EUR-Lex Access to European Union law

This document is an excerpt from the EUR-Lex website

Document 01989L0656-20070627

Council Directive of 30 November 1989 on the minimum health and safety requirements for the use by workers of personal protective equipment at the workplace (third individual directive within the meaning of Article 16 (1) of Directive 89/391/EEC) (89/656/EEC)

Consolidated text: Council Directive of 30 November 1989 on the minimum health and safety requirements for the use by workers of personal protective equipment at the workplace (third individual directive within the meaning of Article 16 (1) of Directive 89/391/EEC) (89/656/EEC)

Council Directive of 30 November 1989 on the minimum health and safety requirements for the use by workers of personal protective equipment at the workplace (third individual directive within the meaning of Article 16 (1) of Directive 89/391/EEC) (89/656/EEC)

1989L0656 — EN — 27.06.2007 — 001.001

This document is meant purely as a documentation tool and the institutions do not assume any liability for its contents

|

COUNCIL DIRECTIVE of 30 November 1989 on the minimum health and safety requirements for the use by workers of personal protective equipment at the workplace (third individual directive within the meaning of Article 16 (1) of Directive 89/391/EEC) (OJ L 393, 30.12.1989, p.18) |

Amended by:

|

|

|

Official Journal |

||

|

No |

page |

date |

||

|

L 165 |

21 |

27.6.2007 |

||

Corrected by:

COUNCIL DIRECTIVE

of 30 November 1989

on the minimum health and safety requirements for the use by workers of personal protective equipment at the workplace (third individual directive within the meaning of Article 16 (1) of Directive 89/391/EEC)

(89/656/EEC)

THE COUNCIL OF THE EUROPEAN COMMUNITIES,

Having regard to the Treaty establishing the European Economic Community and in particular Article 118a thereof,

Having regard to the Commission proposal ( 1 ), submitted after consultation with the Advisory Committee on Safety, Hygiene and Health Protection at Work,

In cooperation with the European Parliament ( 2 ),

Having regard to the opinion of the Economic and Social Committee ( 3 ),

Whereas Article 118a of the Treaty provides that the Council shall adopt, by means of directives, minimum requirements designed to encourage improvements, especially in the working environment, to guarantee greater protection of the health and safety of workers;

Whereas, under the said Article, such directives shall avoid imposing administrative, financial and legal constraints in a way which would hold back the creation and development of small and medium-sized undertakings;

Whereas the Commission communication on its programme concerning safety, hygiene and health at work ( 4 ) provides for the adoption of a directive on the use of personal protective equipment at work;

Whereas the Council, in its resolution of 21 December 1987 concerning safety, hygiene and health at work ( 5 ), noted the Commission's intention of submitting to it in the near future minimum requirements concerning the organization of the safety and health of workers at work;

Whereas compliance with the minimum requirements designed to guarantee greater health and safety for the user of personal protective equipment is essential to ensure the safety and health of workers;

Whereas this Directive is an individual directive within the meaning of Article 16 (1) of Council Directive 89/391/EEC of 12 June 1989 on the introduction of measures to encourage improvements in the safety and health of workers at work ( 6 ); whereas, consequently, the provisions of the said Directive apply fully to the use by workers of personal protective equipment at the workplace, without prejudice to more stringent and/or specific provisions contained in this Directive;

Whereas this Directive constitutes a practical step towards the achievement of the social dimension of the internal market;

Whereas collective means of protection shall be accorded priority over individual protective equipment; whereas the employer shall be required to provide safety equipment and take safety measures;

Whereas the requirements laid down in this Directive should not entail alterations to personal protective equipment whose design and manufacture complied with Community directives relating to safety and health at work;

Whereas provision should be made for descriptions which Member States may use when laying down general rules for the use of individual protective equipment;

Whereas, pursuant to Decision 74/325/EEC ( 7 ), as last amended by the 1985 Act of Accession, the Advisory Committee on Safety, Hygiene and Health Protection at Work is consulted by the Commission with a view to drawing up proposals in this field,

HAS ADOPTED THIS DIRECTIVE:

SECTION I

GENERAL PROVISIONS

Article 1

Subject

1. This Directive, which is the third individual directive within the meaning of Article 16 (1) of Directive 89/391/EEC, lays down minimum requirements for personal protective equipment used by workers at work.

2. The provisions of Directive 89/391/EEC are fully applicable to the whole scope referred to in paragraph 1, without prejudice to more ►C1 stringent ◄ and/or specific provisions contained in this Directive.

Article 2

Definition

1. For the purposes of this Directive, personal protective equipment shall mean all equipment designed to be worn or held by the worker to protect him against one or more hazards likely to endanger his safety and health at work, and any addition or accessory designed to meet this objective.

2. The definition in paragraph 1 excludes:

(a) ordinary working clothes and uniforms not specifically designed to protect the safety and health of the worker;

(b) equipment used by emergency and rescue services;

(c) personal protective equipment worn or used by the military, the police and other public order agencies;

(d) personal protective equipment for means of road transport;

(e) sports equipment;

(f) self-defence or deterrent equipment;

(g) portable devices for detecting and signalling risks and nuisances.

Article 3

General rule

Personal protective equipment shall be used when the risks cannot be avoided or sufficiently limited by technical means of collective protection or by measures, methods or procedures of work organization.

SECTION II

EMPLOYERS’ OBLIGATIONS

Article 4

General provisions

1. Personal protective equipment must comply with the relevant Community provisions on design and manufacture with respect to safety and health.

All personal protective equipment must:

(a) be appropriate for the risks involved, without itself leading to any increased risk;

(b) correspond to existing conditions at the workplace;

(c) take account of ergonomic requirements and the worker's state of health;

(d) fit the wearer correctly after any necessary adjustment.

2. Where the presence of more than one risk makes it necessary for a worker to wear simultaneously more than one item of personal protective equipment, such equipment must be compatible and continue to be effective against the risk or risks in question.

3. The conditions of use of personal protective equipment, in particular the period for which it is worn, shall be determined on the basis of the seriousness of the risk, the frequency of exposure to the risk, the characteristics of the workstation of each worker and the performance of the personal protective equipment.

4. Personal protective equipment is, in principle, intended for personal use.

If the circumstances require personal protective equipment to be worn by more than one person, appropriate measures shall be taken to ensure that such use does not create any health or hygiene problem for the different users.

5. Adequate information on each item of personal protective equipment, required under paragraphs 1 and 2, shall be provided and made available within the undertaking and/or establishment.

6. Personal protective equipment shall be provided free of charge by the employer, who shall ensure its good working order and satisfactory hygienic condition by means of the necessary maintenance, repair and replacements.

However, Member States may provide, in accordance with their national practice, that the worker be asked to contribute towards the cost of certain personal protective equipment in circumstances where use of the equipment is not exclusive to the workplace.

7. The employer shall first inform the worker of the risks against which the wearing of the personal protective equipment protects him.

8. The employer shall arrange for training and shall, if appropriate, organize demonstrations in the wearing of personal protective equipment.

9. Personal protective equipment may be used only for the purposes specified, except in specific and exceptional circumstances.

It must be used in accordance with instructions.

Such instructions must be understandable to the workers.

Article 5

Assessment of personal protective equipment

1. Before choosing personal protective equipment, the employer is required to assess whether the personal protective equipment he intends to use satisfies the requirements of Article 4(1) and (2).

This assessment shall involve:

(a) an analysis and assessment of risks which cannot be avoided by other means;

(b) the definition of the characteristics which personal protective equipment must have in order to be effective against the risks referred to in (a), taking into account any risks which this equipment itself may create;

(c) comparison of the characteristics of the personal protective equipment available with the characteristics referred to in (b).

2. The assessment provided for in paragraph 1 shall be reviewed if any changes are made to any of its elements.

Article 6 ( 8 )

Rules for use

1. Without prejudice to Articles 3, 4 and 5, Member States shall ensure that general rules are established for the use of personal protective equipment and/or rules covering cases and situations where the employer must provide the personal protective equipment, taking account of Community legislation on the free movement of such equipment.

These rules shall indicate in particular the circumstances or the risk situations in which, without prejudice to the priority to be given to collective means of protection, the use of personal protective equipment is necessary.

Annexes I, II and III, which constitute a guide, contain useful information for establishing such rules.

2. When Member States adapt the rules referred to in paragraph 1, they shall take account of any significant changes to the risk, collective means of protection and personal protective equipment brought about by technological developments.

3. Member States shall consult the employers' and workers' organization on the rules referred to in paragraphs 1 and 2.

Article 7

Information for workers

Without prejudice to Article 10 of Directive 89/391/EEC, workers and/or their representatives shall be informed of all measures to be taken with regard to the health and safety of workers when personal protective equipment is used by workers at work.

Article 8

Consultation of workers and workers' participation

Consultation and participation of workers and/or of their representatives shall take place in accordance with Article 11 of Directive 89/391/EEC on the matters covered by this Directive, including the Annexes thereto.

SECTION III

MISCELLANEOUS PROVISIONS

Article 9

Adjustment of the Annexes

Alterations of a strictly technical nature to Annexes I, II and III resulting from:

— the adoption of technical harmonization and standardization directives relating to personal protective equipment, and/or

— technical progress and changes in international regulations and specifications or knowledge in the field of personal protective equipment,

shall be adopted in accordance with the procedure provided for in Article 17 of Directive 89/391/EEC.

Article 10

Final provisions

1. Member States shall bring; into force the laws, regulations and administrative provisions necessary to comply with this Directive not later than 31 December 1992. They shall immediately inform the Commission thereof.

2. Member States shall communicate to the Commission the text of the provisions of national law which they adopt, as well as those already adopted, in the field covered by this Directive.

▼M1 —————

Article 11

This Directive is addressed to the Member States.

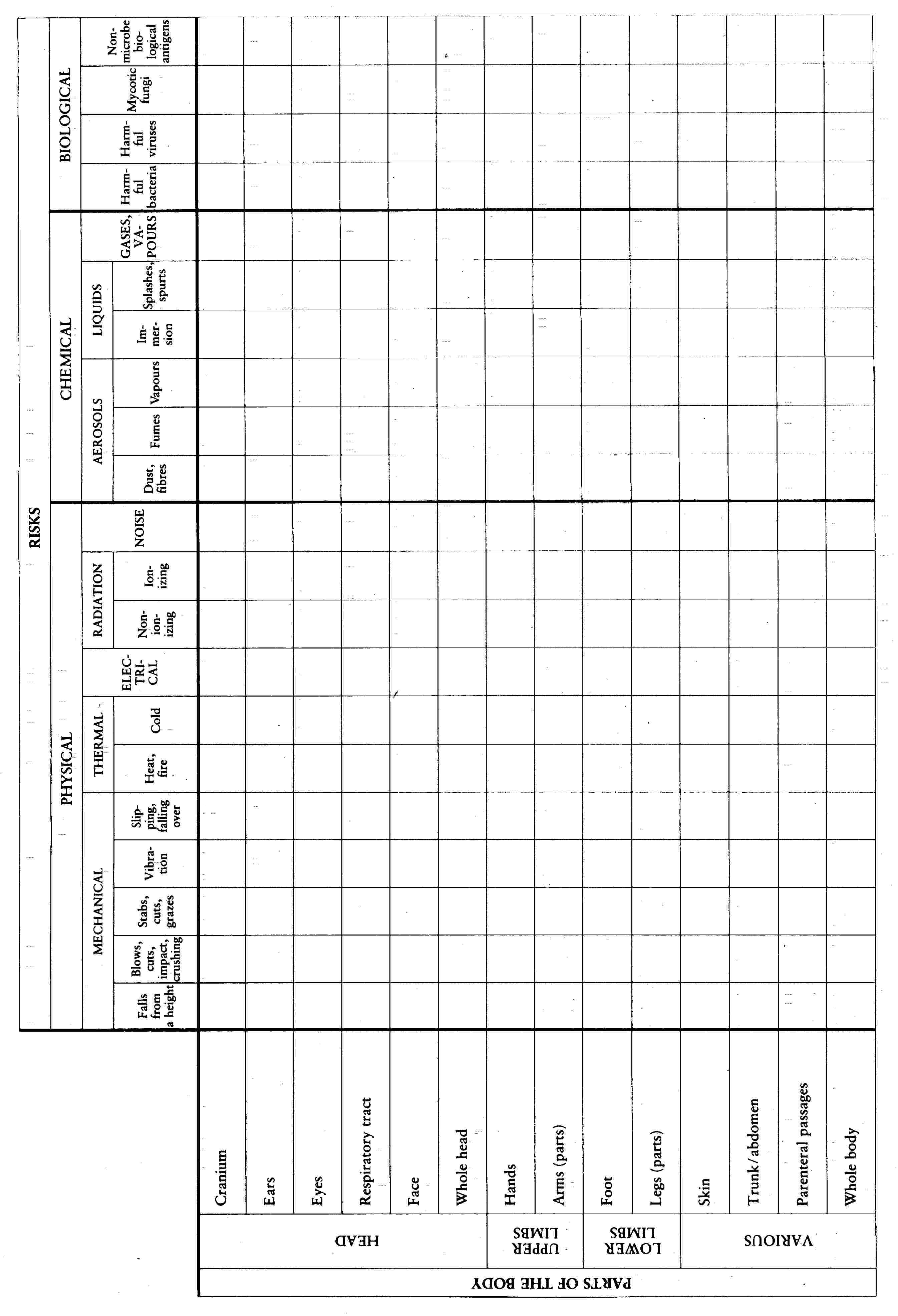

ANNEX I

SPECIMEN RISK SURVEY TABLE FOR THE USE OF PERSONAL PROTECTIVE EQUIPMENT

ANNEX II

NON-EXHAUSTIVE GUIDE LIST OF ITEMS OF PERSONAL PROTECTIVE EQUIPMENT

HEAD PROTECTION

— Protective helmets for use in industry (mines, building sites, other industrial uses).

— Scalp protection (caps, bonnets, hairnets— with or without eye shade).

— Protective headgear (bonnets, caps, sou’westers, etc. in fabric, fabric with proofing, etc.).

HEARING PROTECTION

— Earplugs and similar devices.

— Full acoustic helmets.

— Earmuffs which can be fitted to industrial helmets.

— Ear defenders with receiver for LF induction loop.

— Ear protection with intercom equipment.

EYE AND FACE PROTECTION

— Spectacles.

— Goggles.

— X-ray goggles, laser-beam goggles, ultra-violet, infra-red, visible radiation goggles.

— Face shields.

— Arc-welding masks and helmets (hand masks, headband masks or masks which can be fitted to protective helmets).

RESPIRATORY PROTECTION

— Dust filters, gas filters and radioactive dust filters.

— Insulating appliances with an air supply.

— Respiratory devices including a removable welding mask.

— Diving equipment.

— Diving suits.

HAND AND ARM PROTECTION

— Gloves to provide protection:

—— from machinery (piercing, cuts, vibrations, etc.),

— from chemicals,

— for electricians and from heat.

— Mittens.

— Finger stalls.

— Over sleeves.

— Wrist protection for heavy work.

— Fingerless gloves.

— Protective gloves.

FOOT AND LEG PROTECTION

— Low shoes, ankle boots, calf-length boots, safety boots.

— Shoes which can be unlaced or unhooked rapidly.

— Shoes with additional protective toe-cap.

— Shoes and overshoes with heat-resistant soles.

— Heat-resistant shoes, boots and overboots.

— Thermal shoes, boots and overboots.

— Vibration-resistant shoes, boots and overboots.

— Anti-static shoes, boots and overboots.

— Insulating shoes, boots and overboots.

— Protective boots for chain saw operators.

— Clogs.

— Kneepads.

— Removable instep protectors.

— Gaiters.

— Removable soles (heat-proof, pierce-proof or sweat-proof).

— Removable spikes for ice, snow or slippery flooring.

SKIN PROTECTION

— Barrier creams/ointments.

TRUNK AND ABDOMEN PROTECTION

— Protective waistcoats, jackets and aprons to provide protection from machinery (piercing, cutting, molten metal splashes, etc.).

— Protective waistcoats, jackets and aprons to provide protection from chemicals.

— Heated Waistcoats.

— Life jackets.

— Protective X-ray aprons.

— Body belts.

WHOLE BODY PROTECTION

— Equipment designed to prevent falls

— Fall-prevention equipment (full equipment with all necessary accessories).

— Braking equipment to absorb kinetic energy (full equipment with all necessary accessories).

— Body-holding devices (safety harness).

— Protective clothing

— ‘Safety’ working clothing (two-piece and overalls).

— Clothing to provide protection from machinery (piercing, cutting, etc.).

— Clothing to provide protection from chemicals.

— Clothing to provide protection from molten metal splashes and infra-red radiation.

— Heat-resistant clothing.

— Thermal clothing.

— Clothing to provide protection from radioactive contamination.

— Dust-proof clothing.

— Gas-proof clothing.

— Fluorescent signalling, retro-reflecting clothing and accessories (armbands, gloves, etc.).

— Protective coverings.

ANNEX III

NON-EXHAUSTIVE GUIDE LIST OF ACTIVITIES AND SECTORS OF ACTIVITY WHICH MAY REQUIRE THE PROVISION OF PERSONAL PROTECTIVE EQUIPMENT

1. HEAD PROTECTION (SKULL PROTECTION)

Protective helmets

— Building work, particularly work on, underneath or in the vicinity of scaffolding and elevated workplaces, erection and stripping of formwork, assembly and installation work, work on scaffolding and demolition work.

— Work on steel bridges, steel building construction, masts, towers, steel hydraulic structures, blast furnaces, steel works and rolling mills, large containers, large pipelines, boiler plants and power stations.

— Work in pits, trenches, shafts and tunnels.

— Earth and rock works.

— Work in underground workings, quarries, open diggings, coal stock removal.

— Work with bolt-driving tools.

— Blasting work.

— Work in the vicinity of lifts, lifting gear, cranes and conveyors.

— Work with blast furnaces, direct reduction plants, steelworks, rolling mills, metalworks, forging, drop forging and casting.

— Work with industrial furnaces, containers, machinery, silos, bunkers and pipelines.

— Shipbuilding.

— Railway shunting work.

— Slaughterhouses.

2. FOOT PROTECTION

Safety shoes with puncture-proof soles

— Carcase work, foundation work and road works.

— Scaffolding work.

— The demolition of carcase work.

— Work with concrete and prefabricated parts involving formwork erection and stripping.

— Work in contractors' yards and warehouses.

— Roof work.

Safety shoes without pierce-proof soles

— Work on steel bridges, steel building construction, masts, towers, lifts, steel hydraulic structures, blast furnaces, steelworks and rolling mills, large containers, large pipelines, cranes, boiler plants and power stations.

— Furnace construction heating and ventilation installation and metal assembly work.

— Conversion and maintenance work.

— Work with blast furnaces, direct reduction plants, steelworks, rolling mills, metalworks, forging, drop forging, hot pressing and drawing plants.

— Work in quarries and open diggings, coal stock removal.

— Working and processing of rock.

— Flat glass products and container glassware manufacture, working and processing.

— Work with moulds in the ceramics industry.

— Lining of kilns in the ceramics industry.

— Moulding work in the ceramic ware and building materials industry.

— Transport and storage.

— Work with frozen meat blocks and preserved foods packaging.

— Shipbuilding.

— Railway shunting work.

Safety shoes with heels or wedges and pierce-proof soles

— Roof work.

Protective shoes with insulated soles

— Work with and on very hot or very cold materials.

Safety shoes which can easily be removed

— Where there is a risk of penetration by molten substances.

3. EYE OR FACE PROTECTION

Protective goggles, face shields or screens

— Welding, grinding and separating work.

— Caulking and chiselling.

— Rock working and processing.

— Work with bolt-driving tools.

— Work on stock removing machines for small chippings.

— Drop forging.

— The removal and breaking up of fragments.

— Spraying of abrasive substances.

— Work with acids and caustic solutions, disinfectants and corrosive cleaning products.

— Work with liquid sprays.

— Work with and in the vicinity of molten substances.

— Work with radiant heat.

— Work with lasers.

4. RESPIRATORY PROTECTION

Respirators/breathing apparatus

— Work in containers, restricted areas and gas-fired industrial furnaces where there may be gas or insufficient oxygen.

— Work in the vicinity of the blast furnace charge.

— Work in the vicinity of gas converters and blast furnace gas pipes.

— Work in the vicinity of blast furnace taps where there may be heavy metal fumes.

— Work on the lining of furnaces and ladles where there may be dust.

— Spray painting where dedusting is inadequate.

— Work in shafts, sewers and other underground areas connected with sewage.

— Work in refrigeration plants where there is a danger that the refrigerant may escape.

5. HEARING PROTECTION

Ear protectors

— Work with metal presses.

— Work with pneumatic drills.

— The work of ground staff at airports.

— Pile-driving work.

— Wood and textile working.

6. BODY, ARM AND HAND PROTECTION

Protective clothing

— Work with acids and caustic solutions, disinfectants and corrosive cleaning substances.

— Work with or in the vicinity of hot materials and where the effects of heat are felt.

— Work on flat glass products.

— Shot blasting.

— Work in deep-freeze rooms.

Fire-resistant protective clothing

— Welding in restricted areas.

Pierce-proof aprons

— Boning and cutting work.

— Work with hand knives involving drawing the knife towards the body.

Leather aprons

— Welding.

— Forging.

— Casting.

Forearm protection

— Boning and cutting.

Gloves

— Welding.

— Handling of sharp-edged objects, other than machines where there is a danger of the glove's being caught.

— Unprotected work with acids and caustic solutions.

Metal mesh gloves

— Boning and cutting.

— Regular cutting using a hand knife for production and slaughtering.

— Changing the knives of cutting machines.

7. WEATHERPROOF CLOTHING

— Work in the open air in rain and cold weather.

8. REFLECTIVE CLOTHING

— Work where the workers must be clearly visible.

9. SAFETY HARNESSES

— Work on scaffolding.

— Assembly of prefabricated parts.

— Work on masts.

10. SAFETY ROPES

— Work in high crane cabs.

— Work in high cabs of warehouse stacking and retrieval equipment.

— Work in high sections of drilling towers.

— Work in shafts and sewers.

11. SKIN PROTECTION

— Processing of coating materials.

— Tanning.

( 1 ) OJ No C 161, 20.6.1988, p. 1,

OJ No C 115, 8.5.1989, p. 27 and

OJ No C 287, 15.11.1989, p. 11.

( 2 ) OJ No C 12, 16.1.1989, p. 92 and

OJ No C 256, 9.10.1989, p. 61.

( 3 ) OJ No C 318, 12.12.1988, p. 30.

( 4 ) OJ No C 28, 3.2.1988, p. 3.

( 5 ) OJ No C 28, 3.2.1988, p. 1.

( 6 ) OJ No L 183, 29.6.1989, p. 1.

( 7 ) OJ No L 185, 9.7.1974, p. 15.

( 8 ) See the Commission communication (OJ No C 328, 30.12.1989, p. 3).