EUR-Lex Access to European Union law

This document is an excerpt from the EUR-Lex website

Document 31979L1067

First Commission Directive 79/1067/EEC of 13 November 1979 laying down Community methods of analysis for testing certain partly or wholly dehydrated preserved milk for human consumption

First Commission Directive 79/1067/EEC of 13 November 1979 laying down Community methods of analysis for testing certain partly or wholly dehydrated preserved milk for human consumption

First Commission Directive 79/1067/EEC of 13 November 1979 laying down Community methods of analysis for testing certain partly or wholly dehydrated preserved milk for human consumption

OJ L 327, 24.12.1979, p. 29–52

(DA, DE, EN, FR, IT, NL)

Greek special edition: Chapter 13 Volume 009 P. 56 - 82

Spanish special edition: Chapter 13 Volume 010 P. 264 - 287

Portuguese special edition: Chapter 13 Volume 010 P. 264 - 287

Special edition in Finnish: Chapter 13 Volume 010 P. 150 - 173

Special edition in Swedish: Chapter 13 Volume 010 P. 150 - 173

Special edition in Czech: Chapter 03 Volume 004 P. 112 - 135

Special edition in Estonian: Chapter 03 Volume 004 P. 112 - 135

Special edition in Latvian: Chapter 03 Volume 004 P. 112 - 135

Special edition in Lithuanian: Chapter 03 Volume 004 P. 112 - 135

Special edition in Hungarian Chapter 03 Volume 004 P. 112 - 135

Special edition in Maltese: Chapter 03 Volume 004 P. 112 - 135

Special edition in Polish: Chapter 03 Volume 004 P. 112 - 135

Special edition in Slovak: Chapter 03 Volume 004 P. 112 - 135

Special edition in Slovene: Chapter 03 Volume 004 P. 112 - 135

Special edition in Bulgarian: Chapter 03 Volume 003 P. 125 - 148

Special edition in Romanian: Chapter 03 Volume 003 P. 125 - 148

Special edition in Croatian: Chapter 03 Volume 010 P. 3 - 26

In force

In force

|

24.12.1979 |

EN |

Official Journal of the European Union |

L 327/29 |

FIRST COMMISSION DIRECTIVE

of 13 November 1979

laying down Community methods of analysis for testing certain partly or wholly dehydrated preserved milk for human consumption

(79/1067/EEC)

THE COMMISSION OF THE EUROPEAN COMMUNITIES,

Having regard to the Treaty establishing the European Economic Community,

Having regard to Council Directive 76/118/EEC of 18 December 1975 on the approximation of the laws of the Member States relating to certain partly or wholly dehydrated preserved milk for human consumption (1), and in particular Article 11 thereof,

Whereas under Article 11 of Directive 76/118/EEC, the composition of certain partly or wholly dehydrated preserved milk is required to be verified by Community methods of analysis;

Whereas it is desirable to adopt an initial series of methods in respect of which studies have been completed;

Whereas the measures provided for in this Directive are in accordance with the opinion of the Standing Committee of Foodstuffs,

HAS ADOPTED THIS DIRECTIVE:

Article 1

Member States shall take all measures necessary to ensure that the analyses necessary for verification of the criteria set out in Annex I are carried out in accordance with the methods described in Annex II.

Article 2

Where alternative methods for a single determination are specified, the sample may be analysed by either method. The test report referred to in Annex II must state the method which has been employed.

Article 3

Member States shall bring into force the laws, regulations and administrative provisions necessary to comply with this Directive within 18 months of its notification. They shall forthwith inform the Commission thereof.

Article 4

This Directive is addressed to the Member States.

Done at Brussels, 13 November 1979.

For the Commission

Étienne DAVIGNON

Member of the Commission

(1) OJ No L 24, 30. 1. 1976, p. 49.

ANNEX I

SCOPE OF THE FIRST COMMUNITY METHODS OF ANALYSIS FOR CERTAIN PARTLY OR . WHOLLY DEHYDRATED PRESERVED MILK DIRECTIVE

I. General provisions

II. Determination of dry matter in:

|

— |

unsweetened condensed high fat milk (using method 1, Annex II), |

|

— |

unsweetened condensed milk (using method 1, Annex II), |

|

— |

unsweetened condensed partly skimmed milk (using method 1, Annex II), |

|

— |

unsweetened condensed skimmed milk (using method 1, Annex II), |

|

— |

sweetened condensed milk (using method 1, Annex II), |

|

— |

sweetened condensed partly skimmed milk (using method 1, Annex II), |

|

— |

sweetened condensed skimmed milk (using method 1, Annex II). |

III. Determination of moisture in:

|

— |

dried high fat milk or high fat milk powder (using method 2, Annex II), — dried whole milk or whole milk powder (using method 2, Annex II), |

|

— |

dried partly skimmed milk or partly skimmed-milk powder (using method 2, Annex II), |

|

— |

dried skimmed milk or skimmed-milk powder (using method 2, Annex II). |

IV. Determination of fat in:

|

— |

unsweetened condensed high fat milk (using method 3, Annex II), |

|

— |

unsweetened condensed milk (using method 3, Annex II), |

|

— |

unsweetened condensed partly skimmed milk (using method 3, Annex II), |

|

— |

unsweetened condensed skimmed milk (using method 3, Annex II), |

|

— |

sweetened condensed milk (using method 3, Annex II), |

|

— |

sweetened condensed partly skimmed milk (using method 3, Annex II), |

|

— |

sweetened condensed skimmed milk (using method 3, Annex II), |

|

— |

dried high fat milk or high fat milk powder (using method 4, Annex II), |

|

— |

dried whole milk or whole milk powder (using method 4, Annex II), |

|

— |

dried partly skimmed milk or partly skimmed-milk powder (using method 4, Annex II), |

|

— |

dried skimmed milk or skimmed-milk powder (using method 4, Annex II). |

V. Determination of sucrose in:

|

— |

sweetened condensed milk (using method 5, Annex II), |

|

— |

sweetened condensed partly skimmed milk (using method 5, Annex II), |

|

— |

sweetened condensed skimmed milk (using method 5, Annex II). |

VI. Determination of lactic acid and lactates in:

|

— |

dried high fat milk or high fat milk powder (using method 6, Annex II), |

|

— |

dried whole milk or whole milk powder (using method 6, Annex II), |

|

— |

dried partly skimmed milk or partly skimmed-milk powder (using method 6, Annex II), |

|

— |

dried skimmed milk or skimmed-milk powder (using method 6, Annex II). |

VII. Determination of phosphatase activity in:

|

— |

dried high fat milk or high fat milk powder (using method 7 or 8, Annex II), |

|

— |

dried whole milk or whole milk powder (using method 7 or 8, Annex II), |

|

— |

dried partly skimmed milk or partly skimmed-milk powder (using method 7 or 8, Annex II), |

|

— |

dried skimmed milk or skimmed-milk powder (using method 7 or 8, Annex II). |

ANNEX II

METHODS OF ANALYSIS RELATING TO THE COMPOSITION OF CERTAIN PARTLY OR WHOLLY DEHYDRATED PRESERVED MILK PRODUCTS INTENDED FOR HUMAN CONSUMPTION

GENERAL PROVISIONS

1. PREPARATION OF THE SAMPLE FOR CHEMICAL ANALYSIS

|

1.1. |

Unsweetened condensed high fat milk Unsweetened condensed milk Unsweetened condensed partly skimmed milk Unsweetened condensed skimmed milk Shake and invert the closed can. Open the can and slowly pour the milk into a second container which can be closed hermetically, mixing by repeated transfer. Ensure that all remaining fat and milk adhering to the wall and the ends of the can are mixed in with the sample. Close the container. If the contents are not homogeneous warm the container in a waterbath at 40 oC. Shake vigorously every 15 minutes. After two hours, remove the container from the water-bath and let it cool to room temperature. Remove the lid and thoroughly mix the contents of the container with a spoon or spatula (if the fat has separated the sample should not be tested). Store in a cool place. |

|

1.2. |

Sweetened condensed milk Sweetened condensed partly skimmed milk Sweetened condensed skimmed milk Cans: Warm the closed can in a waterbath at 30 to 40 oC for about 30 minutes. Open the can and thoroughly mix the contents with a spatula or a spoon by making upward, downward, and circular movements in order to obtain an intimate mixture of the top and bottom layers with all the contents. Ensure that the remaining milk adhering to the wall and end of the can is incorporated in the sample. As far as possible, pour the contents into a second container provided with an air-tight lid. Close the container and store in a cool place. Tubes: Cut the end and pour the contents into a container provided with an air-tight lid. Next, cut the tube lengthwise. Scrape out all material adhering to the interior and mix it carefully with the rest of the contents. Store the container in a cool place. |

|

1.3. |

Dried high fat milk or high fat milk powder Dried whole milk or whole milk powder Dried partly skimmed milk or partly skimmed-milk powder Dried skimmed milk or skimmed-milk powder Transfer the milk powder to a clean, dry container (with air-tight lid) of a capacity of twice the volume of the powder. Close the container immediately and thoroughly mix the milk powder by repeatedly shaking and inverting the container. During the preparation of the sample exposure of the milk powder to the atmosphere should be avoided as far as possible to minimize absorption of moisture. |

2. REAGENTS

2.1. Water

|

2.1.1. |

Wherever mention is made of water for dissolution, dilution or washing purposes, distilled water, or demineralized water of at least equivalent purity shall be used. |

|

2.1.2. |

Wherever reference is made to ‘dissolution’, ‘solution’ or ‘dilution’ without further indication, ‘dissolution in water’, ‘solution in water’ and ‘dilution in water’ is meant. |

2.2. Chemicals

All chemicals used shall be of recognized analytical reagent quality except where otherwise specified.

3. EQUIPMENT

3.1. Lists of equipment

The lists of equipment contain only those items with a specialized use and items with a particular specification.

3.2. Analytical balance

Analytical balance means a balance capable of weighing to at least 0,1 mg.

4. EXPRESSION OF RESULTS

4.1. Calculation of percentage

Except where otherwise specified, the results shall be calculated as a percentage by mass of the sample as received by the laboratory.

4.2. Number of significant figures

The result shall not contain more significant figures than are justified by the precision of the method of analysis used.

5. TEST REPORT

The test report shall identify the method of analysis used as well as the results obtained. In addition, it shall mention all details of procedure not specified in the method of analysis, or which are optional, as well as any circumstances that may have influenced the results obtained.

The test report shall give all the information necessary for the complete identification of the sample.

METHOD 1: DETERMINATION OF DRY MATTER CONTENT

(oven 99 oC)

1. SCOPE AND FIELD OF APPLICATION

This method determines the dry matter content of:

|

— |

unsweetened condensed high fat milk, |

|

— |

unsweetened condensed milk, |

|

— |

unsweetened condensed partly skimmed milk, |

|

— |

unsweetened condensed skimmed milk, |

|

— |

sweetened condensed milk, |

|

— |

sweetened condensed partly skimmed milk, |

|

— |

sweetened condensed skimmed milk. |

2. DEFINITION

The dry matter content of condensed milks: dry matter content as determined by the method specified.

3. PRINCIPLE

A known amount of the sample is diluted with water, mixed with sand and dried at a temperature of 99 oC ± 1 oC. The mass after drying is the mass of dry matter and is calculated as a percentage by mass of the sample.

4. REAGENTS

Quartz sand or sea sand, treated with hydrochloric acid (size of the grains: 0,18 to 0,5 mm, that is passing through a 500 micron sieve and retained by a 180 micron sieve). It should meet the following control test:

Heat about 25 g of sand for two hours in the drying oven (5.3) as described in 6.1. to 6.3. Add 5 ml of water, heat again in the oven for two hours, cool and reweigh. The difference between the two masses should not exceed 0,5 mg.

If necessary treat the sand with a 25 % hydrochloric acid solution for three days, mixing occasionally. Wash with water until the acid reaction disappears or the wash water is chloride free. Dry at 160 oC and re-test as above.

5. APPARATUS

|

5.1. |

Analytical balance. |

|

5.2. |

Metal dishes, preferably of nickel, aluminium or stainless steel. The dishes must have lids which fit very well but which are readily removed. Suitable dimensions are: diameter 60 to 80 mm and depth about 25 mm. |

|

5.3. |

Atmospheric-pressure drying oven, well ventilated, thermostatically controlled with temperature regulated at 99 oC ± 1 oC. The temperature should be uniform throughout the oven. |

|

5.4. |

Desiccator, containing freshly activated silica gel with a water content indicator or an equivalent desiccant. |

|

5.5. |

Glass rods, flattened at one end of such a length that they can fit inside the metal dishes (5.2). |

|

5.6. |

Waterbath, boiling. |

6. PROCEDURE

|

6.1. |

Place about 25 g sand (4) and a short glass rod (5.5) in the dish (5.2). |

|

6.2. |

Without covering the dish and contents with the lid, place the dish, contents and lid in the oven (5.3) and heat for two hours. |

|

6.3. |

Replace lid and transfer the dish to the desiccator (5.4). Allow to cool to room temperature and accurately weigh to the nearest 0,1 mg (M0). |

|

6.4. |

Tilt the sand to one side of the dish. Introduce into the clear space about 1,5 g of the sample of sweetened condensed milk and 3,0 g of unsweetened condensed milk. Replace the lid and accurately weigh to the nearest 0,1 mg (M1). |

|

6.5. |

Remove the lid, add 5 ml of water and, with the aid of the glass rod, mix the liquids and then the sand and the liquid portion. Leave the rod in the mixture. |

|

6.6. |

Place the dish on a boiling waterbath (5.6) until the water has evaporated; this usually takes 20 minutes. Stir the mixture from time to time with the rod to keep the mass well aerated so that the mass when dry does not form a cake. Lay the rod inside the dish. |

|

6.7. |

Place the dish and lid in the oven for one and a half hours. |

|

6.8. |

Replace the lid, transfer the dish to the desiccator (5.4), allow to cool to room temperature and accurately weigh to the nearest 0,1 mg. |

|

6.9. |

Replace the dish and lid in the oven, uncover the dish and heat it with its lid for a further hour. |

|

6.10. |

Repeat process 6.8. |

|

6.11. |

Repeat the described processes 6.9 and 6.10 until the difference in mass of two successive weighings is less than 0.5 mg or until the mass increases. If an increase in mass occurs use the lowest mass obtained in the calculation (7.1). Let the final weight recorded be M2 g. |

7. EXPRESSION OF RESULTS

7.1. Method of calculation

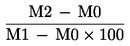

The content of dry matter, calculated as a percentage by mass of the sample, is given by:

where:

|

M0 |

= |

mass, in g of the dish, lid and sand after process 6.3; |

|

M1 |

= |

mass, in g of the dish, lid, sand and sample after process 6.4; |

|

M2 |

= |

mass, in g of the dish, lid, sand and dried sample after process 6.11. |

7.2. Repeatability

The difference between the results of two determinations carried out simultaneously or in rapid succession on the same sample, by the same analyst, under the same conditions, shall not exceed 0,2 g of dry matter per 100 g of the product.

8. CALCULATION OF TOTAL MILK SOLIDS AND MILK SOLIDS NOT FAT

|

8.1. |

The total milk solids content of the sweetened condensed milk is given by: Total dry matter (obtained by method 1, Annex II) — sucrose (obtained by method 5, Annex II). |

|

8.2. |

The milk solids not fat content of the sweetened condensed milks is given by: Total dry matter (obtained by method 1, Annex II) — (sucrose content obtained by method 5, Annex II) and fat content (obtained by method 3, Annex II). |

|

8.3. |

The milk solids not fat content of unsweetened condensed milks is given by: Total dry matter (obtained by method 1, Annex II) — fat content (obtained by method 3, Annex II). |

METHOD 2: DETERMINATION OF MOISTURE

(oven 102 oC) .

1. SCOPE AND FIELD OF APPLICATION

This method determines the loss of mass on drying of:

|

— |

dried high fat milk or high fat milk powder, |

|

— |

dried whole milk or whole milk powder, |

|

— |

dried partly skimmed milk or partly skimmed-milk powder, |

|

— |

dried skimmed milk or skimmed-milk powder. |

2. DEFINITION

Moisture content: the loss of mass on drying as determined by the method specified.

3. PRINCIPLE

The residual mass of a test portion is determined after drying at atmospheric pressure in an oven at 102 oC ± 1 oC to constant mass. The loss of mass is calculated as a percentage by mass of the sample.

4. APPARATUS

|

4.1. |

Analytical balance. |

|

4.2. |

Dishes, preferably of nickel, aluminium, stainless steel or glass. The dishes must have lids which fit very well but which can readily be removed. Suitable dimensions are: diameter 60 to 80 mm and depth about 25 mm. |

|

4.3. |

Atmospheric-pressure drying oven, well ventilated, thermostatically controlled with temperature regulation (at 102 oC ± 1 oC). The temperature should be uniform throughout the oven. |

|

4.4. |

Desiccator, containing freshly activated silica gel with a water content indicator or an equivalent desiccant. |

5. PROCEDURE

|

5.1. |

Uncover the dish (4.2) and place it and its lid in the oven (4.3) and heat for about one hour. |

|

5.2. |

Place the lid on the dish and transfer the covered dish to the desiccator (4.4). Allow it to cool to room temperature and accurately weigh to the nearest 0,1 mg (Mo). |

|

5.3. |

Introduce approximately 2 g of dried milk sample into the dish, cover the dish with the lid and accurately weigh to the nearest 0,1 mg the covered dish as quickly as possible (M1). |

|

5.4. |

Uncover the dish and put it with its lid in the oven for two hours. |

|

5.5. |

Replace the lid, transfer the covered dish to the desiccator, allow it to cool to room temperature and accurately weigh to the nearest 0,1 mg as quickly as possible. |

|

5.6. |

Uncover the dish and heat it and its lid for one hour in the oven. |

|

5.7. |

Repeat process 5.5. |

|

5.8. |

Repeat processes 5.6 and 5.5 until the decrease in mass between the successive weighings does not exceed 0,5 mg or until the mass increases. If an increase in mass occurs use the lowest mass obtained in the calculation (6.1). Let the final weight recorded be M2 g. |

6. EXPRESSION OF RESULTS

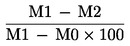

6.1. Method of calculation

Calculate the loss of mass on drying of the sample, expressed as a percentage by mass, by the formula:

where:

|

M0 |

= |

mass, in g of the dish and its lid after process 5.2; |

|

M1 |

= |

mass, in g of the dish, its lid and sample after process 5.3; |

|

M2 |

= |

mass, in g of the dish, its lid and final sample after process 5.5. |

6.2. Repeatability

The difference in results between two determinations carried out simultaneously or in rapid succession on the same sample, by the same analyst, under the same conditions, shall not exceed 0,1 g of moisture per 100 g of product.

METHOD 3: DETERMINATION OF FAT CONTENT IN CONDENSED MILKS (RÖSE-GOTTLIEB METHOD)

1. SCOPE AND FIELD OF APPLICATION

This method determines the fat content of:

|

— |

unsweetened condensed high fat milk, |

|

— |

unsweetened condensed milk, |

|

— |

unsweetened condensed partly skimmed milk, |

|

— |

unsweetened condensed skimmed milk, |

|

— |

sweetened condensed milk, |

|

— |

sweetened condensed partly skimmed milk, |

|

— |

sweetened condensed skimmed milk. |

2. DEFINITION

The fat content of condensed milks: fat content as determined by the method specified.

3. PRINCIPLE

The fat content is determined by extraction of the fat from an ammoniacal alcoholic solution of the sample with diethyl ether and light petroleum followed by evaporation of the solvents and weighing of the residue and calculation as a percentage by mass of the sample, according to the principle of Rose-Gottlieb.

4. REAGENTS

All reagents should conform to the requirements specified in the blank test (6.1). If necessary, reagents may be redistilled in the presence of about 1 g of butterfat for 100 ml of solvent.

|

4.1. |

Ammonia solution, approximately 25 % (m/m) NH3 (density at 20 oC approximately 0.91 g/ml), or a stronger solution of known concentration. |

|

4.2. |

Ethanol, 96 ± 2 % (v/v) or, if not available, ethanol denatured with methanol, ethyl methyl ketone or light petroleum. |

|

4.3. |

Diethyl ether, peroxide-free. Note 1: To test for peroxides, add to 10 ml of the ether in a small glass stoppered cylinder, previously rinsed with the ether, 1 ml freshly prepared 10 % potassium iodide solution. Shake and let stand for one minute. No yellow colour should be observed in either layer. Note 2: Diethyl ether may be maintained free from peroxides by adding wet zinc foil that has been completely immersed in dilute acidified copper sulphate solution for one minute and subsequently washed with water. Use per litre approximately 8 000 mm2 zinc foil; cut in strips long enough to reach at least halfway up the container. |

|

4.4. |

Light petroleum (petroleum ether), with any boiling range between 30 and 60 oC. |

|

4.5. |

Mixed solvent, prepared shortly before use by mixing equal volume of diethyl ether (4.3) and light petroleum (4.4) (where the use of mixed solvent is indicated, it may be replaced by either diethyl ether or light petroleum alone). |

5. APPARATUS

|

5.1. |

Analytical balance. |

|

5.2. |

Suitable extraction tubes or flasks, provided with ground glass stoppers or other closures un-. affected by the solvents used. |

|

5.3. |

Flasks, thin-walled and flat-bottomed, 150 to 250 ml capacity. |

|

5.4. |

Atmospheric pressure drying oven, well ventilated and thermostatically controlled (adjusted to operate at 102 oC ± 1 oC. |

|

5.5. |

Anti-bumping granules, fat-free, non porous, non friable in use, e.g. glass beads or pieces of silicon carbide (the use of this material is optional; see clause 6.2.1. |

|

5.6. |

Siphon, to fit extraction tubes. |

|

5.7. |

Centrifuge (optional). |

6. PROCEDURE

6.1. Blank test

At the same time as the determination of the fat content of the sample, carry out a blank determination on 10 ml of water using the same type of extraction apparatus, the same reagents in the same amounts and the same procedure as described hereafter, excluding clause 6.2.2. If the blank exceeds 0.5 mg, the reagents should be checked and the impure reagent or reagents should be purified or replaced.

6.2. Determination

|

6.2.1. |

Dry a flask (5.3) (together with, if required, some anti-bumping granules (5.5) to promote gentle boiling during the subsequent removal of the solvents) in the oven (5.4) for half to one hour. Allow the flask to cool to the temperature of the balance room and accurately weigh the cooled flask to the nearest 0,1 mg. |

|

6.2.2. |

Stir the prepared sample and immediately weigh, to the nearest 1 mg, 2 to 2,5 g of the sample if sweetened or 4 to 5 g of the sample if unsweetened directly in, or by difference into, the extraction apparatus (5.2). Add water to 10,5 ml and shake gently with slight warming (40 to 50 oC) until the product is completely dispersed. The sample must be dispersed completely otherwise the determination should be repeated. |

|

6.2.3. |

Add 1,5 ml ammonia (25 %) (4.1) or a corresponding volume of a stronger solution, and mix well. |

|

6.2.4. |

Add 10 ml ethanol (4.2) and mix the liquids gently but thoroughly in the unclosed apparatus. |

|

6.2.5. |

Add 25 ml diethyl ether (4.3). Cool under running water. Close the apparatus and shake vigorously and invert repeatedly for one minute. |

|

6.2.6. |

Remove the stopper carefully and add 25 ml light petroleum (4.4) using the first few millilitres to rinse the stopper and inside of the neck of the apparatus, allowing the rinsings to run into the apparatus. Close by replacing the stopper and shake and invert repeatedly for 30 seconds. Do not shake too vigorously if centrifuging is not to be used in 6.2.7. |

|

6.2.7. |

Allow the apparatus to stand until the upper liquid layer has become clear and has distinctly separated from the lower aqueous layer. Alternatively carry out the separation using a suitable centrifuge (5.7). Note: When a centrifuge which is not driven by a three-phase motor, is used, sparks may occur and care must therefore be taken to avoid an explosion or fire from any ether vapours, coming, for example, from a broken tube. |

|

6.2.8. |

Remove the stopper, rinse it and the inside of the neck of the apparatus with a few millilitres of mixed solvent (4.5) and allow the rinsings to run into the apparatus. Carefully transfer as much as possible of the supernatant layer by decantation or by means of a siphon (5.6) into the pre pared flask (6.2.1). Note: If the transfer is not made using a siphon, it may be necessary to add a little water in order to raise the interface between the two layers thus aiding decantation. |

|

6.2.9. |

Rinse the outside and the inside of the neck of the apparatus or the tip and the lower part of the siphon with a few millilitres of mixed solvent (4.5). Allow the rinsings from the outside of the apparatus to run into the flask and the rinsings from the inside of the neck and from the siphon to run into the extraction apparatus. |

|

6.2.10. |

Make a second extraction by repeating the procedure of 6.2.5 to 6.2.9 inclusive but using only 15 ml diethyl ether and 15 ml light petroleum. |

|

6.2.11. |

Make a third extraction by repeating the procedure of 6.2.10 but omit the final rinsing (6.2.9). Note: It is not mandatory to carry out this third extraction when analysing skimmed unsweetened condensed milk and skimmed sweetened condensed milk samples. |

|

6.2.12. |

Carefully evaporate or distil off as much solvent (including the ethanol) as possible. If the flask is of small capacity, it will be necessary to remove some of the solvent as above after each extraction. |

|

6.2.13. |

When there is no appreciable odour of solvent place the flask on its side in the oven and heat for one hour. |

|

6.2.14. |

Remove the flask from the oven, allow to cool to the temperature of the balance room and accurately weigh to the nearest 0,1 mg. |

|

6.2.15. |

Repeat 6.2.13 and 6.2.14 for heating periods of 30 to 60 minutes until the difference in mass of two successive weighings is less than 0.5 mg or until the mass increases. If an increase in mass occurs use the lowest mass obtained in the calculation (7.1). Let the final weight recorded be M1 g. |

|

6.2.16. |

Add 15 to 25 ml light petroleum in order to confirm that the extracted matter is wholly soluble. Warm gently and swirl the solvent until all the fat is dissolved. |

|

6.2.16.1. |

If the extracted matter is wholly soluble in the light petroleum, the mass of fat is the difference between the weights determined at stages 6.2.1 and 6.2.15. |

|

6.2.16.2. |

If any insoluble matter is present, or in case of doubt, completely extract the fat from the flasks by repeated washing with warm light petroleum, allowing the undissolved material to settle before each decantation. Rinse the outside of the neck of the flask three times. Heat the flask, placed on its side, for one hour in the oven, allow to cool to the temperature of the balance room as before (6.2.1) and weigh to the nearest 0,1 mg. The mass of fat is the difference between the mass obtained at 6.2.15 and this final mass. |

7. EXPRESSION OF RESULTS

7.1. Calculation

The mass, in g of fat extracted is:

(M1 — M2) — (B1 — B2)

and the fat content of the sample, expressed as a percentage is:

where:

|

M1 |

= |

mass, in g of flask M with fat after stage 6.2.15; |

|

M2 |

= |

mass, in g of flask M after stage 6.2.1 or, in the case of undissolved material or doubt, stage 6.2.16.2; |

|

B1 |

= |

mass, in g of flask B of the blank after stage 6.2.15; |

|

B2 |

= |

mass, in g of flask B after stage 6.2.1 or, in the case of undissolved material or doubt, stage 6.2.16.2; |

|

S |

= |

mass, in g of sample used. |

7.2. Repeatability

The difference between results of two determinations carried out obtained simultaneously or in rapid succession on the same sample, by the same analyst, under the same conditions, shall not exceed 0,05 g fat per 100 g of the product.

METHOD 4: DETERMINATION OF FAT CONTENT IN DRIED MILKS (RÖSE-GOTTLIEB METHOD)

1. SCOPE AND FIELD AND APPLICATION

This method determines the fat content of:

|

— |

dried high fat milk or high fat milk powder, |

|

— |

dried whole milk or whole milk powder, |

|

— |

dried partly skimmed milk or partly skimmed-milk powder, |

|

— |

dried skimmed milk or skimmed-milk powder. |

2. DEFINITION

The fat content of dried milks: fat content as determined by the method specified.

3. PRINCIPLE

The fat content is determined by extraction of the fat from an ammoniacal alcoholic solution of sample with diethyl ether and light petroleum, followed by evaporation of the solvents and weighing of the residue and calculation as a percentage by mass of the sample, according to the principle of Rose-Gottlieb.

4. REAGENTS

All reagents should conform to the requirements specified in the blank test (6.1). If necessary, reagents may be redistilled in the presence of about 1 g of butterfat per 100 ml of solvent.

|

4.1. |

Ammonia solution, approximately 25 % (m/m) NH3 (density at 20 oC approximately 0.91 g/ml), or stronger solution of known concentration. |

|

4.2. |

Ethanol, 96 ± 2 % (v/v) or, if not available, ethanol denatured with methanol, ethyl methyl ketone or light petroleum. |

|

4.3. |

Diethyl ether, peroxide-free Note 1: To test for peroxide, add to 10 ml of the ether in a small glass stoppered cylinder, previously rinsed with the ether, 1 ml freshly prepared 10 % potassium iodide solution. Shake and let stand for one minute. No yellow colour should be observed in either layer. Note 2: Diethyl ether may be maintained free from peroxides by adding wet zinc foil that has been completely immersed in dilute acidified copper sulphate solution for one minute and subsequently washed with water. Use per litre approximately 8 000 mm2 zinc foil cut in strips long enough to reach at least halfway up the container. |

|

4.4. |

Light petroleum (petroleum ether), with any boiling range between 30 and 60 oC. |

|

4.5. |

Mixed solvent, prepared shortly before use by mixing equal volumes of diethyl ether (4.3) and light petroleum (4.4) (when the use of mixed solvent is indicated, it may be replaced by either diethyl ether or light petroleum alone). |

5. APPARATUS

|

5.1. |

Analytical balance. |

|

5.2. |

Suitable extraction tubes or flasks, provided with ground glass stoppers or other closures unaffected by the solvents used. |

|

5.3. |

Flasks, thin-walled, flat-bottomed, of 150 to 250 ml capacity. |

|

5.4. |

Atmospheric pressure drying oven, well ventilated and thermostatically controlled (adjusted to operate at 102 oC ± 1 oC). |

|

5.5. |

Anti-bumping granules, fat-free, non porous, non friable in use, e.g. glass beads or pieces of silicon carbide (the use of this material is optional: see clause 6.2.1). |

|

5.6. |

Waterbath, at 60 to 70 oC. |

|

5.7. |

Siphon to fit extraction tubes. |

|

5.8. |

Centrifuge (optional). |

6. PROCEDURE

6.1. Blank test

At the same time as the determination of the fat content of the sample, carry out a blank determination on 10 ml of water using the same type of extraction apparatus, the same reagents in the same amounts and the same procedure as described hereafter, excluding clause 6.2.2. If blank exceeds 0.5 mg, the reagents should be checked and the impure reagent or reagents should be purified or replaced.

6.2. Determination

|

6.2.1. |

Dry the flask (5.3) together with, if required, some anti-bumping granules (5.5) to promote gentle boiling during the subsequent removal of the solvents) in the oven (5.4) for half to one hour. Allow the flask to cool to the temperature of the balance room and accurately, weigh the cooled flask to the nearest 0,1 mg. |

|

6.2.2 |

Accurately weigh, to the nearest 1 mg, directly in, or by difference into, the extraction apparatus (5.2) about 1 g of whole milk powder or about 1,5 g of partly skimmed or skimmed-milk powder. Add 10 ml water and shake gently until the milk powder is completely dispersed (heat may be necessary for some samples). |

|

6.2.3. |

Add 1.5 ml ammonia (25 %) (4.1) or a corresponding volume of a stronger solution and heat in a waterbath (5.6) for 15 minutes at 60 to 70 oC, shaking occasionally. Cool, for example, in running water. |

|

6.2.4. |

Add 10 ml ethanol (4.2) and mix the liquids gently but thoroughly in the unclosed apparatus. |

|

6.2.5. |

Add 25 ml diethyl ether (4.3). Cool in running water. Close the apparatus and shake vigorously and invert repeatedly for one minute. |

|

6.2.6. |

Remove the stopper carefully and add 25 ml light petroleum (4.4) using the first few millilitres to rinse the stopper and inside of the neck of the apparatus, allowing the rinsings to run into the apparatus. Close by replacing the stopper and shake and invert repeatedly for 30 seconds. Do not shake too vigorously if centrifuging is not to be used in 6.2.7. |

|

6.2.7. |

Allow the apparatus to stand until the upper liquid layer has become clear and has distinctly separated from the lower aqueous layer. Alternatively carry out the separation using a suitable centrifuge (5.8). Note: When a centrifuge which is not driven by a three-phase motor is used, sparks may occur and care must therefore be taken to avoid an explosion or fire from any ether vapours coming, for example, from a broken tube. |

|

6.2.8. |

Remove the stopper, rinse it and the inside of the neck of the apparatus with a few millilitres of mixed solvent (4.5) and allow the rinsings to run into the apparatus. Carefully transfer as much as possible of the supernatant layer by decantation or by means of a siphon (5.7) into the prepared flask (6.2.1). Note: If the transfer is not made using a siphon, it may be necessary to add a little water in order to raise the interface between the two layers thus aiding decantation. |

|

6.2.9. |

Rinse the outside and the inside of the neck of the apparatus or the tip and the lower part of the siphon with a few millilitres of mixed solvent. Allow the rinsings from the outside of the appara tus to run into the flask and the rinsings from the inside of the neck and from the siphon to run into the extraction apparatus. |

|

6.2.10. |

Make a second extraction by repeating the procedure of 6.2.5 to 6.2.9 inclusive but using only 15 ml diethyl ether and 15 ml light petroleum. |

|

6.2.11. |

Make a third extraction by repeating the procedure of 6.2.10 but omit the final rinsing (6.2.9). Note: It is not mandatory to carry out this third extraction when analysing dried skimmed milk samples. |

|

6.2.12. |

Carefully evaporate or distil off as much solvent (including the ethanol) as possible. If the flask is of small capacity it will be necessary to remove some of the solvent as above after each extraction. |

|

6.2.13. |

When there is no appreciable odour of solvent, place the flask on its side in the oven and heat for one hour. |

|

6.2.14. |

Remove the flask from the oven, allow to cool to the temperature of the balance room as previously (6.2.1) and accurately weigh to the nearest 0,1 mg. |

|

6.2.15. |

Repeat 6.2.13 and 6.2.14 for heating periods of 30 to 60 minutes until the difference in mass of two successive weights is less than 0,5 mg or until the mass increases. If an increase in mass occurs use the lowest mass obtained in the calculation (7.1). Let the final weight recorded be M1 g. |

|

6.2.16. |

Add 15 to 25 ml light petroleum in order to confirm that the extracted matter is wholly soluble. Warm gently and swirl the solvent until all the fat is dissolved. |

|

6.2.16.1. |

If the extracted matter is wholly soluble in the light petroleum, the mass of fat is the difference between the weights determined at stages 6.2.1 and 6.2.15. |

|

6.2.16.2. |

If any insoluble matter is present, or in case of doubt completely extract the fat from the flask by repeated washing with warm light petroleum, allowing the undissolved material to settle before each decantation. Rinse the outside of the neck of the flask three times. Heat the flask, placed on its side, for one hour in the oven, allow to cool to the temperature of the balance room, as before (6.2.1) and weigh to the nearest 0,1 mg. The mass of fat is the difference between the mass under 6.2.15 and this final mass. |

7. EXPRESSION OF RESULTS

7.1. Calculation

The mass, in g of fat extracted is:

(M1 — M2) — (B1 — B2)

and the fat content of the sample, expressed as a percentage, is:

where:

|

M1 |

= |

mass, in g of flask M with fat after stage 6.2.15; |

|

M2 |

= |

mass, in g of flask M after stage 6.2.1 or, in the case of undissolved material or doubt, stage 6.2.16.2; |

|

B1 |

= |

mass, in g of flask B of the blank after stage 6.2.15; |

|

B2 |

= |

mass, in g of flask B after stage 6.2.1 or, in the case of undissolved material or doubt, stage 6.2.16.2; |

|

S |

= |

mass, in g of sample used. |

7.2. Repeatability

The difference between results of two determinations carried out simultaneously or in rapid succession on the same sample, the same analyst, under the same conditions, shall not exceed 0,2 g fat per 100 g of product with the exception of skimmed-milk powder for which the difference must not exceed 0,1 g fat per 100 g of product.

METHOD 5: DETERMINATION OF SUCROSE CONTENT (POLARIMETERIC METHOD)

1. SCOPE AND FIELD OF APPLICATION

This method determines the sucrose content of:

|

— |

sweetened condensed milk, |

|

— |

sweetened condensed partly skimmed milk, |

|

— |

sweetened condensed skimmed milk. |

Samples must not contain invert sugar.

2. DEFINITION

The sucrose content of sweetened condensed milks: the sucrose content as determined by the method specified.

3. PRINCIPLE

The method is based on the principle of the Clerget inversion, a mild treatment of the sample with acid which produces complete hydrolysis of sucrose but almost none of lactose or other sugars. The sucrose content is obtained from the change in rotating power of the solution.

A clear filtrate of the sample, without mutarotation by lactose, is prepared by treatment of the solution with ammonia followed by neutralization and clearing by the successive addition of zinc acetate and potassium hexacyanoferrate II solutions.

In a portion of the filtrate the sucrose is hydrolyzed in a specified manner.

From the rotation of the filtrate before and after inversion, the sucrose content is calculated using the appropriate formulae.

4. REAGENTS

|

4.1. |

Zinc acetate solution, 1 M: dissolve 21,9 g crystallized zinc acetate dihydrate Zn(C2H.O2)2.2H2O and 3 ml glacial acetic acid in water and make up to 100 ml with water. |

|

4.2. |

Potassium hexacyanoferrate (II) solution, 0,25 M: dissolve 10,6 g crystallized potassium hexacyanoferrate (II) trihydrate K4[Fe(CN)6]. 3H2O in water and make up to 100 ml with water. |

|

4.3. |

Hydrochloric acid solution, 6,35 ± 0,20 M (20 to 22 %) or 5,0 ± 0,2 M (16 to 18 %). |

|

4.4. |

Ammonia solution, 2,0 ± 0,2 M (3,5 %). |

|

4.5. |

Acetic acid solution, 2,0 ± 0,2 M (12 %). |

|

4.6. |

Bromothymol blue indicator, 1 % (m/v) solution in ethanol. |

5. APPARATUS

|

5.1. |

Balance, sensitivity 10 mg. |

|

5.2. |

Polarimeter tube, 2dm, of exactly calibrated length. |

|

5.3. |

Polarimeter or saccarimeter:

|

|

5.4. |

Water bath, regulated at 60 oC ± 1 oC. |

6. PROCEDURE

6.1. Control determination

In order to standardize the procedure, reagents and apparatus, carry out a control determination in duplicate as described below using a mixture of 100 g of milk and 18 g pure sucrose or a mixture of 110 g of skimmed milk and 18 g pure sucrose, each corresponding to 40 g of condensed milk containing 45 % sucrose. Calculate the sugar content using the formulae under 7, substituting for M, F and P respectively in formula 1 the quantity of milk taken and the fat and protein content of this milk, and in formula 2 for M, the value of 40,00. The mean of the values found shall not differ by more than 0,2 % from 45,0 %.

6.2. Determination

|

6.2.1. |

Weigh to within 10 mg, approximately 40 g of the well mixed sample into a 100 ml glass beaker. Add 50 ml of hot water (80 to 90 oC) and mix well. |

|

6.2.2. |

Transfer the mixture quantitatively to a 200 ml measuring flask, rinsing the beaker with successive quantities of water at 60 oC, until the total volume is between 120 and 150 ml. Mix and cool to room temperature. |

|

6.2.3. |

Add 5 ml of the dilute ammonia solution (4.4). Mix again and then allow to stand for 15 minutes. |

|

6.2.4. |

Neutralize the ammonia by adding an equivalent quantity of the diluted solution of acetic acid (4.5). Determine the exact number of ml beforehand by titration of the ammonia solution using bromothymol blue as indicator (4.6). Mix. |

|

6.2.5. |

Add, with gently mixing by rotating the tilted flask, 12.5 ml of zinc acetate solution (4.1). |

|

6.2.6. |

Add 12.5 ml of potassium hexacyanoferrate (II) solution (4.2) in the same way as for the acetate solution. |

|

6.2.7. |

Bring the contents of the flask to 20 oC and make up to the 200 ml mark with water at 20 oC. Note: During any of the stages so far described all additions of water or reagents should have been made in such manner as to avoid the formation of air bubbles, and with the same object in view, all mixing should have been carried out by rotation of the flask rather than by shaking. If air bubbles are found to be present before making up to 200 ml volume, their removal can be assisted by temporarily connecting the flask to a vacuum pump, and rotating the flask. |

|

6.2.8. |

Close the flask with a dry stopper and mix thoroughly by vigorous shaking. |

|

6.2.9. |

Allow to stand for a few minutes and then filter through a dry filter paper, rejecting the first 25 ml of filtrate. |

|

6.2.10. |

Direct polarization: determine the optical rotation of the filtrate at 20 oC ± 1 oC. |

|

6.2.11. |

Inversion: pipette 40 ml of the filtrate obtained above into a 50 ml volumetric flask. Add 6,0 ml of 6,35 M hydrochloric acid or 7,5 ml of 5,0 M hydrochloric acid (4.3). Place the flask in a waterbath of 60 oC for 15 minutes, ensuring that the entire bulb of the flask has been immersed. Mix by a rotatory movement during the first five minutes, in which time the contents of the flask should have attained the temperature of the bath. Cool to 20 oC, and make up to volume with water at 20 oC. Mix and allow to stand for one hour at this temperature. |

|

6.2.12. |

Invert polarization

Determine the rotation of the inverted solution at 20 oC ± 0.2 oC. (However, if temperature T of the liquid in the polarization tube differs by more than 0.2 oC during the measurement, the temperature correction referred to under 7.2 must be applied.) |

7. EXPRESSION OF RESULTS

7.1. Method of calculation

Calculate the sucrose content by means of the following formulae:

|

(1) |

v =

|

|

(2) |

S =

|

where:

|

S |

= |

sucrose content; |

|

M |

= |

mass of the weighed sample in grams; |

|

F |

= |

percentage of fat in the sample; |

|

P |

= |

percentage Of protein (N x 6.38) in the sample; |

|

V |

= |

volume in ml to which the sample is diluted before filtration; |

|

v |

= |

correction in ml for the volume of the precipitate formed during clarification; |

|

D |

= |

direct polarimeter reading (polarization before inversion); |

|

I |

= |

polarimeter reading after inversion; |

|

L |

= |

length in dm of the polarimeter tube; |

|

Q |

= |

inversion factor, the values of which are given below. |

Remarks:

|

(a) |

When exactly 40,00 g of condensed milk are weighed and a polarimeter with sodium light, angular degrees and a 2dm polarimeter tube at 20,0 oC ± 0,1 oC is used the sucrose content of normal condensed milk (C = 9) can be calculated from the following formula: S = (D — 1,25 I) x (2,833 — 0,00612 F — 0,00878 P) |

|

(b) |

If the invert polarization is measured at a temperature other than 20 oC, the figures should be multiplied by: (1 + 0,0037 (T — 20). |

7.2. Values of the inversion factor Q

The following formulae give accurate values for Q, for various sources of light with corrections for concentration and temperature:

Sodium light and polarimeter with angular degrees:

|

Q |

= |

0,8825 + 0,0006 (C — 9) — 0,0033 (T — 20). |

Mercury green light and polarimeter with angular degrees:

|

Q |

= |

1,0392 + 0,0007 (C — 9) — 0,0039 (T — 20). |

White light with dichromate filter and saccharimeter with international sugar scale degrees:

|

Q |

= |

2,549 + 0,0017 (C — 9) — 0,0095 (T — 20). |

In the above formulae:

|

C |

= |

Percentage of total sugars in the inverted solution as polarized, |

|

T |

= |

Temperature of the inverted solution in the polarimetric reading. |

Note 1:

The percentage of total sugars C in the inverted solution may be calculated from the direct reading and the change on inversion in the usual manner, using the usual values for the specific rotations of sucrose, lactose and invert sugar.

The correction 0,0006 (C — 9) etc., is only accurate when C is approximately 9; for normal condensed milk, this correction can be neglected, C being close to 9.

Note 2:

Variation in temperature from 20 oC of 1 oC makes little difference in the direct reading, but variation of over 0,2 oC in the invert reading necessitates a correction. The correction - 0,0033 (T — 20) etc., is only accurate between 18 oC and 22 oC.

7.3. Repeatability

The difference between results of two determinations carried out simultaneously or in rapid succession on the same sample, by the same analyst, under the same conditions, shall not exceed 0,3 g of sucrose per 100 g of condensed milk.

METHOD 6: DETERMINATION OF LACTIC ACID AND LACTATES CONTENT

1. SCOPE AND FIELD OF APPLICATION

This method determines the lactic acid and lactates, expressed as lactic acid, contents of:

|

— |

dried high fat milk or high fat milk powder, |

|

— |

dried whole milk or whole milk powder, |

|

— |

dried partly skimmed milk or partly skimmed-milk powder, |

|

— |

dried skimmed milk or skimmed-milk powder. |

2. DEFINITION

Lactic acid and lactates content of dried milks: the lactic acid and lactates, expressed as lactic acid, contents as determined by the method specified.

3. PRINCIPLE

Fat, protein and lactose are simultaneously removed from a solution of the sample by addition of copper sulphate and calcium hydroxide followed by filtration.

The lactic acid and lactates in the filtrate are converted into acetaldehyde by concentrated sulphuric acid in the presence of copper II sulphate.

The lactic acid content is determined colorimetrically using p-hydroxydiphenyl.

The lactic acid and lactates content is expressed as mg of lactic acid per 100 g of solids-non-fat.

4. REAGENTS

|

4.1. |

Copper (II) sulphate solution: dissolve 250 g of copper (II) sulphate (CuSO4.5H2O) in water and dilute to 1 000 ml with water. |

|

4.2. |

Calcium hydroxide suspension. |

|

4.2.1. |

Grind 300 g of calcium hydroxide (Ca(OH)2) in a mortar with water, using totally 900 ml. The suspension should be freshly prepared before use. |

|

4.2.2. |

Calcium hydroxide suspension: grind 300 g of calcium hydroxide (Ca(OH)2) in a mortar with water, using totally 1 400 ml. The suspension should be freshly prepared before use. |

|

4.3. |

Sulphuric acid — copper (II) sulphate solution: Add to 300 ml of sulphuric acid, 95,9 to 97,0 % (m/m) of H2SO4, 0,5 ml of the copper (II) sulphate solution (4.1). |

|

4.4. |

p-hydroxydiphenyl (C6H5C6H4OH) solution: dissolve, by shaking and by heating slightly 0,75 g of p-hydroxydiphenyl in 5 ml of an aqueous solution of sodium hydroxide, containing 5 g of NaOH per 100 ml. Dilute to 50 ml with water in a volumetric flask. Keep the solution in a brown coloured glass bottle in a dark and cool place. Do not use if the colour changes or tubidity occurs. The maximum shelf life is 72 hours. |

|

4.5. |

Lactic acid standard solution: dissolve, shortly before use, 0,1067 g of lithium lactate (CH3 CHOHCOOLi) in water and dilute to 1 000 ml in a volumetric flask. 1 ml of this solution corresponds to 0,1 mg of lactic acid. |

|

4.6. |

Standard reconstituted milk: analyse in advance several samples of high quality dried milk. For the preparation of the calibration curve select the sample having the lowest lactic acid content, containing not more than 30 mg of lactic acid per 100 g of solids-non-fat. Follow the operating procedure described under 6.2.1 and 6.2.2 below. |

5. APPARATUS

|

5.1. |

Analytical balance. |

|

5.2. |

Spectrophotometer suitable for readings at a wavelength of 570 nm. |

|

5.3. |

Waterbath at 30 oC ± 2 oC. |

|

5.4. |

Mortar and pestle. |

|

5.5. |

Filter paper (Schleicher and Schull 595, Whatman 1 or equivalent). |

|

5.6. |

Test tubes, pyrex or equivalent (dimensions 25 x 150 mm). Note: All glassware must be perfectly clean and designated for use solely in this determination. Rinse glassware containing precipitate residues with concentrated hydrochloric acid before washing. |

6. PROCEDURE

6.1. Blank test

Carry out a blank test by placing 30 ml of water into a 50 ml graduated tube and treating this tube as described under 6.2.4 to 6.2.11 inclusive. If the blank measured against water exceeds an equivalent of 20 mg of lactic acid per 100 g solids-non-fat, the reagents should be checked and the impure reagents or reagent should be replaced. Carry out the blank test at the same time as the analysis of the sample.

6.2. Determination

Note: Avoid contamination with impurities especially with saliva and sweat.

|

6.2.1. |

Determine the solids-non-fat content (a) g of the sample by subtracting the fat content (obtained by method 4) and the moisture content (obtained by method 2) from 100. |

|

6.2.2. |

Weigh

|

|

6.2.3. |

Pipette 5 ml of the solution obtained into a 50 ml graduated tube and dilute with water to about 30 ml. |

|

6.2.4. |

Add slowly while shaking, 5 ml of the copper (II) sulphate solution (4.1) and allow to stand for 10 minutes. |

|

6.2.5. |

Add slowly while shaking, 5 ml of the calcium hydroxide suspension (4.2.1) or 10 ml of the calcium hydroxide suspension (4.2.2). |

|

6.2.6. |

Dilute to 50 ml with water, shake vigorously, allow to stand for 10 minutes then filter. Discard the first runnings. |

|

6.2.7. |

Pipette 1 ml of the filtrate into a test tube (5.6). |

|

6.2.8. |

Add to the tube by means of a burette or graduated pipette 6.0 ml of the sulphuric acid-copper (II) sulphate solution (4.3). Mix. |

|

6.2.9. |

Heat in the boiling water bath for five minutes. Cool to ambient temperature under running water. |

|

6.2.10. |

Add two drops of p-hydroxydiphenyl reagent (4.4) and shake vigorously to spread the reagent evenly throughout the liquid. Place the tube in the waterbath at 30 oC ± 2 oC; leave for 15 minutes shaking from time to time. |

|

6.2.11. |

Place the tube in the boiling waterbath for 90 seconds. Cool to ambient temperature under running water. |

|

6.2.12. |

Measure the optical density against the blank test (6.1) within three hours at the wavelength specified under 5.2. |

|

6.2.13. |

If the optical density exceeds that of the highest point of the standard curve, repeat the test using an adequate dilution of the filtrate obtained under 6.2.6. |

6.3. Preparation of the standard

|

6.3.1. |

Pipette 5 ml of the reconstituted milk (4.6) into five 50 ml graduated tubes. Pipette into these tubes 0, 1, 2, 3 and 4 ml respectively of the standard solution (4.5), so as to obtain a range of standards corresponding to 0, 20, 40, 60 and 80 mg of added lactic acid per 100 g of solids-non-fat, of the dried milk. |

|

6.3.2. |

Dilute with water to about 30 ml and treat as described under 6.2.4 to 6.2.11. |

|

6.3.3. |

Measure the optical densities of the standards (6.3.1) against the blank test (6.1) at the wavelength specified under 5.2. Plot in a diagram the optical densities against the quantities of lactic acid given under 6.3.1, i.e. 0 mg, 20 mg, 40 mg, 60 mg and 80 mg per 100 g of solids-non-fat. Draw the best fitting straight line through the points and prepare the standard curve by moving this line parallel to itself in such a way that it passes through the origin. |

7. EXPRESSION OF RESULTS

7.1. Method of calculation

Convert the optical density measured under 6.2.12 or 6.2.13 into mg of lactic acid per 100 g of solids-non-fat in the sample by reference to the standard curve. Multiply this result by the dilution factor where the filtrate has been diluted according to 6.2.13.

7.2. Repeatability

The difference between the results of two determinations carried out simultaneously or in rapid succession on the same sample, by the same analyst, under the same conditions, shall not exceed 8 mg of lactic acid per 100 g of solids-non-fat for contents up to 80 mg. For higher values, this difference may not exceed 10 % of the lowest value.

METHOD 7: DETERMINATION OF PHOSPHATASE ACTIVITY (MODIFIED SANDERS AND SAGER PROCEDURE)

1. SCOPE AND FIELD OF APPLICATION

This method describes the determination of phosphatase activity in:

|

— |

dried high fat milk or high fat milk powder, |

|

— |

dried whole milk or whole milk powder, |

|

— |

dried partly skimmed milk or partly skimmed-milk powder, |

|

— |

dried skimmed milk or skimmed-milk powder. |

2. DEFINITION

The phosphatase activity of dried milks is a measure of the quantity of active alkaline phosphatase present. It is expressed as the quantity of phenol in μg liberated by 1 ml of reconstituted milk, as determined by the procedure described below.

3. PRINCIPLE

The phosphatase activity of dried milks is determined by the ability of the phosphatase to liberate the phenol from disodiumphenylphosphate. The quantity of phenol liberated under prescribed conditions is determined by a spectrophotometric measurement of the colour developed with Gibb's reagent.

4. REAGENTS

4.1. Solution A

Barium borate hydroxide buffer: pH 10,6 ± 0,1 at 20 o C.

Dissolve: 25,0 g of barium hydroxide (Ba(OH)2.8H2O) in water and dilute to 500 ml.

Dissolve: 11,0 g of boric acid (H3BO3) in water and dilute to 500 ml.

Warm the two solutions to 50 o C and mix.

Shake and cool the mixture to room temperature.

Adjust the pH to 10,6 ± 0,1 with the barium hydroxide solution and filter.

Store the solution in a tightly stoppered container.

Before use, dilute the buffer with an equal quantity of water.

4.2. Solution B:

Colour development buffer.

Dissolve: 6,0 g of sodium metaborate (NaBO2) (or 12,6 g of NaBO2.4H2O) and 20,0 g of sodium chloride (NaCl) in water and dilute to 1 000 ml with water.

4.3. Solution C

Buffer substrate solution.

|

4.3.1. |

Dissolve 0,5 g of disodiumphenylphosphate (Na2C6H5PO4.2H2O) in 4,5 ml of Solution B (4.2). Add 2 drops of Solution E (4.5) and allow to stand 30 minutes. Extract the colour with 2,5 ml butanol (4.10). If necessary, repeat the colour extraction. After separation, discard the butanol. This solution can be kept for several days in a refrigerator. Develop and extract the colour once more before use. |

|

4.3.2. |

Pipette 1 ml of this solution into a 100 ml volumetric flask and make up to volume with Solution A. Prepare the buffer solution immediately before use. |

4.4. Solution D

Precipitant.

Dissolve 3,0 g of zinc sulphate (ZnSO4.7H2O) and 0,6 g of copper (II) sulphate (CUSO4.5H2O) in water and make up to 100 ml with water.

4.5. Solution E

Gibb's reagent.

Dissolve 0,040 g of 2,6-dibromoquinone 1,4 — chloroimide (O.C6H2Br2.NCl) in 10 ml of 96 % ethanol. Store the solution in a dark glass bottle kept in a refrigerator. Discard this reagent when it has become discoloured.

4.6. Colour dilution buffer

Dilute 10 ml of Solution B (4.2), colour development buffer, to 100 ml with water.

4.7. Copper sulphate solution

Dissolve 0,05 g of copper (II) sulphate (CUSO4.5H2O) in water and make to 100 ml with water.

4.8. Phenol standard solution

Dissolve 0,200 ± 0,001 g of pure phenol in water and make up to 100 ml in a volumetric flask with water. This solution can be stored for several months in a refrigerator. Dilute 10 ml of this solution to 100 ml with water. This diluted solution contains 200 μg of phenol in 1 ml and can be used for preparing more dilute solutions.

|

4.9. |

Boiled distilled water. |

|

4.10. |

n-Butanol. |

5. APPARATUS

|

5.1. |

Analytical balance. |

|

5.2. |

Waterbath, thermostatically controlled at 37 oC ± 1 oC. |

|

5.3. |

Spectrophotometer suitable for readings at a wavelength of 610 nm. |

|

5.4. |

Filter paper (Schleicher and Schull 597, Whatman 42 or equivalent filter paper). |

|

5.5. |

Waterbath, boiling. |

|

5.6. |

Aluminium foil. |

6. PROCEDURE

Precautions:

|

1. |

Avoid direct exposure to sunlight. |

|

2. |

All the glassware, stoppers and removal material should be perfectly clean. It is recommended that they be rinsed and boiled with water or that they be treated with steam. |

|

3. |

Avoid using plastic materials (stoppers for example) as they may contain phenols. |

|

4. |

Saliva contains phosphatase; contamination by traces of saliva must therefore be carefully avoided. |

6.1. Preparation of the sample

|

6.1.1. |

Weigh, to within 0.1 g, 10 g of the sample and dissolve in 90 ml of water. The temperature for dissolving the powder shall, under no circumstances, exceed 35 oC. |

6.2. Determination

|

6.2.1. |

Introduce in each of two test tubes 1 ml of reconstituted milk prepared as described in 6.1.1. |

|

6.2.2. |

Heat one of the tubes in boiling water for two minutes. Cover the tube and the waterbath (5.5) or, for example, a beaker with aluminium foil (5.6) to ensure that the entire tube will be heated. Cool in cold water to room temperature. Use this tube for the blank test. For all subsequent operations treat the two tubes identically. |

|

6.2.3. |

Add 10 ml of Solution C (4.3.2). Mix and place the tube in the waterbath at 37 oC (5.2). |

|

6.2.4. |

Incubate for 60 minutes in the waterbath shaking periodically. |

|

6.2.5. |

Transfer the tubes immediately to a boiling waterbath (5.5) and heat for two minutes; cool to room temperature in cold water. |

|

6.2.6. |

Add 1 ml of Solution D (4.4), mix and filter through a dry filter paper; discard the first filtrates until a clear liquid is obtained. |

|

6.2.7. |

Put 5 ml of each filtrate into test tubes, add 5 ml of Solution B (4.2) and 0.1 ml of Solution E (4.5). Mix. |

|

6.2.8. |

Allow the colour to develop at room temperature for 30 minutes away from direct sunlight. |

|

6.2.9. |

Measure the optical density of the sample solution, against the blank, at the wavelength indicated in 5.3. |

|

6.2.10. |

Repeat the determination if the optical density of the solution is above that of the standard sample with 20 μg of phenol prepared according to 7. If this limit is exceeded, dilute a suitable volume of reconstituted milk according to 6.1.1 with a suitable volume of this milk carefully boiled as indicated in 6.2.2 to inactivate the phosphatase present. |

7. PREPARATION OF THE STANDARD CURVE

|

7.1. |

Pipette into four 100 ml volumetric flasks, 1, 3, 5 and 10 ml of the standard solution diluted according to 4.8 and make up to volume with water; these dilutions contain respectively 2, 6, 10 and 20 μg of phenol per ml. |

|

7.2. |

Pipette 1 ml of water or 1 ml of each standard solution (7.1) into the test tubes in order to obtain a series of samples containing 0 (blank value obtained using the 1 ml of water) — 2 — 6 — 10 and 20 μg of phenol. |

|

7.3. |

Pipette successively into each test tube 1 ml of the solution of copper (II) sulphate (4.7), 5 ml of the colour dilution buffer solution (4.6), 3 ml of water and 0.1 ml of Solution E (4.5). Mix. |

|

7.4. |

Leave the test tubes for 30 minutes at room temperature away from direct sunlight. |

|

7.5. |

Measure the absorbance of the solutions in each of the tubes, compared to the blank value, at the wavelength indicated in 5.3. |

|

7.6. |

Prepare the standard curve by plotting the absorbance values against the quantities of phenol in μg as indicated in 7.2. |

8. EXPRESSION OF THE RESULTS

8.1. Calculation

|

8.1.1. |

Convert the figures as determined under 6.2.9 to μg of phenol, by reference to the standard curve. |

|

8.1.2. |

Calculate the phosphatase activity expressed as μg of phenol per ml of reconstituted milk according to the following formula: Phosphatase activity = 2,4 x P where P = the quantity of phenol in μg according to 8.1.1. |

|

8.1.3. |

If it was necessary to dilute as indicated under 6.2.10 multiply the result obtained in 8.1.2 by the dilution factor. |

8.2. Repeatability

The difference between the results of two determinations carried out simultaneously or in rapid succession on the same sample, by the same analyst, under the same conditions, shall not exceed 2 μg of phenol liberated by 1 ml of reconstituted milk.

METHOD 8: DETERMINATION OF PHOSPHATASE ACTIVITY (ASCHAFFENBURG AND MÜLLEN PROCEDURE)

1. SCOPE AND FIELD OF APPLICATION

This method describes the determination of phosphatase activity in:

|

— |

dried high fat milk or high fat milk powder, |

|

— |

dried whole milk or whole milk powder, |

|

— |

dried partly skimmed milk or partly skimmed-milk powder, |

|

— |

dried skimmed milk or skimmed-milk powder. |

2. DEFINITION

The phosphatase activity of dried milks is a measure of the quantity of active alkaline phosphatase present in the product. It is expressed as the quantity of p-nitrophenol in micrograms liberated by 1 ml of the reconstituted sample, under the conditions described.

3. PRINCIPLE

The reconstituted sample is diluted with a buffer substrate at pH 10,2 and incubated at a temperature of 37 oC for two hours. Any alkaline phosphatase present in the sample will, under these circumstances, liberate p-nitrophenol from added disodium p-nitrophenyl phosphate. The p-nitrophenol liberated is determined by direct comparison with standard colour glasses in a simple comparator using reflected light.

4. REAGENTS

|

4.1. |

Sodium carbonate-bicarbonate buffer solution. Dissolve 3,5 g of anhydrous sodium carbonate and 1,5 g of sodium bicarbonate in water and dilute to 1 000 ml in a volumetric flask with water. |

|

4.2. |

Buffer substate. Dissolve 1,5 g of disodium p-nitrophenylphosphate in sodium carbonate-bicarbonate buffer (4.1) and dilute to 1 000 ml in a volumetric flask with buffer (4.1). This solution is stable if stored in a refrigerator (≤ 4 oC) for one month but a colour control test should be carried out on such stored solutions — see 6, precaution number 3. |

|

4.3. |

Clarification solutions. |

|

4.3.1. |

Zinc sulphate solution. Dissolve 30,0 g of zinc sulphate (ZnSO4) in water and dilute to 100 ml in a volumetric flask with water. |

|

4.3.2. |

Potassium hexacyanoferrate (II) solution. Dissolve 17,2 g of potassium hexacyanoferrate (II) trihydrate (K4Fe(CN)6.3H20) and dilute to 100 ml in a volumetric flask with water. |

5. APPARATUS

|

5.1. |

Analytical balance. |

|

5.2. |

Waterbath, thermostatically controlled at 37 oC ± 1 oC. |

|

5.3. |

Comparator, with special disc containing standard colour glasses calibrated in μg p-nitrophenol per ml milk, and 2 x 25 mm cells. |

6. PROCEDURE

Precautions:

|

1. |

After use, test tubes must be emptied, rinsed in water, washed in hot water containing an al kaline detergent, followed by thorough rinsing in clean hot tap water. Finally, they must be rinsed in water and dried before use. Pipettes must be thoroughly rinsed in clean cold tap water immediately after use, followed by rinsing in water and dried before use. |

|

2. |

The test tube stoppers must be thoroughly rinsed in hot tap water immediately after use, followed by boiling for two minutes in water. |

|

3. |

The buffer substrate solution (4.2) should remain stable for at least one month if stored in a refrigerator at 4 oC or less. Any instability is denoted by the formation of a yellow colour. Whilst the test is always read against a boiled product control containing the same buffer substrate solution, it is recommended that the solution should not be used if it gives a colour reading in excess of 10 μg when read in a 25 mm cell in the comparator using distilled water in the other 25 mm cell. |

|

4. |

Use a separate pipette for each sample and avoid contaminating the pipette with saliva. |

|

5. |

The test must not be exposed to direct sunlight at any time. |

6.1. Preparation of sample

Dissolve 10 g of the powder in 90 ml of water. The temperature for dissolving the powder must not exceed 35 oC.

6.2. Determination

|

6.2.1. |

Pipette 15 ml of buffer substrate (4.2) into a clean, dry test tube, followed by 2 ml of the reconstituted sample (6.1) to be tested. Stopper the tube, mix by inversion and place in the 37 oC water bath (5.2). |

|

6.2.2. |

At the same time, place in the water bath a control tube containing 15 ml of buffer substrate and 2 ml of boiled reconstituted sample similar to that under test. |

|

6.2.3. |

After two hours remove both tubes from the water bath, add 0,5 ml of zinc sulphate precipitant (4.3.1), replace the stopper, shake vigorously and allow to stand for three minutes. Add 0,5 ml of potassium hexacyanoferrate (II) precipitant (4.3.2), mix thoroughly and filter through the fluted filter paper (5.4) and collect the clear filtrate in the clean test tube. |

|

6.2.4. |

Transfer the filtrate to a 25 mm cell and compare against the filtrate of the boiled sample control in the comparator using the special disc (5.3). |

7. EXPRESSION OF RESULTS

7.1. Calculation

The direct reading obtained under 6.2.4 is recorded as μg p-nitrophenol per ml sample or per ml of reconstituted sample.

7.2. Repeatability

The difference between the results of two determinations carried out simultaneously or in rapid succession on the same sample, by the same analyst, under the same conditions, shall not exceed 2 μg of p-nitrophenol liberated by 1 ml of reconstituted milk.