EUR-Lex Access to European Union law

This document is an excerpt from the EUR-Lex website

Document 31980L0766

Commission Directive 80/766/EEC of 8 July 1980 laying down the Community method of analysis for the official control of the vinyl chloride monomer level in materials and articles which are intended to come into contact with foodstuffs

Commission Directive 80/766/EEC of 8 July 1980 laying down the Community method of analysis for the official control of the vinyl chloride monomer level in materials and articles which are intended to come into contact with foodstuffs

Commission Directive 80/766/EEC of 8 July 1980 laying down the Community method of analysis for the official control of the vinyl chloride monomer level in materials and articles which are intended to come into contact with foodstuffs

OJ L 213, 16.8.1980, p. 42–46

(DA, DE, EN, FR, IT, NL)

Greek special edition: Chapter 15 Volume 001 P. 250 - 254

Spanish special edition: Chapter 13 Volume 011 P. 42 - 46

Portuguese special edition: Chapter 13 Volume 011 P. 42 - 46

Special edition in Finnish: Chapter 13 Volume 010 P. 221 - 225

Special edition in Swedish: Chapter 13 Volume 010 P. 221 - 225

Special edition in Czech: Chapter 13 Volume 006 P. 45 - 49

Special edition in Estonian: Chapter 13 Volume 006 P. 45 - 49

Special edition in Latvian: Chapter 13 Volume 006 P. 45 - 49

Special edition in Lithuanian: Chapter 13 Volume 006 P. 45 - 49

Special edition in Hungarian Chapter 13 Volume 006 P. 45 - 49

Special edition in Maltese: Chapter 13 Volume 006 P. 45 - 49

Special edition in Polish: Chapter 13 Volume 006 P. 45 - 49

Special edition in Slovak: Chapter 13 Volume 006 P. 45 - 49

Special edition in Slovene: Chapter 13 Volume 006 P. 45 - 49

Special edition in Bulgarian: Chapter 13 Volume 005 P. 112 - 116

Special edition in Romanian: Chapter 13 Volume 005 P. 112 - 116

No longer in force, Date of end of validity: 30/04/2011; Arna aisghairm le 32011R0010

No longer in force, Date of end of validity: 30/04/2011; Arna aisghairm le 32011R0010

|

16.8.1980 |

EN |

Official Journal of the European Communities |

L 213/42 |

COMMISSION DIRECTIVE

of 8 July 1980

laying down the Community method of analysis for the official control of the vinyl chloride monomer level in materials and articles which are intended to come into contact with foodstuffs

(80/766/EEC)

THE COMMISSION OF THE EUROPEAN COMMUNITIES,

Having regard to the Treaty establishing the European Communities,

Having regard to Council Directive 78/142/EEC of 30 January 1978 on the approximation of the laws of the Member States relating to materials and articles which contain vinyl chloride monomer and are intended to come into contact with foodstuffs (1), and in particular Article 3 thereof,

Whereas Article 2 of Directive 78/142/EEC lays down that such materials and articles must not contain vinyl chloride monomer in a quantity exceeding 1 milligram per kilogram in the final product and Article 3 that this limit must be controlled by a Community analysis method;

Whereas, on the basis of a series of inter-laboratory collaborative trials, the method described in the Annex has proved to be sufficiently accurate and reproducible to be adopted as a Community method;

Whereas the measures provided for in this Directive are in accordance with the opinion of the Standing Committee on Foodstuffs,

HAS ADOPTED THIS DIRECTIVE:

Article 1

The Member States shall require that the analysis necessary for official control of the vinyl chloride monomer level in materials and articles intended to come into contact with foodstuffs, referred to in the Annex as ‘materials and articles’, shall be performed according to the method described in the Annex.

Article 2

The Member States shall bring into force the laws, regulations and administrative provisions necessary to comply with this Directive not later than 18 months following its notification. They shall forthwith inform the Commission thereof.

Article 3

This Directive is addressed to the Member States.

Done at Brussels, 8 July 1980.

For the Commission

Etienne DAVIGNON

Member of the Commission

(1) OJ No L 44, 15. 2. 1978, p. 15.

ANNEX

DETERMINATION OF THE VINYL CHLORIDE MONOMER LEVEL IN MATERIALS AND ARTICLES

1. SCOPE AND FIELD OF APPLICATION

The method determines the vinyl chloride monomer level in materials and articles.

2. PRINCIPLE

The level of vinyl chloride monomer level (VC) in materials or articles is determined by means of gas-chromatography using the ‘headspace’ method after dissolution or suspension of the sample in N,N-dimethylacetamide.

3. REAGENTS

|

3.1. |

Vinyl chloride (VC), of purity greater than 99.5 % (v/v). |

|

3.2. |

N,N-dimethylacetamide (DMA), free from any impurity with the same retention time as VC or as the internal standard (3.3) under the conditions of the test. |

|

3.3. |

Diethyl ether or cis-2-butene, in DMA (3.2) as the internal standard solution. These internal standards must not contain any impurity with the same retention time as VC, under the conditions of the test. |

4. APPARATUS

N.B.

An instrument or piece of apparatus is mentioned only if it is special or made to particular specifications. Usual laboratory apparatus is assumed to be available.

|

4.1. |

Gas-chromatograph fitted with automatic head-space sampler or with facilities for manual sample injection. |

|

4.2. |

Flame ionization detector or other detectors mentioned in point 7. |

|

4.3. |

Gas-chromatographic column. The column must permit the separation of the peaks of air, of VC and of the internal standard, if used. Furthermore, the combined 4.2 and 4.3 system must allow the signal obtained with a solution containing 0·02 mg VC/litre DMA or 0.02 mg VC/kg DMA to be equal to at least five times the background noise. |

|

4.4. |

Sample phials or flasks fitted with silicon or butyl rubber septa. When using manual sampling techniques the taking of a sample from the headspace with a syringe may cause a partial vacuum to form inside the phial or flask. Hence, for manual techniques where the phials are not pressurized before the sample is taken, the use of large phials is recommended. |

|

4.5. |

Micro-syringes. |

|

4.6. |

Gas-tight syringes for manual headspace sampling. |

|

4.7. |

Analytical balance accurate to 0·1 mg. |

5. PROCEDURE

CAUTION: VC is a hazardous substance and a gas at ambient temperature, therefore the preparation of solutions should be carried out in a well-ventilated fume cupboard.

N.B.

|

— |

Take all the necessary precautions to ensure that no VC or DMA is lost; |

|

— |

When employing manual sampling techniques an internal standard (3.3) should be used; |

|

— |

When using an internal standard, the same solution must be utilized throughout the procedure. |

5.1. Preparation of concentrated standard VC solution at approximately 2 000 mg/kg

Accurately weigh to the nearest 0·1 mg a suitable glass vessel and place in it a quantity (e.g. 50 ml) of DMA (3.2). Re-weigh. Add to the DMA a quantity (e.g. 0·1 g) of VC (3.1) in liquid or gas form, injecting it slowly on to the DMA. The VC may also be added by bubbling it into the DMA, provided that a device is used which will prevent loss of DMA. Re-weigh to the nearest 0·1 mg. Wait two hours to allow equilibrium to be attained. Keep the standard solution in a refrigerator.

5.2. Preparation of dilute standard VC solution

Take a weighed amount of concentrated standard solution of VC (5.1) and dilute, to a known volume or a known weight, with DMA (3.2) or with internal standard solution (3.3). The concentration of the resultant dilute standard solution is expressed as mg/l or mg/kg respectively.

5.3. Preparation of the calibration curve

N.B.

|

— |

the curve must comprise at least seven pairs of points, |

|

— |

the repeatability of the responses (1) must be lower than 0·02 mg VC/l or kg of DMA, |

|

— |

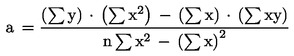

the curve must be calculated from these points by the least squares technique, i.e. the regression line must be calculated using the following equation y = a1x + a0 where: and: where:

|

|

— |

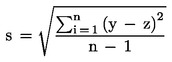

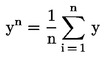

the curve must be linear, i.e. the standard deviation (s) of the differences between the measured responses (yi) and the corresponding value of the responses calculated from the regression line (zi) divided by the mean value (y) of all the measured responses shall not exceed 0·07: This shall be calculated from:

|

Prepare two series of at least seven phials (4.4). Add to each phial volumes of dilute standard VC solution (5.2) and DMA (3.2) or internal standard solution in DMA (3.3) such that the final VC concentration of the duplicate solutions will be approximately equal to 0; 0·050; 0·075; 0·100; 0·125; 0·150; 0·200, etc. mg/1 or mg/kg of DMA and that all the phials contain the same quantity of DMA that is to be used under point 5.5. Seal the phials and proceed as described under point 5.6. Construct a graph in which the ordinate values show the areas (or heights) of the VC peaks of the duplicate solutions or the ratio of these areas (or heights) to those of the relevant internal standard peaks and the abscissa values show the VC concentrations of the duplicate solutions.

5.4. Validation of preparation of standard solutions obtained in points 5.1 and 5.2

Repeat the procedure described under points 5.1 and 5.2 to obtain a second diluted standard solution with a concentration equal to 0·1 mg VC/1 or 0·1 mg/kg of DMA or internal standard solution. The average of two gas-chromatographic determinations of this solution must not differ by more than 5 % from the corresponding point of the calibration curve. If the difference is greater than 5 %, reject all the solutions obtained in points 5.1, 5.2, 5.3 and 5.4 and repeat the procedure from the beginning.

5.5. Preparation of the samples of materials or articles

Prepare two phials (4.4). Weigh into each phial not less than 200 mg, to the nearest 0·1 mg, of the sample obtained from a single material or article under investigation which has been reduced to small pieces. Try to ensure that an equal quantity is weighed into each phial. Close the phial immediately. Add to each phial for each gram of the sample 10 ml or 10 g of DMA (3.2) or 10 ml or 10 g of internal standard solution (3.3). Seal the phials and proceed as described under point 5.6.

5.6. Gas-chromatographic determinations

|

5.6.1. |

Agitate the phials avoiding contact between the contained liquid and the septum (4.4) to obtain a solution or suspension of the samples of material or article (5.5) as homogeneous as possible. |

|

5.6.2. |

Put all the sealed phials (5.3, 5.4 and 5.5) in a waterbath for two hours at 60 o ± 1 oC to allow equilibrium to be attained. Agitate again, if necessary. |

|

5.6.3. |

Take a sample from the headspace in the phial. When utilizing manual sampling techniques care must be exercised in obtaining a reproducible sample (see point 4.4), in particular the syringe must be pre-warmed to the temperature of the sample. Measure the area (or height) of the peaks relating to the VC and to the internal standard if used. |

|

5.6.4. |

Remove from the column (4.3) excess DMA using an appropriate method as soon as peaks of DMA appear on the chromatogram. |

6. CALCULATION OF THE RESULTS

|

6.1. |

Find by interpolation on the curve, the unknown concentration of each of the two solutions of the sample taking account of the internal standard solution if used. Calculate the amount of VC in each of the two samples of material or article under investigation by applying the following formula:

where:

|

|

6.2. |

The concentration of VC in the material and article under investigation expressed in mg/kg shall be the average of the two concentrations of VC (mg/kg) determined in point 6.1 provided that the repeatability criterion in point 8 is satisfied. |

7. CONFIRMATION OF THE VC LEVEL

In cases where the content of VC in materials and articles as calculated under point 6.2 exceeds the maximum permissible amount the results obtained by the analysis of each of the two samples (5.6 and 6.1) must be confirmed in one of three ways:

|

— |

by using at least one other column (4.3) having a stationary phase with a different polarity. This procedure should continue until a chromatogram is obtained with no evidence of overlap of the VC and/or internal standard peaks with constituents of the sample of the material or article, |

|

— |

by using other detectors, e.g. the micro-electrolytic conductivity detector (2), |

|

— |

by using mass-spectrometry. In this case, if molecular ions with parent masses (m/e) of 62 and 64 are found in the ratio of 3: 1, it may be regarded with high probability as confirming the presence of VC. In case of doubt the total mass spectrum must be checked. |

8. REPEATABILITY

The difference between the results of two determinations (6.1) carried out simultaneously or in rapid succession on the same sample, by the same analyst, under the same conditions, must not exceed 0·2 mg VC/kg of material or article.

(1) See recommendation ISO DIS 5725: 1977.

(2) See Journal of Chromatographic Science, Vol. 12, March 1974, p. 152.