurements shall be performed with an average detector.

3.3. Measurements

The Technical Service shall perform the test at the intervals specified in the CISPR 12 (fifth edition 2001 and Amd1: 2005) standard throughout the frequency range 30 to 1 000 MHz.

Alternatively, if the manufacturer provides measurement data for the whole frequency band from a test laboratory accredited to the applicable parts of ISO 17025 (second edition 2005 and Corrigendum: 2006) and recognised by the Approval Authority, the Technical Service may divide the frequency range in 14 frequency bands — 30-34, 34-45, 45-60, 60-80, 80-100, 100-130, 130-170, 170-225, 225-300, 300-400, 400-525, 525-700, 700-850, 850-1 000 MHz — and perform tests at the 14 frequencies giving the highest emission levels within each band to confirm that the vehicle meets the requirements of this annex.

In the event that the limit is exceeded during the test, investigations shall be made to ensure that this is due to the vehicle and not to background radiation including broadband radiation from any ESA.

3.4. Readings

The maximum of the readings relative to the limit (horizontal and vertical polarisation and antenna location on the left and right-hand sides of the vehicle) in each of the 14 frequency bands shall be taken as the characteristic reading at the frequency at which the measurements were made.

ANNEX 6

Method of testing for immunity of vehicles to electromagnetic radiation

1. GENERAL

1.1. The test method described in this annex shall only be applied to vehicles. This method concerns both configurations of vehicle:

|

(a) |

Other than ‘RESS in charging mode coupled to the power grid’. |

|

(b) |

‘RESS in charging mode coupled to the power grid’. |

1.2. Test method

This test is intended to demonstrate the immunity of the vehicle electronic systems. The vehicle shall be subject to electromagnetic fields as described in this annex. The vehicle shall be monitored during the tests.

If not otherwise stated in this annex the test shall be performed according to ISO 11451-2, third edition 2005.

1.3. Alternative test methods

The test may be alternatively performed in an outdoor test site for all vehicles. The test facility shall comply with (national) legal requirements regarding the emission of electromagnetic fields.

If a vehicle is longer than 12 m and/or wider than 2,60 m and/or higher than 4,00 m, BCI (bulk current injection) method according to ISO 11451-4 (first edition 1995) can be used in the frequency range 20 to 2 000 MHz with levels defined in paragraph 6.7.2.1 of this Regulation.

2. VEHICLE STATE DURING TESTS

2.1. Vehicle in configuration other than ‘RESS in charging mode coupled to the power grid’.

2.1.1. The vehicle shall be in an unladen condition except for necessary test equipment.

2.1.1.1. The engine shall normally turn the driving wheels at a steady speed of 50 km/h if there is no technical reason due to the vehicle to define a different condition. For vehicles of categories L1 and L2 the steady speed shall normally be turned at 25 km/h. The vehicle shall be on an appropriately loaded dynamometer or alternatively supported on insulated axle stands with minimum ground clearance if no dynamometer is available. Where appropriate, transmission shafts, belts or chains may be disconnected (e.g. trucks, two- and three-wheel vehicles).

2.1.1.2. Basic vehicle conditions