ISSN 1977-091X

Official Journal

of the European Union

C 128

English edition

Information and Notices

Volume 59

12 April 2016

|

ISSN 1977-091X |

||

|

Official Journal of the European Union |

C 128 |

|

|

||

|

English edition |

Information and Notices |

Volume 59 |

|

Contents |

page |

|

|

|

II Information |

|

|

|

INFORMATION FROM EUROPEAN UNION INSTITUTIONS, BODIES, OFFICES AND AGENCIES |

|

|

|

European Commission |

|

|

2016/C 128/01 |

|

|

IV Notices |

|

|

|

NOTICES FROM EUROPEAN UNION INSTITUTIONS, BODIES, OFFICES AND AGENCIES |

|

|

|

Council |

|

|

2016/C 128/02 |

||

|

|

European Commission |

|

|

2016/C 128/03 |

|

|

V Announcements |

|

|

|

PROCEDURES RELATING TO THE IMPLEMENTATION OF COMPETITION POLICY |

|

|

|

European Commission |

|

|

2016/C 128/04 |

Prior notification of a concentration (Case M.7744 — HeidelbergCement/Italcementi) ( 1) |

|

|

2016/C 128/05 |

Prior notification of a concentration (Case M.7998 — Pacific Mezz/Oaktree/Railpool) — Candidate case for simplified procedure ( 1) |

|

|

2016/C 128/06 |

Prior notification of a concentration (Case M.7859 — OMV/EconGas) — Candidate case for simplified procedure ( 1) |

|

|

2016/C 128/07 |

Prior notification of a concentration (Case M.7801 — Wabtec/Faiveley Transport) ( 1) |

|

|

2016/C 128/08 |

Prior notification of a concentration (Case M.7989 — Griffin/LVS II Lux XX/Redefine/Echo Prime JV) — Candidate case for simplified procedure ( 1) |

|

|

|

|

|

(1) Text with EEA relevance |

|

EN |

|

II Information

INFORMATION FROM EUROPEAN UNION INSTITUTIONS, BODIES, OFFICES AND AGENCIES

European Commission

|

12.4.2016 |

EN |

Official Journal of the European Union |

C 128/1 |

COMMUNICATION FROM THE COMMISSION

Requirements and procedure for inclusion of facilities located in third countries in the European List of ship recycling facilities

Technical guidance note under Regulation (EU) No 1257/2013 on ship recycling

(2016/C 128/01)

The purpose of this ‘Technical guidance note on requirements and procedure for inclusion of facilities located in third countries in the European List of ship recycling facilities’ is to clarify certain aspects of Regulation (EU) No 1257/2013 (‘the Regulation’), which entered into force on 30 December 2013. This note has been adopted by the European Commission, following discussions with Member States and stakeholders.

Article 15(4)§3 of the Regulation provides that the European Commission ‘may issue technical guidance notes in order to facilitate [the] certification’ of ship recycling facilities located in a third country, with a view to their application for inclusion on the European List of ship recycling facilities (‘the European List’). The present document clarifies the following elements mentioned or referred to in Article 15(4):

|

— |

the object of the certification, i.e. the design, construction, operational, management, monitoring and administrative requirements to be met by the facilities, |

|

— |

the status and qualifications of the certifying entity (the ‘independent verifier’), |

|

— |

the procedure for inspection of facilities and later verifications, |

|

— |

the modalities of submission of the application to the European List to the European Commission. |

The present document provides clarifications in accordance with the relevant Hong Kong Convention provisions and taking into account the relevant guidelines of the IMO, the ILO and of the Basel Convention. However, while most of the requirements in the Regulation stem from the Hong Kong Convention, a few requirements are new and require clarification not necessarily found in IMO and other existing guidelines.

This technical guidance note may be updated as necessary in light of the experience with the implementation of the Regulation. The Commission reserves the right to publish further technical guidance notes on the subject matter, e.g. on the mid-term compliance reviews provided for in Article 15(4)§1 of the Regulation.

This document reflects the views of the European Commission and as such is not legally binding. The binding interpretation of EU legislation is the exclusive competence of the Court of Justice of the European Union (CJEU). The views expressed in this guidance document cannot prejudge the position that the Commission might take before the CJEU.

Abbreviations

|

HKC |

Hong Kong Convention |

|

IMO |

International Maritime Organisation |

|

ILO |

International Labour Organisation |

|

BC TG |

Basel Convention Technical Guidelines |

|

SRFP |

Ship Recycling Facility Plan |

|

PPE |

Personal Protective Equipment |

TABLE OF CONTENTS

|

1. |

General questions on the European List of ship recycling facilities | 3 |

|

1.1. |

What is the European List of facilities? | 3 |

|

1.2. |

Who can apply for inclusion on the European List? | 3 |

|

1.3. |

How to apply for inclusion in the European List? | 3 |

|

1.4. |

What should be included in an application file? | 4 |

|

1.5. |

When can applications be submitted? | 4 |

|

1.6. |

How will the European Commission assess the applications? | 4 |

|

1.7. |

How will the European List be established? | 4 |

|

1.8. |

Can a facility be removed from the European List? | 4 |

|

2. |

Requirements for inclusion on the European List | 5 |

|

2.1. |

General requirements | 5 |

|

2.1.1. |

Which authorisations and permits are needed to be eligible for inclusion in the European List? | 5 |

|

2.1.2. |

What should a Ship Recycling Facility Plan cover? | 5 |

|

2.1.3. |

What constitutes a compliant ‘Emergency preparedness and response plan’? | 6 |

|

2.1.4. |

What constitute appropriate management and monitoring systems? | 6 |

|

2.2. |

Environmental requirements | 7 |

|

2.2.1. |

What is meant by ‘prevention of adverse effects on the environment’ and ‘control of any leakage, in particular in intertidal zones’? | 8 |

|

2.2.2. |

What is meant by ‘impermeable floors’ and ‘effective drainage systems’? | 8 |

|

2.2.3. |

What is meant by ‘containment of hazardous materials’? | 9 |

|

2.2.4. |

What is meant by ‘built structures’? | 10 |

|

2.2.5. |

What constitutes compliant waste management in the context of the Regulation? | 12 |

|

2.3. |

Health and safety requirements | 14 |

|

2.3.1. |

What is meant by ‘prevention of adverse effects on human health’? | 14 |

|

2.3.2. |

What constitutes appropriate personal protective equipment? | 15 |

|

2.3.3. |

What are the obligations with respect to training? | 15 |

|

2.3.4. |

What constitutes compliant record-keeping on incidents, accidents, occupational diseases and chronic effects? | 16 |

|

3. |

Certification and inspections | 16 |

|

3.1. |

What are the main features of the inspections regime under the new Regulation? | 16 |

|

3.2. |

What is the role of Independent Verifiers? | 18 |

|

3.3. |

Who can be an Independent Verifier? | 18 |

|

3.4. |

Will the European Commission publish a list of Independent Verifiers? | 18 |

|

3.5. |

Which accreditations and qualifications should Independent Verifiers possess? | 18 |

|

3.6. |

Can the European Commission decide to further inspect a facility? | 19 |

1. General questions on the European List of ship recycling facilities

1.1. What is the European List of facilities?

|

Article 2(1): ‘This Regulation […] shall apply to ships flying the flag of a Member State’ Article 6(2)(a): ‘Shipowners shall ensure that ships destined to be recycled are only recycled at ship recycling facilities that are included in the European List.’ Article 16(1)(b): ‘The Commission shall adopt implementing acts to establish a European List of ship recycling facilities which […] are located in a third country and whose inclusion is based on an assessment of the information and supporting evidence provided or gathered in accordance with Article 15.’ |

As per Article 16(1)(b) of the Regulation, the European Commission will establish a list (the ‘European List’) of ship recycling facilities meeting the requirements of the Regulation. The European List will include both facilities located in the EU and outside the EU.

In accordance with the Regulation (Articles 2(1) on scope and 6(2)(a) on general requirements for shipowners), owners of ships flying the flag of an EU Member State shall send their ships for dismantling only to facilities included in the European List.

1.2. Who can apply for inclusion on the European List?

|

Article 15(1): ‘A ship recycling company owning a ship recycling facility located in a third country and intending to recycle ships flying the flag of a Member State shall submit an application to the Commission for inclusion of that ship recycling facility in the European List.’ |

The procedure for the listing of facilities depends on the geographical location of the facility. Facilities located inside the EU will be listed by their respective national competent authorities, which will then communicate their national lists to the European Commission for direct inclusion in the European List. Facilities located outside the EU will have to submit an application to the European Commission.

While the practical modalities of the listing on national lists are determined by each Member State, the Regulation requires that facilities located inside and outside the EU observe the same performance requirements found in Article 13 of the Regulation.

1.3. How to apply for inclusion in the European List?

|

Article 15(1): ‘A ship recycling company owning a ship recycling facility located in a third country and intending to recycle ships flying the flag of a Member State shall submit an application to the Commission for inclusion of that ship recycling facility in the European List.’ |

Under the Regulation, a ship recycling company owning a ship recycling facility (SRF) located outside the EU and intending to recycle ships flying the flag of EU Member States shall submit an application to the European Commission for inclusion of that SRF in the European List.

The application should be sent electronically to env-ship-recycling@ec.europa.eu and two hard copies should be sent by postal mail (1) to:

|

European Commission |

|

Waste Management and Recycling Unit |

|

Directorate-General for the Environment |

|

Avenue de Beaulieu 9, BU5/107 |

|

1049 Bruxelles/Brussel |

|

BELGIQUE/BELGIË |

The European Commission will send written acknowledgement of receipt to the ship recycling company, along with an estimate of when a decision will be taken on the application. The European Commission will further send written notification of the decision to include or not the applying SRF in the European List.

1.4. What should be included in an application file?

|

Article 15(2): ‘The application referred to in [Article 15(1)] shall be accompanied by evidence that the ship recycling facility concerned complies with the requirements set out in Article 13 in order to conduct ship recycling and to be included in the European List in accordance with Article 16.’ |

Article 15 of the Regulation requires that the ship recycling company submits an application file to provide evidence that the facility complies with the requirements of the Regulation. The file should consist of:

|

1. |

a completed form on ‘Information and documentation related to the application for inclusion in the European List of ship recycling facilities’, along with supporting documents, as provided in the Commission Implementing Decision (EU) 2015/2398 on information and documentation related to an application for a facility located in a third country for inclusion in the European List of ship recycling facilities (2); |

|

2. |

a copy of the certification of the ship recycling facility by an Independent Verifier (template in Annex 1 of this document); |

|

3. |

a copy of the Ship Recycling Facility Plan |

All documents are to be written in English or accompanied by a translation into English, French or German.

1.5. When can applications be submitted?

Applications can be submitted at any time. Once the European List is published, it will be regularly updated to include facilities which have submitted a successful application and to remove facilities which have ceased to comply with the requirements of the Regulation (see Q&A 1.8 below).

For a facility to be listed before the end of 2016, the application file should be submitted before Friday 1 July 2016.

1.6. How will the European Commission assess the applications?

The European Commission (Directorate-General for the Environment) will assess the applications received from ship recycling facilities located outside the EU against the requirements in the Regulation. Only complete application files will be reviewed. Should an application file be incomplete, the missing element(s) will be requested from the company.

1.7. How will the European List be established?

The European List is to be established and updated through the adoption of Implementing Acts under Article 291 of the Treaty on the Functioning of the European Union. Proposals for inclusion on the European List will be examined by the Ship Recycling Regulation Committee, comprising representatives of the Member States, which will deliver its opinion according to the examination procedure laid out in Article 5 of Regulation (EU) No 182/2011 (3).

Article 16(2) of the Regulation requires the European Commission to publish the European List no later than 31 December 2016. It shall be divided into two sub-lists containing the ship recycling facilities located inside and outside the EU respectively.

The European List will be published in the Official Journal of the European Union and on the website of the European Commission. The European List will be regularly updated to include or remove ship recycling facilities, as appropriate.

1.8. Can a facility be removed from the European List?

|

Article 16(4)(b): ‘The Commission shall adopt implementing acts to regularly update the European List, in order to […] remove a ship recycling facility from the European List where (i) the ship recycling facility ceases to comply with the requirements set out in Article 13; or (ii) the updated evidence is not provided at least three months prior to expiry of the five-year period as set out in paragraph 3 of this Article.’ |

Yes. Should the European Commission establish that a facility no longer complies with the requirements of the Regulation, a procedure to exclude the facility from the European List will be launched. The ship recycling company targeted by the procedure will be given an opportunity to present its case and give answers to any questions raised by the European Commission.

Removing a facility located in a third country from the European List will also require the adoption of an Implementing Act, through the procedure described in Q&A 1.7.

While the decision to remove a facility from the European List is final, nothing prevents a company from subsequently re-submitting an application for inclusion in the List for its facility.

2. Requirements for inclusion on the European List

This section addresses the various requirements provided in the Regulation for ship recycling facilities wishing to recycle EU ships. For the sake of clarity, the various requirements have been grouped under three headers (general, environmental, health and safety). Certain requirements may fall under more than one header as they could serve several purposes. Where that is the case, requirements are described according to their core matter.

2.1. General requirements

2.1.1. Which authorisations and permits are needed to be eligible for inclusion in the European List?

|

Article 13(1)(a): The ship recycling facility shall be ‘authorised by its competent authorities to conduct ship recycling operations’. |

The very first requirement for a facility to be listed on the European List is to have been authorised to recycle ships by the Competent Authorities of its own country. The European Commission will not list facilities which have not been authorised to operate by their own national authorities. Should a listed facility lose its national authorisation to recycle ships, it shall be removed from the European List. The European Commission may contact the concerned authorities directly to verify that the authorisation document(s) provided with the application file are genuine.

For the purpose of the Regulation, authorisation modalities covered by Article 13(1)(a) depend on the law of the country where the facility is located.

If the respective competent authority/-ies does/do not issue a specific permit, licence or authorisation to conduct ship recycling, the applicant shall clearly state this in his application and submit other relevant permits, licences or authorisations relating to the activities of the company.

2.1.2. What should a Ship Recycling Facility Plan cover?

|

Article 13(1)(e): The ship recycling facility shall ‘prepare a ship recycling facility plan’. |

The SRFP is a cornerstone document introduced by the Hong Kong Convention and mirrored in the Regulation. Analysing the contents of the Ship Recycling Facility Plan will allow the Commission to check compliance with the substantive requirements of the Regulation. When presenting evidence of compliance with the requirements of the Regulation, it is recommended to refer to the relevant parts of the Ship Recycling Facility Plan.

As indicated in the IMO guidelines for safe and environmentally sound ship recycling (4), ‘the SRFP shall be adopted by the board or appropriate governing body of the Recycling Company […] It is […] critical that the SRFP should fully describe the operations and procedures that are in place at the Ship Recycling Facility to ensure compliance with the Convention.’ In addition, the SRFP should fully describe the operations and procedures that are in place at the Ship Recycling Facility to ensure compliance with the Regulation where it adds to HKC requirements (see notably questions under 2.2 below on specific requirements).

The recommended format for the SRFP is included in Appendix 1 of the IMO guidelines for safe and environmentally sound ship recycling (5).

2.1.3. What constitutes a compliant ‘Emergency preparedness and response plan’?

|

Article 13(1)(h): The ship recycling facility shall ‘establish and maintain an emergency preparedness and response plan’. |

Guidance given in Section 3.3.5 of the IMO guidelines for safe and environmentally sound ship recycling, as well as Sections 4.6 and 16 of the ILO guidelines (6) and Sections 4.5 and 6.2 of the Basel Convention Technical Guidelines for the Environmentally Sound Management of the Full and Partial Dismantling of Ships (hereinafter referred to as ‘BC TG’) (7), describe how to develop an emergency preparedness and response plan (EPRP).

In addition, a proper EPRP reflects the current layout of the recycling facility and is communicated to all the workers on the facility, including contractor personnel and employees hired for a short period of time.

2.1.4. What constitute appropriate management and monitoring systems?

|

Article 13(1)(d): The ship recycling facility shall ‘establish management and monitoring systems, procedures and techniques which have the purpose of preventing, reducing, minimising and to the extent practicable eliminating health risks to the workers concerned and to the population in the vicinity of the ship recycling facility, and adverse effects on the environment caused by ship recycling’. |

Management and monitoring systems cover waste and hazardous materials, environmental damage caused by the ship recycling activity in general as well as safety and health concerns. These systems support implementation of procedures and techniques which have the purpose of preventing, reducing, minimising and to the extent practicable eliminating health risks and adverse effects on the environment.

Management and monitoring systems serve to control the implementation of the processes and conditions described in the SRFP. They apply to the entire process: from accepting a ship for recycling to waste management (8) (if carried out at the ship recycling facility). This includes — but is not limited to — assessing the hazards on board the ship (including on the basis of the Inventory of Hazardous Materials and the Ready-for-Recycling certificate); identifying and complying with any legal requirements for ships to be recycled; carrying out the ship recycling process in a safe and environmentally sound manner (including storage and management of materials and wastes present on board the ship and generated by the ship recycling process) and offering the required training and carrying out documentation controls for the entire process.

(a)

In the context of the Regulation, the BC TG guidelines on developing and implementing environmental management systems (9) is a suitable international source relevant to Article 13(1)(d) as far as adverse effects on the environment are concerned.

As per the IMO guidelines (10) on environmental monitoring, an environmental monitoring programme covers ‘possible negative impacts during ship recycling [which can] be divided into four main categories: releases of Hazardous Materials to ground and sediments; releases of Hazardous Materials to water; emissions of Hazardous Materials to air; and noise/vibrations’. Exposure to high temperatures is another possible negative impact to be considered.

The IMO guidelines for safe and environmentally sound ship recycling further specify that ‘the monitoring programme […] should be Facility-specific, taking into account the Facility’s characteristics, such as the use of dry dock, jetty/piers and/or recycling plots on land-sea interface, and should identify chemical, biological and physical changes in the environment surrounding the Ship Recycling Facility’. ‘The monitoring programme […] should utilise well-established standards for the sampling and analysis of relevant environmental parameters’.

(b)

Comprehensive management and monitoring systems which have the purpose of preventing, reducing, minimising and to the extent practicable eliminating health risks to the workers concerned and to the population in the vicinity of the ship recycling facility caused by ship recycling are understood as covering two essential aspects in the sense of the ILO guidelines:

|

(a) |

the facility has established Occupational Safety and Health management systems (11); |

|

(b) |

workers have the rights mentioned in the ILO guidelines (12) to enable them to take ownership of and ultimately help improve the health and safety management systems. |

The ILO guidelines (13) assumes that employers ‘make arrangements for the identification and periodic assessment of the hazards and risks to safety and health from hazardous ambient factors at each permanent or temporary workplace, generated by the use of different operations, tools, machines, equipment and substances’ and ‘implement appropriate preventive and protective measures required to prevent those hazards and risks, or to reduce them to the lowest reasonable and practicable level, in conformity with national laws and regulations’.

The IMO guidelines for safe and environmentally sound ship recycling further elaborates on the role of the ship recycling company, which is to conduct ‘job-hazard assessments to determine the proper approach to maximising worker safety. Responsibility for job hazard assessments should be assigned to a competent person for the specific hazards of each job. It is recommended that the assessments should be conducted by a team of personnel including the competent person, a representative of management and workers with the appropriate level of expertise.’ (14)

As per Article 3(3) of the Regulation, ‘a competent person may be a trained worker or a managerial employee capable of recognising and evaluating occupational hazards, risks, and employee exposure to potentially hazardous materials or unsafe conditions in a ship recycling facility, and who is capable of specifying the necessary protection and precautions to be taken to eliminate or reduce those hazards, risks or that exposure’.

The second leg of health and safety management systems concerns the need for the ship recycling company to ensure information to, participation of and feedback from workers to improve safety. The list of relevant workers’ rights is found in the ILO guidelines (15). It ranges from the right to bring safety risks to the attention of the competent authority to the right to adequate medical treatment or the right to elect their representatives as specified by national laws, regulation and practice. In any case, the ship recycling company makes the necessary arrangements to ensure information to, participation of and feedback from workers on health and safety matters.

Monitoring of health and safety parameters may be deemed as achieved if the ship recycling company has implemented the relevant ILO guidelines (16). IMO guidelines for safe and environmentally sound ship recycling further mention that the facility has ‘procedures to be used for monitoring exposure and for medical surveillance’ (17).

2.2. Environmental requirements

This section draws essentially on Section 3 of the IMO’s 2012 Guidelines for safe and environmentally sound ship recycling. Guidance is also taken from the following material:

|

— |

Part II of the ILO’s Safety and health in shipbreaking guidelines (18) , |

|

— |

Section 5 of the Basel Convention’s Technical Guidelines for the Environmentally Sound Management of the Full and Partial Dismantling of Ships (19) , |

|

— |

the Basel Convention Secretariat’s Guidance for Competent Authorities of Ship Recycling Facilities (‘the BCS 2013 Guidance’) (20) . |

In particular, this section acknowledges that ‘applying environmentally sound management principles and compliance with regulations for recycling a ship will rely, at least partly, on developing appropriate infrastructure’ (21). Operationally, it follows from the answers provided in Q&A 2.2.1 to 2.2.3 that the transfer of elements from the ship to the facility’s impermeable floor is done without the elements coming in contact with the sea, the intertidal zone or any other permeable surface such as sand or gravel (22).

2.2.1. What is meant by ‘prevention of adverse effects on the environment’ and ‘control of any leakage, in particular in intertidal zones’?

|

Article 13(1)(f): The ship recycling facility shall ‘prevent adverse effects on human health and the environment, including the demonstration of the control of any leakage, in particular in intertidal zones’. |

Essential guidance on prevention of adverse effects on the environment is found in the IMO guidelines on prevention of adverse effects to the environment (23). Pointers to what constitute appropriate operations to prevent adverse effects are also given in the BC TG (24).

By requiring that the ship recycling facility ‘prevents adverse effects on human health and the environment’, the Regulation puts the emphasis on prevention. In a facility ‘designed, constructed and operated in a safe and environmentally sound manner’ (25), both measures and infrastructure are in place to prevent leakages to the environment.

The facility is furthermore required to ‘demonstrate the control of any leakage’, i.e. to prove it is capable of preventing and — when prevention has failed despite compliant design, construction and operation — of responding to and mitigating any sort of leakage (spills, air emissions, etc.).

Examples of control systems include — but are not limited to — the following: prior assessment of pollutants remaining on board the ship; rapid-response teams; oil absorption booms; oil containment booms (26); drainage canals and impermeable floors (further details on the latter are given in the next Q&A).

The intertidal zone is understood as the zone between the lowest and the highest tide marks. Although each area of the facility deserves attention, intertidal zones in particular are referred to in the Regulation as they present specific challenges when it comes to control of leakages, due to constantly changing conditions stemming from tides.

2.2.2. What is meant by ‘impermeable floors’ and ‘effective drainage systems’?

|

Article 13(1)(g)(i): The ship recycling facility ‘ensures safe and environmentally sound management and storage of hazardous materials and waste, including […] the handling of hazardous materials, and of waste generated during the ship recycling process, only on impermeable floors with effective drainage systems’. |

The Regulation requires that ‘hazardous materials’ as well as ‘waste generated during the ship recycling process’ are handled ‘only on impermeable floors with effective drainage systems’.

‘Handling’ is a very broad notion, going beyond waste management operations. It starts with the cutting/separation of elements from the ship and includes sorting and transportation of hazardous materials and of waste generated during the ship recycling process.

All elements separated from the ship, including large blocks, constitute either ‘hazardous materials’ or ‘waste generated during the ship recycling process’.

‘Floors’ are continuous, level and supporting surfaces. ‘Impermeable floors’ are floors which do not allow fluids to pass through. This reflects the need to not only contain hazardous fluids, but also to counter the possibility of hazardous materials being washed away into the environment. The steel of the ship itself can be considered as an impermeable floor in the context of the Regulation if certain conditions are met (see below) or in the case of floating docks.

In the context of the Regulation, ‘effective drainage systems’ are understood as drainage connected to a water treatment plant (be it onsite or shared/municipal) or, as defined in the BCS 2013 guidelines, ‘simple infrastructure (e.g. a concrete base) that acts as a barrier to the escape of polluting materials. There would be drainage for contaminants and the capacity for the drainage channels to be periodically cleaned, for example by installing removable grilles over the drainage channels’ (27). The volume of the drainage systems is to be defined on the basis of meteorological data (e.g. rainfall), possible volumes of spills, types of spills, the size of the impermeable floor area and ingress of external waters.

As the handling of hazardous materials, and of waste generated during the ship recycling process, should be carried out ‘only’ on impermeable floors, whenever an element is separated from the ship, it should not enter into contact with non-impermeable floors such as sand. It can however be lifted (e.g. with a crane) onto an impermeable floor.

The interior of the ship itself can be considered as an impermeable floor in the context of the Regulation if:

|

(a) |

the hull is sealed, integrity of the bottom of the hull has been analysed and has not been compromised; |

|

(b) |

harmful substances falling from the vessel during cutting operations are controlled as per Q&A 2.2.1, e.g. collected and managed in an environmentally sound manner; |

|

(c) |

oil containment booms are deployed from the ship’s hull to the shore/quay prior to any activity posing a threat to the environment and oil skimmers are readily available; |

|

(d) |

blocks are lifted in a safe manner to cutting areas with impermeable floor; |

|

(e) |

the release of paint chips and toxic coatings into the sea/permeable surface is controlled as per Q&A 2.2.1; |

|

(f) |

as early as is feasible, transfer of the remainder of the ship’s bottom itself to impermeable floor areas is carried out in a safe and environmentally sound manner, e.g. through the use of cranes, sleds or beams coupled with winches, to allow for the cutting of the bottom to take place above an impermeable floor with effective drainage system, including above a floating structure such as a floating dry dock, a flat top barge or equivalent with an effective drainage system. |

2.2.3. What is meant by ‘containment of hazardous materials’?

|

Article 13(1)(g)(i): The ship recycling facility ‘ensures safe and environmentally sound management and storage of hazardous materials and waste, including the containment of all hazardous materials present on board during the entire ship recycling process so as to prevent any release of those materials into the environment’. |

The Regulation requires ‘containment of all hazardous materials’, at all times (‘during the entire ship recycling process’) (28), with a view to prevention of ‘any release […] into the environment’. This means that all hazardous materials are removed from the ship and collected, stored, transported and disposed of without coming in direct contact with the environment or the workers (e.g. bare-handed contact, direct contact with the respiratory tract, etc.). This Q&A focuses on removal, collection and storage of hazardous materials, while Q&A 2.2.5 focuses on waste management aspects.

IMO guidelines for safe and environmentally sound ship recycling, as well as Sections 4.2 (Identification of potential contaminants and prevention of releases), 5.3 (Design and construction) and 5.4 (Operation) of the BC TG, point to the relevant measures to handle specific materials, in particular the following:

|

— |

asbestos-removing activities taking place on board the ship (29), |

|

— |

asbestos-removing activities taking place outside the ship itself (30), |

|

— |

paints and coatings found on the ship’s hull (31) (the use of special respiratory equipment advised in the BC TG is actually covered under Article 13(1)(i) of the Regulation), |

|

— |

liquid waste (32). |

Other elements to be taken into account in this context include:

|

(a) |

measures providing equivalent levels of protection to those laid in Directive 2009/148/EC of 30 November 2009 on the protection of workers from the risks related to exposure to asbestos at work (33) applies to activities in which workers remove asbestos. It describes measures to be taken by the workers’ employer when the single maximum limit value for airborne concentration of asbestos at 0,1 fibres per cm3 as an eight-hour time-weighted average (TWA) is likely to be exceeded; |

|

(b) |

The use of elevated tanks to store oily residues is recommended as it will facilitate the task of the Independent Verifier when checking that the containment has not failed underneath. |

2.2.4. What is meant by ‘built structures’?

|

Article 13(1)(c): The ship recycling facility ‘operates from built structures’. |

The Regulation requires that facilities operate from built structures. The purpose of built structures is to enable safe and environmentally sound ship recycling operations, ensuring worker safety, control of leakage, containment of hazardous materials and impermeable support for hazardous materials and for waste generated during the ship recycling process.

The requirement to operate from built structures does not necessarily mean that a facility be completely built up, as long as compliance with the requirements of the Regulation is reached. Built structures may be complemented e.g. by ‘machinery with tracked wheels or low ground pressure tyres’ (34), mobile settling tanks and floating cranes where the installation of fixed cranes is not possible. This applies in particular to temporary installations, where e.g. temporary fencing may be deemed as equivalent to walls provided that it achieves a similar level of protection. The Regulation does not exclude temporary ship recycling installations whereby additional equipment is fitted to a base facility (e.g. to a port, quay or jetty), provided that the base facility itself complies with the design and construction requirements of the Regulation.

In the context of the Regulation, examples of built structures in the ship recycling areas where primary cutting takes place may include — but are not limited to — the following:

|

— |

pontoons, |

|

— |

slipways and access ramps, |

|

— |

quays, |

|

— |

docks, |

|

— |

dry-docks, |

|

— |

ship lifts, |

|

— |

bridge-like structures (trestles), |

|

— |

canals, |

|

— |

canopies; |

|

— |

floodgates. |

Examples of built structures which provide support for ‘fixed plants’ as defined in the BCS 2013 guidelines (35) include — but are not limited to — the following:

|

— |

‘Fixed cranes and other lifting devices […] used within their design limits (e.g. taking care not to exceed the gross weight that a crane can lift)’, |

|

— |

‘Winching gear and cables for safely pulling a ship further away from the shore line while undergoing dismantling’, |

|

— |

‘Pumps to transfer liquids [to] pump liquids from drainage catchpits’, |

|

— |

‘Generators to provide electrical power for lighting [to] enable safer working under low light conditions’. |

Examples of built structures in areas of the ship recycling facility dedicated to secondary cutting are referred to in relevant Basel guidelines include — but are not limited to — the following:

|

— |

‘Workstations for secondary dismantling and sequential breakdown into component elements’ and ‘specially-equipped workstations for removal of hazardous and toxic waste’ (36), |

|

— |

‘Bunded partitions’ (37) and tanks, |

|

— |

‘Walls […](wood, concrete, steel)[…] made with access from one side to enable materials to be stored and loaded’ (38), |

|

— |

‘Temporary storage areas for benign materials and steelwork’ (39), |

|

— |

‘Storage areas for fully processed equipment and materials that are ready for reuse, recycling or disposal’ (40). |

Examples of built structures applied to the health and safety-related requirements of the Regulation include — but are not limited to — the following:

|

— |

‘Firm, level roadways (a simple road base can be constructed initially with e.g. crushed concrete)’ or ‘a compacted road base’ making it possible for an ambulance and a fire truck to reach the ship and station next to it (41) or, in the case of a dry-dock, reach the escape way (e.g. lift), |

|

— |

‘Fixed cranes and other lifting devices […] used within their design limits (e.g. taking care not to exceed the gross weight that a crane can lift)’ (see above), |

|

— |

stable exit gangways, |

|

— |

additional elements referred to in the ILO guidelines (42), notably drinking water supply, location and conditions of operations of sanitary and washing facilities and cloakrooms as well as shelters and facilities for food and drink, |

|

— |

additional elements referred to in the IMO guidelines for safe and environmentally sound ship recycling (43): ‘washing facilities, showers, eating and recreation areas, toilet facilities and changing rooms […] to control exposure and avoid the spread of Hazardous Materials’; ‘Sanitary and washing facilities conveniently accessible and situated so that they are not at risk of contamination from the workplace’; ‘Separate and appropriate changing rooms and sanitary and washing facilities provided for exclusive use by workers handling asbestos’; ‘Separate and uncontaminated areas for workers to use for eating, drinking and other breaks’. |

2.2.5. What constitutes compliant waste management in the context of the Regulation?

|

Article 13(1)(g)(ii): The ship recycling facility shall ensure ‘that all waste generated from the ship recycling activity and their quantities are documented and are only transferred to waste management facilities, including waste recycling facilities, authorised to deal with their treatment without endangering human health and in an environmentally sound manner’. |

|

Article 15(5): ‘For the purposes of Article 13, with regard to the waste recovery or disposal operation concerned, environmentally sound management may only be assumed to be in place provided the ship recycling company can demonstrate that the waste management facility which receives the waste will be operated in accordance with human health and environmental protection standards that are broadly equivalent to relevant international and Union standards’. |

The Regulation includes several requirements on the management of hazardous and other waste generated during the ship recycling process.

Depending on the facility, all, part or none of the waste recovery or disposal might take place onsite. For example, some ship recycling facilities are equipped with incinerators; some facilities will be able to handle certain waste streams but not others, while a number of facilities might decide to entirely outsource the recovery or disposal of waste to external waste management facilities. The Regulation does not impose any arrangement in particular. However, it requires that the ship recycling company can demonstrate that the different waste streams are treated according to certain standards, irrelevant of where waste recovery or disposal takes place. It is therefore advised that the facility makes it clear in its application form which waste streams it is able and authorised to recycle/dispose of itself, and which waste streams it will transfer to external downstream waste management facilities.

(a)

Compliance with the part of Article 13(1)(g)(ii) on documentation and transfer of waste may be assumed if, in accordance with the IMO guidelines for safe and environmentally sound ship recycling (44), the facility establishes ‘procedures for tracking Hazardous Materials and wastes as they are transported from the Ship Recycling Facility to their ultimate destination, and for managing and storing documentation, including that of subcontractors.’

(b)

The Regulation requires that the ship recycling company ensures that the waste management facility has been authorised to operate without endangering human health and in an environmentally sound manner. This requirement mirrors the IMO guidelines for safe and environmentally sound ship recycling (45).

The waste management facility covered by this requirement is either:

|

— |

part of the ship recycling facility itself, if the ship recycling facility recovers or disposes of the waste itself, |

|

— |

an external waste management facility, if the ship recycling facility has outsourced this part of the operations, |

|

— |

both, if the ship recycling facility manages some waste streams itself and outsources management of the rest. |

The authorisation referred to in the requirement is the authorisation given by the relevant Competent Authority/Authorities in the country where the waste management facility is located. This includes documentation related to import/export of waste and — where applicable — prior informed consent (PIC) related documentation, in the event that the waste management facility is located in a different country than the ship recycling facility. A copy of the relevant authorisations should be included in the application form, set out in Implementing Decision (EU) 2015/2398.

(c)

Non-EU facilities applying for listing on the European List are asked to demonstrate that the waste management facility(ies) follow(s) standards broadly equivalent to international and EU standards.

The requirement does not imply full compliance with EU requirements stemming from legal acts other than the Regulation and other international standards, but rather the need to ensure that the requirements/standards applied in the waste management facility ensure a similar level of protection of human health and the environment.

Applicant companies should sign the documents as requested in Implementing Decision (EU) 2015/2398 and attach a copy of any document relevant to its scope.

Broad equivalence with international and EU standards is deemed as established if the following main principles derived from international standards and EU Directives are applied at the waste management facility:

— International standards:

The list of relevant guidelines developed at the international level can be found in Annex VIII of Regulation (EC) No 1013/2006 on shipments of waste, including Technical Guidelines on the Environmentally Sound Management of the Full and Partial Dismantling of Ships where it regards downstream waste management. Updates of technical guidelines developed under the Basel Convention can be found on the Convention’s website (46).

In addition, the Parties to the Basel Convention have adopted a Framework for the environmentally sound management (ESM) of hazardous wastes and other wastes (47). This framework sets out a common understanding of what ESM encompasses and refers to e.g. a number of guiding principles and actions for waste management facilities to ensure ESM.

— Union standards:

European Union standards on human health and environmental protection relevant to waste management facilities are found in the EU Waste Framework Directive and in stream-specific waste legislation.

The main requirements of Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on waste and repealing certain Directives (48) (a.k.a. the Waste Framework Directive) cover the following:

|

— |

the waste hierarchy (Article 4): the following waste hierarchy shall apply as a priority order: (a) prevention; (b) preparing for reuse; (c) recycling; (d) other recovery, e.g. energy recovery; and (e) disposal, |

|

— |

protection of human health and the environment (Article 13): waste management is carried out without endangering human health, without harming the environment and, in particular: (a) without risk to water, air, soil, plants or animals; (b) without causing a nuisance through noise or odours; and (c) without adversely affecting the countryside or places of special interest, |

|

— |

dangerous waste (Articles 17, 18, 19): Dangerous waste is stored and treated in conditions that ensure the protection of health and the environment. It is not, in any case, mixed with other dangerous waste and is packaged and labelled. |

In addition to the main principles of the Waste Framework Directive, the following pieces of EU legislation cover waste treatment operations standards relevant to Article 15(5) of the Regulation:

|

— |

Council Directive 1999/31/EC of 26 April 1999 on the landfill of waste (49), |

|

— |

Directive 2000/76/EC of the European Parliament and of the Council of 4 December 2000 on the incineration of waste and amending acts (50), |

|

— |

Directive 2010/75/EU of the European Parliament and of the Council of 24 November 2010 on industrial emissions (51). |

Finally, stream-specific waste treatment operations standards relevant to Article 15(5) of the Regulation are included in the following pieces of EU legislation:

|

— |

Council Directive 96/59/EC of 16 September 1996 on the disposal of polychlorinated biphenyls and polychlorinated terphenyls (52), |

|

— |

Directive 2006/66/EC of the European Parliament and of the Council of 6 September 2006 on batteries and accumulators and waste batteries and accumulators and repealing Directive 91/157/EEC (53), |

|

— |

disposal of electrical and electronic equipment follows the main operational principles of Directive 2002/96/EC of the European Parliament and of the Council of 27 January 2003 on waste electrical and electronic equipment (54). |

2.3. Health and safety requirements

2.3.1. What is meant by ‘prevention of adverse effects on human health’?

|

Article 13(1)(f): The ship recycling facility ‘prevents adverse effects on the human health’. |

Beyond physical arrangements (see Q&A 2.2.4 above on built structures), the ILO guidelines refers to a broad range of operational arrangements, from prevention of the worst forms of child labour or ensuring appropriate living accommodation, in so far as accommodation is located on the facility or otherwise under the responsibility of the ship recycling company, and hearing protection. These various physical and operational elements taken together constitute the ‘safe operations’, ‘workers’ safety’ and ‘procedures and techniques which have the purpose of preventing, reducing, minimising and to the extent practicable eliminating health risks’ referred to in the Regulation (55).

Compliance with the safety-related requirements may be assumed if the facility has implemented the above-mentioned operational arrangements and, in accordance with the IMO guidelines (56), ‘has plans and procedures for protecting worker health and safety’ and is able to ‘demonstrate knowledge and understanding of applicable worker safety and occupational health processes, procedures, laws, regulations and guidance.’ The facility should also establish and maintain ‘an effective evacuation plan so that all personnel are evacuated speedily and safely’ (57).

In addition, the facility employs ‘one or more key personnel who possess the level of training and experience necessary to effectively ensure that safe conditions are maintained during operations at the Ship Recycling Facility, including one or more Competent persons for the performance of specific work. Depending upon the size of the Ship Recycling Facility and the number of workers, the [ship recycling facility could employ] a hierarchy of safety and health management staff, including an overall manager, supervisory staff and general workers’ (58). The Regulation defines competent persons as ‘a person with suitable qualifications, training, and sufficient knowledge, experience and skill, for the performance of the specific work’ (59). This person ‘may be a trained worker or a managerial employee capable of recognising and evaluating occupational hazards, risks, and employee exposure to potentially hazardous materials or unsafe conditions in a ship recycling facility, and who is capable of specifying the necessary protection and precautions to be taken to eliminate or reduce those hazards, risks or that exposure’ (60).

Finally, the IMO guidelines explicitly refer to international conventions of relevance to ship recycling, including the convention of the Worst Forms of Child Labour of 1999 and the Minimum Age Convention of 1973. Some countries where ship recycling takes place may not yet have ratified all these conventions. Nevertheless, for the purpose of compliance with the requirements of the Regulation, ship recycling companies are themselves expected to implement at their own level the various provisions of relevance to workers’ health and safety found in international conventions referred to in Appendix 4 of the IMO guidelines.

2.3.2. What constitutes appropriate personal protective equipment?

|

Article 13(1)(i): The ship recycling facility ‘provides for worker safety […], including ensuring the use of personal protective equipment for operations requiring such use’. |

Personal protective equipment (PPE) means any device or appliance designed to be worn or held by an individual for protection against one or more health and safety hazards (61). PPE in the sense of the Regulation is fully detailed in the IMO guidelines for safe and environmentally sound ship recycling (62) and the ILO guidelines (63).

2.3.3. What are the obligations with respect to training?

|

Article 13(1)(i): The ship recycling facility ‘provides for worker […] training […]’. |

Compliance with the training-related requirement is assumed if the facility has implemented the relevant ILO guidelines (64) and it has, in accordance with the IMO guidelines for safe and environmentally sound ship recycling (65), ‘training procedures to ensure the appropriate level of worker safety and environmental protection. The training programmes should cover all workers and members of the ship recycling facility, including contractor personnel and employees, […] and should identify the type and frequency of training.’

In relation to fire protection and prevention, specific consideration is given to IMO guidelines (66) which state that the facility has ‘procedures for providing suitable training, instruction and information to all supervisors and workers […] about the hazards of fires, appropriate precautions to be taken and use of fire-extinguishing equipment, so that adequately trained personnel are readily available during all working periods.’ Demonstration of compliance with these requirements is best achieved by following the relevant IMO guidelines (‘Records of training and drills/exercises should be maintained, including such information as type of training/drill, role of person trained, equipment used, duration, location, date and time’).

2.3.4. What constitutes compliant record-keeping on incidents, accidents, occupational diseases and chronic effects?

|

Article 13(1)(j): The ship recycling facility ‘establishes records on incidents, accidents, occupational diseases and chronic effects and, if requested by its competent authorities, reports any incidents, accidents, occupational diseases or chronic effects causing, or with the potential for causing, risks to workers’ safety, human health and the environment’. |

Records on occupational diseases and chronic effects are obtained through annual medical check-ups including at least blood and urine sampling, as well as hair sampling if possible. Information on the origins of diseases and chronic effects are best obtained through soil, air and dust sampling.

Ensuring that records are complete starts with knowing who works at the facility. The facility records the identity of all the workers, including contractor personnel and employees hired for a short period of time, and ensure that a list of all workers on any given day is always available.

Compliance with Article 13(1)(i) and (j) of the Regulation also presupposes that the facility follows the recommendations of the IMO guidelines for safe and environmentally sound ship recycling (67) and ILO (68) guidelines.

Furthermore, as pointed out in the ILO guidelines, the purpose of the records is to actually ‘be used to protect the health of workers’. The results are ‘clearly explained by professional health personnel to the workers concerned or to persons of their choice’, are ‘not used for unwarranted discrimination’, are ‘available, where requested by the competent authority, or by any other party agreed by both employers and workers, to prepare appropriate health statistics and epidemiological studies, provided anonymity is maintained’. The IMO guidelines for safe and environmentally sound ship recycling further state that ‘if national requirements do not specify a time period, it is recommended that records should be kept for five years’.

3. Certification and inspections

3.1. What are the main features of the inspections regime under the new Regulation?

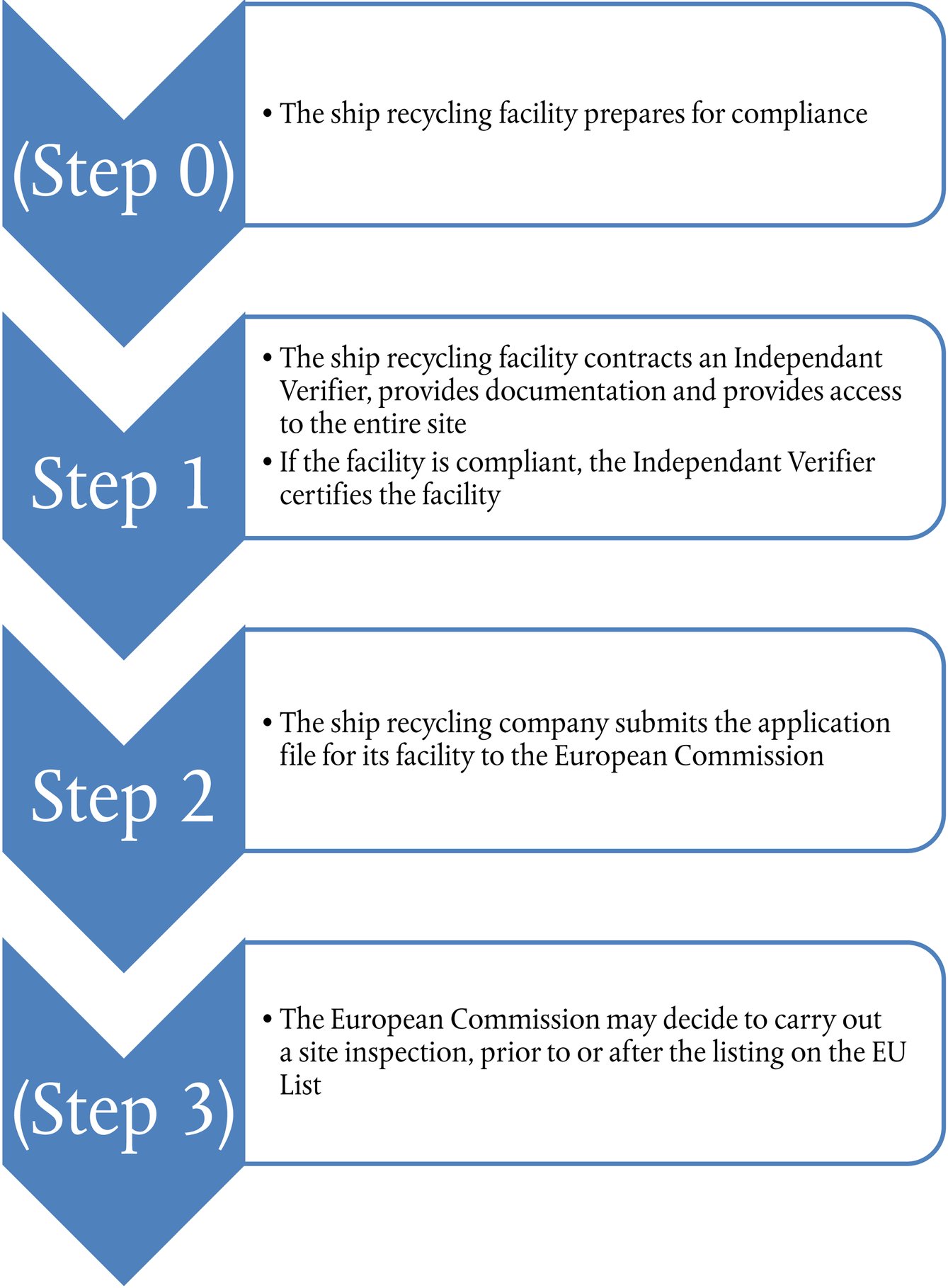

Article 15(4) of the Regulation introduces a two-step inspection and verification regime for facilities located in third countries willing to recycle ships flying the flag of an EU Member State.

|

Article 15(4)§1: In order to be included in the European List, compliance by ship recycling facilities located in third countries with the requirements set out in Article 13 shall be certified following a site inspection by an independent verifier with appropriate qualifications. The certification shall be submitted to the Commission by the ship recycling company when applying for inclusion in the European List and, every five years thereafter, upon renewal of the inclusion in the European List. The initial inclusion on the list and the renewal thereof shall be supplemented by a mid-term review to confirm compliance with the requirements set out in Article 13. Article 15(4)§2: By applying for inclusion in the European List, ship recycling companies accept the possibility of the ship recycling facility concerned being subject to site inspections by the Commission or agents acting on its behalf prior to or after their inclusion in the European List in order to verify compliance with the requirements set out in Article 13. The independent verifier, the Commission or agents acting on its behalf shall cooperate with the competent authorities of the third country where the ship recycling facility is located in order to carry out those site inspections. |

The first step (Article 15(4)§1) takes place before the facility applies for inclusion in the European List. It consists in a site inspection of the facility by an Independent Verifier (‘IV’) to assess compliance with the requirements of the Regulation.

In a later step (Article 15(4)§2), the European Commission may decide to verify compliance of the facility via site inspections. These verifications may take place before or after a decision has been made on the inclusion of the facility on the European List.

Graph

Main steps of the inspection and verification process for ship recycling facilities located outside the EU

3.2. What is the role of Independent Verifiers?

Independent Verifiers are tasked with certifying the facility against the requirements of the Regulation. They are to conduct their work independently; to that effect, the contract between the owner of the ship recycling facility and an Independent Verifier entitles the latter to carry out all activities needed to check and report on the compliance of the facility with the requirements of the Regulation. Contractual obligations of Independent Verifiers do not in any way prevent or limit activities of the latter.

The European Commission is ready to provide advice to Independent Verifiers upon request.

3.3. Who can be an Independent Verifier?

The term Independent Verifier should not be interpreted as being a single physical person. The effective performance of the Independent Verifier’s tasks will normally require involving a team with a wide range of qualifications. Independent Verifiers are in good standing with the laws and regulations of the country they operate in; they are authorised businesses according to national legislation, where applicable.

3.4. Will the European Commission publish a list of Independent Verifiers?

No. The Commission will not provide a list of Independent Verifiers, as this is not provided for in the Regulation. A Company owning or operating a ship recycling facility should contract an Independent Verifier and ensure that it is independent and has the necessary qualifications.

3.5. Which accreditations and qualifications should Independent Verifiers possess?

The Regulation requires that verifiers certifying compliance with the requirements of Article 13 are ‘independent’ and possess ‘appropriate qualifications’. Although the Regulation does not impose the accreditation of Independent Verifiers, seeking accreditation against a standard from EU accreditation bodies or ILAC/MRA signatory bodies is the most effective way to demonstrate independence and necessary qualifications. Further details are explained below.

The EU has developed an accreditation system, under which accreditation against a specific standard may be obtained from a national accreditation body appointed by an EU Member State according to Regulation (EC) No 765/2008 (69). The accreditation obtained from one such body is automatically recognised throughout the EU. Accreditation may also be obtained from an accreditation body outside the EU that is a signatory to the relevant scope (in the present case: ISO/IEC 17020 (70)) of the mutual recognition arrangement (MRA) of the International Laboratory Accreditation Cooperation (ILAC) (71) (72).

In the context of the Regulation, independence and aptitude is best demonstrated via compliance with requirements for third party (‘Type A’) inspection bodies contained in the ISO/IEC 17020 standard, which outlines the requirements for the operation of various bodies performing inspections.

|

ISO/IEC 17020:2012(E) This international standard has been drawn up with the objective of promoting confidence in bodies performing inspection. Inspection bodies carry out assessments on behalf of private clients, their parent organisations, or authorities, with the objective of providing information about the conformity of inspected items with regulations, standards, specifications, inspection schemes or contracts. |

ISO/IEC 17020 contains detailed requirements for inspection bodies. In particular, inspection bodies assessed according to ISO/IEC 17020 have to provide evidence of their impartiality and independence (see Annex A of the standard), detail their legal setup, their organisational and management structures, their inspection methods and procedures, as well as employ a sufficient number of qualified personnel (directly or via subcontracting), keep various records, issue inspection reports and certificates, have complaints and appeal procedures and management systems in place. These detailed requirements are used as a checklist for accreditation attesting to the competence to perform specific inspection tasks — in this case the verification of ship recycling facilities according to Regulation (EU) No 1257/2013. The requirements are always geared to a specific activity and never looked at in insolation.

It is recommended that ship recycling companies contractually require the Independent Verifier whom they invite to assess their conformity with the requirements of the Regulation to possess qualifications in the following areas:

|

— |

naval architect or equivalent qualifications in shipbuilding and/or deconstruction of large steel structures, |

|

— |

environmental and occupational health and safety management systems, |

|

— |

management of hazardous materials and waste management, including management of hazardous waste. |

It is also recommended that the team leader of the Independent Verifier has a minimum of five years of experience in at least two of the above fields and that other team members have a minimum of three years of experience in at least two of the above fields.

The European Commission may organise training activities and workshops specifically targeted at Independent Verifiers in order to harmonise certification practices.

3.6. Can the European Commission decide to further inspect a facility?

By applying for inclusion in the European List, ship recycling companies accept the possibility of the concerned facility to be subject to site inspections — including unannounced — by the European Commission or agents acting on its behalf. These inspections shall be carried out in cooperation with the authorities of the country where the facility is located. The costs of the inspections will not be borne by the ship recycling company.

Decisions by the European Commission to conduct inspections of certified facilities will follow a risk-based prioritisation. All certified facilities located in a third country may be inspected by the European Commission or agents acting on its behalf. The decision to inspect a given facility will be taken in light of the quality and completeness of the information provided in the application file.

Additional aspects that increase the chance of further inspections by the European Commission or agents acting on its behalf include — but are not limited to — complaints and concerns submitted to the European Commission regarding the functioning of the facility.

(1) Voluminous documents such as the Ship Recycling Facility Plan can be sent via e-mail only.

(2) OJ L 332, 18.12.2015, p. 145.

(3) Regulation (EU) No 182/2011 of the European Parliament and of the Council of 16 February 2011 laying down the rules and general principles concerning mechanisms for control by Member States of the Commission’s exercise of implementing powers (OJ L 55, 28.2.2011, p. 13).

(4) IMO, Resolution MEPC.210(63) adopted on 2 March 2012, 2012 Guidelines for safe and environmentally sound ship recycling, pp. 7-36.

(5) IMO MEPC.210(63) Appendix 1, p. 37.

(6) ILO, Safety and health in shipbreaking, guidelines for Asian countries and Turkey, 2004 (hereafter referred to as ‘ILO SHG’), Section 4.6, p. 32 and Section 16, pp. 128-133.

(7) Basel Convention, Technical Guidelines for the Environmentally Sound Management of the Full and Partial Dismantling of Ships (hereafter referred to as ‘BC TG’), Section 4.5, pp. 63-64 and Section 6.2, pp. 84-88.

(8) See Q&A 2.2.5 for more details on waste management requirements under the Regulation.

(9) BC TG, Section 6.2, pp. 85-87.

(10) IMO MEPC.210(63) Section 3.4.1, p. 24.

(11) ILO SHG, pp. 28-33.

(12) ILO SHG, pp. 21-23.

(13) ILO SHG, Section 3.4.2, p. 19 and Annex III, pp. 155-172.

(14) IMO MEPC.210(63), Section 3.3.3.

(15) ILO SHG, Section 3.6, pp. 21-23.

(16) ILO SHG, Annex I (Workers’ health surveillance), Sections 2 and 3, pp. 147-150, and Annex II (Surveillance of the working environment), pp. 152-154.

(17) IMO MEPC.210(63), Section 3.3.4.11, p. 21.

(18) ILO SHG, Part II, pp. 47-140 (with the exception of Sections 14 and 16, which are referred to in the next chapter of the present Guidelines).

(19) BC TG, Section 5, pp. 66-83.

(20) Secretariat of the Basel Convention, Guidance for competent authorities of ship recycling facilities, 4.8.2013.

(21) The BCS 2013 Guidance, page 13.

(22) As blocks not only constitute ‘waste generated during the ship recycling process’, but also typically present a high risk of being covered with oily residues and/or paint and coating particles generated during cutting, they cannot be dropped and/or scraped on the intertidal zone or any other permeable surface such as sand or gravel, as that procedure would entail a breach in the control of leakages (Article 13(1)(f)), containment (Article 13(1)(g)(i)) and handling on impermeable floors (Article 13(1)(g)(ii)).

(23) IMO MEPC.(210)63, Section 3.4.4, pp. 33-36.

(24) BC TG, pp. 81-83.

(25) Article 13(1)(b) of the Regulation.

(26) The type of oil containment boom to use will differ depending on the location and conditions of the ship recycling facility. Two containment levels may prove necessary, especially in facilities where ships are landed under their own power, potentially causing spoiled run-off water going into the sea: a first layer of sorbent oil containment booms deployed around the ship being dismantled and a second, more permanent layer of non-sorbent coastal or oceanic booms.

(27) BC 2013 Guidance, p. 14.

(28) ‘containment of all hazardous materials’, ‘during the entire ship recycling process’ (Article 13(1)(g)(i)).

(29) IMO MEPC.(210)63, Section 3.4.3.1, p. 29 and BC TG, p. 82.

(30) IMO MEPC.(210)63, Section 3.4.3.1, p. 30 and BC TG, p. 80.

(31) IMO MEPC.(210)63, Section 3.4.3.4.1, p. 32 and BC TG, pp. 82-83.

(32) IMO MEPC.(210)63, Section 3.4.3.5 Hazardous liquids, residues and sediments (such as oil, bilge and ballast water), p. 32 and BC TG, p. 81.

(33) OJ L 330, 16.12.2009, p. 28.

(34) BCS 2013 Guidance, p. 17.

(35) BCS 2013 Guidance, p. 15.

(36) BC TG, p. 68.

(37) BCS 2013 Guidance, p. 16.

(38) See footnote 37.

(39) See footnote 36.

(40) See footnote 36.

(41) Pursuant to Article 13(1)(h) of the Regulation (the ship recycling facility ensures rapid access for emergency response equipment, such as fire-fighting equipment and vehicles, ambulances and cranes, to the ship and all areas of the ship recycling facility), facilities where emergency vehicles cannot park next to the ship itself (‘to the ship’) or next to the exit gangway, for example because of watery, unstable grounds inadequate for supporting vehicles, do not comply with requirements of the Regulation.

(42) ILO SHG, pp. 138-140.

(43) IMO MEPC.(210)63, Section 3.3.4.9, p. 20.

(44) IMO MEPC.(210)63, Section 3.4.2.6§3.

(45) IMO MEPC.(210)63, Section 3.2.6: ‘Where materials or wastes are removed from the Ship Recycling Facility for further processing and/or disposal, the SRFP should provide details of the procedures that will be used to ensure that they are transferred only to a facility that is authorised to deal with their treatment and/or disposal in an environmentally sound manner.’

(46) For further information, see: http://www.basel.int/Implementation/TechnicalMatters/DevelopmentofTechnicalGuidelines/AdoptedTechnicalGuidelines/tabid/2376/Default.aspx

(47) For further information, see: http://www.basel.int/Implementation/CountryLedInitiative/EnvironmentallySoundManagement/ESMFramework/tabid/3616/Default.aspx

(48) OJ L 312, 22.11.2008, p. 3.

(49) OJ L 182, 16.7.1999, p. 1.

(50) OJ L 332, 28.12.2000, p. 91.

(51) OJ L 334, 17.12.2010, p. 17.

(52) OJ L 243, 24.9.1996, p. 31.

(53) OJ L 266, 26.9.2006, p. 1.

(54) OJ L 37, 13.2.2003, p. 24.

(55) See Article 13(1)(b), Article 13(1)(d)(i) and Article 13(1)(i).

(56) IMO MEPC.(210)63, Section 3.3.1, p. 11.

(57) IMO MEPC.(210)63, Section 3.3.6§6, p. 23.

(58) IMO MEPC.210(63), Section 3.3.2.

(59) Article 3(1)13 of the Regulation.

(60) Article 3(3) of the Regulation.

(61) Definition according to Council Directive 89/686/EEC of 21 December 1989 on the approximation of the laws of the Member States relating to personal protective equipment (OJ L 399, 30.12.1989, p. 18).

(62) IMO MEPC.(210)63, Section 3.3.4.10, p. 21.

(63) ILO SHG, Section 15, pp. 122-127.

(64) ILO SHG, Section 14, pp. 117-121.

(65) IMO MEPC.(210)63, Section 3.1.2, p. 8.

(66) IMO MEPC.(210)63, Section 3.3.6§7, p. 23.

(67) IMO MEPC.(210)63, Section 3.1.4, p. 9.

(68) ILO SHG, Section 5, pp. 34-40 and Annex I (Workers’ health surveillance) Section 4, pp. 150-151.

(69) Regulation (EC) No 765/2008 of the European Parliament and of the Council of 9 July 2008 setting out the requirements for accreditation and market surveillance relating to the marketing of products and repealing Regulation (EEC) No 339/93 (OJ L 218, 13.8.2008, p. 30).

(70) ISO/IEC 17020:2012, Requirements for the operation of various types of bodies performing inspection.

(71) A list of such bodies can be found on http://www.european-accreditation.org/mla-and-bla-signatories#6 and https://www.ilac.org/documents/mra_signatories.pdf

(72) Article 11(2) of Regulation (EC) No 765/2008 foresees that national authorities are to recognise the equivalence of the services delivered by those accreditation bodies which have successfully undergone peer evaluation, and thereby accept the accreditation certificates of those bodies and the attestations issued by the conformity assessment bodies accredited by them.

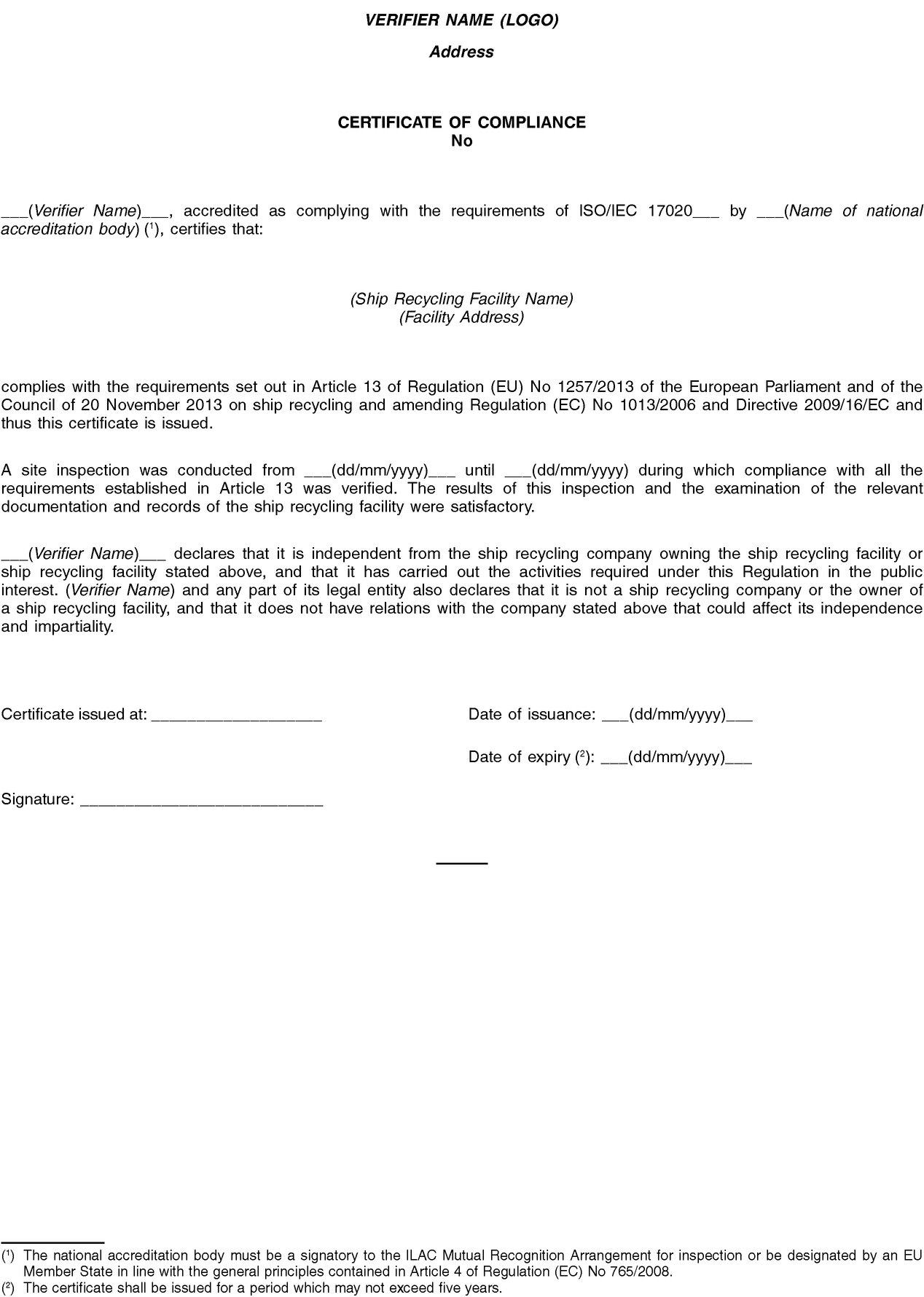

ANNEX 1

Copy of certification by an Independent Verifier

VERIFIER NAME (LOGO)

Address

CERTIFICATE OF COMPLIANCE

No

___(Verifier Name)___, accredited as complying with the requirements of ISO/IEC 17020___ by ___(Name of national accreditation body) (1), certifies that:

(Ship Recycling Facility Name)

(Facility Address)

complies with the requirements set out in Article 13 of Regulation (EU) No 1257/2013 of the European Parliament and of the Council of 20 November 2013 on ship recycling and amending Regulation (EC) No 1013/2006 and Directive 2009/16/EC and thus this certificate is issued.

A site inspection was conducted from ___(dd/mm/yyyy)___ until ___(dd/mm/yyyy) during which compliance with all the requirements established in Article 13 was verified. The results of this inspection and the examination of the relevant documentation and records of the ship recycling facility were satisfactory.

___(Verifier Name)___ declares that it is independent from the ship recycling company owning the ship recycling facility or ship recycling facility stated above, and that it has carried out the activities required under this Regulation in the public interest. (Verifier Name) and any part of its legal entity also declares that it is not a ship recycling company or the owner of a ship recycling facility, and that it does not have relations with the company stated above that could affect its independence and impartiality.

Certificate issued at: ___________________

Date of issuance: ___(dd/mm/yyyy)___

Date of expiry (2): ___(dd/mm/yyyy)___

Signature: ___________________________

(1) The national accreditation body must be a signatory to the ILAC Mutual Recognition Arrangement for inspection or be designated by an EU Member State in line with the general principles contained in Article 4 of Regulation (EC) No 765/2008.

(2) The certificate shall be issued for a period which may not exceed five years.

ANNEX 2

Sources and external references

IMO, Hong Kong International Convention for the Safe and Environmentally Sound Recycling of Ships, 2009.

http://ec.europa.eu/environment/waste/ships/pdf/Convention.pdf

IMO, Resolution MEPC.211(63) adopted on 2 March 2012, 2012 Guidelines for the authorisation of ship recycling facilities.

http://www.imo.org/OurWork/Environment/ShipRecycling/Documents/211(63).pdf

IMO, Resolution MEPC.210(63) adopted on 2 March 2012, 2012 Guidelines for safe and environmentally sound ship recycling.

http://www.imo.org/OurWork/Environment/ShipRecycling/Documents/210(63).pdf

ILO, Safety and health in shipbreaking, guidelines for Asian countries and Turkey, 2004.

http://ilo.org/safework/info/standards-and-instruments/codes/WCMS_107689/lang--en/index.htm

(Please note that this document is also available in French, Spanish, Chinese, Bengali and Hindi)

Basel Convention, Technical Guidelines for the Environmentally Sound Management of the Full and Partial Dismantling of Ships.

http://www.basel.int/Portals/4/Basel%20Convention/docs/meetings/sbc/workdoc/techgships-e.pdf

Secretariat of the Basel Convention, Guidance for competent authorities of ship recycling facilities, 4.8.2013.

http://www.basel.int/Portals/4/download.aspx?d=UNEP-CHW-SHIPS-GUID-CompetentAuthorities.English.pdf

IV Notices

NOTICES FROM EUROPEAN UNION INSTITUTIONS, BODIES, OFFICES AND AGENCIES

Council

|

12.4.2016 |

EN |

Official Journal of the European Union |

C 128/22 |

Notice for the attention of the persons to which measures provided for in Council Decision 2011/235/CFSP, as amended by Council Decision (CFSP) 2016/565 and in Council Regulation (EU) No 359/2011, as implemented by Council Implementing Regulation (EU) 2016/556 concerning restrictive measures directed against certain persons, entities and bodies in view of the situation in Iran apply

(2016/C 128/02)

The following information is brought to the attention of the persons that appear in the Annex to Council Decision 2011/235/CFSP (1), as amended by Council Decision (CFSP) 2016/565 (2), and in Annex I to Council Regulation (EU) No 359/2011 (3), as implemented by Council Implementing Regulation (EU) 2016/556 (4) concerning restrictive measures directed against certain persons, entities and bodies in view of the situation in Iran.

The Council of the European Union has decided that the persons that appear in the above-mentioned Annexes should continue be included in the list of persons and entities subject to restrictive measures provided for in Decision 2011/235/CFSP and in Regulation (EU) No 359/2011.

The attention of the persons concerned is drawn to the possibility of making an application to the competent authorities of the relevant Member State(s) as indicated on the websites in Annex II to Regulation (EU) No 359/2011, in order to obtain an authorisation to use frozen funds for basic needs or specific payments (cf. Article 4 of the Regulation).

The persons concerned may submit a request to the Council, together with supporting documentation, that the decision to include them on the above-mentioned list should be reconsidered, to the following address:

|

Council of the European Union |

|

DG C 1C — Horizontal Issues Unit |

|

General Secretariat |

|

Rue de la Loi 175/Wetstraat 175 |

|

1048 Bruxelles/Brussel |

|

BELGIQUE/BELGIË |

|

Email: sanctions@consilium.europa.eu |

The attention of the persons concerned is also drawn to the possibility of challenging the Council’s decision before the General Court of the European Union, in accordance with the conditions laid down in Article 275, second paragraph, and Article 263, fourth and sixth paragraphs, of the Treaty on the Functioning of the European Union.

(1) OJ L 100, 14.4.2011, p. 51.

(2) OJ L 96, 12.4.2016, p. 41.

(3) OJ L 100, 14.4.2011, p. 1.

European Commission

|