EUR-Lex Access to European Union law

This document is an excerpt from the EUR-Lex website

Document 52020XC0612(08)

Commission Notice providing guidance on food safety management systems for food retail activities, including food donations 2020/C 199/01

Commission Notice providing guidance on food safety management systems for food retail activities, including food donations 2020/C 199/01

Commission Notice providing guidance on food safety management systems for food retail activities, including food donations 2020/C 199/01

C/2020/2941

OJ C 199, 12.6.2020, p. 1–57

(BG, ES, CS, DA, DE, ET, EL, EN, FR, HR, IT, LV, LT, HU, MT, NL, PL, PT, RO, SK, SL, FI, SV)

|

12.6.2020 |

EN |

Official Journal of the European Union |

C 199/1 |

COMMISSION NOTICE

providing guidance on food safety management systems for food retail activities, including food donations

(2020/C 199/01)

1. INTRODUCTION

In accordance with Article 4 of Regulation (EC) No 852/2004 of the European Parliament and of the Council (1), all food business operators (FBOs) shall comply with the general hygiene requirements laid down in the Annexes I (primary production and associated operations) or II (other FBOs) of the Regulation. In addition, Article 5 provides that FBOs, other than primary producers, must put in place, implement and maintain a permanent procedure or procedures based on the Hazard Analysis and Critical Control Points (HACCP) principles.

The general hygiene requirements, together with specific hygiene requirements laid down in Annex III of Regulation (EC) No 853/2004 of the European Parliament and of the Council (2) are considered as prerequisite programmes (PRPs) (3), which, together with the procedures based on the HACCP principles, must result in an integrated Food Safety Management System (FSMS) for each food business as explained in the ‘Commission Notice on the implementation of food safety management systems covering prerequisite programs (PRPs) and procedures based on the HACCP principles, including the facilitation/flexibility on the implementation in certain food businesses’ (4), adopted in 2016 (‘the 2016 Commission Notice’).

The procedures based on the HACCP principles must consist of identifying any hazards that must be prevented, eliminated or reduced to acceptable levels as part of the hazard analysis, being the first of HACCP principle in accordance with Article 5(2)(a) of Regulation (EC) No 852/2004. The need for additional steps in the procedures based on the HACCP principles (points (b) to (g) of Article 5(2)) depends on the outcome of the hazard analysis, e.g. if the hazard analysis indicates the need to identify critical control points (CCPs). Recital 15 of Regulation (EC) No 852/2004 recognises that, in certain food businesses, it is not possible to identify CCPs and that, in some cases, good hygiene practices (the general and specific hygiene requirements referred to above) can replace the monitoring of CCPs.

Recital 15 of Regulation (EC) No 852/2004 explicitly refers to the need of this flexibility in case of small businesses. In accordance with Article 5(4)(a) the nature and size of the food business must be taken into account when verifying compliance with the procedures based on the HACCP principles.

The former Food and Veterinary Office (FVO) of the Commission’s Health and Food Safety Directorate-General carried out a desk study, fact-finding missions and consultations of Member States and private stakeholders’ organisations on a state of play of the implementation of HACCP in the EU and areas for improvement. Based on this exercise, the FVO published in 2015 an ‘Overview Report on the State of Implementation of HACCP in the EU and Areas for Improvement’ (5) (‘the 2015 FVO Report’). The 2015 FVO Report recommends to extend guidance on FSMS and provides several suggestions for improvement, including guidance on hazard analysis and setting of CCPs. The 2016 Commission Notice addresses the recommendations in the FVO report but is not activity-specific.

Food retailers (e.g. restaurants, butchers, bakeries, caterers, groceries, pubs, etc.) are often small businesses, lacking the scientific knowledge and resources to carry out hazard analysis as part of their obligation to apply an FSMS.

Food donation often occurs at retail level and the consideration and possible identification of additional hazards due to this activity must be included in the hazard analysis. Facilitating food donation is a priority under the Circular Economy Action Plan of the Commission (6) as a means of preventing food waste and promoting food security, in line with the United Nations Sustainable Development Goals. This objective may in some instances be challenging from a food safety point of view given the involvement of additional actors (e.g. food banks and other charity organisations) and given that food which is redistributed may be approaching the end of its shelf-life when considered for food donation.

In order to provide support to retailers for their hazard analysis, the Commission first requested the European Food Safety Authority (EFSA) to provide recommendations on hazard analysis approaches for retail establishments. EFSA adopted two Opinions. In 2017, it adopted an Opinion on ‘Hazard analysis approaches for certain small retail establishments in view of the application of their food safety management systems’ (7) focussing on butcher shops, groceries, bakeries, fish shops and ice cream shops. In 2018, EFSA adopted a ‘Second scientific opinion on hazard analysis approaches for certain small retail establishments and food’ (8) focussing on distribution centres, supermarkets and restaurants (including pubs and catering) and addressing, within the hazard analysis, potential additional hazards in case of food donations at retail level.

2. PURPOSE AND CONTENT

The purpose of this guidance is to facilitate and harmonise the implementation of the EU requirements for an FSMS with a central role of the hazard analysis for the following retailers: butcher, grocery, bakery, fish and ice cream shops, distribution centres, supermarkets, restaurants, catering services and pubs.

This Notice therefore provides guidance on how these retailers, within their activity, can implement Regulation (EC) No 852/2004, in particular its Article 4 and Annex II as regards general hygiene requirements and its Article 5 as regards procedures based on the HACCP principles. It is at the same time an example how the retail sector can specifically implement the guidelines, including those on facilitation/flexibility, recommended in the 2016 Commission Notice, specifically at retail level. Competent authorities may also use this guidance to verify implementation of the EU requirements by these food businesses.

The parts related to food donation supplement the EU guidelines on food donation (9), which clarify relevant provisions in EU legislation in order to facilitate compliance of providers and recipients of surplus food with the requirements laid down in the EU regulatory framework (e.g. food safety, food hygiene, food information, traceability, liability, etc.). In the area of food hygiene, for instance, the guidelines outline the need for FBOs (including food banks and other charities) to apply good hygiene practices and have in place a self-checking system based on the HACCP principles related to food redistribution activities.

This Notice addresses a number of recommendations from the FVO Report and translates the scientific advice provided by the two EFSA opinions into a document, ready for use by FBOs.

This Notice starts with general guidance in line with the EFSA opinions to apply a simplified approach for an FSMS for retailers in Section 3. An overview is provided of specific PRPs, relevant as basis for an FSMS at retail level in Section 4, supplemented in Section 5 by those PRPs specifically intended to ensure consumers’ safety in case of food donations.

The simplified approach in Section 3 was used to provide guidance on hazard analysis, the next step in an FSMS that starts from the development of a flow diagram, explained in Section 6. Starting from a specific flow diagram, Sections 7 to 14 provide a generic hazard analysis as guidance for each activity, which is just an example and may have to be adapted to the specific activities of the retailers (processes or steps can be added or deleted). Guidance on how possible hazards during food donations can be included in the hazard analysis has been addressed in Section 15 in a horizontal way as it can be applied in a similar way in the different retail activities.

The recommendations in this guidance are not binding and might not be relevant for each of the retailer activities included. Retailers may apply the ‘simplified approach’ to food safety management as described in this Notice and in the EFSA Opinions (‘simplified FSMS’). However, if the flow diagram showing their detailed activities does not correspond to the ones illustrated in this Notice it is important that individual retail establishments tailor their FSMS in a clear and user-friendly way based on the other specific processes (stages) and products relevant to their business. This could be done by adapting the relevant flow diagram.

This EU guidance may be supplemented or replaced by guidance at national level to better take into account specific local or national situations. In addition, national rules may exist on issues which are not regulated and harmonised at EU level (for example, in regard to food donations). It is therefore recommended to consult national authorities on the possible existence of such national rules and/or guidance. In order to facilitate sharing of information on national food donation practices, the Commission publishes guidelines existing in the EU Member States on its website dedicated to food waste prevention (10).

The Commission consulted experts from the Member States in order to examine and reach consensus on these issues. Experiences from Member States, already applying certain EFSA recommendations, on the practical applications of the simplified approach were considered to further improve the current guidance.

This Notice is intended to assist certain retail businesses in the application of Regulation (EC) No 852/2004. Only the Court of Justice of the European Union is competent to authoritatively interpret Union law.

3. GUIDANCE FOR A SIMPLIFIED FSMS IN THE RETAIL SECTOR

Based on the recommendations in the EFSA Opinions a ‘simplified’ approach for FSMS, compliant with the requirements of Regulation (EC) No 852/2004 can be described as follows:

|

(1) |

the retail establishment needs only to be aware of groups of hazards (biological, chemical, physical or allergen) that may occur at a particular stage, without having an in-depth knowledge of each specific hazard (e.g. knowing there may be a biological hazard associated with raw meat without knowing whether it might be Salmonella, Campylobacter or Shiga-toxin producing Escherichia coli); this is possible because control activities for each group of hazards are the same at retail level; |

|

(2) |

the retail establishment must understand that failure to perform certain risk-reducing activities, such as separating raw and ready-to-eat (RTE) foods, constitutes a risk; |

|

(3) |

there is no requirement to understand or apply risk ranking; |

|

(4) |

allergens are treated as a separate hazard, as opposed to a chemical hazard; and |

|

(5) |

PRPs must always be in place and, if justified based on the outcome of the mandatory hazard identification and (absence of) identification of critical control points (hazard analysis), such PRPs might be sufficient and don’t need to be supplemented by additional steps in the procedures based on the HACCP principles (e.g. identification of CCPs). |

|

How to use this guide in practice to obtain an FSMS for your business?

|

4. OVERVIEW OF PRPS RELEVANT FOR ANY RETAIL ACTIVITY

PRPs are preventive practices and conditions needed prior to and during the implementation of HACCP and which are essential for food safety. The PRPs needed depend on the segment of the food chain in which the sector operates and the type of activity. Examples of activity-specific equivalent terms at different stages of food production are Good Agriculture Practices (GAPs), Good Veterinarian Practices (GVPs), Good Manufacturing Practices (GMPs), Good Hygiene Practices (GHPs), Good Production Practices (GPPs), Good Distribution Practices (GDPs) and Good Trading Practices (GTPs). In Codex Alimentarius texts (11), PRPs are referred to as ‘Codes of Practice’ or ‘GHPs’ in a broad understanding. More details in PRPs in general can be found in the 2016 Commission Notice, while more details on the PRPs specific for retailers can be found in the EFSA Opinions.

Table 1 below (and Table 2 in Section 5) provides for each PRP guidance on how hazards can be controlled by the PRP (column 2), if and how the application of the PRP should be monitored in the food business (column 3), if there is a need for record keeping on the monitoring applied (column 4) and which corrective action should be applied when monitoring results demonstrate that the PRP is not properly applied (column 5).

Table 1

A summary of PRPs relevant for retail activities based on the 2016 Commission Notice and the EFSA opinions

|

PRP |

Control infrastructure/activities |

Monitoring |

Record keeping (yes/no) (*1) |

Corrective action |

|

PRP 1: Infrastructure (building and equipment, including movable or temporary premises). |

Hygienic infrastructure and fit for purpose building and equipment. |

Monthly visual check based on checklist of infrastructure (hygiene and condition). |

Yes, but only when there is remedial work required. |

Proper maintenance of premises and equipment. |

|

PRP 2: Cleaning and disinfection. |

Cleaning and disinfection schedule and/or ‘clean as you go’ policy. |

Spot visual checks. Daily visual checks. Regular microbiological testing. Frequency may depend on the size of the establishment and results of previous testing. |

Yes, when there is a non-compliance. |

Cleaning and disinfection of area/equipment affected. Review and if necessary retrain staff and/or revise frequency and method of disinfection. |

|

PRP 3: Pest control: focus on prevention. |

Pest control activities. |

Weekly in-house check. |

Yes, but only when there is remedial work required or logbook when using external company. |

Revise and/or renew pest control activities. |

|

PRP 4: Technical maintenance and calibration. |

Maintain all equipment. Calibrate measuring devices (e.g. thermometer, balance, etc.). |

On-going monitoring of equipment. Periodic calibration status or back-up check by using different thermometer. |

No. Yes, status of calibration/back-up check. |

Repair or replace equipment as necessary. Review maintenance and calibration programme. |

|

PRP 5: Physical and chemical contamination from production environment. |

Ensure all materials are stored correctly. Ensure all surfaces are properly rinsed/wiped after disinfection in accordance with manufacturer’s instructions. |

Visual check during processing. Monthly check based on checklist or visual inspection of infrastructure (hygiene and condition). |

Yes, but only when there is remedial work required. |

Review storage, cleaning and disinfection procedures, etc. |

|

For bakery products, high temperatures will promote acrylamide formation. |

Ensure correct baking (T/duration) conditions. |

Visual check during processing and of end product. |

No. |

Disposal of ‘over-cooked’ products. |

|

PRP 6: Allergens. |

Control the absence of unintentional allergens in raw materials. Keep an up-to-date inventory of food products with potential allergens including sources (e.g. raw material, cross-contamination, etc.). Potential sources of cross-contamination identified and controlled. |

Raw material specifications from suppliers. Activities to prevent cross-contamination are implemented on a continuous basis. |

No. Some records should be kept (at least on corrective actions) if an allergen incident occurs. |

Stop using potentially ‘contaminated’ raw materials. Review suppliers/supplier requirements. Revise acceptance criteria. Review and correct activities designed to prevent cross-contamination. If despite all actions mentioned above cross-contamination cannot be avoided, following a risk assessment FBOs should evaluate whether to provide information on the possible and unintentional presence of allergens in food. |

|

PRP 7: Waste management. |

Complete separation of waste from raw materials or foods. Comply with the specific legal requirements for the storage and disposal of waste for foods of animal origin (animal by-products). |

Routine visual check to ensure the food business’s policy on waste management is being fully complied with. |

No. |

Remove waste without undue delay from areas where food is handled. Review and revise current waste management activities. Retrain staff as required. |

|

PRP 8: Water control, including ice making (if other water is used than supply of potable municipal water). |

Control of source and good condition of water distribution infrastructure with absence of toxic contact materials. |

Ongoing monitoring of water treatment. Periodic microbiological and chemical testing. |

Yes, results of microbiological and chemical testing. |

Revise water treatment. |

|

PRP 9: Personnel (hygiene, health status). |

Presence of hygiene rules and agreements with personnel adapted to the nature of the activities. Health status of personnel. |

Daily visual check during processing. Medical check and awareness training for all personnel. |

Documentation of hygiene instructions. Medical check and training record keeping. |

Address any personnel issues immediately. Advise and inform personnel. |

|

PRP 10: Raw materials (supplier selection, specifications). |

Raw materials are fulfilling legal requirements. Retailers have acceptance criteria based on, preferably written specifications (e.g. odour, smell, …). |

Presence of specifications from suppliers or presence of labels of packaged materials. Acceptance criteria are checked upon each delivery. |

Yes, but only when there is a non-compliance, e.g. the raw materials were not delivered at the correct temperature. |

Do not use affected raw materials. Review suppliers/supplier requirements. Revise acceptance criteria. |

|

PRP 11: Temperature control of storage environment. |

Temperature of storage environment (cooling or deep freezing) is adequate to reach product temperature requirements. |

Automatic monitoring with alarm and/or automated record keeping. Manual monitoring/daily check or more checks of the temperature of storage facilities and product. |

As appropriate (See 2016 Commission notice). |

Replace/repair/reset chilling/freezing equipment. Based on the extent of the non-compliance consider disposal of the affected product. |

|

PRP 12: Working methodology. |

Personnel following clear, preferably written, work instructions, (standard operating procedures (SOP)), including instructions with regards to products approaching the end of shelf-life. For bakery products, where high temperatures will promote acrylamide formation, instruction on the disposal of ‘over-cooked’ product should be added. |

Daily visual check. |

No. |

Retrain personnel. |

|

PRP 13: Product information and consumer awareness. |

All products at retail level should be accompanied by sufficient verbal or written information to promote proper handling, storage and preparation by consumers. Allergen and shelf-life information should also be provided if appropriate. |

Routine checks to ensure this information is provided. |

No. |

Review and revise the information as necessary. |

5. OVERVIEW OF ADDITIONAL PRPS MOST RELEVANT FOR RETAIL INVOLVED IN FOOD DONATION

As regards food donation, four additional PRPs set out below, have been recommended by EFSA that apply to all FBOs involved in food donation, both donors and recipients.

While they may partly overlap with the 13 PRPs in Table 1, these four PRPs may be required to provide control for specific activities within supermarkets, restaurants, food distribution and other retailers (in particular PRPs 14 and 15) but especially related to food donation which presents unique challenges in relation to shelf-life, handing returned foods and freezing to preserve food intended for food donation.

5.1. PRP 14: Shelf-life control

Shelf-life is the period of time during which a food maintains its acceptable or desirable characteristics under specified storage and handling conditions. These acceptable or desirable characteristics may be related to the safety or quality of the food and can be microbiological, chemical or physical in nature. Articles 9(1)(f) and 24 and Annex X, points 1 and 2 of Regulation (EU) No 1169/2011 of the European Parliament and of the Council (12) require that food is labelled either with a date of minimum durability (‘best before’ date) or a ‘use by’ date. The FBOs (usually the food manufacturers) are responsible for deciding whether a ‘best before’ or ‘use by’ date is required as well as the length of the shelf-life.

Many foods that are past their ‘best before’ date may still be safe to eat, but their quality may have deteriorated. In contrast, some perishable foods may constitute an immediate danger to human health after a relatively short period of time and, for these foods, the shelf-life is indicated on the labelling as a ‘use by’ date, the date up until which the food may be consumed safely, assuming correct storage. A ‘use by’ date is often used for fresh meat, fresh fish and chilled ready-to-eat foods. After the ‘use by’ date, a food shall be deemed to be unsafe in accordance with Article 14(2) to (5) of Regulation (EC) No 178/2002 of the European Parliament and of the Council (13); therefore, it is prohibited to place food on the market past the ‘use by’ date and the food should not be consumed. The FBOs should routinely check foods to ensure the removal of foods before the end of the ‘use by’ date indicated on the labelling and, in the case of food donation, their redistribution before the end of this date.

A date of minimum durability (‘best before’ date) is not required for certain prepacked foods (e.g. whole fresh fruit and vegetables, wines and other beverages containing 10 % or more alcohol by volume, certain bakery products, vinegar, cooking salt, solid sugar, confectionery products and chewing gums).

For non-prepacked foods, the provision of date marking is not required by EU rules on food information to consumers. However, specific obligations may be laid down in national legislation.

5.2. PRP 15: Handling returned foods (e.g. food returns from supermarkets to central distribution centres)

FBOs should ensure that food returns are held and kept separate until they are:

|

(a) |

ascertained to be safe and fit for human consumption; |

|

(b) |

destroyed or otherwise used or disposed of in a safe and legal way; |

|

(c) |

returned to its supplier; |

|

(d) |

sent for donation if the product is fit for human consumption; or |

|

(e) |

further processed. |

It is important that there is full traceability of returned food products.

5.3. PRP 16: Evaluation for food donation including assessment of remaining shelf-life

|

1. |

The following types of foods may be considered for food donation:

|

|

2. |

Food intended for donation should not be distributed nor consumed after the ‘use by’ date indicated on the labelling. However, in the case of food labelled with a ‘best before’ date, as food safety is not directly impacted, products exceeding this date could still be distributed for food donation purposes if the following conditions apply:

In all cases, the original ‘best before‘ date should remain visible so that the donor and recipient can make up their own mind about redistribution and/or consumption of the food. The remaining food product shelf-life must be assessed both upon sending and receipt of the product made available for food donation. |

|

3. |

The tasks of donors in relation to shelf-life of foods include:

|

|

4. |

Donors and recipients should ensure timely transportation of foods at each stage of food redistribution, under proper and documented storage conditions and at the temperature indicated on the labelling, so that their products retain their remaining shelf-life. |

|

5. |

Tasks of recipients in relation to the shelf-life of foods:

|

5.4. PRP 17: Freezing food intended for donation

Freezing of foods before the end of the ‘use by’ date indicated on the labelling in order to extend shelf-life and facilitate safe redistribution would facilitate donation as food received by redistribution organisations and charities cannot always be delivered to the customer before this date. However, for hygienic reasons, Regulation (EC) No 853/2004 (16) prescribes that meat intended for freezing must be frozen without undue delay after production. This requirement applies to retailers supplying other FBOs such as food banks and freezing meat at retail is therefore not allowed in this case. Member States may, however, adopt national measures to allow the freezing of meat for redistribution purposes, provided that such retail activity is marginal, localised and restricted in accordance with Article 1(5)(b)(ii) of this Regulation. National measures should be adopted accordingly and notified to the Commission and other Member States.

Freezing of foods labelled with a ‘use by’ date should be done as early as possible and definitely before the end of the ‘use by’ date indicated on the labelling, and to a temperature of – 18 °C or lower. This temperature must be maintained throughout distribution.

In the case of non-prepacked foods which are donated such as non-prepacked fresh meat, fresh fish, surplus food from restaurants/catering, which do not need to have a ‘use by’ date, the recipient should be informed about the storage time and conditions of these foods to allow an assessment of the suitability for freezing or consumption (Table 2).

Freezing of food can be done both by food donors or recipients, if permissible by the Member State and provided that national provisions are respected. In doing so, the period of time the food can be used or consumed or shelf-life can be extended provided that this does not mislead the consumer or otherwise reduce the level of consumer protection and taking into account relevant national provisions or guidance in this regard. Additional conditions might be considered by Member States such as use of the food within a certain period, an indication of the original ‘use by’ or ‘best before’ date (if provided) of the food, the date it was frozen, possible provision of information on the period of time the food can be used or consumed, and instructions for proper thawing practices or timeframe for consumption after thawing.

Table 2

Summary and associated monitoring, record-keeping and corrective activities with the additional PRPs 14, 15, 16 and 17 most relevant for food donations

|

PRP |

Control infrastructure/activities conducted by both donors and recipients |

Monitoring |

Record keeping (*2) |

Corrective action |

||||||||||

|

PRP 14: Shelf-life control. |

Compliance with Regulation (EU) No 1169/2011 on food information regarding date marking (‘use by’ and ‘best-before’ dates). Proper storage of foods according to the conditions of temperature, light and moisture conditions, recommended by the manufacturer. |

Foods should be routinely checked to ensure the removal of products before the end of the ‘use by’ date. FBOs may also take this opportunity to check the integrity of the packaging, proper storage conditions, etc. |

No |

Disposal, or refuse or return of foods in the following cases:

|

||||||||||

|

PRP 15: Handling returned foods. |

Proper warehouse facilities for different types of storage (chilled, frozen, ambient) with segregation from non-returned products. Logistics and traceability systems using first in-first out approach. |

Batch inspection of package integrity and other visual defects, no visible signs of spoilage. Temperature monitoring at receiving. Decision on acceptability for donation. |

Yes. Record of the basic description of the returned food, date of return, why is was returned, origin of the food, and its destination. |

Disposal of foods deemed unfit for human consumption or that were not timely placed in proper storage. Re-processing of foods to be rendered safe. |

||||||||||

|

PRP 16: Evaluation for food donation and assessment of remaining shelf-life. |

Products with the shortest remaining shelf-life-first out logistics for chilled and ambient delivery. Facilities and working methodology for sensory evaluation. Traceability systems. |

Evaluation if a ‘best before’ or ‘use by’ date is present on prepacked foods and decide how much time still can be allocated. In case of prepacked foods for which ‘best before’ date is not required (e.g. prepacked fruits and vegetables, bakery wares, wine, etc. – see list PRP 14) a sensory evaluation (e.g. smell, taste, colour, …) and decision if still fit for consumption. In the case of food with a ‘best before’ date, foods past this date may be considered for food donation but this food should be routinely checked to ensure; (1) integrity of packing material (no damage, no opening, no condensation, etc.); (2) proper storage of the food according to required temperature and other conditions (e.g. deep freezing at – 18 °C or dry storage); (3) in case of food frozen before the end of shelf-life for food donation purposes, checking the information regarding the freezing date; (4) evaluate sensory properties (still fit for human consumption (e.g. absence of moulds, rancidity etc.); and (5) no exposure to any other significant food safety hazards or other health risk. |

Yes, logging of initial labelling or information upon reception. |

Disposal, or recall of foods past the ‘use by’ date. Disposal of foods that require but do not have a shelf-life date. |

||||||||||

|

PRP 17: Freezing for food donations. |

Rapid freezing and frozen storage infrastructure. Logistics. Compliance with Regulation (EU) No 1169/2011 on food information regarding date marking (‘use by’ and ‘best-before’ dates). Compliance with Regulation (EC) No 853/2004 laying down specific hygiene rules for food of animal origin. |

Temperature monitoring. Inspection of package integrity. Labelling inspection. Checking the information on the freezing date and any other information provided on the period of time the food can be used or consumed (where available, additional guidance established at national level should be taken into account). |

No. |

Disposal of foods in the following cases:

|

6. FLOW DIAGRAMS AND HAZARD ANALYSIS

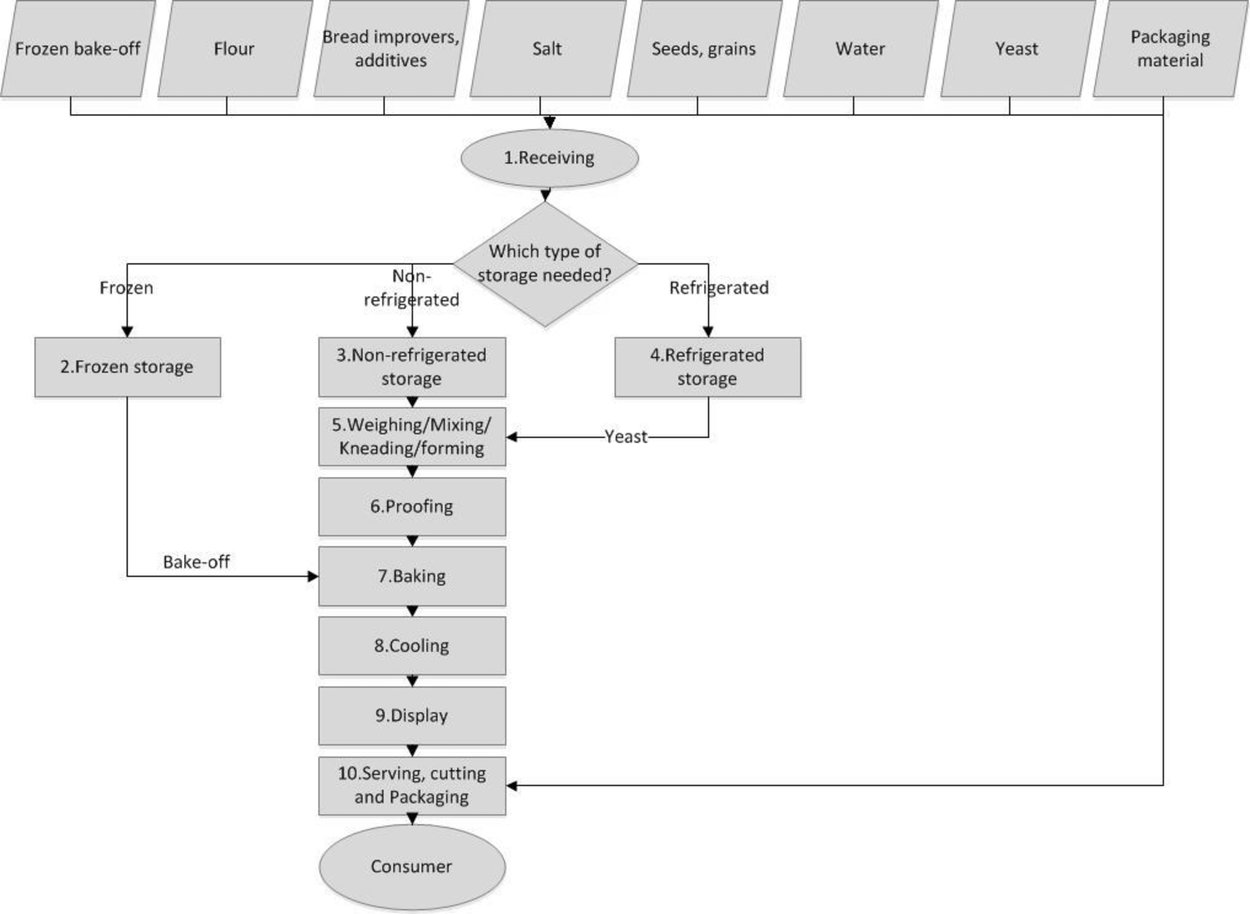

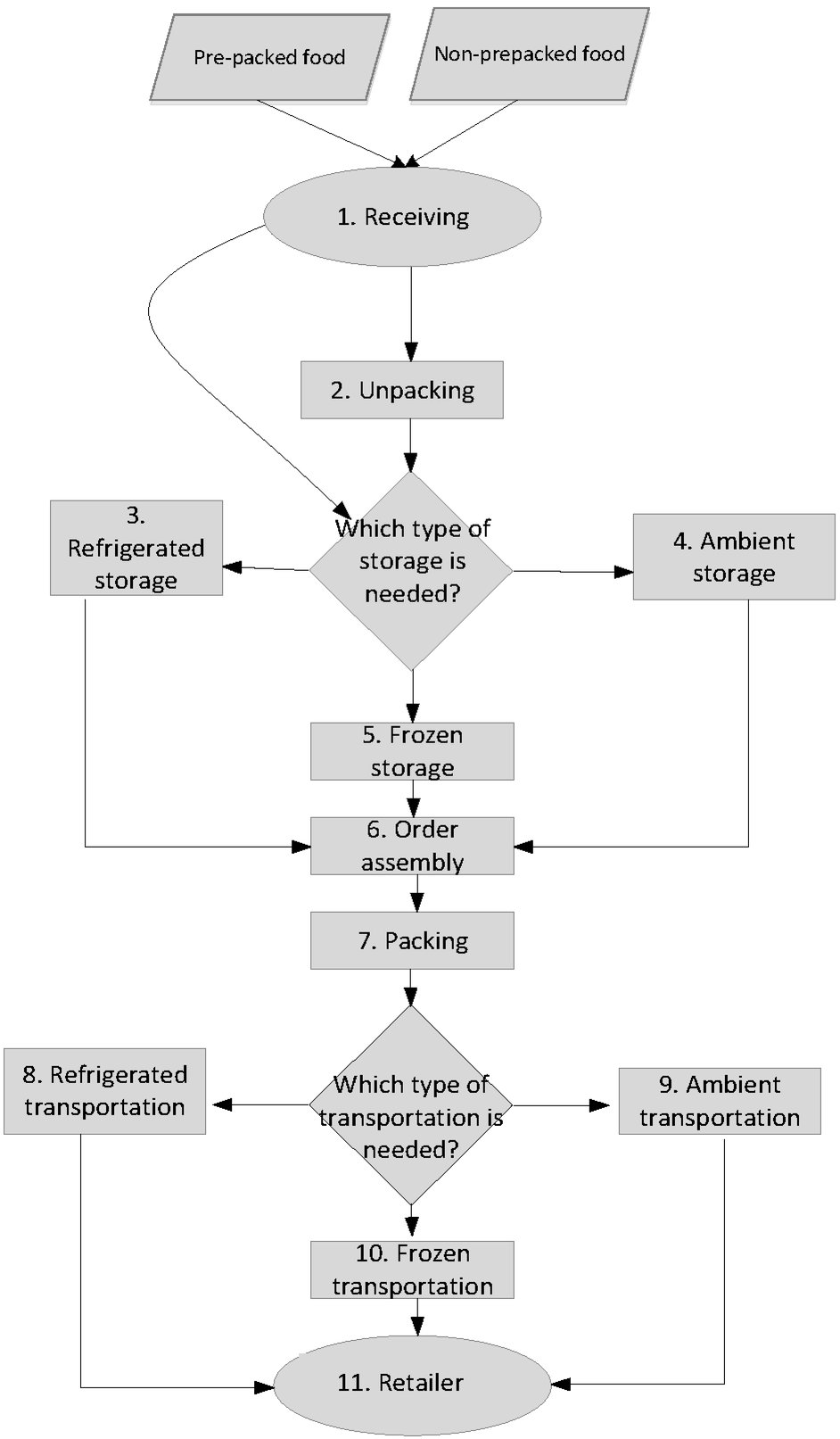

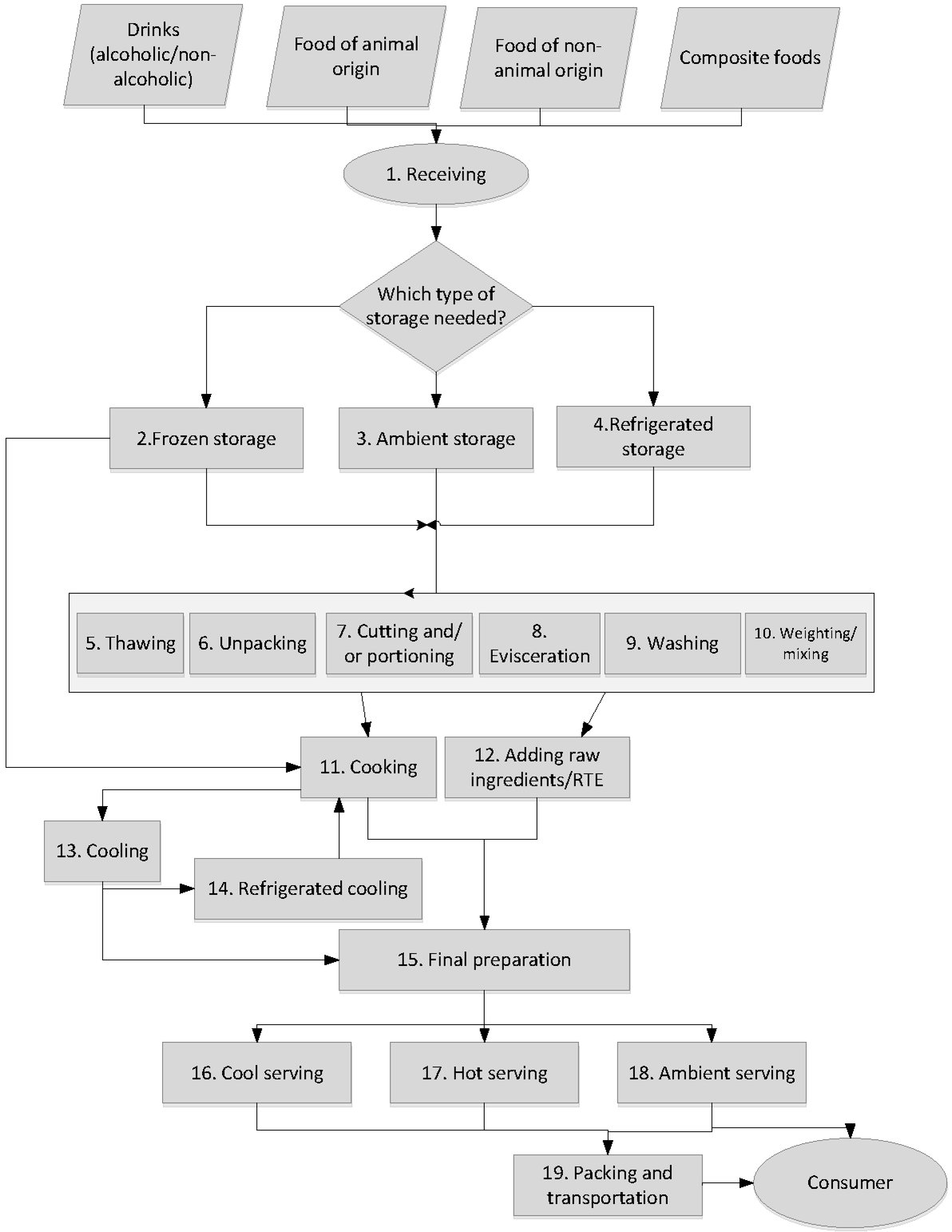

Generic flow diagrams and hazard analysis for butcher shops, grocery shops (fruit and vegetables), bakery shops, fish shops, ice cream shops, distribution centres (including food banks), supermarkets and restaurants, catering services and pubs are provided in Sections 7, 8, 9, 10, 11, 12, 13 and 14 respectively.

The legend for the flow diagrams is as follows:

|

|

process step |

|

|

start-end of production process |

|

|

raw materials, intermediate product or final product |

|

|

decision between different possible production steps |

Each food business operator should initiate a hazard analysis starting by developing a flow diagram. It should represent all activities and consecutive steps or stages in a food business. The generic flow diagrams in Sections 7 to 14 may represent the activities, but some may have to be added or removed to reflect a specific food business.

The hazard analysis tables (Tables 3 to 10) follow the steps or activities indicated in the flow diagram of a food business (column 1).

The other columns of the tables represent the hazard analysis itself:

|

— |

columns 2 and 3 represent the hazard identification at each stage being:

|

|

— |

column 4 represents the ‘control activities’ to prevent the occurrence of a hazard. These control activities are the relevant PRPs described in Section 4 of this Notice. |

7. BUTCHER SHOP

Table 3

Generic Hazard Analysis for a butcher

|

Stage |

Hazards (1) |

Activities contributing to increased occurrence of the hazard |

Control activities |

|||

|

B |

C |

P |

A |

|||

|

Receiving |

Y |

Y |

Y |

Y |

Failure to ensure the microbiological quality of incoming raw materials |

PRP 10: Raw materials (supplier selection, specifications) PRP 11: Temperature control of storage environment PRP 12: Working methodology |

|

Presence of chemical or physical hazards or allergens in incoming raw materials |

PRP 6: Allergens PRP 10: Raw materials (supplier selection, specifications) PRP 12: Working methodology |

|||||

|

Refrigerated and frozen storage |

Y |

Y |

Y |

Y |

Microbial growth due to failure to chill properly |

PRP 4: Technical maintenance and calibration PRP 11: Temperature control of storage environment |

|

Cross-contamination due to a failure to separate raw from RTE products |

PRP 12: Working methodology |

|||||

|

Contamination with chemical or physical hazards from the environment, personnel, etc. |

PRP 3: Pest control: focus on prevention PRP 5: Physical and chemical contamination from production environment |

|||||

|

Contamination with allergens |

PRP 6: Allergens |

|||||

|

Ambient storage |

Y |

Y |

Y |

Y |

Microbial growth due to failure to store in dry conditions |

PRP 1: Infrastructure (building and equipment) PRP 2: Cleaning and disinfection |

|

Contamination with chemical or physical hazards from the environment, personnel, etc. |

PRP 1: Infrastructure (building and equipment) PRP 3: Pest control: focus on prevention PRP 5: Physical and chemical contamination from production environment |

|||||

|

Contamination with allergens |

PRP 6: Allergens |

|||||

|

Cutting and portioning |

Y |

Y |

Y |

N |

Contamination with biological, chemical or physical hazards due to a failure to clean and disinfect equipment properly, lack of personal hygiene, knives and equipment, cross-contamination with waste |

PRP 2: Cleaning and disinfection PRP 4: Technical maintenance and calibration PRP 5: Physical and chemical contamination from production environment PRP 7: Waste management PRP 9: Personnel (hygiene, health status) |

|

Mincing |

Y |

Y |

N |

Y |

Cross-contamination with biological hazards due to a failure to clean, disinfect and store equipment properly or lack of personal hygiene |

PRP 2: Cleaning and disinfection PRP 9: Personnel (hygiene, health status) |

|

Contamination with chemical hazards |

PRP 2: Cleaning and disinfection |

|||||

|

Contamination with allergens |

PRP 6: Allergens |

|||||

|

Processing |

Y |

Y |

Y |

Y |

Contamination with biological, chemical or physical hazards due to a failure to clean and disinfect equipment properly, lack of personal hygiene, environment, higher concentration of additives than allowed |

PRP 2: Cleaning and disinfection PRP 5: Physical and chemical contamination from the production environment PRP 9: Personnel (hygiene, health status) PRP 12: Working methodology PRP 4: Technical maintenance and calibration (weighting of additives) |

|

Contamination with allergens |

PRP 6: Allergens |

|||||

|

Display in counter |

Y |

Y |

N |

Y |

Microbial growth due to failure to chill properly |

PRP 4: Technical maintenance and calibration PRP 11: Temperature control of storage environment |

|

Cross-contamination with biological hazards due to a failure to separate raw from RTE products |

PRP 12: Working methodology |

|||||

|

Contamination with chemical hazards |

PRP 2: Cleaning and disinfection PRP 5: Physical and chemical contamination from the production environment |

|||||

|

Contamination with allergens |

PRP 6: Allergens |

|||||

|

Refrigerated storage |

Y |

Y |

Y |

Y |

Microbial growth due to failure to chill properly |

PRP 4: Technical maintenance and calibration PRP 11: Temperature control of storage environment |

|

Cross-contamination due to a failure to separate raw from RTE products |

PRP 12: Working methodology |

|||||

|

Contamination with chemical or physical hazards from the environment, personnel, etc. |

PRP 2: Cleaning and disinfection PRP 3: Pest control: focus on prevention PRP 5: Physical and chemical contamination from production environment |

|||||

|

Contamination with allergens |

PRP 6: Allergens |

|||||

|

Slicing, serving and packing |

Y |

Y |

Y |

Y |

Contamination with biological, chemical or physical hazards or allergens due to failure in working methodology and lack of personal hygiene. |

PRP 2: Cleaning and disinfection PRP 5: Physical and chemical contamination from the production environment PRP 6: Allergens PRP 9: Personnel (hygiene, health status) PRP 12: Working methodology |

|

Failure to inform the consumer of potential allergens and storage mode, time, etc. |

PRP 6: Allergens PRP 13: Product information and consumer awareness |

|||||

8. GROCERY SHOP (FRUIT AND VEGETABLES)

Table 4

Generic Hazard Analysis for a grocery shop (fruit and vegetables)

|

Stage |

Hazards (2) |

Activities contributing to increased occurrence of the hazard |

Control activities |

|||

|

B |

C |

P |

A |

|||

|

Receiving |

Y |

Y |

Y |

Y |

Failure to ensure the microbiological quality of incoming raw materials |

PRP 10: Raw materials (supplier selection, specifications) PRP 11: Temperature control of storage environment PRP 12: Working methodology |

|

Presence of chemical or physical hazards or allergens in incoming raw materials |

PRP 6: Allergens PRP 10: Raw materials (supplier selection, specifications) PRP 12: Working methodology |

|||||

|

Ambient storage |

Y |

Y |

Y |

Y |

Contamination with biological, chemical or physical hazards from the environment, personnel, etc. |

PRP 1: Infrastructure (building and equipment) PRP 3: Pest control: focus on prevention PRP 5: Physical and chemical contamination from production environment |

|

Contamination with allergens |

PRP 6: Allergens |

|||||

|

Refrigerated and frozen storage |

Y |

Y |

Y |

Y |

Microbial growth due to failure to chill properly |

PRP 4: Technical maintenance and calibration PRP 11: Temperature control of storage environment |

|

Contamination with chemical or physical hazards from the environment, personnel, etc. |

PRP 3: Pest control: focus on prevention PRP 5: Physical and chemical contamination from production environment |

|||||

|

Contamination with allergens |

PRP 6: Allergens |

|||||

|

Washing |

Y |

Y |

Y |

N |

Contamination with biological, chemical and physical hazards from water, the environment, personnel, etc. |

PRP 2: Cleaning and disinfection PRP 4: Technical maintenance and calibration PRP 5: Physical and chemical contamination from production environment PRP 8: Water and air control PRP 9: Personnel (hygiene, health status) |

|

Display |

Y |

Y |

Y |

Y |

Contamination with biological, chemical or physical hazards or allergens from the environment, personnel, etc. |

PRP 1: Infrastructure (building and equipment) PRP 2: Cleaning and disinfection PRP 5: Physical and chemical contamination from the production environment PRP 6: Allergens PRP 7: Waste management |

|

Display in refrigerated counter |

Y |

Y |

Y |

Y |

Microbial growth due to failure to chill properly |

PRP 4: Technical maintenance and calibration PRP 11: Temperature control of storage environment |

|

Contamination with biological, chemical or physical hazards or allergens from the environment, personnel, etc. |

PRP 1: Infrastructure (building and equipment) PRP 2: Cleaning and disinfection PRP 5: Physical and chemical contamination from the production environment PRP 6: Allergens PRP 7: Waste management |

|||||

|

Spraying |

Y |

Y |

Y |

N |

Contamination with biological, chemical and physical hazards from water, the environment, personnel, etc. |

PRP 2: Cleaning and disinfection PRP 4: Technical maintenance and calibration PRP 5: Physical and chemical contamination from production environment PRP 8: Water and air control PRP 9: Personnel (hygiene, health status) |

|

Serving and packing |

Y |

Y |

Y |

Y |

Contamination with biological, chemical or physical hazards or allergens from the environment, personnel, etc. |

PRP 2: Cleaning and disinfection PRP 5: Physical and chemical contamination from the production environment PRP 6: Allergens PRP 9: Personnel (hygiene, health status) PRP 12: Working methodology |

|

Failure to inform the consumer of potential allergens and storage mode, time, etc. |

PRP 6: Allergens PRP 13: Product information and consumer awareness |

|||||

9. BAKERY SHOP

Table 5

Generic Hazard Analysis for a bakery shop

|

Stage |

Hazards (3) |

Activities contributing to increased/decreased occurrence of the hazard |

Control activities |

|||

|

B |

C |

P |

A |

|||

|

Receiving |

Y |

Y |

Y |

Y |

Failure to ensure the microbiological quality of incoming raw materials |

PRP 10: Raw materials (supplier selection, specifications) PRP 11: Temperature control of storage environment PRP 12: Working methodology |

|

Presence of chemical or physical hazards or non-declared allergens in incoming raw materials |

PRP 6: Allergens PRP 10: Raw materials (supplier selection, specifications) PRP 12: Working methodology |

|||||

|

Ambient storage |

Y |

Y |

Y |

Y |

Microbial growth due to failure to store in dry conditions |

PRP 1: Infrastructure (building and equipment) PRP 2: Cleaning and disinfection |

|

Contamination with chemical or physical hazards from the environment, personnel, etc. |

PRP 1: Infrastructure (building and equipment) PRP 3: Pest control: focus on prevention PRP 5: Physical and chemical contamination from production environment |

|||||

|

Contamination with allergens |

PRP 6: Allergens |

|||||

|

Refrigerated and frozen storage |

Y |

Y |

Y |

Y |

Microbial growth due to failure to chill properly |

PRP 4: Technical maintenance and calibration PRP 11: Temperature control of storage environment |

|

Cross-contamination due to a failure to separate raw from cooked/RTE products |

PRP 12: Working methodology |

|||||

|

Contamination with chemical or physical hazards from the environment, personnel, etc. |

PRP 2: Cleaning and disinfection PRP 3: Pest control: focus on prevention PRP 5: Physical and chemical contamination from production environment |

|||||

|

Contamination with allergens |

PRP 6: Allergens |

|||||

|

Weighing, mixing and kneading |

N |

Y |

Y |

Y |

Contamination with chemical or physical hazards and allergens from the environment, personnel, higher levels of additives than allowed, etc. |

PRP 4: Technical maintenance and calibration (weighting of additives) PRP 5: Physical and chemical contamination from the production environment PRP 6: Allergens PRP 12: Working methodology |

|

Proofing |

N |

Y |

Y |

Y |

Contamination with chemical or physical hazards from the environment, personnel, etc. |

PRP 5: Physical and chemical contamination from the production environment PRP 12: Working methodology |

|

Contamination with allergens |

PRP 6: Allergens |

|||||

|

Baking |

Y |

Y |

N |

N |

Survival of microbial hazards due to failure to achieve sufficiently high temperatures |

PRP 4: Technical maintenance and calibration PRP 12: Working methodology |

|

Formation of acrylamide due to overcooking. |

PRP 12: Working methodology |

|||||

|

Cooling |

Y |

Y |

N |

N |

Microbial growth due to failure to chill quickly |

PRP 4: Technical maintenance and calibration PRP 12: Working methodology |

|

Contamination with chemical hazards |

PRP 5: Physical and chemical contamination from the production environment |

|||||

|

Display |

Y |

Y |

Y |

Y |

Contamination with biological, chemical or physical hazards or allergens from the environment, personnel, etc. |

PRP 1: Infrastructure (building and equipment) PRP 2: Cleaning and disinfection PRP 5: Physical and chemical contamination from the production environment PRP 6: Allergens PRP 7: Waste management |

|

Serving, cutting and packing |

Y |

Y |

Y |

Y |

Contamination with biological, chemical or physical hazards or allergens due to a failure to clean and disinfect equipment properly. |

PRP 2: Cleaning and disinfection PRP 5: Physical and chemical contamination from the production environment PRP 6: Allergens PRP 9: Personnel (hygiene, health status) PRP 12: Working methodology |

|

Failure to inform the consumer of potential allergens and storage mode, time, etc. |

PRP 6: Allergens PRP 13: Product information and consumer awareness |

|||||

10. FISH SHOP

Table 6

Generic Hazard Analysis for a fish shop

|

Stage |

Hazards (4) |

Activities contributing to increased/decreased occurrence of the hazard |

Control activities |

|||

|

B |

C |

P |

A |

|||

|

Receiving |

Y |

Y |

Y |

Y |

Presence of biological hazards in incoming raw materials |

PRP 10: Raw materials (supplier selection, specifications) PRP 11: Temperature control of storage environment PRP 12: Working methodology |

|

Presence of chemical or physical hazards or non-declared allergens in incoming raw materials |

PRP 6: Allergens PRP 10: Raw materials (supplier selection, specifications) PRP 12: Working methodology |

|||||

|

Ice making |

Y |

Y |

Y |

N |

Presence of chemical or physical hazards due to failure to ensure the quality of the water used |

PRP 5: Physical and chemical contamination from the production environment PRP 8: Water and air control |

|

Survival of biological or physical hazards due to failure to maintain, clean and disinfect equipment |

PRP 2: Cleaning and disinfection PRP 4: Technical maintenance and calibration |

|||||

|

Storage on ice |

Y |

Y |

N |

N |

Microbial growth due to failure to chill properly |

PRP 11: Temperature control of storage environment PRP 12: Working methodology |

|

Microbial growth and subsequent production of histamine because of inadequate storage conditions (time/temperature) |

PRP 12: Working methodology |

|||||

|

Contamination with chemical hazards |

PRP 2: Cleaning and disinfection PRP 5: Physical and chemical contamination from the production environment PRP 8: Water and air control |

|||||

|

Refrigerated storage |

Y |

Y |

Y |

Y |

Microbial growth due to failure to chill properly |

PRP 4: Technical maintenance and calibration PRP 11: Temperature control of storage environment |

|

Contamination with biological, chemical or physical hazards from the environment, personnel, etc. |

PRP 2: Cleaning and disinfection PRP 3: Pest control: focus on prevention PRP 5: Physical and chemical contamination from production environment PRP 12: Working methodology |

|||||

|

Contamination with allergens |

PRP 6: Allergens |

|||||

|

Microbial growth and subsequent production of histamine because of inadequate storage conditions (time/temperature) |

PRP 12: Working methodology |

|||||

|

Frozen storage |

Y |

Y |

Y |

N |

Microbial growth due to failure in freezing temperature |

PRP 4: Technical maintenance and calibration PRP 11: Temperature control of storage environment |

|

Contamination with chemical or physical hazards from the environment, etc. |

PRP 5: Physical and chemical contamination from production environment |

|||||

|

Ambient storage |

Y |

Y |

Y |

Y |

Microbial growth due to failure to store in dry conditions |

PRP 1: Infrastructure (building and equipment) PRP 2: Cleaning and disinfection |

|

Contamination with chemical or physical hazards from the environment, personnel, etc. |

PRP 1: Infrastructure (building and equipment) PRP 3: Pest control: focus on prevention PRP 5: Physical and chemical contamination from production environment |

|||||

|

Contamination with allergens |

PRP 6: Allergens |

|||||

|

Thawing |

Y |

Y |

N |

N |

Microbial growth due to failure to maintain low temperatures |

PRP 11: Temperature control of storage environment |

|

Microbial growth and subsequent histamine formation due to inadequate time temperature conditions |

PRP 12: Working methodology |

|||||

|

Contamination with chemical hazards |

PRP 2: Cleaning and disinfection PRP 5: Physical and chemical contamination from production environment |

|||||

|

Evisceration |

Y |

Y |

Y |

N |

Verification of visible parasites from the gut or muscles |

PRP 10: Raw materials (supplier selection, specifications) |

|

Cross-contamination with biological hazards from the gut to the meat |

PRP 7: Waste management PRP 12: Working methodology |

|||||

|

Contamination with biological, chemical and physical hazards from the environment, personnel, etc. |

PRP 2: Cleaning and disinfection PRP 5: Physical and chemical contamination from production environment PRP 9: Personnel (hygiene, health status) |

|||||

|

Sorting, cleaning and washing |

Y |

Y |

Y |

N |

Contamination with biological, chemical and physical hazards from water, the environment, personnel, working method, etc. |

PRP 2: Cleaning and disinfection PRP 5: Physical and chemical contamination from production environment PRP 8: Water and air control PRP 9: Personnel (hygiene, health status) PRP 12: Working methodology |

|

Cutting |

Y |

Y |

Y |

N |

Contamination with biological, chemical or physical hazards due to a failure to clean and disinfect equipment properly, the environment, personnel, waste, work method. |

PRP 2: Cleaning and disinfection PRP 5: Physical and chemical contamination from production environment PRP 7: Waste management PRP 9: Personnel (hygiene, health status) PRP 12: Working methodology |

|

Refrigerated storage |

Y |

Y |

Y |

Y |

Microbial growth due to failure to chill properly |

PRP 4: Technical maintenance and calibration PRP 11: Temperature control of storage environment |

|

Contamination with biological, chemical or physical hazards from the environment, personnel, etc. |

PRP 2: Cleaning and disinfection PRP 3: Pest control: focus on prevention PRP 5: Physical and chemical contamination from production environment PRP 12: Working methodology |

|||||

|

Contamination with allergens |

PRP 6: Allergens |

|||||

|

Microbial growth and subsequent histamine formation due to inadequate time temperature conditions) |

PRP 11: Temperature control of storage environment PRP 12: Working methodology |

|||||

|

Display in refrigerated counter |

Y |

Y |

Y |

Y |

Microbial growth due to failure to chill properly |

PRP 4: Technical maintenance and calibration PRP 11: Temperature control of storage environment |

|

Contamination with biological, chemical or physical hazards or allergens from the environment, personnel, etc. |

PRP 1: Infrastructure (building and equipment) PRP 2: Cleaning and disinfection PRP 5: Physical and chemical contamination from the production environment PRP 6: Allergens PRP 7: Waste management |

|||||

|

Microbial growth and subsequent histamine formation due to inadequate time temperature conditions |

PRP 6: Allergens PRP 11: Temperature control of storage environment PRP 12: Working methodology |

|||||

|

Serving and packing |

Y |

Y |

Y |

Y |

Contamination with biological, chemical or physical hazards or allergens from the environment, personnel, etc. |

PRP 2: Cleaning and disinfection PRP 5: Physical and chemical contamination from the production environment PRP 6: Allergens PRP 9: Personnel (hygiene, health status) PRP 12: Working methodology |

|

Failure to inform the consumer of potential allergens and storage mode, time, etc. |

PRP 6: Allergens PRP 13: Product information and consumer awareness |

|||||

11. ICE CREAM SHOP

Table 7

Generic Hazard Analysis for an ice cream shop

|

Stage |

Hazards (5) |

Activities contributing to increased/decreased occurrence of the hazard |

Control activities |

|||

|

B |

C |

P |

A |

|||

|

Receiving |

Y |

Y |

Y |

Y |

Failure to ensure the microbiological quality of incoming raw materials |

PRP 10: Raw materials (supplier selection, specifications) PRP 11: Temperature control of storage environment PRP 12: Working methodology |

|

Presence of chemical or physical hazards or allergens in incoming raw materials |

PRP 6: Allergens PRP 10: Raw materials (supplier selection, specifications) PRP 12: Working methodology |

|||||

|

Ambient Storage |

Y |

Y |

Y |

Y |

Microbial growth due to failure to store in dry conditions |

PRP 1: Infrastructure (building and equipment) PRP 2: Cleaning and disinfection |

|

Contamination with chemical or physical hazards from the environment, personnel, etc. |

PRP 1: Infrastructure (building and equipment) PRP 3: Pest control: focus on prevention PRP 5: Physical and chemical contamination from production environment |

|||||

|

Contamination with allergens |

PRP 6: Allergens |

|||||

|

Refrigerated storage |

Y |

Y |

Y |

Y |

Microbial growth due to failure to chill properly |

PRP 4: Technical maintenance and calibration PRP 11: Temperature control of storage environment |

|

Cross-contamination due to a failure to separate raw from cooked/RTE products |

PRP 12: Working methodology |

|||||

|

Contamination with chemical or physical hazards from the environment, personnel, etc. |

PRP 2: Cleaning and disinfection PRP 3: Pest control: focus on prevention PRP 5: Physical and chemical contamination from production environment |

|||||

|

Contamination with allergens |

PRP 6: Allergens |

|||||

|

Frozen storage |

Y |

Y |

Y |

N |

Microbial growth due to failure in freezing temperature |

PRP 4: Technical maintenance and calibration PRP 11: Temperature control of storage environment |

|

Contamination with chemical or physical hazards from the environment, etc. |

PRP 5: Physical and chemical contamination from production environment |

|||||

|

Weighing and mixing |

Y |

Y |

Y |

Y |

Microbial growth due to long period of weighing and mixing |

PRP 12: Working methodology |

|

Contamination with chemical or physical hazards and allergens from the environment, personnel, etc. |

PRP 2: Cleaning and disinfection PRP 5: Physical and chemical contamination from the production environment PRP 6: Allergens PRP 9: Personnel (hygiene, health status) PRP 12: Working methodology |

|||||

|

Cooking |

Y |

Y |

N |

N |

Failure to achieve sufficiently high temperatures |

PRP 4: Technical maintenance and calibration PRP 12: Working methodology |

|

Contamination with chemical hazards |

PRP 2: Cleaning and disinfection PRP 5: Physical and chemical contamination from the production environment |

|||||

|

Cooling |

Y |

Y |

N |

N |

Failure to chill quickly |

PRP 4: Technical maintenance and calibration PRP 12: Working methodology |

|

Contamination with chemical hazards |

PRP 2: Cleaning and disinfection PRP 5: Physical and chemical contamination from the production environment |

|||||

|

Ageing |

Y |

N |

N |

N |

Microbial growth due to failure to chill properly |

PRP 4: technical maintenance and calibration PRP 11: Temperature control of storage environment |

|

Air incorporation/whipping |

Y |

Y |

Y |

N |

Microbial growth due to failure to chill properly |

PRP 4: Technical maintenance and calibration PRP 11: Temperature control of storage environment |

|

Contamination with chemical or physical hazards from the environment, personnel, etc. |

PRP 2: Cleaning and disinfection PRP 5: Physical and chemical contamination from the production environment PRP 8: Air and water control PRP 12: Working methodology |

|||||

|

Packaging |

Y |

Y |

Y |

N |

Contamination with microbial, chemical or physical hazards from the packaging materials, environment, personnel, etc. |

PRP 2: Cleaning and disinfection PRP 5: Physical and chemical contamination from the production environment PRP 9: Personnel (hygiene, health status) PRP 12: Working methodology |

|

Hardening |

Y |

Y |

N |

N |

Microbial growth due to failure in freezing temperature |

PRP 4: Technical maintenance and calibration PRP 11: Temperature control of storage environment |

|

Contamination with chemical hazards |

PRP 5: Physical and chemical contamination from the production environment |

|||||

|

Frozen storage |

Y |

Y |

N |

N |

Microbial growth due to failure in freezing temperature |

PRP 4: Technical maintenance and calibration PRP 11: Temperature control of storage environment |

|

Contamination with chemical hazards |

PRP 5: Physical and chemical contamination from the production environment |

|||||

|

Portioning and serving |

Y |

Y |

Y |

Y |

Contamination with biological, chemical or physical hazards or allergens due to a failure to clean and disinfect equipment properly. |

PRP 2: Cleaning and disinfection PRP 5: Physical and chemical contamination from the production environment PRP 6: Allergens PRP 9: Personnel (hygiene, health status) PRP 12: Working methodology |

|

Failure to inform the consumer of potential allergens and storage mode, time, etc. |

PRP 6: Allergens PRP 13: Product information and consumer awareness |

|||||

12. DISTRIBUTION CENTRES

Table 8

Generic hazard analysis for a food distribution centre

|

Stage |

Hazards (6) |

Activities contributing to increased/decreased occurrence of the hazard |

Control activities |

|||

|

|

B |

C |

P |

A |

|

|

|

All stages |

|

|

|

|

|

PRPs 1, 2, 3, 9, 12 |

|

Receiving |

Y |

Y |

Y |

Y |

Failure to ensure the microbiological quality of incoming raw materials |

PRP 10: Raw materials (supplier selection, specifications) PRP 11: Temperature control PRP 14: Shelf-life control |

|

Presence of chemical/physical hazards or allergens in incoming raw materials |

PRP 6: Allergens PRP 10: Raw materials (supplier selection, specifications) |

|||||

|

Growth of pathogenic or spoilage microorganisms because of incomplete/wrong shelf-life data or storage conditions |

PRP 14: Shelf-life control |

|||||

|

Contamination with biological/chemical/physical hazards or allergens hazards due to returns with other products |

PRP 15: Returns management |

|||||

|

Unpacking |

Y |

Y |

Y |

Y |

Contamination with biological, chemical or physical hazards or allergens from the environment, personnel, etc. |

PRP 5: Physical and chemical contamination from production environment PRP 6: Allergens |

|

Cross-contamination with microbial hazards due to a failure to separate raw from cooked/RTE products |

PRP 4: Technical maintenance and calibration |

|||||

|

Chemicals released from food contact materials |

PRP 10: Raw materials (supplier selection, specifications) |

|||||

|

Growth of pathogenic or spoilage microorganisms because of incomplete/wrong shelf-life data or storage conditions |

PRP 13: Product information and consumer awareness PRP 14: Shelf-life control |

|||||

|

Contamination with chemical hazards and allergens |

PRP 5: Physical and chemical contamination from production environment PRP 6: Allergens |

|||||

|

Refrigerated storage |

Y |

Y |

Y |

Y |

Microbial growth due to failure to chill properly (i.e. correct temperature and time), or due to storage for too long period |

PRP 4: Technical maintenance and calibration PRP 11: Temperature control PRP 14: Shelf-life control |

|

Cross-contamination due to a failure to separate raw from cooked/RTE products |

PRP 5: Physical and chemical contamination from production environment PRP 6: Allergens |

|||||

|

Contamination with biological/chemical/physical hazards or allergens from the environment, personnel, etc. |

PRP 5: Physical and chemical contamination from production environment PRP 6: Allergens |

|||||

|

Ambient storage |

Y |

Y |

Y |

Y |

Microbial growth due to failure to store in dry conditions |

PRP 8: Water and air control PRP 11: Temperature control PRP 14: Expiration date control PRP 16: Evaluation for food donation and allocation of remaining shelf-life |

|

Contamination with microbial/chemical/physical hazards or allergens from the environment, personnel, etc. |

PRP 5: Physical and chemical contamination from production environment PRP 6: Allergens |

|||||

|

Contamination with allergens due to contact between allergen-containing (including dust, aerosols, …) and non-allergen-containing food or food ingredients. |

PRP 6: Allergens |

|||||

|

Frozen storage |

Y |

Y |

Y |

Y |

Microbial growth due to failure in freezing temperature |

PRP 4: Technical maintenance and calibration PRP 11: Temperature control PRP 14: Expiration date control |

|

Contamination with microbial/chemical/physical hazards due to environment |

PRP 5: Physical and chemical contamination from production environment PRP 6: Allergens |

|||||

|

Order assembly |

Y |

Y |

Y |

Y |

Contamination with biological/chemical/physical hazards or allergens from the environment, personnel, etc. |

PRP 5: Physical and chemical contamination from production environment PRP 6: Allergens |

|

Packing |

Y |

Y |

Y |

Y |

Contamination with biological/chemical/physical hazards or allergens from the environment, personnel, etc. |

PRP 5: Physical and chemical contamination from production environment PRP 6: Allergens |

|

Cross-contamination with microbial hazards due to a failure to separate raw from cooked/RTE products |

PRP 4: Technical maintenance and calibration |

|||||

|

Chemicals released from food contact materials |

PRP 10: Raw materials (supplier selection, specifications) |

|||||

|

Growth of pathogenic or spoilage microorganisms because of incomplete/wrong shelf-life data or storage conditions |

PRP 13: Product information and consumer awareness PRP 14: Expiration date control |

|||||

|

Ambient transportation |

Y |

Y |

Y |

Y |

Microbial growth due to failure to store in dry conditions |

PRP 8: Water and air control PRP 11: Temperature control PRP 14: Expiration date control PRP 16: Evaluation for food donation and allocation of remaining shelf-life |

|

Contamination with microbial/chemical/physical hazards or allergens from the environment, personnel, etc. |

PRP 5: Physical and chemical contamination from production environment PRP 6: Allergens |

|||||

|

Contamination with allergens due to contact between allergen-containing (including dust, aerosols, …) and non-allergen-containing food or food ingredients. |

PRP 6: Allergens |

|||||

|

Refrigerated transportation |

Y |

Y |

Y |

Y |

Microbial growth due to failure to chill properly (i.e. correct temperature and time), or due to storage for too long period |

PRP 4: Technical maintenance and calibration PRP 11: Temperature control PRP 14: Expiration date control |

|

Cross-contamination due to a failure to separate raw from cooked/RTE products |

PRP 5: Physical and chemical contamination from production environment PRP 6: Allergens |

|||||

|

Contamination with biological/chemical/physical hazards or allergens from the environment, personnel, etc. |

PRP 5: Physical and chemical contamination from production environment PRP 6: Allergens |

|||||

|

Frozen transportation |

Y |

Y |

Y |

Y |

Microbial growth due to failure in freezing temperature |

PRP 4: Technical maintenance and calibration PRP 11: Temperature control PRP 14: Expiration date control |

|

Contamination with microbial/chemical/physical hazards due to environment |

PRP 5: Physical and chemical contamination from production environment PRP 6: Allergens |

|||||

13. SUPERMARKETS

Table 9

General hazard analysis for a supermarket

|

Stage |

Hazards (7) |

Activities contributing to increased/decreased occurrence of the hazard |

Control measures |

|||||

|

B |

C |

P |

A |

|||||

|

All stages |

|

|

|

|

|

PRPs 1, 2, 3, 9, 12 |

||

|

Receiving |

Y |

Y |

Y |

Y |

Failure to ensure the microbiological quality of incoming raw materials |

PRP 10: Raw materials (supplier selection, specifications) PRP 11: Temperature control PRP 14: Expiration date control |

||

|

Presence of chemical/physical hazards or allergens in incoming raw materials |

PRP 6: Allergens PRP 10: Raw materials (supplier selection, specifications) |

|||||||

|

Growth of pathogenic or spoilage microorganisms because of incomplete/wrong shelf-life data or storage conditions |

PRP 14: Expiration date control |

|||||||

|

Contamination with biological/chemical/physical hazards or allergens hazards due to mixing returns with other products |

PRP 15: Returns management |

|||||||

|

Storage (not yet in display) |

||||||||

|

Ambient storage |

Y |

Y |

Y |

Y |

Contamination with biological/chemical/physical hazards or allergens via contaminated serving utensils and/or improper handling |

PRP 8: Water and air control PRP 11: Temperature control PRP 14: Expiration date control PRP 16: Evaluation for food donation and allocation of remaining shelf-life |

||

|

Contamination with microbial/chemical/physical hazards or allergens from the environment, personnel, etc. |

PRP 5: Physical and chemical contamination from production environment PRP 6: Allergens |

|||||||

|

Contamination with allergens due to contact between allergen-containing (including dust, aerosols, …) and non-allergen-containing food or food ingredients. |

PRP 6: Allergens |

|||||||

|

Refrigerated storage |

Y |

Y |

Y |

Y |

Microbial growth due to failure to chill properly (i.e. correct temperature and time), or due to storage for too long period |

PRP 4: Technical maintenance and calibration PRP 11: Temperature control PRP 14: Expiration date control |

||

|

Cross-contamination due to a failure to separate raw from cooked/RTE products |

PRP 5: Physical and chemical contamination from production environment PRP 6: Allergens |

|||||||

|

Contamination with biological/chemical/physical hazards or allergens from the environment, personnel, etc. |

PRP 5: Physical and chemical contamination from production environment PRP 6: Allergens |

|||||||

|

Frozen storage |

Y |

Y |

Y |

Y |

Microbial growth due to failure in freezing temperature |

PRP 4: Technical maintenance and calibration PRP 11: Temperature control PRP 14: Expiration date control |

||

|

Contamination with biological/chemical/physical hazards or allergens from the environment, personnel, etc. |

PRP 5: Physical and chemical contamination from production environment PRP 6: Allergens |

|||||||

|

Pre-packed foods in display counter (display and self-service by customer) |

||||||||

|

Ambient storage |

Y |

Y |

Y |

Y |

As above |

As above |

||

|

Refrigerated storage |

Y |

Y |

Y |

Y |

As above |

As above |

||

|

Frozen storage |

Y |

Y |

Y |

Y |

As above |

As above |

||

|

Non-pre-packed in display counter |

||||||||

|

Foods in the butcher counter, fish counter, bakery counter and/or fruit & vegetables |

|

|

|

|

See; EFSA (2017) Scientific opinion on hazard analysis approaches for certain small retail establishments in view of the application of their food safety management systems. EFSA Journal 2017;15(3):4697, 52 pp. doi:10.2903/j.efsa.2017.4697. |

|

||

|

Other non-pre-packed foods in display counter |

||||||||

|

||||||||

|

Cutting and/or portioning |

Y |

Y |

Y |

Y |

Contamination with biological, chemical or physical hazards and allergens due to a failure to clean and disinfect equipment properly, lack of personal hygiene |

PRP 4: Technical maintenance and calibration PRP 5: Physical and chemical contamination from production environment PRP 6: Allergens |

||

|

Display in counter (ambient, refrigerated or hot) |

Y |

Y |

Y |

Y |

Microbial growth due to failure to store at the required temperature |

PRP 4: Technical maintenance and calibration |

||

|

Contamination with biological, chemical or physical hazards or allergens from the environment, personnel, etc. |

PRP 5: Physical and chemical contamination from production environment PRP 6: Allergens |

|||||||

|

Display in counter (frozen) |

Y |

Y |

Y |

Y |

Microbial growth due to failure in freezing temperature |

PRP 4: Technical maintenance and calibration PRP 11: Temperature control PRP 14: Expiration date control |

||

|

Contamination with biological/chemical/physical hazards or allergens from the environment, personnel, etc. |

PRP 5: Physical and chemical contamination from production environment PRP 6: Allergens |

|||||||

|

Refrigerated storage |

Y |

Y |

Y |

Y |

As above |

As above |

||

|

Self-service by consumer: portioning and packaging by consumer |

Y |

Y |

Y |

Y |

Contamination with microbial, chemical or physical hazards or allergens due to failure in working methodology and lack of personal hygiene by consumers. Although the hygiene of self-service is dependent on the customer, retailers can facilitate this by providing supervision, guidance as well as clean utensils, gloves, etc. and proper packaging material |

PRP 10: Raw materials (supplier selection, specifications) PRP 13: Product information and consumer awareness |

||

|

||||||||

|

Cooking |

Y |

Y |

N |

Y |

Survival of pathogens or presence of toxins due to failure to achieve sufficient temperatures/time |

PRP 4: Technical maintenance and calibration PRP 11: Temperature control |

||

|

Growth of pathogens and spoilage bacteria due to insufficient temperatures due to low heat transfer due to improper cleaning of heated containers or to defective equipment |

PRP 4: Technical maintenance and calibration PRP 11: Temperature control |

|||||||

|

Formation of process contaminants, e.g. acrylamide or PAHs |

PRP 5: Physical and chemical contamination from the production environment |

|||||||

|

Contamination with chemical hazards and allergens by improperly cleaned cooking tools, or reused oil and water |

PRP 5: Physical and chemical contamination from the production environment PRP 6: Allergens |

|||||||

|

Cooling |

Y |

Y |

N |

Y |

Microbial growth due to failure to achieve low temperatures within a certain time |

PRP 4: Technical maintenance and calibration PRP 11: Temperature control |

||

|

Contamination with chemical hazards and allergens |

PRP 5: Physical and chemical contamination from production environment PRP 6: Allergens |

|||||||

14. RESTAURANTS, CATERING SERVICES AND PUBS

Table 10

General hazard analysis for a restaurant, catering service and pub

|

Stage |

Hazards (8) |

Activities contributing to increased/decreased occurrence of the hazard |

Control measures |

|||

|

B |

C |

P |

A |

|||

|

All stages |

|

|

|

|

|

PRPs 1, 2, 3, 9, 12 |

|

Receiving |

Y |

Y |

Y |

Y |

Failure to ensure the microbiological quality of incoming raw materials |

PRP 10: Raw materials (supplier selection, specifications) PRP 11: Temperature control PRP 14: Expiration date control |

|

Presence of chemical/physical hazards or allergens in incoming raw materials |

PRP 6: Allergens PRP 10: Raw materials (supplier selection, specifications) |

|||||

|

Growth of pathogenic or spoilage microorganisms because of incomplete/wrong shelf-life data or storage conditions |

PRP 14: Shelf-life control |

|||||

|

Contamination with biological/chemical/physical hazards or allergens hazards due to mixing returns with other products |

PRP 15: Returns management |

|||||

|

Ambient storage |

Y |

Y |

Y |

Y |

Contamination with biological/chemical/physical hazards or allergens via contaminated serving utensils and/or improper handling |

PRP 8: Water and air control PRP 11: Temperature control PRP 14: Shelf-life control PRP 16: Evaluation for food donation and allocation of remaining shelf-life |

|