1997L0068 — EN — 06.10.2016 — 010.001

This text is meant purely as a documentation tool and has no legal effect. The Union's institutions do not assume any liability for its contents. The authentic versions of the relevant acts, including their preambles, are those published in the Official Journal of the European Union and available in EUR-Lex. Those official texts are directly accessible through the links embedded in this document

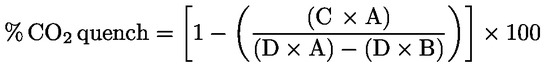

Amended by:

Amended by:

Corrected by:

▼B

DIRECTIVE 97/68/EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL

of 16 December 1997

on the approximation of the laws of the Member States relating to measures against the emission of gaseous and particulate pollutants from internal combustion engines to be installed in non-road mobile machinery

Article 1

Objectives

This Directive aims at approximating the laws of the Member States relating to emission standards and type-approval procedures for engines to be installed in non-road mobile machinery. It will contribute to the smooth functioning of the internal market, while protecting human health and the environment.

Article 2

Definitions

For the purposes of this Directive:

—

non-road mobile machinery shall mean any mobile machine, transportable industrial equipment or vehicle with or without body work, not intended for the use of passenger- or goods-transport on the road, in which an internal combustion engine as specified in Annex I section 1 is installed,

—

type-approval shall mean the procedure whereby a Member State certifies that an internal combustion engine type or engine family with regard to the level of emission of gaseous and particulate pollutants by the engine(s), satisfies the relevant technical requirements of this Directive,

—

engine type shall mean a category of engines which do not differ in such essential engine characteristics as specified in Annex II, Appendix 1,

—

engine family shall mean a manufacturer's grouping of engines which, through their design, are expected to have similar exhaust emission characteristics and which comply with the requirements of this Directive,

—

parent engine shall mean an engine selected from an engine family in such a way that it complies with the requirements set out in sections 6 and 7 of Annex I,

—

engine power output shall mean net power as specified in section 2.4 of Annex I,

—

engine production date shall mean the date when the engine passes the final check after it has left the production line. At this stage the engine is ready to be delivered or to be put on stock,

▼M2

—

placing on the market shall mean the action of making an engine available for the first time on the market, for payment or free of charge, with a view to distribution and/or use in the Community,

▼B

—

manufacturer shall mean the person or body who is responsible to the approval authority for all aspects of the type-approval process and for ensuring conformity of production. It is not essential that the person or body is directly involved in all stages of the construction of the engine,

—

approval authority shall mean a Member State's competent authority or authorities responsible for all aspects of type-approval of an engine or of an engine family, for issuing and withdrawing approval certificates, for serving as the contact point with the approval authorities of the other Member States, and for verifying the manufacturer's conformity of production arrangements,

—

technical service shall mean the organization(s) or body(ies) that has(have) been appointed as a testing laboratory to carry out tests or inspections on behalf of the approval authority of a Member State. This function may also be carried out by the approval authority itself,

—

information document shall mean the document set out in Annex II that prescribes the information to be supplied by an applicant,

—

information folder shall mean the total folder or file of data, drawings, photographs, etc. supplied by the applicant to the technical service or the approval authority as prescribed in the information document,

—

information package shall mean the information folder plus any test reports or other documents that the technical service or the approval authority have added to the information folder in the course of carrying out their functions,

—

index to the information package shall mean the document in which the contents of the information package, suitably numbered or otherwise marked to clearly identify all pages, are listed,

▼M2

—

replacement engines shall mean a newly built engine to replace an engine in a machine, and which has been supplied for this purpose only,

—

hand-held engine shall mean an engine that meets at least one of the following requirements:

—

(a) the engine must be used in a piece of equipment that is carried by the operator throughout the performance of its intended function(s);

(b) the engine must be used in a piece of equipment that must operate multipositionally, such as upside down or sideways, to complete its intended function(s);

(c) the engine must be used in a piece of equipment for which the combined engine and equipment dry weight is under 20 kilograms and at least one of the following attributes is also present:

(i) the operator must alternatively provide support or carry the equipment throughout the performance of its intended function(s);

(ii) the operator must provide support or attitudinal control for the equipment throughout the performance of its intended function(s);

(iii) the engine must be used in a generator or a pump,

—

non-hand-held engine shall mean an engine which does not fall under the definition of a hand-held engine,

—

professional use multipositional hand-held engine shall mean a hand-held engine which meets the requirements of both (a) and (b) of the hand-held engine definition and in relation to which the engine manufacturer has satisfied an approval authority that a Category 3 Emissions Durability Period (according to section 2.1 of Appendix 4 to Annex IV) would be applicable to the engine,

—

emission durability period shall mean the number of hours indicated in Annex IV, Appendix 4, used to determine the deterioration factors,

—

small volume engine family shall mean a spark-ignition (SI) engine family with a total yearly production of fewer than 5 000 units,

—

small volume engine manufacturer of SI engines shall mean a manufacturer with a total yearly production of fewer than 25 000 units,

▼C1

—

inland waterway vessel shall mean a vessel intended for use on inland waterways having a length of 20 metres or more and having a volume of 100 m3 or more according to the formula defined in Annex I, Section 2, point 2.8a, or tugs or pusher craft having been built to tow or to push or to move alongside vessels of 20 metres or more,

— This definition does not include:

—

— vessels intended for passenger transport carrying no more that 12 people in addition to the crew,

— recreational craft with a length of less than 24 metres (as defined in Article 1(2) of Directive 94/25/EC of the European Parliament and of the Council of 16 June 1994 on the approximation of the laws, regulations and administrative provisions of the Member States relating to recreational craft (

1

),

— service craft belonging to supervisory authorities,

— fishing vessels on the fishing vessels register of the Community,

— sea-going vessels, including sea-going tugs and pusher craft operating or based on tidal waters or temporarily on inland waterways, provided that they carry a valid navigation or safety certificate as defined in Annex I, Section 2, point 2.8b,

—

original equipment manufacturer (OEM) shall mean a manufacturer of a type of non-road mobile machine,

—

flexibility scheme shall mean the procedure allowing an engine manufacturer to place on the market, during the period between two successive stages of limit values, a limited number of engines, to be installed in non-road mobile machinery, that only comply with the previous stage of emission limit values.

▼B

Article 3

Application for type-approval

1. Application for engine or engine family type-approval shall be submitted by the manufacturer to the approval authority of a Member State. An application shall be accompanied by an information folder, the contents of which are given in the information document in Annex II. An engine conforming to the engine type characteristics described in Annex II, Appendix 1, shall be submitted to the technical service responsible for conducting the approval tests.

2. In the case of an application for type-approval of an engine family, if the approval authority determines that, with regard to the selected parent engine, the submitted application does not fully represent the engine family described in Annex II, Appendix 2, an alternative and, if necessary, an additional parent engine which is determined by the approval authority shall be provided for approval according to paragraph 1.

3. No application in respect of one engine type or engine family may be submitted to more than one Member State. A separate application shall be submitted for each engine type or engine family to be approved.

Article 4

Type-approval procedure

1. The Member State receiving the application shall grant type-approval to all engine types or engine families which conform to the particulars in the information folder and which meet the requirements of this Directive.

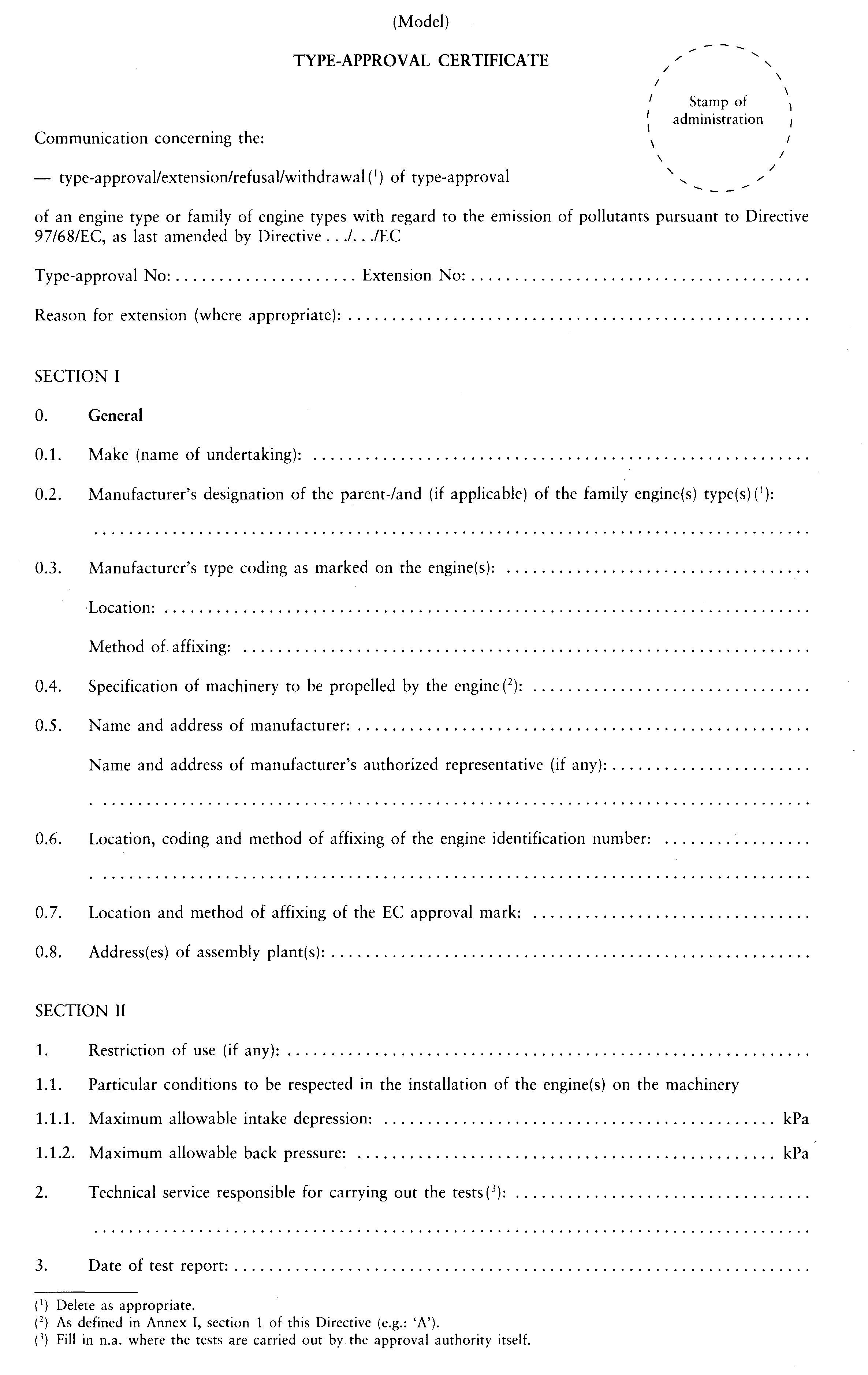

2. The Member State shall complete all applicable sections of the type-approval certificate, the model being given in

►M2

Annex VII ◄ , for each engine type or engine family which it approves and shall compile or verify the contents of the index to the information package. Type-approval certificates shall be numbered in accordance with the method described in

►M2

Annex VIII ◄ . The completed type-approval certificate and its attachments shall be delivered to the applicant.

►M5

The Commission shall amend Annex VIII. Those measures, designed to amend non-essential elements of this Directive, shall be adopted in accordance with the regulatory procedure with scrutiny referred to in Article 15(2). ◄

3. Where the engine to be approved fulfils its function or offers a specific feature only in conjunction with other parts of the non-road mobile machinery, and for this reason compliance with one or more requirements can be verified only when the engine to be approved operates in conjunction with other machinery parts, whether real or simulated, the scope of the type-approval of the engine(s) must be restricted accordingly. The type-approval certificate for an engine type or engine family shall then include any restrictions on its use and shall indicate any conditions for fitting it.

4. The approval authority of each Member State shall:

(a) send monthly to the approval authorities of the other Member States a list (containing the particulars shown in

►M2

Annex IX ◄ ) of the engine and engine family type-approvals it has granted, refused to grant or withdrawn during that month;

(b) on receiving a request from the approval authority of another Member State, send forthwith:

— a copy of the engine or engine family type-approval certificate with/without information package for each engine type or engine family which it has approved or refused to approve or withdrawn, and/or

— the list of engines produced according to type-approvals granted, as described in Article 6(3), containing the particulars shown in

►M2

Annex X ◄ , and/or

— a copy of the declaration described in Article 6(4).

5. The approval authority of each Member State shall yearly, or in addition on receiving a corresponding application, send the Commission a copy of the data sheet as shown in

►M2

Annex XI ◄ related to the engines approved since the last notification was made.

▼M7

6. Compression ignition engines for use other than in the propulsion of railcars and inland waterway vessels may be placed on the market under a flexibility scheme in accordance with the procedure referred to in Annex XIII in addition to paragraphs 1 to 5.

▼B

Article 5

Amendments to approvals

1. The Member State which has granted type-approval must take the necessary measures to ensure that it is informed of any change in the particulars appearing in the information package.

2. The application for the amendment or extension of a type-approval shall be submitted exclusively to the approval authority of the Member State which granted the original type-approval.

3. If particulars appearing in the information package have changed, the approval authority of the Member State in question shall:

— issue revised page(s) of the information package as necessary, marking each revised page to show clearly the nature of the change and the date of re-issue. Wherever revised pages are issued the index to the information package (which is attached to the type-approval certificate) shall also be amended to show the latest dates of revised pages, and

— issue a revised type-approval certificate (denoted by an extension number) if any information on it (excluding its attachments) has changed or if the standards of this Directive have changed since the date currently on the approval. The revised certificate shall show clearly the reason for revision and the date of re-issue.

If the approval authority of the Member State in question finds that an amendment to an information package warrants fresh tests or checks, it shall inform the manufacturer thereof and issue the documents mentioned above only after the conduct of successful fresh tests or checks.

Article 6

Conformity

1. The manufacturer shall affix to each unit manufactured in conformity with the approved type the markings as defined in section 3 of Annex I, including the type-approval number.

2. Where the type-approval certificate, in accordance with Article 4(3), includes restrictions on use, the manufacturer shall deliver with each unit manufactured, detailed information on these restrictions and shall indicate any conditions for fitting it. Where a series of engine types is delivered to one single manufacturer of machinery, it is sufficient that he will be provided with only one such information document, at the latest on the delivery date of the first engine, which additionally lists the relevant engine identification numbers.

3. The manufacturer shall send on demand to the approval authority which granted the type-approval, within 45 days after the end of each calendar year, and without delay after each application date when the requirements of this Directive change, and immediately following each additional date the authority may stipulate, a list which contains the range of identification numbers for each engine type produced in accordance with the requirements of this Directive since the last reporting was made, or since the requirements of this Directive were first applicable. Where not clarified by the engine coding system, this list must specify correlations of the identification numbers to the corresponding engine types or engine families and to the type-approval numbers. Additionally, this list must contain particular information if the manufacturer ceases to produce an approved engine type or engine family. Where this list is not required to be regularly sent to the approval authority, the manufacturer must maintain these records for a minimum period of 20 years.

4. The manufacturer shall send to the approval authority which granted the type-approval, within 45 days after the end of each calendar year and at each application date referred to in Article 9, a declaration specifying the engine types and engine families together with the relevant engine identification codes for those engines he intends to produce from this date on.

▼M3

5. Compression ignition engines placed on the market under a ‘flexible scheme’ shall be labelled in accordance with Annex XIII.

▼B

Article 7

Acceptance of equivalent approvals

1. The European Parliament and the Council, acting on a proposal from the Commission, may acknowledge the equivalence between the conditions and provisions for type-approval of engines established by this Directive and the procedures established by international regulations or regulations of third countries, in the framework of multilateral or bilateral agreements between the Community and third countries.

▼M2

2. Member States shall accept type-approvals and, where applicable, the pertaining approval marks listed in Annex XII as being in conformity with this Directive.

▼M3

Article 7a

Inland waterway vessels

1. The following provisions shall apply to engines to be installed in inland waterway vessels. Paragraphs 2 and 3 shall not apply until the equivalence between the requirements established by this Directive and those established in the framework of the Mannheim Convention for the Navigation of the Rhine is recognised by the Central Commission of Navigation on Rhine (hereinafter: CCNR) and the Commission is informed thereof.

2. Until 30 June 2007, Member States may not refuse the placing on the market of engines which meet the requirements established by CCNR stage I, the emission limit values for which are set out in Annex XIV.

3. As from 1 July 2007 and until the entry into force of a further set of limit values which would result from further amendments to this Directive, Member States may not refuse the placing on the market of engines which meet the requirements established by CCNR stage II, the emission limit values for which are set out in Annex XV.

▼M5

4. The Commission shall adapt Annex VII to integrate the additional and specific information which may be required as regards the type-approval certificate for engines to be installed in inland waterway vessels. Those measures, designed to amend non-essential elements of this Directive, shall be adopted in accordance with the regulatory procedure with scrutiny referred to in Article 15(2).

▼C1

5. For the purposes of this Directive, as far as inland waterway vessels are concerned, any auxiliary engine with a power of more than 560 kW shall be subject to the same requirements as propulsion engines.

▼B

Article 8

▼M3

Placing on the market

1. Member States may not refuse the placing on the market of engines, whether or not already installed in machinery, which meet the requirements of this Directive.

▼B

2. Member States shall only permit registration, where applicable, or placing on the market of new engines, whether or not already installed in machinery, which meet the requirements of this Directive.

▼M3

2a. Member States shall not issue the Community Inland Water Navigation certificate established by Council Directive 82/714/EC of 4 October 1982 laying down technical requirements for inland waterway vessels (

2

) to any vessels whose engines do not meet the requirements of this Directive.

▼B

3. The approval authority of a Member State granting a type-approval shall take the necessary measures in relation to that approval to register and control, if need be in cooperation with the approval authorities of the other Member States, the identification numbers of those engines produced in conformity with the requirements of this Directive.

4. An additional control of the identification numbers may take place in conjunction with the control of conformity of production as described in Article 11.

5. With regard to the control of the identification numbers, the manufacturer or his agents established in the Community shall without delay give, on request, to the responsible approval authority all the information needed related to his/their purchasers together with the identification numbers of the engines reported as produced in accordance with Article 6(3). Where engines are sold to a manufacturer of machinery, further information is not required.

6. If, at the request of the approval authority, the manufacturer is not able to verify the requirements as specified in Article 6 particularly in conjunction with paragraph 5 of this Article, the approval granted in respect of the corresponding engine type or family pursuant to this Directive may be withdrawn. The information procedure shall then be carried out as described in Article 12(4).

Article 9

▼M2

Timetable-compression ignition engines

▼B

1. GRANT OF TYPE-APPROVALS

After 30 June 1998, Member States may not refuse to grant type-approval for an engine type or engine family or to issue the document as described in

►M2

Annex VII ◄ , and may not impose any other type-approval requirements with regard to air-polluting emissions for non-road mobile machinery in which an engine is installed, if the engine meets the requirements specified in this Directive as regards the emissions of gaseous and particulate pollutants.

2. TYPE-APPROVALS STAGE I

Member States shall refuse to grant type-approval for an engine type or engine family and to issue the document as described in

►M2

Annex VII ◄ , and shall refuse to grant any other type-approval for non-road mobile machinery in which an engine is installed:

after 30 June 1998 for engines of a power output:

|

— A:

|

130 kW ≤ P ≤ 560 kW,

|

|

— B:

|

75 kW ≤ P < 130 kW,

|

|

— C:

|

37 kW ≤ P < 75 kW,

|

if the engine fails to meet the requirements specified in this Directive and where the emissions of gaseous and particulate pollutants from the engine do not comply with the limit values as set out in the table in

►M2

section 4.1.2.1 of Annex I ◄ .

3. TYPE-APPROVALS STAGE II

▼M3

Member States shall refuse to grant type-approval for an engine type or engine family and to issue the document as described in Annex VII and shall refuse to grant any other type-approval for non-road mobile machinery, in which an engine, not already placed on the market, is installed:

▼B

|

— D:

|

after 31 December 1999 for engines of a power output: 18 kW ≤ P < 37 kW,

|

|

— E:

|

after 31 December 2000 for engines of a power output: 130 kW ≤ P ≤ 560 kW,

|

|

— F:

|

after 31 December 2001 for engines of a power output: 75 kW ≤ P < 130 kW,

|

|

— G:

|

after 31 December 2002 for engines of a power output: 37 kW ≤ P < 75 kW,

|

if the engine fails to meet the requirements specified in this Directive and where the emissions of gaseous and particulate pollutants from the engine do not comply with the limit values as set out in the table in

►M2

section 4.1.2.3 of Annex I ◄ .

▼M3

3a. TYPE-APPROVAL OF STAGE IIIA ENGINES (ENGINE CATEGORIES H, I, J and K)

Member States shall refuse to grant type-approval for the following engine types or families and to issue the document as described in AnnexVII, and shall refuse to grant any other type-approval for non-road mobile machinery in which an engine, not already placed on the market, is installed:

— H: after 30 June 2005 for engines — other than constant speed engines — of a power output: 130 kW ≤ P ≤ 560 kW,

— I: after 31 December 2005 for engines — other than constant speed engines — of a power output: 75 kW ≤ P < 130 kW,

— J: after 31 December 2006 for engines — other than constant speed engines — of a power output: 37 kW ≤ P < 75 kW,

— K: after 31 December 2005 for engines — other than constant speed engines — of a power output: 19 kW ≤ P < 37 kW,

where the engine fails to meet the requirements specified in this Directive and where the emissions of particulate and gaseous pollutants from the engine do not comply with the limit values as set out in the table in section 4.1.2.4 of Annex I.

3b. TYPE-APPROVAL OF STAGE IIIA CONSTANT SPEED ENGINES (ENGINE CATEGORIES H, I, J and K)

Member States shall refuse to grant type-approval for the following engine types or families and to issue the document as described in Annex VII, and shall refuse to grant any other type-approval for non-road mobile machinery in which an engine, not already placed on the market, is installed:

— Constant speed H engines: after 31 December 2009 for engines of a power output: 130 kW ≤ P < 560 kW,

— Constant speed I engines: after 31 December 2009 for engines of a power output: 75 kW ≤ P < 130 kW,

— Constant speed J engines: after 31 December 2010 for engines of a power output: 37 kW ≤ P < 75 kW,

— Constant speed K engines: after 31 December 2009 for engines of a power output: 19 kW ≤ P < 37 kW,

where the engine fails to meet the requirements specified in this Directive and where the emissions of particulate and gaseous pollutants from the engine do not comply with the limit values set out in the table in Section 4.1.2.4 of Annex I.

3c. TYPE-APPROVAL OF STAGE III B ENGINES (ENGINE CATEGORIES L, M, N and P)

Member States shall refuse to grant type-approval for the following engine types or families and to issue the document as described in Annex VII, and shall refuse to grant any other type-approval for non-road mobile machinery in which an engine, not already placed on the market, is installed:

— L: after 31 December 2009 for engines — other than constant speed engines — of a power output: 130 kW ≤ P ≤ 560 kW,

— M: after 31 December 2010 for engines — other than constant speed engines — of a power output: 75 kW ≤ P < 130 kW,

— N: after 31 December 2010 for engines — other than constant speed engines — of a power output: 56 kW ≤ P < 75 kW,

— P: after 31 December 2011 for engines — other than constant speed engines — of a power output: 37 kW ≤ P < 56 kW,

where the engine fails to meet the requirements specified in this Directive and where the emissions of particulate and gaseous pollutants from the engine do not comply with the limit values set out in the table in Section 4.1.2.5 of Annex I.

3d. TYPE-APPROVAL OF STAGE IV ENGINES (ENGINE CATEGORIES Q and R)

Member States shall refuse to grant type-approval for the following engine types or families and to issue the document as described in Annex VII, and shall refuse to grant any other type-approval for non-road mobile machinery in which an engine, not already placed on the market, is installed:

— Q: after 31 December 2012 for engines — other than constant speed engines — of a power output: 130 kW ≤ P ≤ 560 kW,

— R: after 30 September 2013 for engines — other than constant speed engines — of a power output: 56 kW ≤ P < 130 kW,

where the engine fails to meet the requirements specified in this Directive and where the emissions of particulate and gaseous pollutants from the engine do not comply with the limit values set out in the table in Section 4.1.2.6 of Annex I.

3e. TYPE-APPROVAL OF STAGE III A PROPULSION ENGINES USED IN INLAND WATERWAY VESSELS (ENGINE CATEGORIES V)

Member States shall refuse to grant type-approval for the following engine types or families and to issue the document as described in Annex VII:

— V1:1: after 31 December 2005 for engines of power output at or above 37 kW and swept volume below 0,9 litres per cylinder,

— V1:2: after 30 June 2005 for engines with swept volume at or above 0,9 but below 1,2 litres per cylinder,

— V1:3: after 30 June 2005 for engines with swept volume at or above 1,2 but below 2,5 litres per cylinder and an engine power output of: 37 kW ≤ P < 75 kW,

— V1:4: after 31 December 2006 for engines with swept volume at or above 2,5 but below 5 litres per cylinder,

— V2: after 31 December 2007 for engines with swept volume at or above 5 litres per cylinder,

where the engine fails to meet the requirements specified in this Directive and where the emissions of particulate and gaseous pollutants from the engine do not comply with the limit values as set out in the table in section 4.1.2.4 of Annex I.

3f. TYPE-APPROVAL OF STAGE III A PROPULSION ENGINES USED IN RAILCARS

Member States shall refuse to grant type-approval for the following engine types or families and to issue the document as described in Annex VII:

— RC A: after 30 June 2005 for engines of power output above 130 kW

where the engine fails to meet the requirements specified in this Directive and where the emissions of particulate and gaseous pollutants from the engine do not comply with the limit values as set out in the table in section 4.1.2.4 of Annex I.

3g. TYPE-APPROVAL OF STAGE III B PROPULSION ENGINES USED IN RAILCARS

Member States shall refuse to grant type-approval for the following engine types or families and to issue the document as described in Annex VII:

— RC B: after 31 December 2010 for engines of power output above 130 kW

where the engine fails to meet the requirements specified in this Directive and where the emissions of particulate and gaseous pollutants from the engine do not comply with the limit values as set out in the table in section 4.1.2.5 of Annex I.

3h. TYPE-APPROVAL OF STAGE III A PROPULSION ENGINES USED IN LOCOMOTIVES

Member States shall refuse to grant type-approval for the following engine types or families and to issue the document as described in Annex VII:

— RL A: after 31 December 2005 for engines of power output: 130 kW ≤ P ≤ 560 kW

— RH A: after 31 December 2007 for engines of power output: 560 kW < P

where the engine fails to meet the requirements specified in this Directive and where the emissions of particulate and gaseous pollutants from the engine do not comply with the limit values as set out in the table in section 4.1.2.4 of Annex I. The provisions of this paragraph shall not apply to the engine types and families referred to where a contract has been entered into to purchase the engine before 20 May 2004 and provided that the engine is placed on the market no later than two years after the applicable date for the relevant category of locomotives.

3i. TYPE-APPROVAL OF STAGE III B PROPULSION ENGINES USED IN LOCOMOTIVES

Member States shall refuse to grant type-approval for the following engine types or families and to issue the document as described in Annex VII:

— R B: after 31 December 2010 for engines of power output above 130 kW

where the engine fails to meet the requirements specified in this Directive and where the emissions of particulate and gaseous pollutants from the engine do not comply with the limit values as set out in the table in section 4.1.2.5 of Annex I. The provisions of this paragraph shall not apply to the engine types and families referred to where a contract has been entered into to purchase the engine before 20 May 2004 and provided that the engine is placed on the market no later than two years after the applicable date for the relevant category of locomotives.

▼B

4.

►M3

►C1

PLACING ON THE MARKET: ENGINE PRODUCTION DATES ◄

◄

After the dates referred to hereafter, with the exception of machinery and engines intended for export to third countries, Member States shall permit the registration, where applicable, and

►M2

placing on the market of engines ◄ , whether or not already installed in machinery, only if they meet the requirements of this Directive, and only if the engine is approved in compliance with one of the categories as defined in paragraphs 2 and 3.

Stage I

— category A: 31 December 1998

— category B: 31 December 1998

— category C: 31 March 1999

Stage II

— category D: 31 December 2000

— category E: 31 December 2001

— category F: 31 December 2002

— category G: 31 December 2003

Nevertheless, for each category, Member States may postpone each date mentioned in the above requirement for two years in respect of engines with a production date prior to the said date.

The permission granted for stage I-engines shall be terminated with effect from the mandatory implementation of stage II.

▼M3

4a. Without prejudice to Article 7a and to Article 9(3g) and (3h), after the dates referred to hereafter, with the exception of machinery and engines intended for export to third countries, Member States shall permit the placing on the market of engines, whether or not already installed in machinery, only if they meet the requirements of this Directive, and only if the engine is approved in compliance with one of the categories as defined in paragraphs 2 and 3.

Stage III A other than constant speed engines

— category H: 31 December 2005

— category I: 31 December 2006

— category J: 31 December 2007

— category K: 31 December 2006

Stage III A inland waterway vessel engines

— category V1:1: 31 December 2006

— category V1:2: 31 December 2006

— category V1:3: 31 December 2006

— category V1:4: 31 December 2008

— categories V2: 31 December 2008

Stage III A constant speed engines

— category H: 31 December 2010

— category I: 31 December 2010

— category J: 31 December 2011

— category K: 31 December 2010

Stage III A railcar engines

— category RC A: 31 December 2005

Stage III A locomotive engines

— category RL A:31 December 2006

— category RH A:31 December 2008

Stage III B other than constant speed engines

— category L: 31 December 2010

— category M: 31 December 2011

— category N: 31 December 2011

— category P: 31 December 2012

Stage III B railcar engines

— category RC B: 31 December 2011

Stage III B locomotive engines

— category R B: 31 December 2011

Stage IV other than constant speed engines

— category Q: 31 December 2013

— category R: 30 September 2014

For each category, the above requirements shall be postponed by two years in respect of engines with a production date prior to the said date.

The permission granted for one stage of emission limit values shall be terminated with effect from the mandatory implementation of the next stage of limit values.

▼M9

By way of derogation from the first subparagraph, Member States may authorise, on request by an OEM, the placing on the market of engines that meet Stage III A emission limit values, provided that those engines are intended for installation in non-road mobile machinery to be used in potentially explosive atmospheres, as defined in point (5) of Article 2 of Directive 2014/34/EU of the European Parliament and of the Council (

3

).

Manufacturers shall provide the approval authority with evidence that the engines are installed exclusively in non-road mobile machinery certified as fulfilling those requirements. A label bearing the text ‘Engine for restricted use in machinery manufactured by’, followed by the name of the OEM and the unique reference of the associated derogation shall be affixed to any such engines, beside the engine statutory marking set out in section 3 of Annex I.

By way of derogation from the first subparagraph, Member States may grant EU type-approval and authorise the placing on the market of engines of category RLL with a maximum net power greater than 2 000 kW that do not comply with the emission limits set out in Annex II, that are to be installed in locomotives which only run on a technically isolated 1 520 mm railway network. Those engines shall, as a minimum, comply with the emission limits that engines had to meet to be placed on the market on 31 December 2011.

▼M3

4b. LABELLING TO INDICATE EARLY COMPLIANCE WITH THE STANDARDS OF STAGES IIIA, IIIB AND IV

For engine types or engine families meeting the limit values set out in the table in section 4.1.2.4, 4.1.2.5 and 4.1.2.6 of Annex I before the dates laid down in paragraph 4 of this Article, Member States shall allow special labelling and marking to show that the equipment concerned meets the required limit values before the dates laid down.

▼M2

Article 9a

Timetable — Spark ignition engines

1. DIVIDING INTO CLASSES

For the purpose of this Directive, spark-ignition engines shall be divided into the following classes.

|

Main class S

|

:

|

small engines with a net power ≤ 19 kW

|

The main class S shall be divided into two categories:

|

H

|

:

|

engines for hand-held machinery

|

|

N

|

:

|

engines for non-hand-held machinery

|

|

Class/category

|

Displacement (cubic cm)

|

|

Hand-held engines

Class SH:1

|

< 20

|

|

Class SH:2

|

≥ 20

< 50

|

|

Class SH:3

|

≥ 50

|

|

Non-hand-held engines

Class SN:1

|

< 66

|

|

Class SN:2

|

≥ 66

< 100

|

|

Class SN:3

|

≥ 100

< 225

|

|

Class SN:4

|

≥ 225

|

2. GRANT OF TYPE APPROVALS

After 11 August 2004, Member States may not refuse to grant type-approval for an SI engine type or engine family or to issue the document as described in Annex VII, and may not impose any other type-approval requirements with regard to air-polluting emissions for non-road mobile machinery in which an engine is installed, if the engine meets the requirements specified in this Directive as regards the emissions of gaseous pollutants.

3. TYPE-APPROVALS STAGE 1

Member States shall refuse to grant type-approval for an engine type or engine family and to issue the documents as described in Annex VII, and shall refuse to grant any other type-approval for non-road mobile machinery in which an engine is installed after 11 August 2004 if the engine fails to meet the requirements specified in this Directive and where the emissions of gaseous pollutants from the engine do not comply with the limit values as set out in the table in section 4.2.2.1 of Annex I.

4. TYPE-APPROVALS STAGE II

Member States shall refuse to grant type-approval for an engine type or engine family and to issue the documents as described in Annex VII, and shall refuse to grant any other type-approval for non-road mobile machinery in which an engine is installed:

after 1 August 2004 for engine classes SN:1 and SN:2

after 1 August 2006 for engine class SN:4

after 1 August 2007 for engine classes SH:1, SH:2 and SN:3

after 1 August 2008 for engine class SH:3,

if the engine fails to meet the requirements specified in this Directive and where the emissions of gaseous pollutants from the engine do not comply with the limit values as set out in the table in section 4.2.2.2 of Annex I.

5. PLACING ON THE MARKET: ENGINE PRODUCTION DATES

Six months after the dates for the relevant category of engine in paragraphs 3 and 4, with the exception of machinery and engines intended for export to third countries, Member States shall permit placing on the market of engines, whether or not already installed in machinery, only if they meet the requirements of this Directive.

6. LABELLING OF EARLY COMPLIANCE WITH STAGE II

For engine types or engine families meeting the limit values set out in the table in section 4.2.2.2 of Annex I, before the dates laid down in point 4 of this Article, Member States shall allow special labelling and marking to show that the equipment concerned meets the required limit values before the dates laid down.

7. EXEMPTIONS

The following machinery shall be exempted from the implementation dates of stage II emission limit requirements for a period of three years after the entry into force of those emission limit requirements. For those three years, the stage I emission limit requirements shall continue to apply:

|

—

|

hand-held chainsaw : a hand-held device designed to cut wood with a saw chain, designed to be supported with two hands and having an engine capacity in excess of 45 cm3, according to EN ISO 11681-1,

|

|

—

|

top handle machine (i.e., hand-held drills and tree service chainsaws) : a hand-held device with the handle on top of the machine designed to drill holes or to cut wood with a saw chain (according to ISO 11681-2),

|

|

—

|

hand-held brush cutter with an internal combustion engine : a hand-held device with a rotating blade made of metal or plastic intended to cut weeds, brush, small trees and similar vegetation. It must be designed according to EN ISO 11806 to operate multi-positionally, such as horizontally or upside down, and have an engine capacity in excess of 40 cm3,

|

|

—

|

hand-held hedge trimmer : a hand-held device designed for trimming hedges and bushes by means of one or more reciprocating cutter blades, according to EN 774,

|

|

—

|

hand-held power cutter with an internal combustion engine : a hand-held device intended for cutting hard materials such as stone, asphalt, concrete or steel by means of a rotating metal blade with a displacement in excess of 50 cm3, according to EN 1454, and

|

|

—

|

non-hand-held, horizontal shaft class SN:3 engine : only those class SN:3 non-hand-held engines with a horizontal shaft that produce power equal to or less than 2,5 kW and are used mainly for select, industrial purposes, including tillers, reel cutters, lawn aerators and generators.

|

▼M6

Notwithstanding the first subparagraph, an extension of the derogation period is granted until 31 July 2013, within the category of top handle machines, for professional use, multi-positional, hand-held hedge trimmers and top handle tree service chainsaws in which engines of classes SH:2 and SH:3 are installed.

▼M2

8. OPTIONAL IMPLEMENTATION DELAY

Nevertheless, for each category, Member States may postpone the dates in paragraphs 3, 4 and 5 for two years in respect of engines with a production date prior to those dates.

▼B

Article 10

Exemptions and alternative procedures

▼M3

1. The requirements of Article 8(1) and (2), Article 9(4) and Article 9a(5) shall not apply to:

— engines for use by the armed services,

— engines exempted in accordance with paragraphs 1a and 2,

— engines for use in machines intended primarily for the launch and recovery of lifeboats,

— engines for use in machines intended primarily for the launch and recovery of beach launched vessels.

1a. Without prejudice to Article 7a and to Article 9(3g) and (3h), replacement engines, except for railcar, locomotive and inland waterway vessel propulsion engines, shall comply with the limit values that the engine to be replaced had to meet when originally placed on the market.

▼M7 —————

▼M7

1b. By way of derogation from Article 9(3g), (3i) and (4a), Member States may authorise the placing on the market of the following engines for railcars and locomotives:

(a) replacement engines that meet the Stage III A limits, where they are to replace engines for railcars and locomotives that:

(i) do not meet the Stage III A standard; or

(ii) meet the Stage III A standard but do not meet the Stage III B standard;

(b) replacement engines that do not meet Stage III A limits, where they are to replace engines for railcars without driving control and not capable of independent movement, so long as such replacement engines meet a standard no lower than the standard met by engines fitted to existing railcars of the same type.

Authorisations under this paragraph may be granted only in cases where the approval authority of the Member State is satisfied that the use of a replacement engine that meets the requirements of the latest applicable emissions stage in the railcar or locomotive in question will involve significant technical difficulties.

1c. A label bearing the text ‘REPLACEMENT ENGINE’ and bearing the unique reference of the associated derogation shall be affixed to engines covered by paragraph 1a or 1b.

1d. The Commission shall assess the environmental impacts of, and possible technical difficulties in respect of compliance with, paragraph 1b. In the light of that assessment, the Commission shall, by 31 December 2016, submit to the European Parliament and the Council a report reviewing paragraph 1b accompanied, if appropriate, by a legislative proposal including an end date for the application of that paragraph.

▼B

2. Each Member State may, at the request of the manufacturer, exempt end-of-series engines which are still in stock, or stocks of non-road mobile machinery in respect of their engines, from the time limit(s) for placing on the market set out in Article 9(4) in accordance with the following conditions:

— the manufacturer must submit an application to the approval authorities of that Member State which approved the corresponding engine type(s) or engine family(ies) before the entry into force of the time limit(s),

— the application of the manufacturer must include a list as defined in Article 6(3) of those new engines which are not placed on the market within the time limit(s); in the case of engines covered by this Directive for the first time, he must submit his application to the type-approval authority of that Member State where the engines are stored,

— the request must specify the technical and/or economic reasons on which it is based,

— the engines must conform to a type or family for which the type-approval is no longer valid, or which did not need a type-approval before, but which have been produced according to the time limit(s),

— the engines must have been physically stored within the Community within the time limit(s),

— the maximum number of new engines of one or more types placed on the market in each Member State by the application of this exemption must not exceed 10 % of the new engines of all types concerned placed on the market in that Member State during the previous year,

— if the request is accepted by the Member State, the latter must, within one month, send the approval authorities of the other Member States particulars of, and reasons for, the exemptions granted to the manufacturer,

— the Member State granting exemptions according to this Article shall be responsible for ensuring that the manufacturer complies with all corresponding obligations,

— the approval authority shall release for each engine in question a certificate of conformity on which a special entry has been made. If applicable a consolidated document that contains all engine identification numbers in question may be used,

— Member States shall each year send the Commission a list of exemptions granted specifying the reasons.

This option shall be limited to a period of 12 months as from the date on which the engines for the first time were subject to the time limit(s) for placing on the market.

▼M2

3. The requirements of Article 9a(4) and (5) shall be postponed by three years for small volume engine manufacturers.

4. The requirements of Article 9a(4) and (5) shall be replaced by the corresponding stage I requirements for a small volume engine family to a maximum of 25 000 units providing that the various engine families involved all have different cylinder displacements.

▼M3

5. Engines may be placed on the market under a ‘flexible scheme’ in accordance with the provisions in Annex XIII.

6. Paragraph 2 shall not apply to propulsion engines to be installed in inland waterway vessels.

▼M7

7. Member States shall permit the placing on the market of engines, as defined in points A(i), A(ii) and A(v) of Section 1 of Annex I, under the flexibility scheme in accordance with the provisions set out in Annex XIII.

▼M9

8. Member States may decide not to apply this Directive to engines installed in cotton harvesting machinery.

▼B

Article 11

Conformity of production arrangements

1. The Member State granting a type-approval shall take the necessary measures to verify, with regard to the specifications laid down in section 5 of Annex I, if need be in cooperation with the approval authorities of the other Member States, that adequate arrangements have been made to ensure effective control of the conformity of production before it grants type-approval.

2. The Member State which has granted a type-approval shall take the necessary measures to verify, with regard to the specifications laid down in section 5 of Annex I, if need be in cooperation with the approval authorities of the other Member States, that the arrangements referred to in paragraph 1 continue to be adequate and that each production engine bearing a type-approval number pursuant to this Directive continues to conform to the description as given in the approval certificate and its Annexes for the approved engine type or family.

Article 12

Non-conformity with the approved type or family

1. There shall be failure to conform to the approved type or family where deviations from the particulars in the type-approval certificate and/or the information package are found to exist and where these deviations have not been authorized, pursuant to Article 5(3), by the Member State which granted the type-approval.

2. If a Member State which has granted type-approval finds that engines accompanied by a certificate of conformity or bearing an approval mark do not conform to the type or family it has approved, it shall take the necessary measures to ensure that the engines in production again conform to the approved type or family. The approval authorities of that Member State shall advise those of the other Member States of the measures taken which may, where necessary, extend to withdrawal of type-approval.

3. If a Member State demonstrates that engines bearing a type-approval number do not conform to the approved type or family it may request the Member State which granted the type-approval to verify that engines in production conform to the approved type or family. Such action shall be taken within six months of the date of the request.

4. The approval authorities of the Member States shall inform each other within one month of any withdrawal of type-approval and of the reasons for such measure.

5. If the Member State which granted type-approval disputes the failure to conform notified to it, the Member States concerned shall endeavour to settle the dispute. The Commission shall be kept informed and shall, where necessary, hold appropriate consultations for the purpose of reaching a settlement.

Article 13

Worker protection requirements

The provisions of this Directive shall not affect Member States' entitlement to lay down, in due observance of the Treaty, such requirements as they may deem necessary to ensure that workers are protected when using the machinery referred to in this Directive, provided that this does not affect the placing on the market of the engines in question.

▼M5

Article 14

The Commission shall adopt any amendments which are necessary in order to adapt the Annexes, with the exception of the requirements specified in section 1, sections 2.1 to 2.8 and section 4 of Annex I, to technical progress.

Those measures, designed to amend non-essential elements of this Directive, shall be adopted in accordance with the regulatory procedure with scrutiny referred to in Article 15(2).

Article 14a

The Commission shall study possible technical difficulties in complying with the stage II requirements for certain uses of the engines, in particular mobile machinery in which engines of classes SH:2 and SH:3 are installed. If the Commission studies conclude that for technical reasons certain mobile machinery, in particular, multi-positional, hand-held engines intended for professional use, cannot meet those requirements by the deadlines laid down, it shall submit, by 31 December 2003, a report accompanied by appropriate proposals for extensions of the period referred to in Article 9a(7) and/or further derogations, not exceeding five years in duration, save in exceptional circumstances, for such machinery. Those measures, designed to amend non-essential elements of this Directive by supplementing it, shall be adopted in accordance with the regulatory procedure with scrutiny referred to in Article 15(2).

▼M2

Article 15

Committee

1. The Commission shall be assisted by the Committee on Adaptation to Technical Progress of the Directives on the Removal of Technical Barriers to Trade in the Motor Vehicle Sector (hereinafter referred to as ‘the Committee’).

▼M5

2. Where reference is made to this paragraph, Article 5a(1) to (4) and Article 7 of Decision 1999/468/EC shall apply, having regard to the provisions of Article 8 thereof.

▼M5 —————

▼B

Article 16

Approval authorities and technical services

The Member States shall notify to the Commission and to the other Member States the names and addresses of the approval authorities and technical services that are responsible for the purposes of this Directive. The notified services must satisfy the requirements as laid down in Article 14 of Directive 92/53/EEC.

Article 17

Transposal into national law

1. Member States shall bring into force the laws, regulations and administrative provisions necessary to comply with this Directive not later than 30 June 1998. They shall forthwith inform the Commission thereof.

When Member States adopt these measures, they shall contain a reference to this Directive or shall be accompanied by such reference on the occasion of their official publication. The methods of making such a reference shall be laid down by Member States.

2. Member States shall communicate to the Commission the texts of the provisions of national law which they adopt in the field governed by this Directive.

Article 18

Entry into force

This Directive shall enter into force on the 20th day following its publication in the Official Journal of the European Communities.

Article 19

Further reduction in emission limit values

The European Parliament and the Council shall decide, by the end of the year 2000 on a proposal which the Commission will submit before the end of 1999, on a further reduction in emission limit values, taking into account the global availability of techniques for controlling air-polluting emissions from compression ignition engines and the air quality situation.

Article 20

Addressees

This Directive is addressed to the Member States.

▼M2

List of Annexes

|

ANNEX I

|

Scope, definitions, symbols and abbreviations, engine markings, specifications and tests, specification of conformity of production assessments, parameters defining the engine family, choice of the parent engine

|

|

Appendix 1

|

Requirements to ensure the correct operation of NOx control measures

|

|

Appendix 2

|

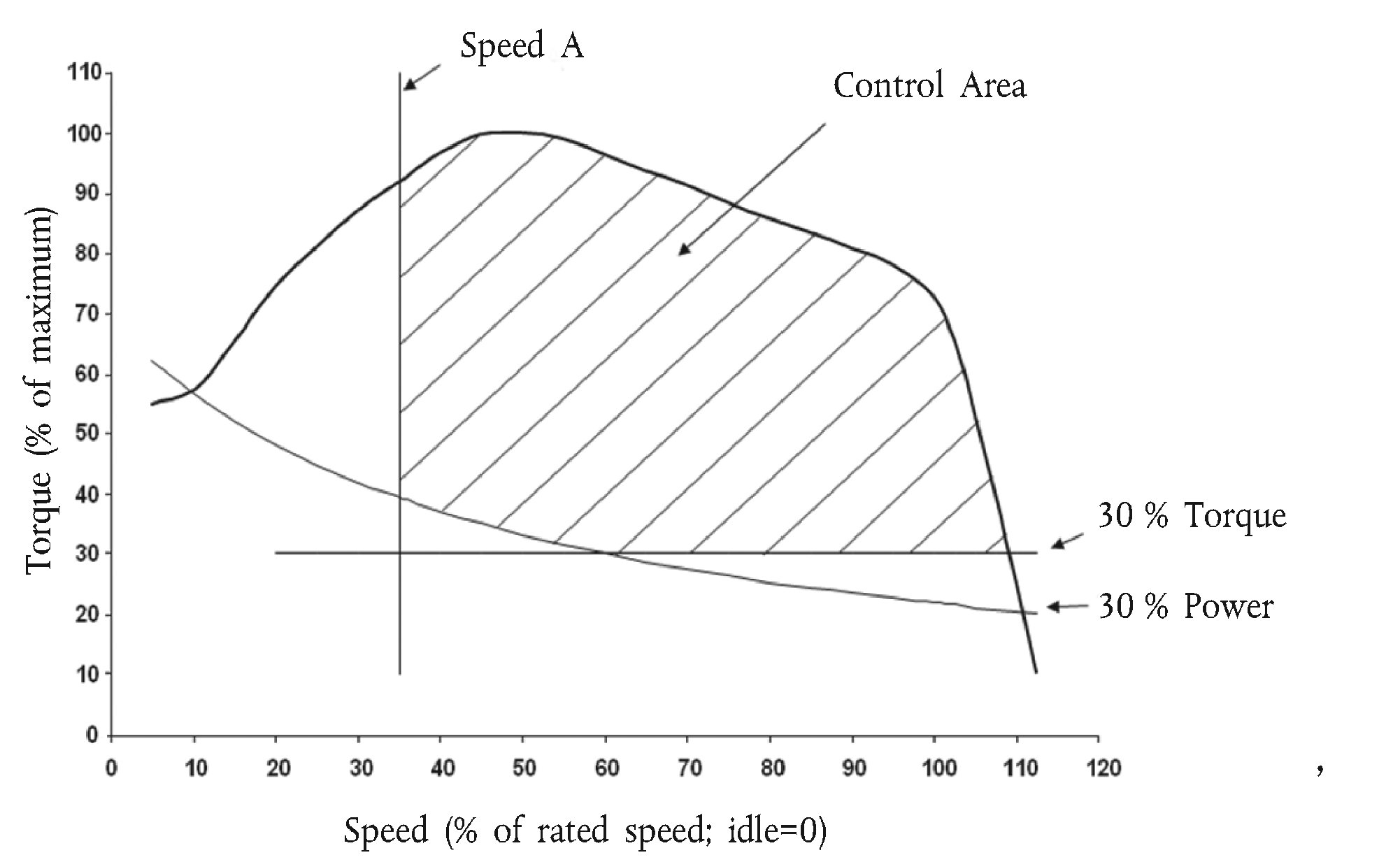

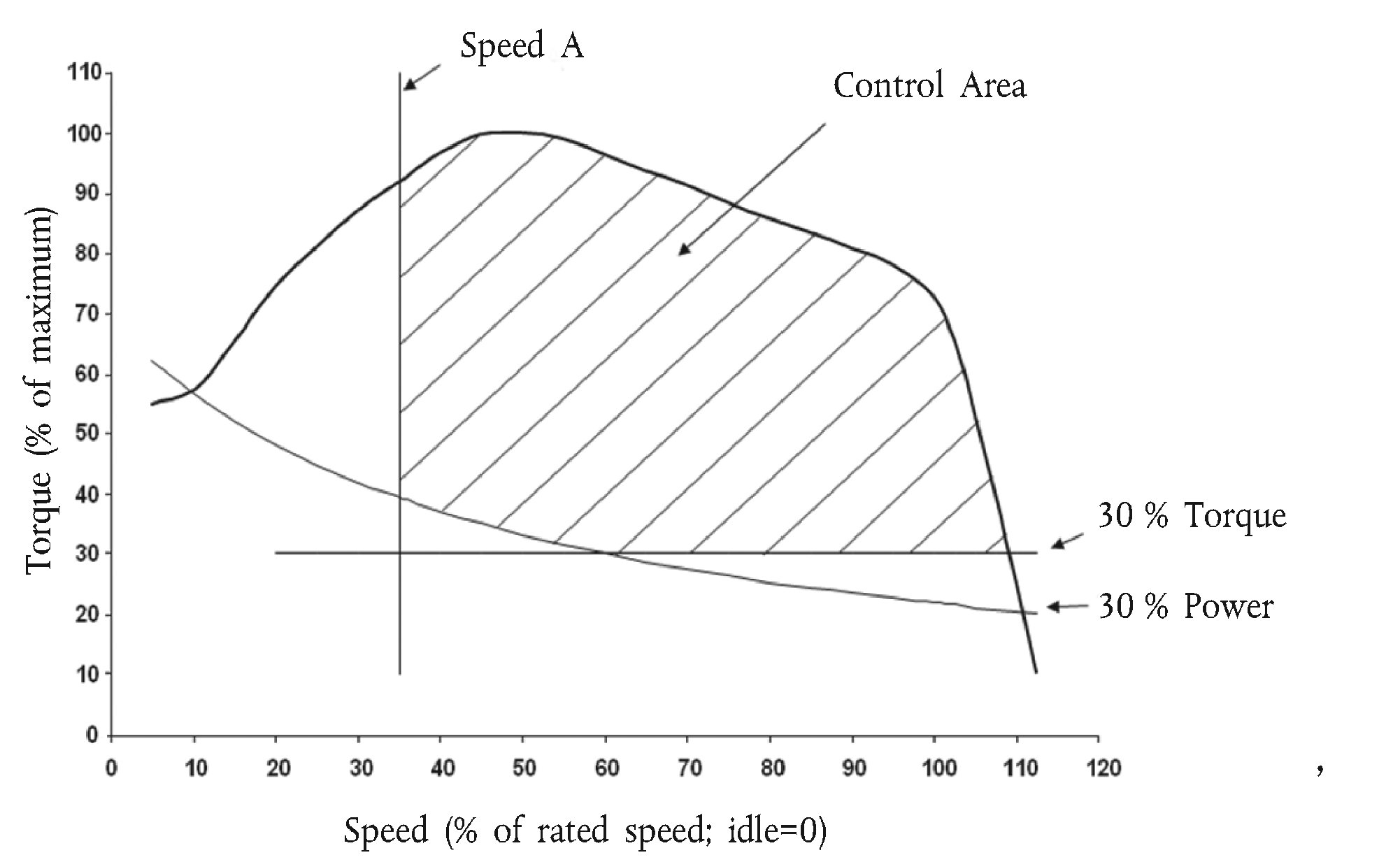

Control Area requirements for stage IV engines

|

|

ANNEX II

|

Information documents

|

|

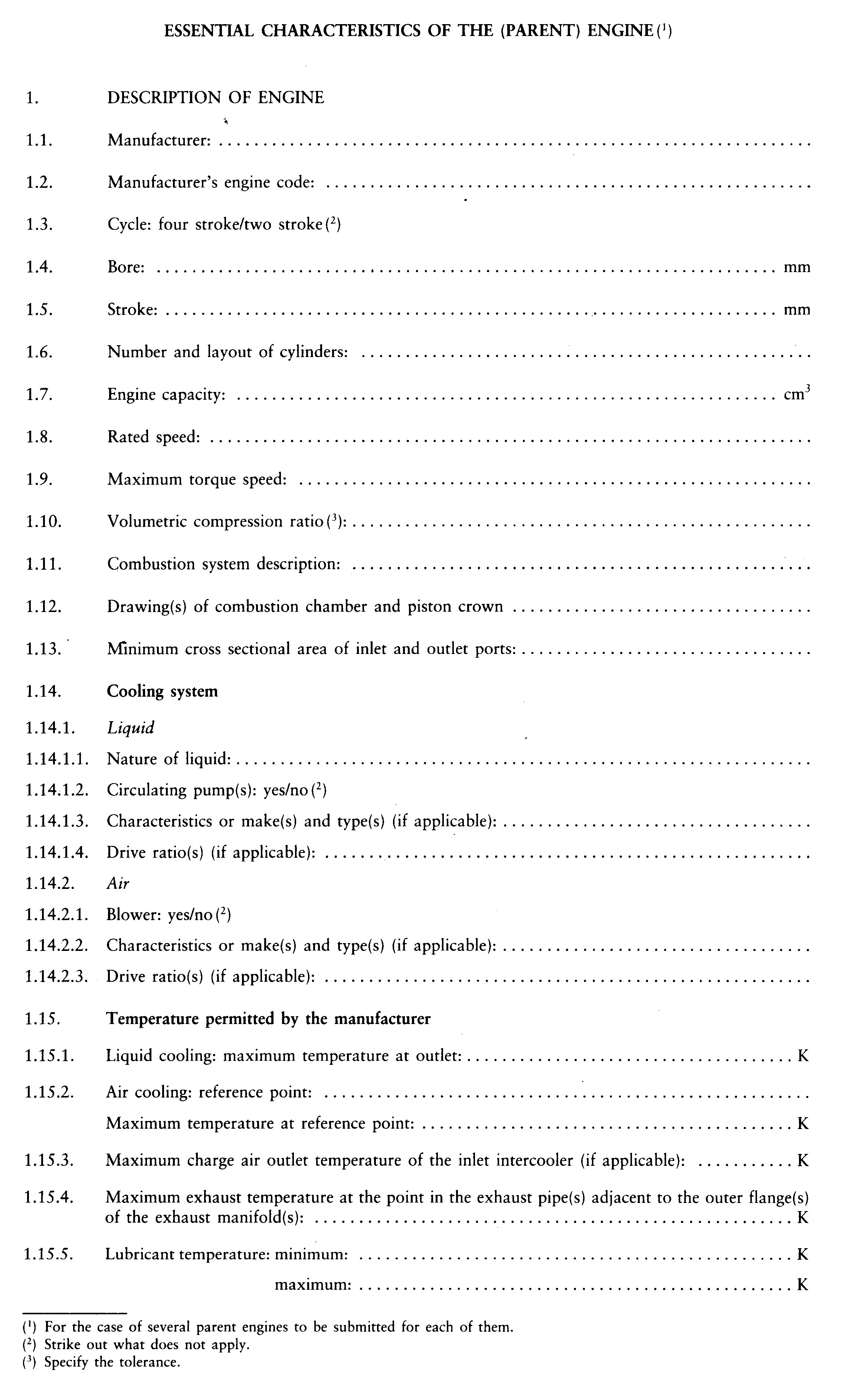

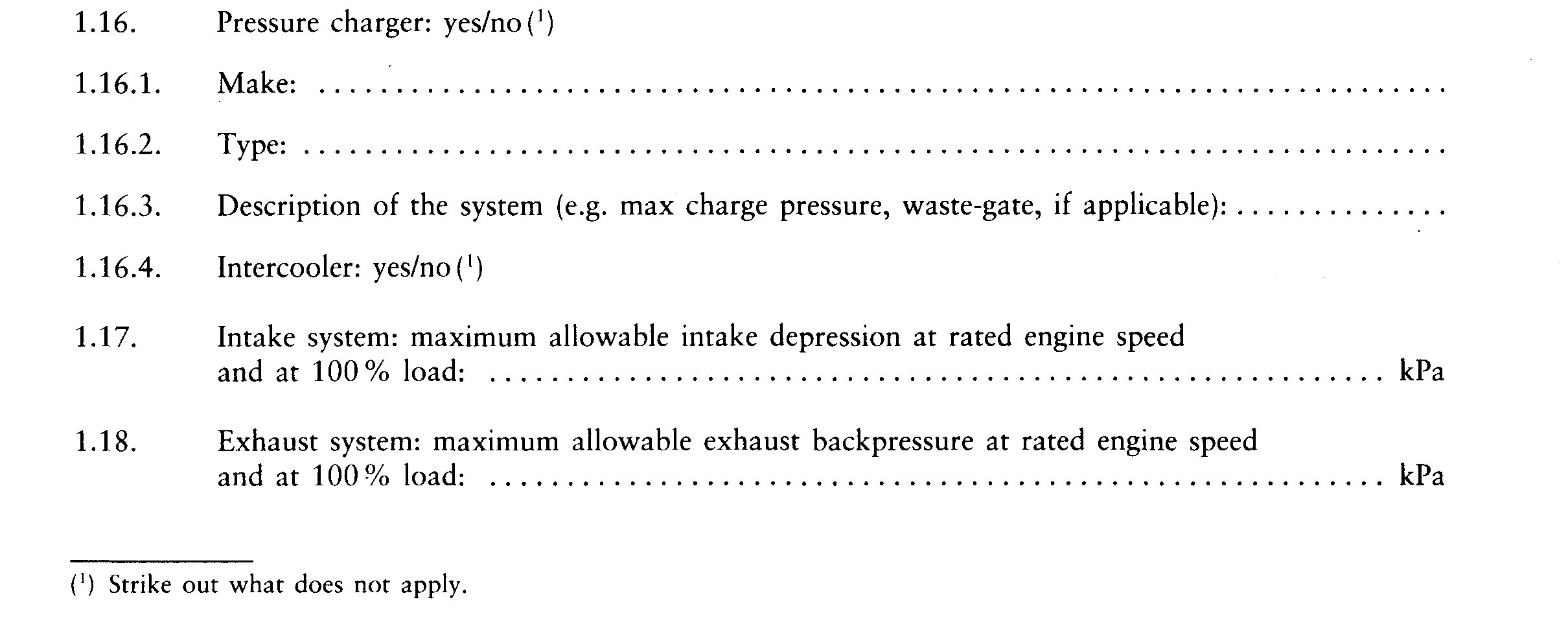

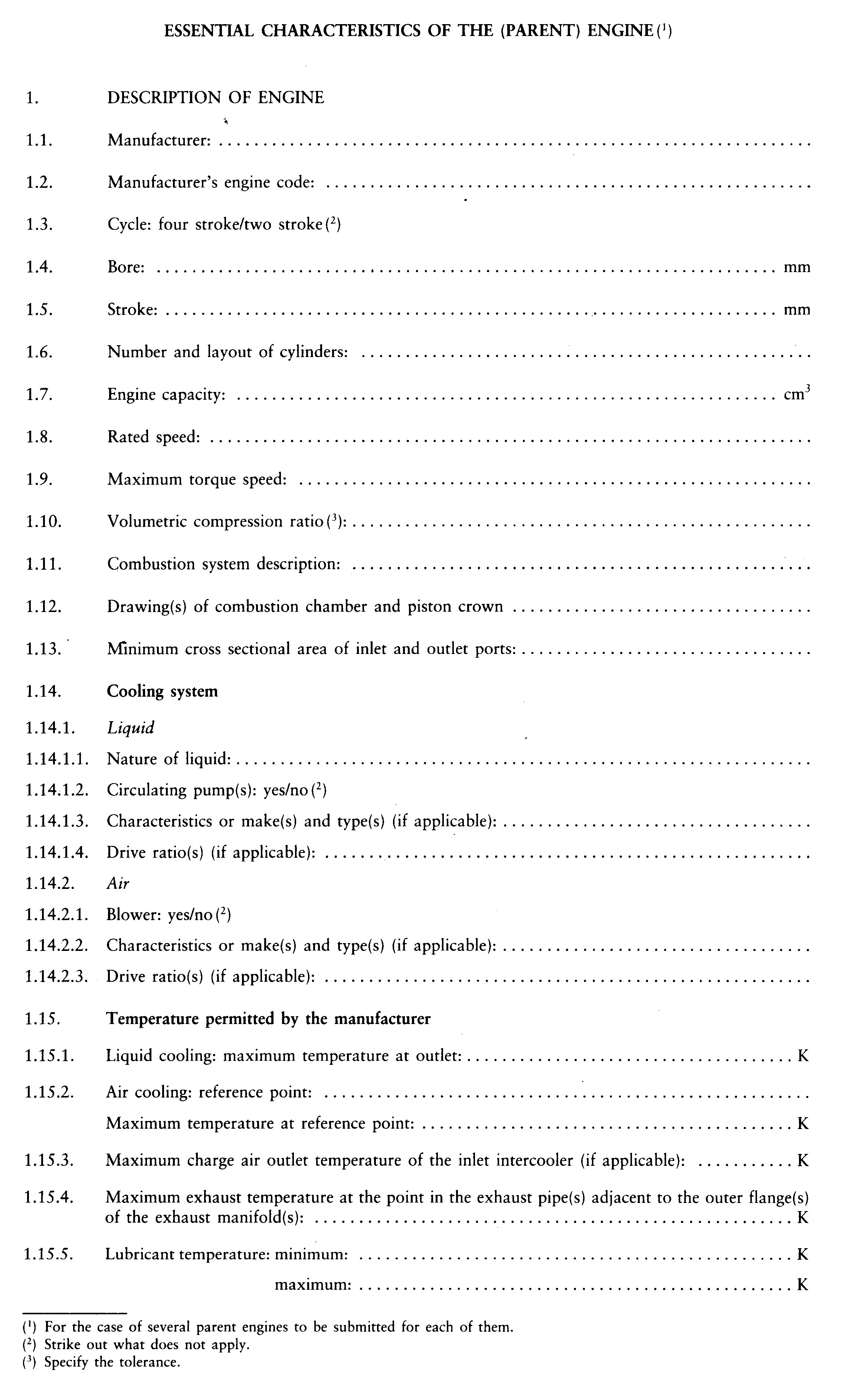

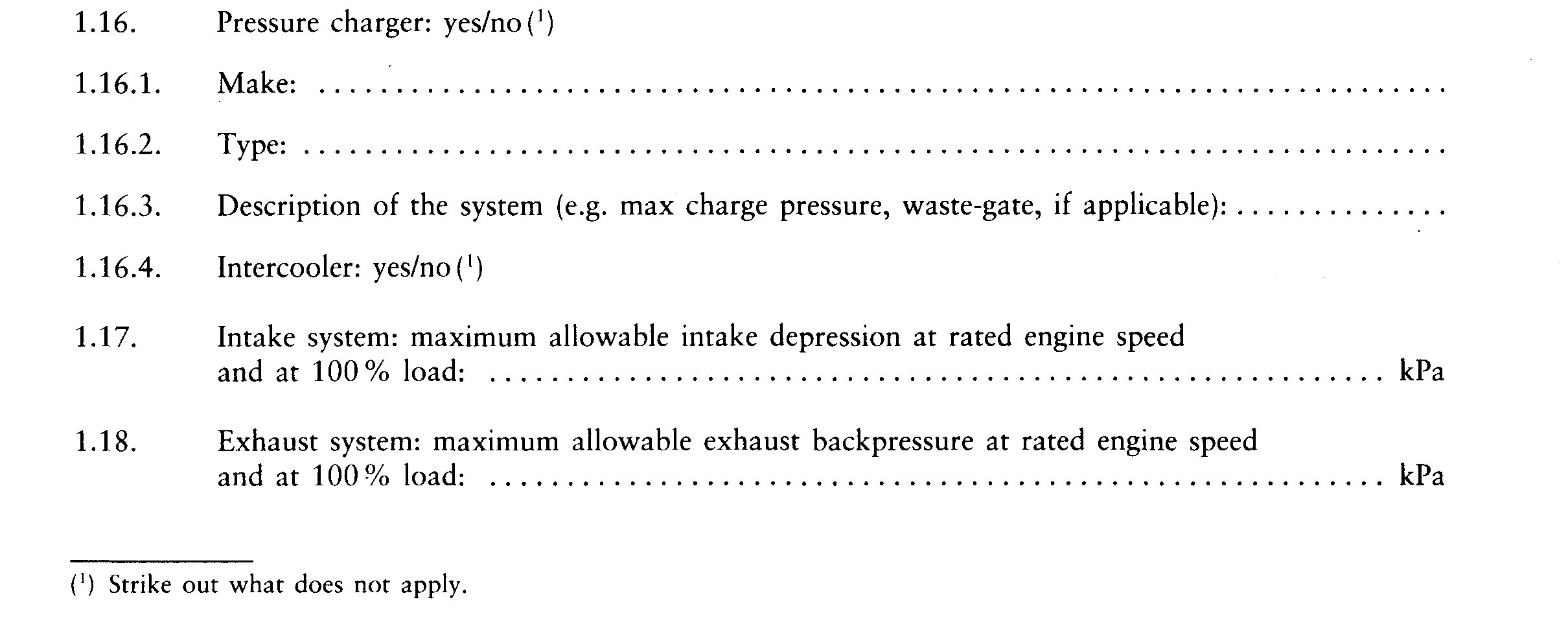

Appendix 1

|

Essential characteristics of the (parent) engine

|

|

Appendix 2

|

Essential characteristics of the engine family

|

|

Appendix 3

|

Essential characteristics of engine type within family

|

|

ANNEX III

|

Test procedure for CI Engines

|

|

▼M3

|

|

Appendix 1

|

Measurement and sampling procedures

|

|

Appendix 2

|

Calibration procedure (NRSC, NRTC(1))

|

|

▼M2

|

|

Appendix 3

|

►M3

►C1

Data evaluation and calculations ◄

◄

|

|

▼M3

|

|

Appendix 4

|

NRTC engine dynamometer schedule

|

|

Appendix 5

|

Durability requirements

|

|

▼M2

|

|

Appendix 6

|

Determination of CO2 Emissions for Stage I, II, IIIA, IIIB and IV Engines

|

|

Appendix 7

|

Alternative determination of CO2 emissions

|

|

ANNEX IV

|

Test procedure — Spark ignition engines

|

|

Appendix 1

|

Measurement and sampling procedures

|

|

Appendix 2

|

Calibration of the analytical instruments

|

|

Appendix 3

|

Data evaluation and calculations

|

|

Appendix 4

|

Deterioration factors

|

|

ANNEX V

|

►M3

►C1

Technical characteristics of reference fuel prescribed for approval tests and to verify conformity of production ◄

◄

|

|

▼M3

|

|

ANNEX VI

|

Analytical and sampling system

|

|

▼M2

|

|

ANNEX VII

|

Type approval certificate

|

|

Appendix 1

|

Test report for compression ignition engines test results

|

|

Appendix 2

|

Test result for SI engines

|

|

Appendix 3

|

Equipment and auxiliaries to be installed for the test to determine engine power

|

|

ANNEX VIII

|

Approval certificate numbering system

|

|

ANNEX IX

|

List of engine/engine family type-approvals issued

|

|

ANNEX X

|

List of engines produced

|

|

ANNEX XI

|

Data sheet of type-approved engines

|

|

ANNEX XII

|

Recognition of alternative type-approvals

|

|

▼M3

|

|

ANNEX XIII

|

PROVISIONS FOR ENGINES PLACED ON THE MARKET UNDER A ‘FLEXIBLE SCHEME’

|

|

ANNEXE XIV

|

|

|

ANNEXE XV

|

|

▼B

ANNEX I

SCOPE, DEFINITIONS, SYMBOLS AND ABBREVIATIONS, ENGINE MARKINGS, SPECIFICATIONS AND TESTS, SPECIFICATION OF CONFORMITY OF PRODUCTION ASSESSMENTS, PARAMETERS DEFINING THE ENGINE FAMILY, CHOICE OF THE PARENT ENGINE

1. SCOPE

▼M2

This Directive applies to all engines to be installed in non-road mobile machinery and to secondary engines fitted into vehicles intended for passenger or goods transport on the road.

▼B

This Directive does not apply to engines for the propulsion of:

— vehicles as defined by Directive 70/156/EEC (

4

), and by Directive 92/61/EEC (

5

),

— agricultural tractors as defined by Directive 74/150/EEC (

6

).

Additionally, in order to be covered by this Directive, the engines have to be installed in machinery which meets the following specific requirements:

▼M3

A. intended and suited, to move, or to be moved with or without road, and with

(i) a C.I. engine having a net power in accordance with section 2.4. that is higher than or equal to 19 kW but not more than 560 kW and that is operated under intermittent speed rather than a single constant speed; or

(ii) a C.I. engine having a net power in accordance with section 2.4. that is higher than or equal to 19 kW but not more than 560 kW and that is operated under constant speed. Limits only apply from 31 December 2006; or

(iii) a petrol fuelled S.I. engine having a net power in accordance with section 2.4. of not more than 19 kW; or

(iv) engines designed for the propulsion of railcars, which are self propelled on-track vehicles specifically designed to carry goods and/or passengers; or

(v) engines designed for the propulsion of locomotives which are self-propelled pieces of on-track equipment designed for moving or propelling cars that are designed to carry freight, passengers and other equipment, but which themselves are not designed or intended to carry freight, passengers (other than those operating the locomotive) or other equipment. Any auxiliary engine or engine intended to power equipment designed to perform maintenance or construction work on the tracks is not classified under this paragraph but under A(i).

▼M2

The Directive is not applicable for the following applications:

▼M3

B. ships, except vessels intended for use on inland waterways;

▼M3 —————

▼M2

E. recreational vehicles, e.g.

▼B

2. DEFINITIONS, SYMBOLS AND ABBREVIATIONS

For the purpose of this Directive,

|

2.1.

|

compression ignition (C.I.) engine shall mean an engine which works on the compression-ignition principle (e.g. diesel engine);

|

|

2.2.

|

gaseous pollutants shall mean carbon monoxide, hydrocarbons (assuming a ratio of C1: H1.85 and oxides of nitrogen, the last named being expressed in nitrogen dioxide (NO2 equivalent;

|

|

2.3.

|

particulate pollutants shall mean any material collected on a specified filter medium after diluting C.I. engine exhaust gas with clean filtered air so that the temperature does not exceed 325 K (52 oC);

|

|

2.4.

|

net power shall mean the power in ‘EEC kW’ obtained on the test bench at the end of the crankshaft, or its equivalent, measured in accordance with the EEC method of measuring the power of internal combustion engines for road vehicles as set out in Directive 80/1269/EEC (

7

), except that the power of the engine cooling fan is excluded (

8

) and the test conditions and reference fuel specified in this Directive are adhered to;

|

|

2.5.

|

rated speed shall mean the maximum full load speed allowed by the governor as specified by the manufacturer;

|

|

2.6.

|

per cent load shall mean the fraction of the maximum available torque at an engine speed;

|

|

2.7.

|

maximum torque speed shall mean the engine speed at which the maximum torque is obtained from the engine, as specified by the manufacturer;

|

|

2.8.

|

intermediate speed shall mean that engine speed which meets one of the following requirements:

— for engines which are designed to operate over a speed range on a full load torque curve, the intermediate speed shall be the declared maximum torque speed if it occurs between 60 % and 75 % of rated speed,

— if the declared maximum torque speed is less than 60 % of rated speed, then the intermediate speed shall be 60 % of the rated speed,

— if the declared maximum torque speed is greater than 75 % of the rated speed then the intermediate speed shall be 75 % of rated speed,

▼M2

— for engines to be tested on cycle G1, the intermediate speed shall be 85 % of the maximum rated speed (see section 3.5.1.2 of Annex IV);

|

▼M3

|

2.8a.

|

volume of 100 m

3

or more with regard to a vessel intended for use on inland waterways means its volume calculated on the formula LxBxT, ‘L’ being the maximum length of the hull, excluding rudder and bowsprit, ‘B’ being the maximum breadth of the hull in metres, measured to the outer edge of the shell plating (excluding paddle wheels, rubbing strakes, etc.) and ‘T’ being the vertical distance between the lowest moulded point of the hull or the keel and the maximum draught line;

|

|

2.8b.

|

valid navigation or safety certificate shall mean:

(a) a certificate proving conformity with the 1974 International Convention for the Safety of Life at Sea (SOLAS), as amended, or equivalent, or

(b) a certificate proving conformity with the 1966 International Convention on Load Lines, as amended, or equivalent, and an IOPP certificate proving conformity with the 1973 International Convention for the Prevention of Pollution from Ships (MARPOL), as amended;

|

|

2.8c.

|

defeat device shall mean a device which measures, senses or responds to operating variables for the purpose of activating, modulating, delaying or deactivating the operation of any component or function of the emission control system such that the effectiveness of the control system is reduced under conditions encountered during the normal non-road mobile machinery use unless the use of such a device is substantially included in the applied emission test certification procedure;

|

|

2.8d.

|

irrational control strategy shall mean any strategy or measure that, when the non-road mobile machinery is operated under normal conditions of use, reduces the effectiveness of the emission control system to a level below that expected in the applicable emission test procedures;

|

▼M2

|

2.9.

|

adjustable parameter shall mean any physically adjustable device, system or element of design which may affect emission or engine performance during emission testing or normal operation;

|

|

2.10.

|

after-treatment shall mean the passage of exhaust gases through a device or system whose purpose is chemically or physically to alter the gases prior to release to the atmosphere;

|

|

2.11.

|

spark ignition (SI) engine shall mean an engine which works on the spark-ignition principle;

|

|

2.12.

|

auxiliary emission control device shall mean any device that senses engine operation parameters for the purpose of adjusting the operation of any part of the emission control system;

|

|

2.13.

|

emission control system shall mean any device, system or element of design which controls or reduces emissions;

|

|

2.14.

|

fuel system shall mean all components involved in the metering and mixture of the fuel;

|

|

2.15.

|

secondary engine shall mean an engine installed in or on a motor vehicle, but not providing motive power to the vehicle;

|

|

2.16.

|

mode length means the time between leaving the speed and/or torque of the previous mode or the preconditioning phase and the beginning of the following mode. It includes the time during which speed and/or torque are changed and the stabilisation at the beginning of each mode;

|

▼M3

|

2.17.

|

test cycle shall mean a sequence of test points, each with a defined speed and torque, to be followed by the engine under steady state (NRSC test) or transient operating conditions (NRTC test);

|

▼M3

|

2.18.

|

Symbols and abbreviations 2.18.1. Symbols for test parameters

|

Symbol

|

Unit

|

Term

|

|

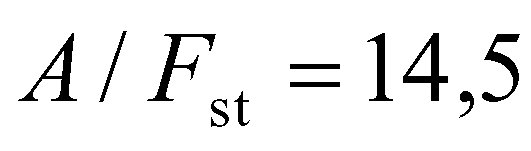

A/Fst

|

-

|

Stoichiometric air/fuel ratio

|

|

AP

|

m2

|

Cross sectional area of the isokinetic sampling probe

|

|

AT

|

m2

|

Cross sectional area of the exhaust pipe

|

|

Aver

|

|

Weighted average values for:

|

|

m3/h

|

— volume flow

|

|

kg/h

|

— mass flow

|

|

C1

|

-

|

Carbon 1 equivalent hydrocarbon

|

|

Cd

|

-

|

Discharge coefficient of the SSV

|

|

Conc

|

ppm

|

Concentration (with suffix of the component nominating)

|

|

Concc

|

ppm

|

Background corrected concentration

|

|

Concd

|

ppm

|

Concentration of the pollutant measured in the dilution air

|

|

Conce

|

ppm

|

Concentration of the pollutant measured in the diluted exhaust gas

|

|

d

|

m

|

Diameter

|

|

DF

|

-

|

Dilution factor

|

|

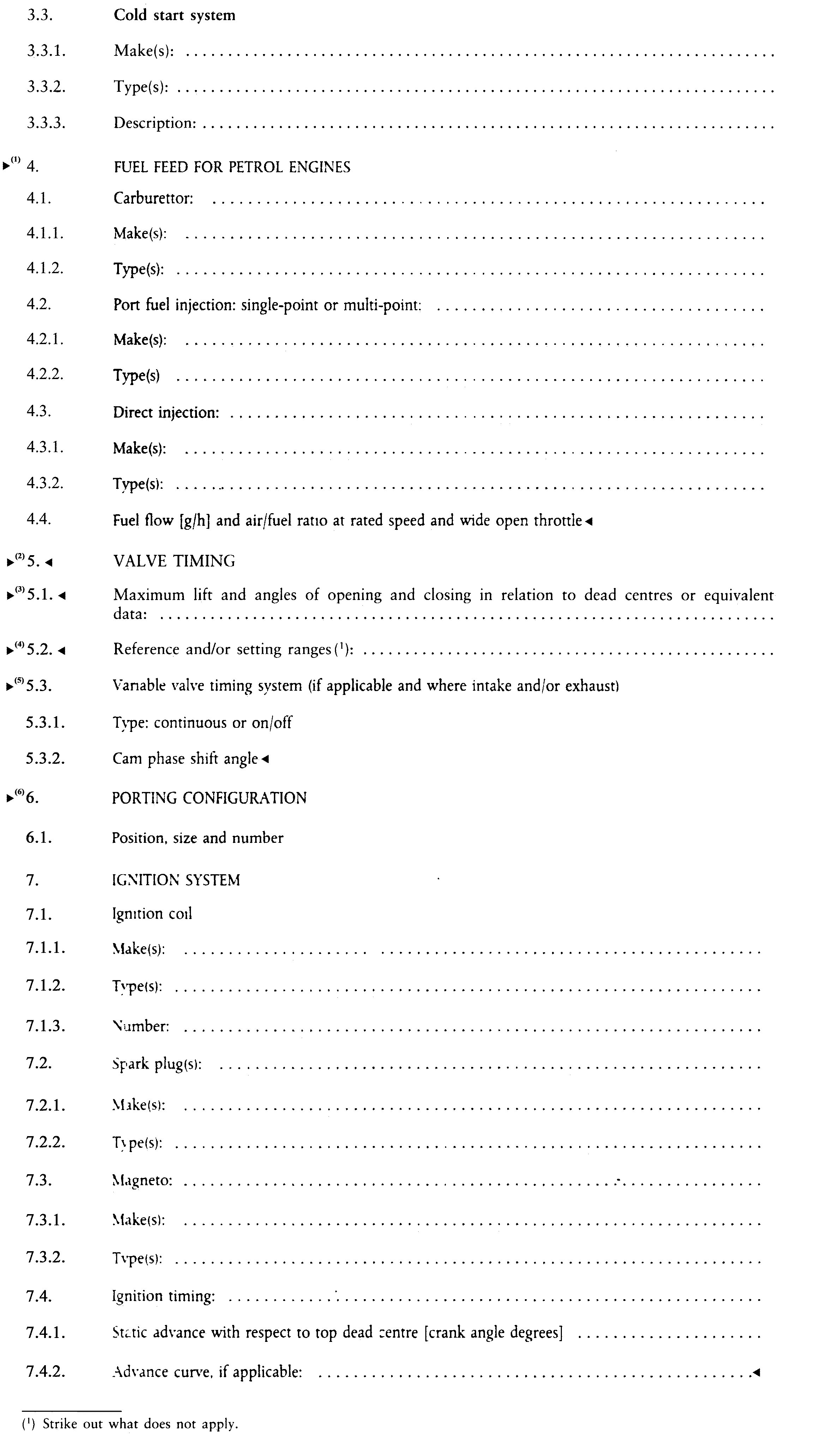

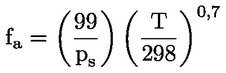

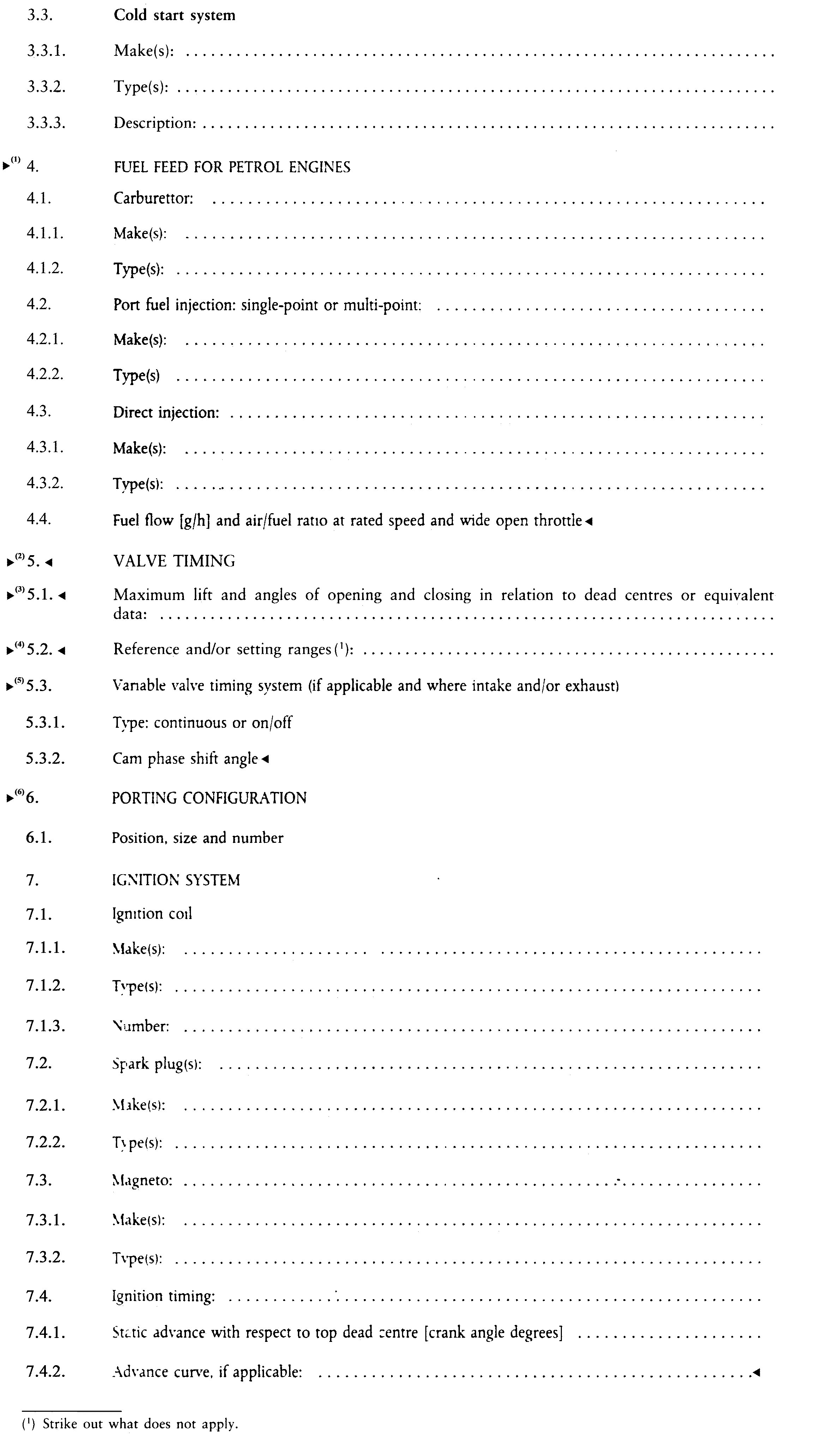

fa

|

-

|

Laboratory atmospheric factor

|

|

GAIRD

|

kg/h

|

Intake air mass flow rate on dry basis

|

|

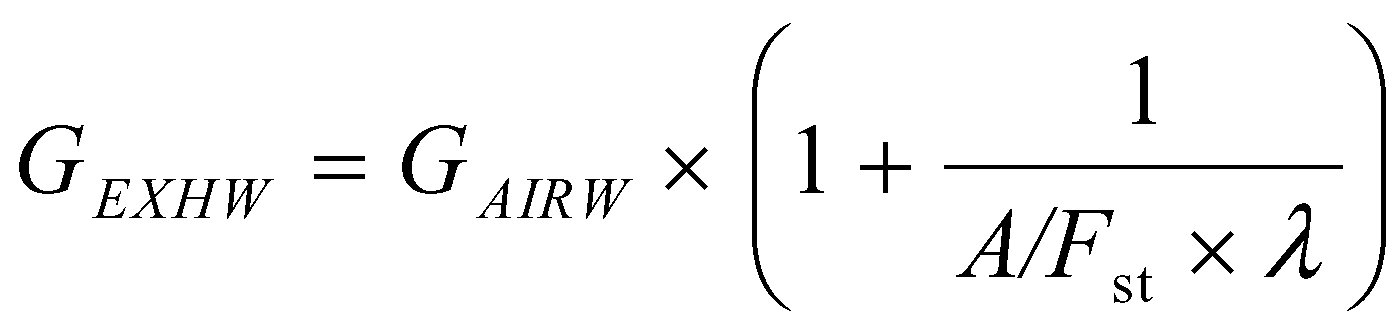

GAIRW

|

kg/h

|

Intake air mass flow rate on wet basis

|

|

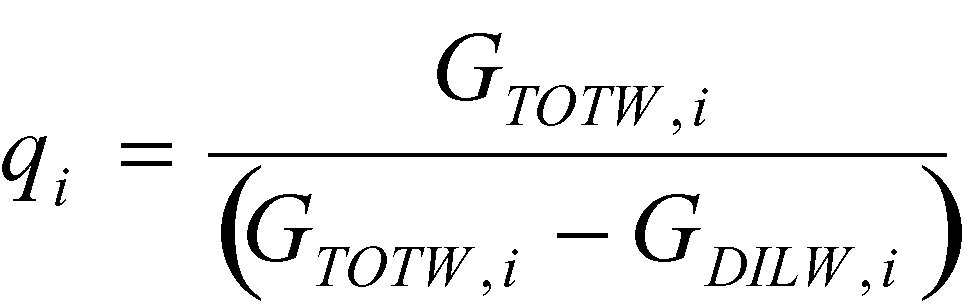

GDILW

|

kg/h

|

Dilution air mass flow rate on wet basis

|

|

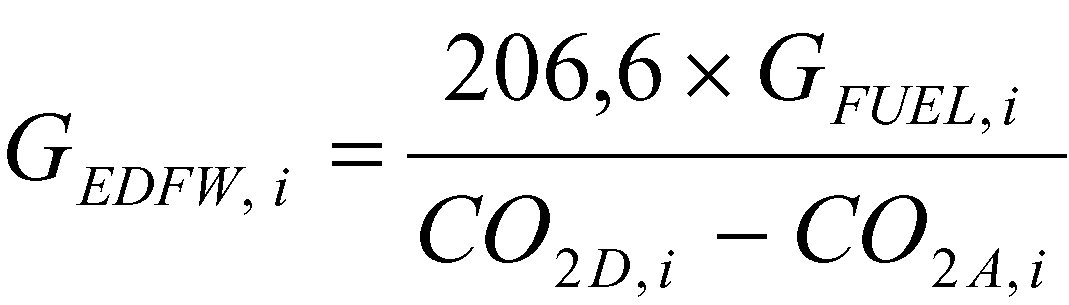

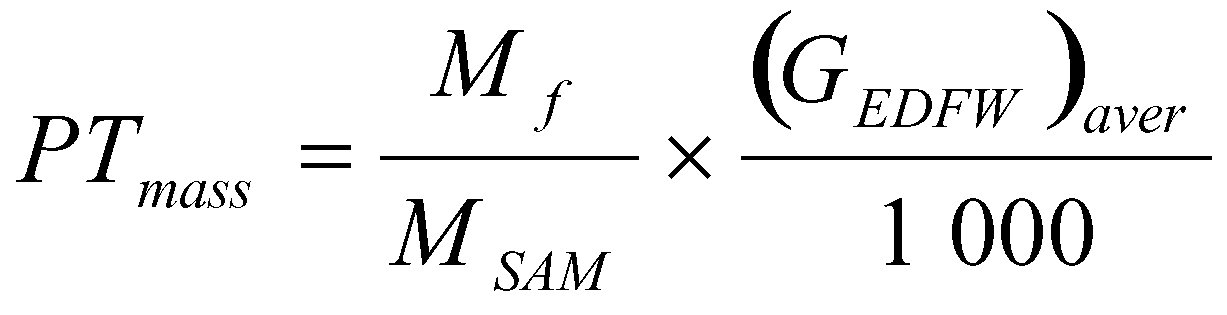

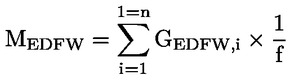

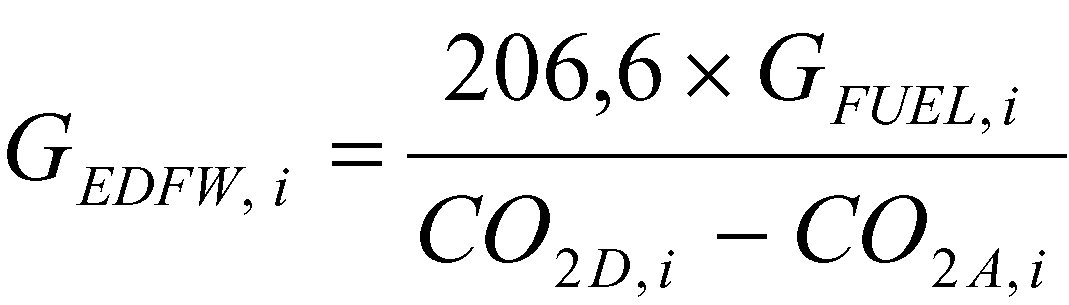

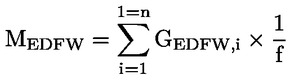

GEDFW

|

kg/h

|

Equivalent diluted exhaust gas mass flow rate on wet basis

|

|

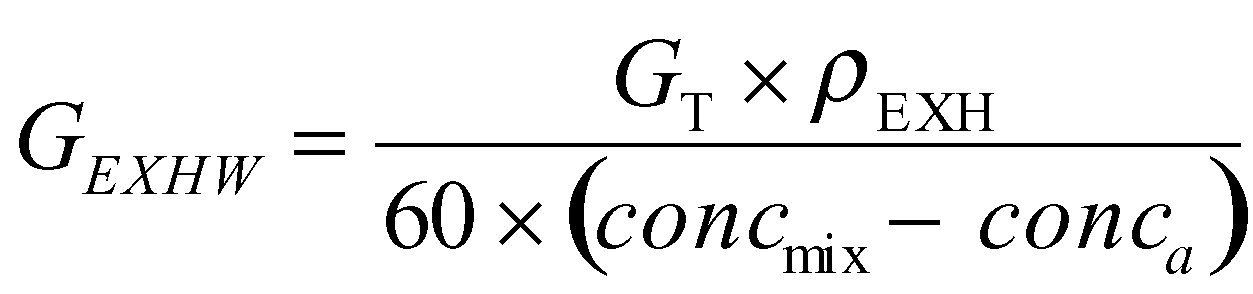

GEXHW

|

kg/h

|

Exhaust gas mass flow rate on wet basis

|

|

GFUEL

|

kg/h

|

Fuel mass flow rate

|

|

GSE

|

kg/h

|

Sampled exhaust mass flow rate

|

|

GT

|

cm3/min

|

Tracer gas flow rate

|

|

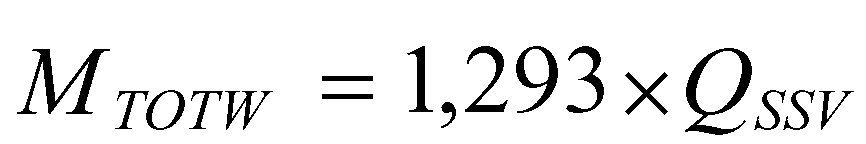

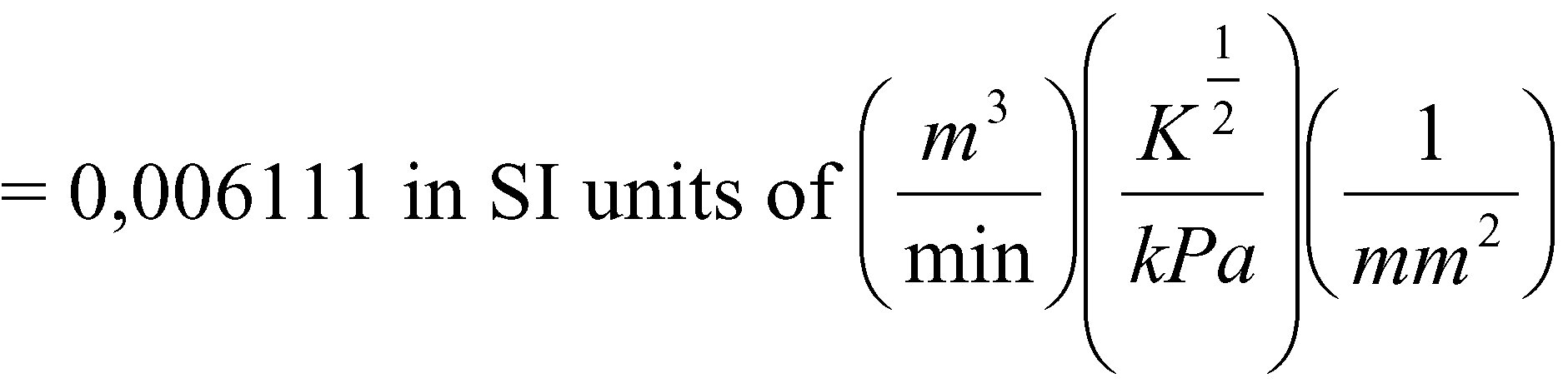

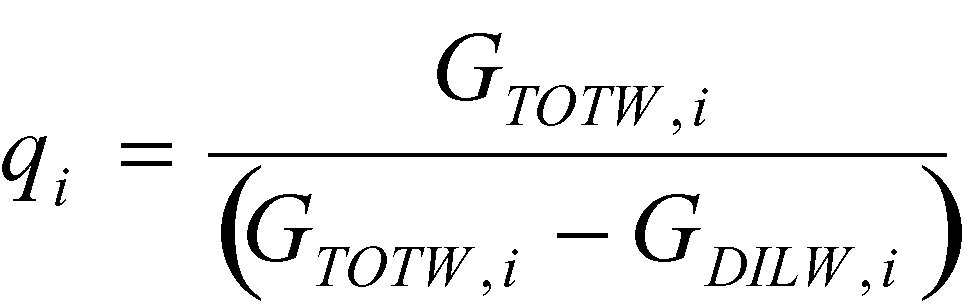

GTOTW

|

kg/h

|

Diluted exhaust gas mass flow rate on wet basis

|

|

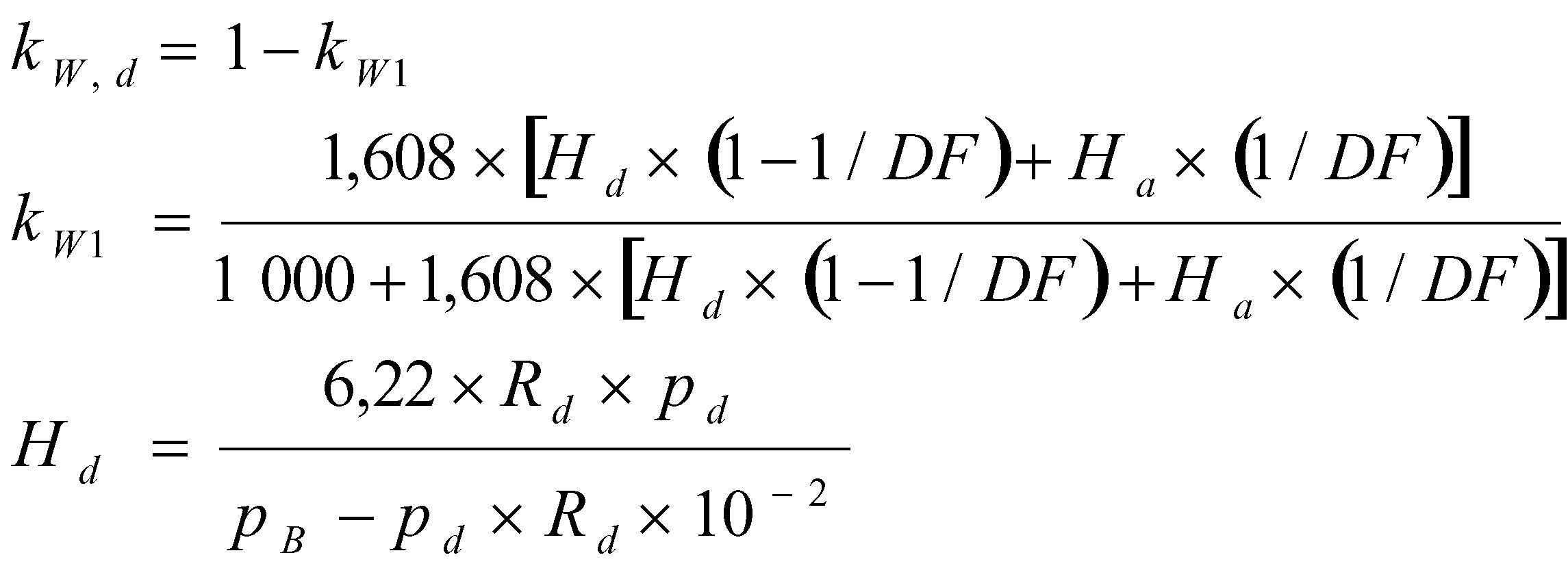

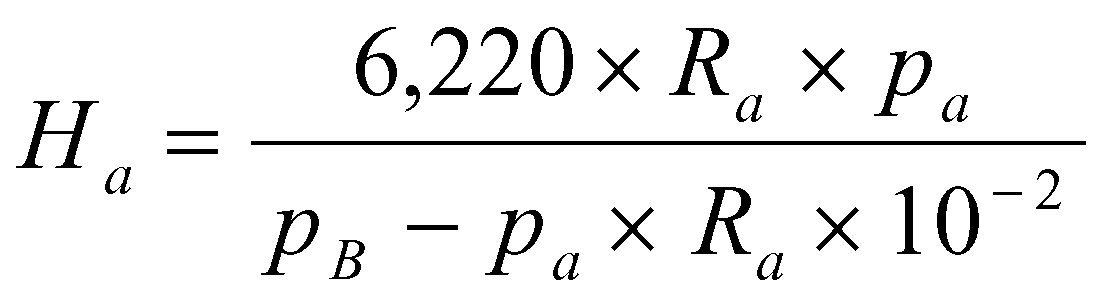

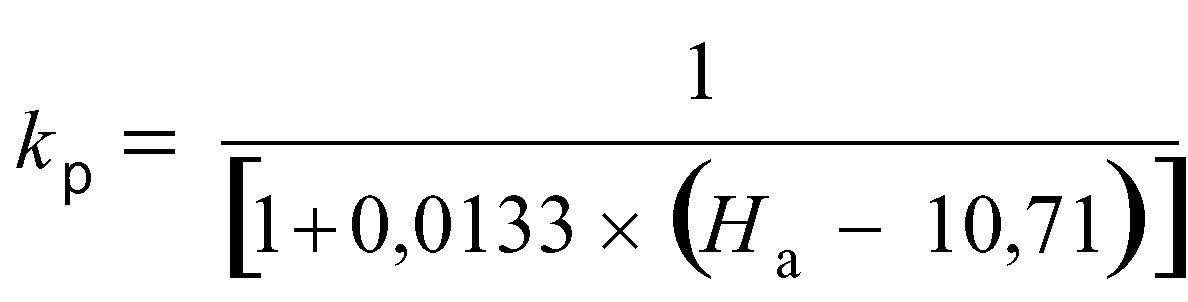

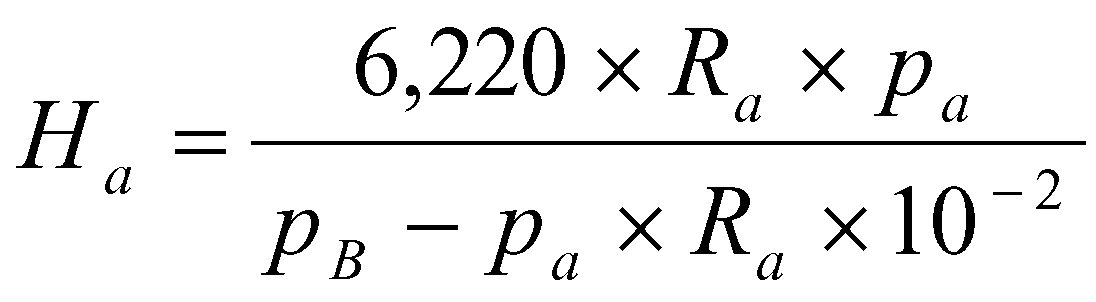

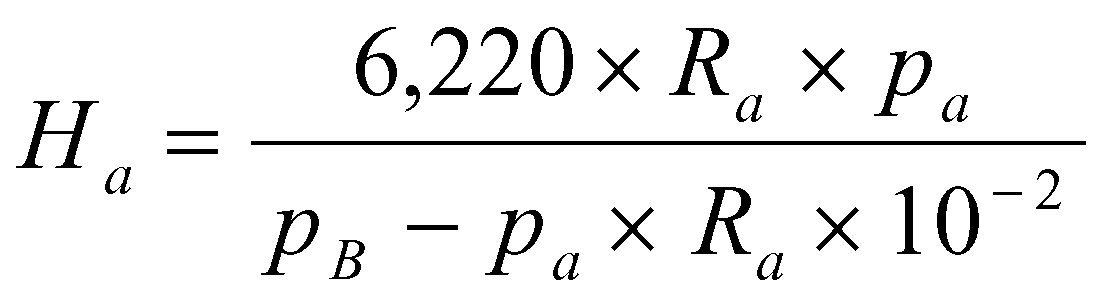

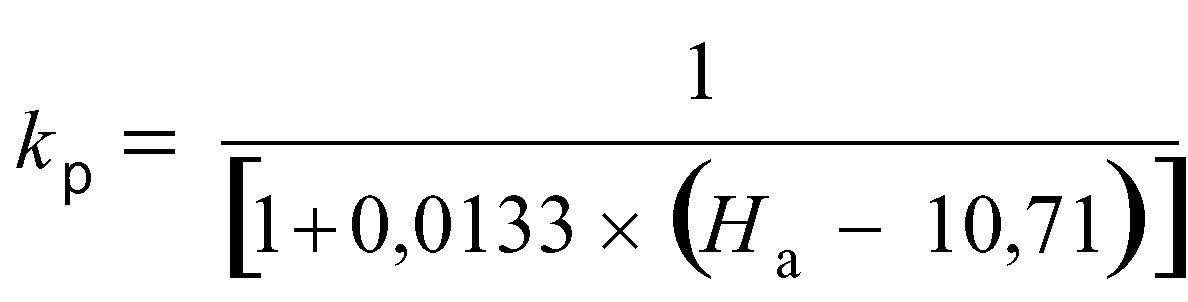

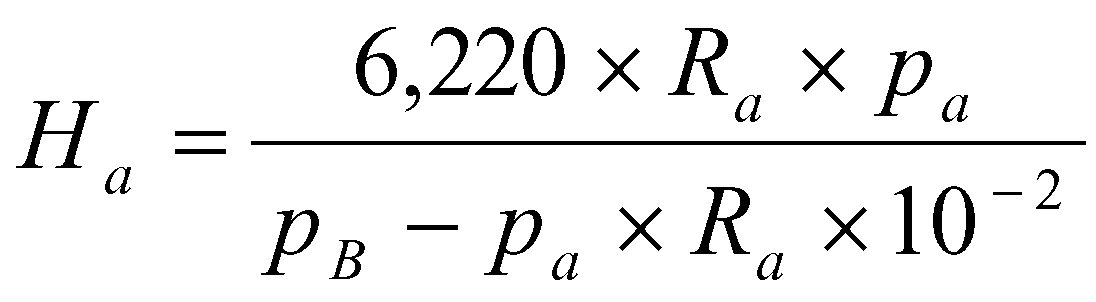

Ha

|

g/kg

|

Absolute humidity of the intake air

|

|

Hd

|

g/kg

|

Absolute humidity of the dilution air

|

|

HREF

|

g/kg

|

Reference value of absolute humidity (10,71 g/kg)

|

|

i

|

-

|

Subscript denoting an individual mode (for NRSC test)or an instantaneous value (for NRTC test)

|

|

KH

|

-

|

Humidity correction factor for NOx

|

|

Kp

|

-

|

Humidity correction factor for particulate

|

|

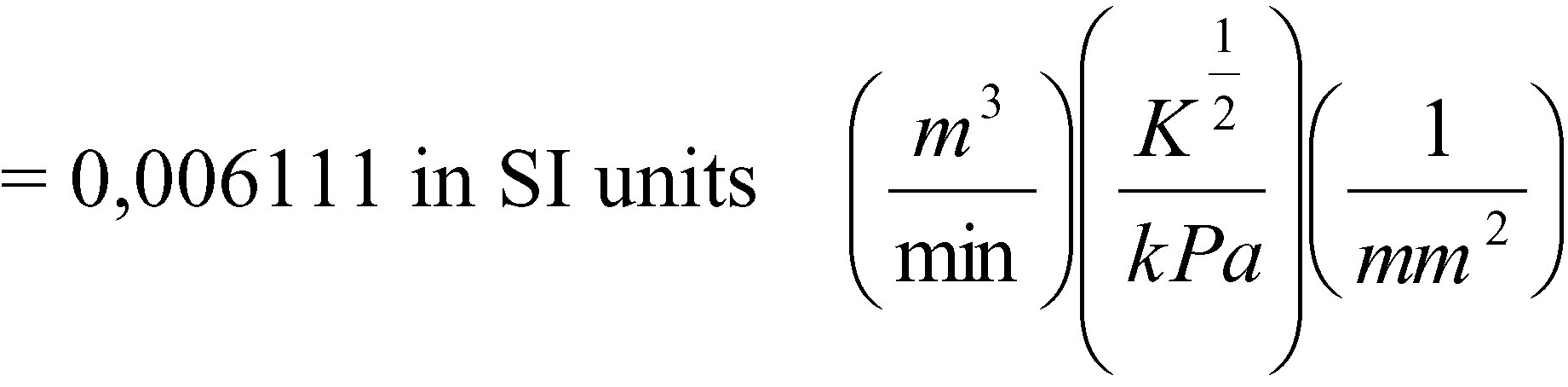

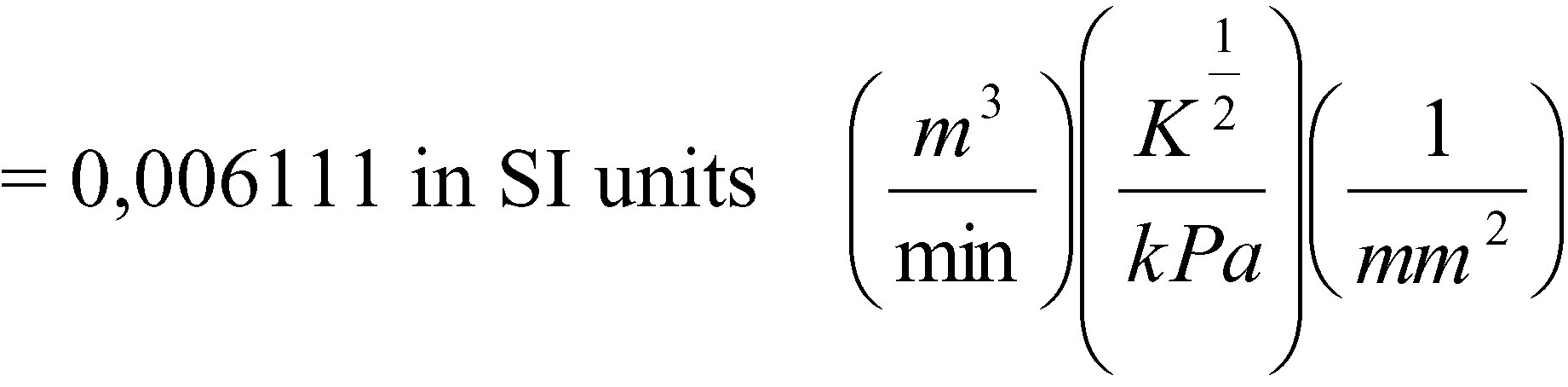

KV

|

-

|

CFV calibration function

|

|

KW, a

|

-

|

Dry to wet correction factor for the intake air

|

|

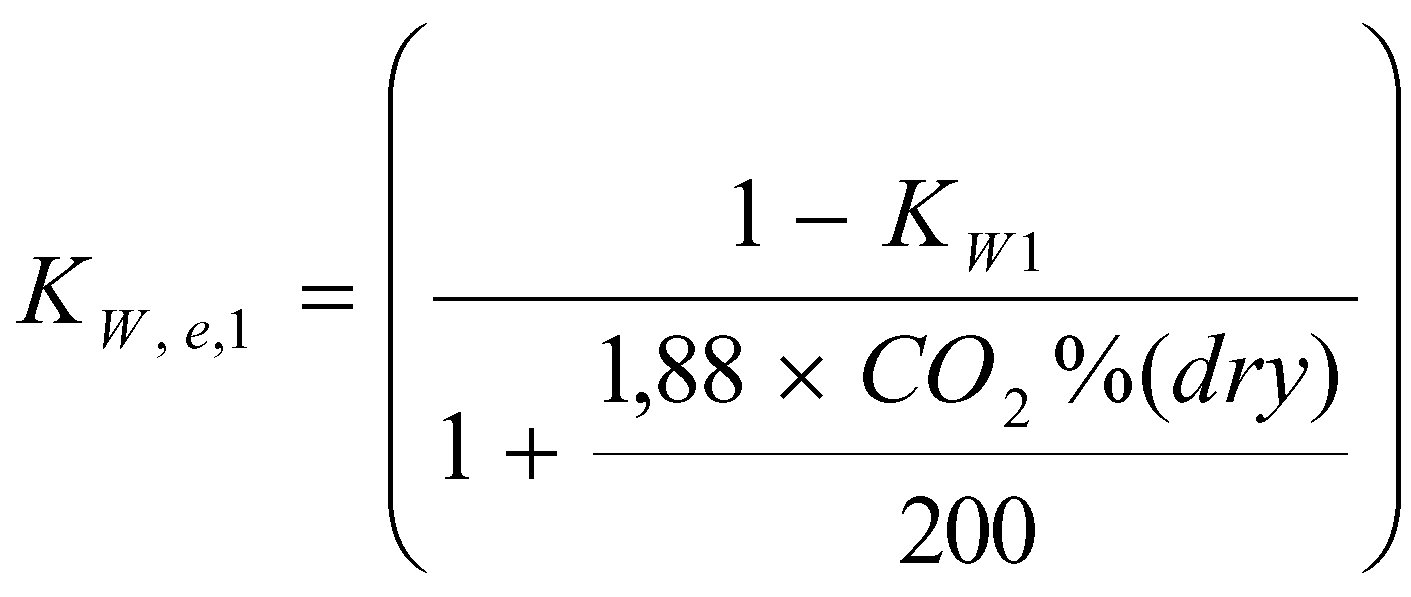

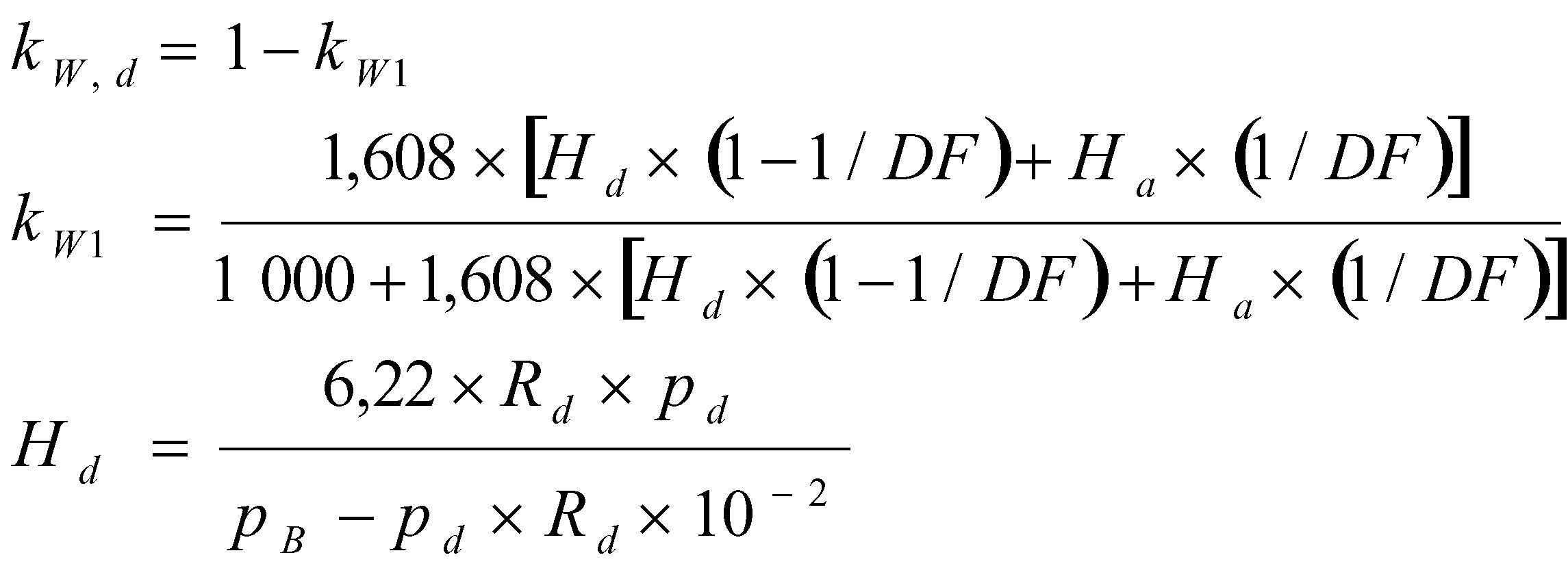

KW, d

|

-

|

Dry to wet correction factor for the dilution air

|

|

KW, e

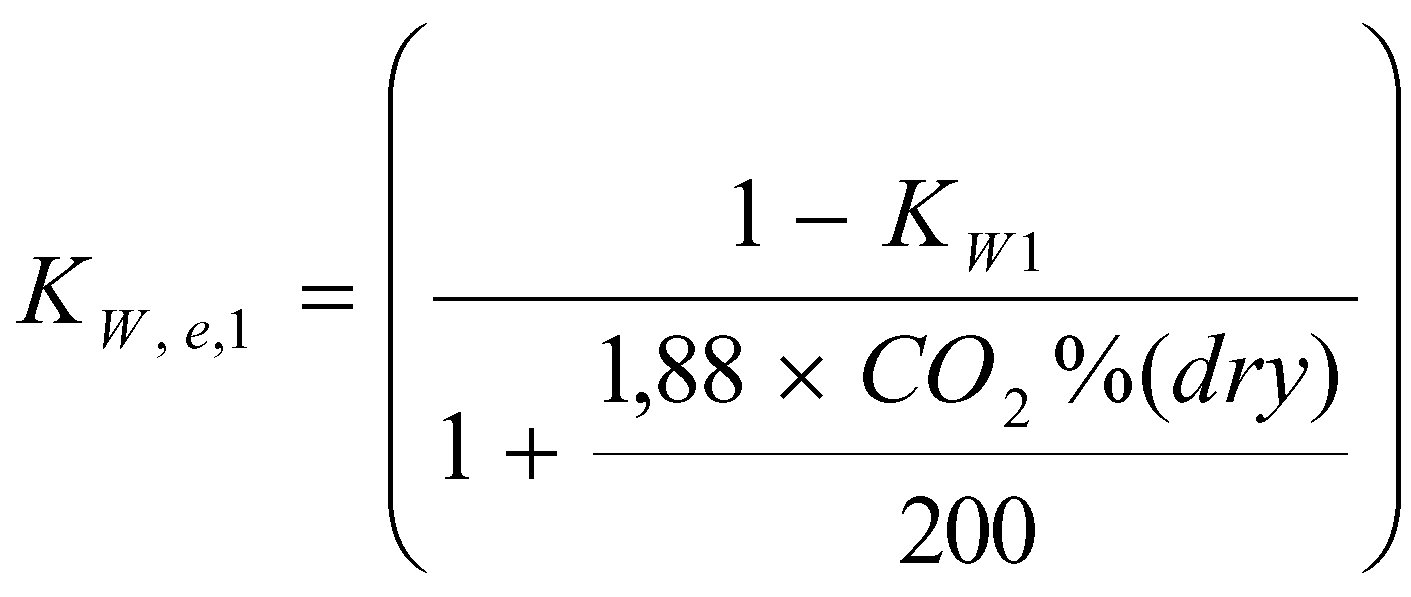

|

-

|

Dry to wet correction factor for the diluted exhaust gas

|

|

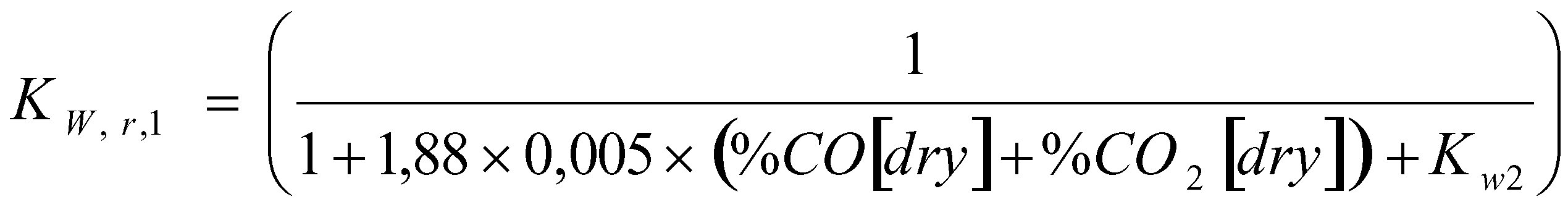

KW, r

|

-

|

Dry to wet correction factor for the raw exhaust gas

|

|

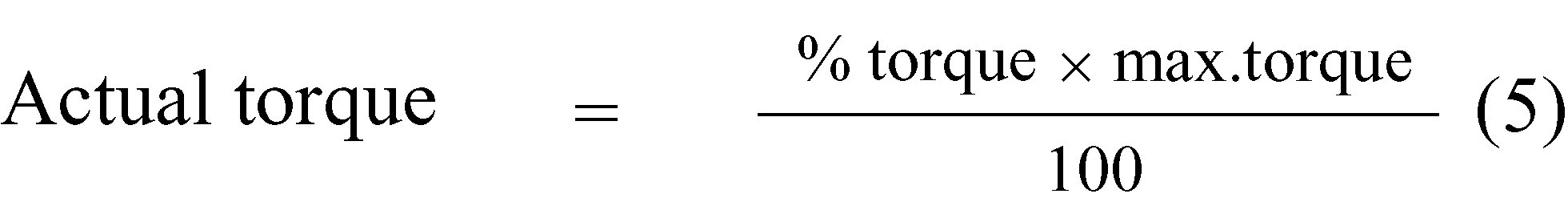

L

|

%

|

Percent torque related to the maximum torque for the test speed

|

|

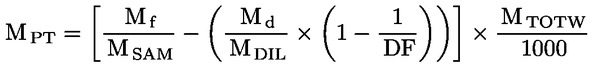

Md

|

mg

|

Particulate sample mass of the dilution air collected

|

|

MDIL

|

kg

|

Mass of the dilution air sample passed through the particulate sampling filters

|

|

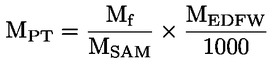

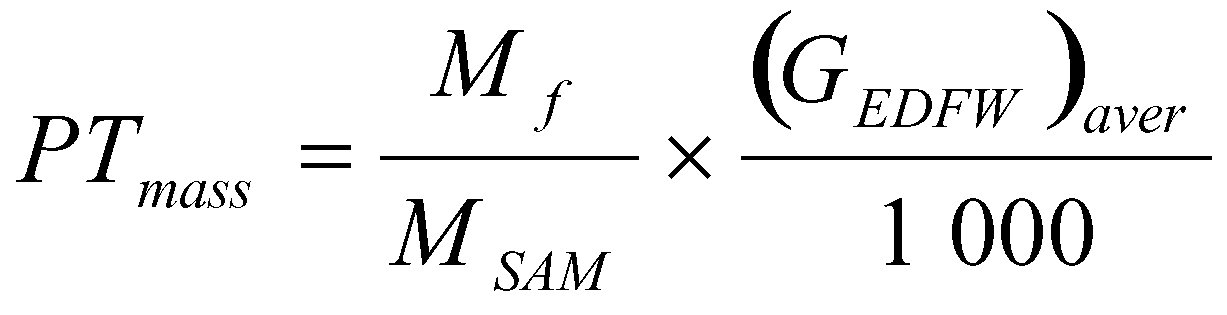

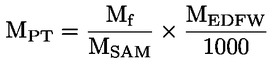

MEDFW

|

kg

|

Mass of equivalent diluted exhaust gas over the cycle

|

|

MEXHW

|

kg

|

Total exhaust mass flow over the cycle

|

|

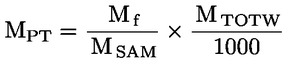

Mf

|

mg

|

Particulate sample mass collected

|

|

Mf,p

|

mg

|

Particulate sample mass collected on primary filter

|

|

Mf,b

|

mg

|

Particulate sample mass collected on back-up filter

|

|

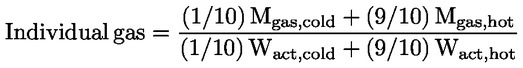

Mgas

|

g

|

Total mass of gaseous pollutant over the cycle

|

|

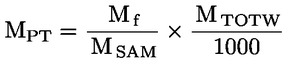

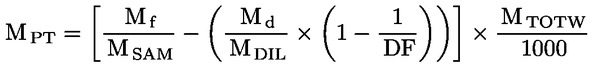

MPT

|

g

|

Total mass of particulate over the cycle

|

|

MSAM

|

kg

|

Mass of the diluted exhaust sample passed through the particulate sampling filters

|

|

MSE

|

kg

|

Sampled exhaust mass over the cycle

|

|

MSEC

|

kg

|

Mass of secondary dilution air

|

|

MTOT

|

kg

|

Total mass of double diluted exhaust over the cycle

|

|

MTOTW

|

kg

|

Total mass of diluted exhaust gas passing the dilution tunnel over the cycle on wet basis

|

|

MTOTW,I

|

kg

|

Instantaneous mass of diluted exhaust gas passing the dilution tunnel on wet basis

|

|

mass

|

g/h

|

Subscript denoting emissions mass flow (rate)

|

|

NP

|

-

|

Total revolutions of PDP over the cycle

|

|

nref

|

min-1

|

Reference engine speed for NRTC test

|

|

nsp

|

s-2

|

Derivative of the engine speed

|

|

P

|

kW

|

Power, brake uncorrected

|

|

p1

|

kPa

|

Pressure drop below atmospheric at the pump inlet of PDP

|

|

PA

|

kPa

|

Absolute pressure

|

|

Pa

|

kPa

|

Saturation vapour pressure of the engine intake air (ISO 3046: psy=PSY test ambient)

|

|

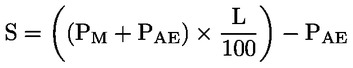

PAE

|

kW

|

Declared total power absorbed by auxiliaries fitted for the test which are not required by paragraph 2.4. of this Annex

|

|

PB

|

kPa

|

Total atmospheric pressure (ISO 3046: Px=PX Site ambient total pressure Py=PY Test ambient total pressure)

|

|

pd

|

kPa

|

Saturation vapour pressure of the dilution air

|

|

PM

|

kW

|

Maximum power at the test speed under test conditions (see Annex VII, Appendix 1)

|

|

Pm

|

kW

|

Power measured on test bed

|

|

ps

|

kPa

|

Dry atmospheric pressure

|

|

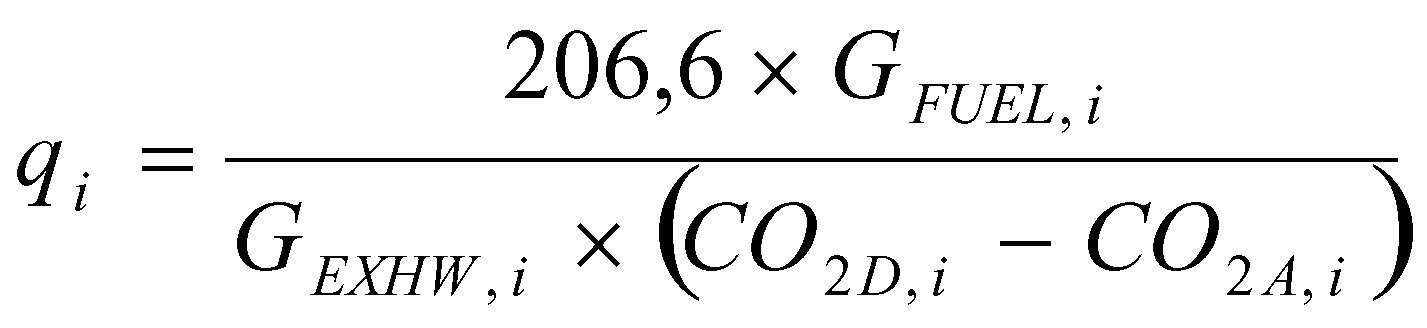

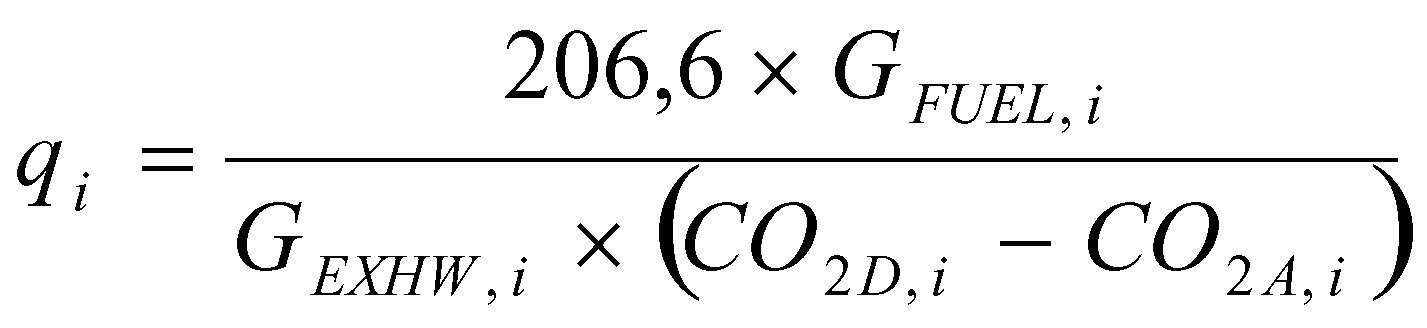

q

|

-

|

Dilution ratio

|

|

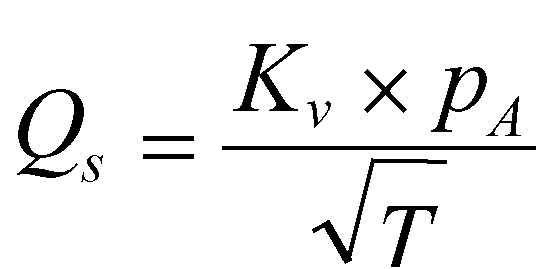

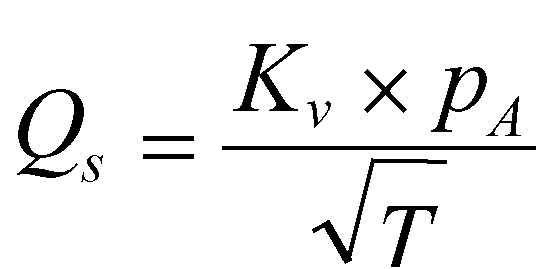

Qs

|

m3/s

|

CVS volume flow rate

|

|

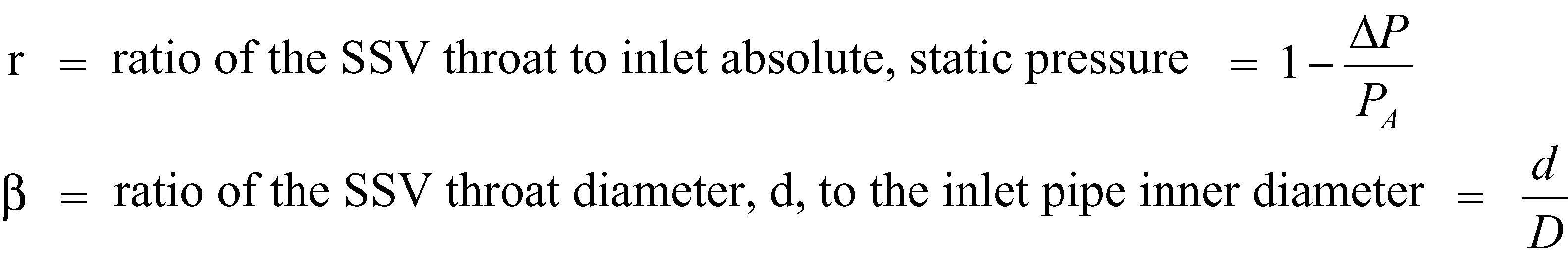

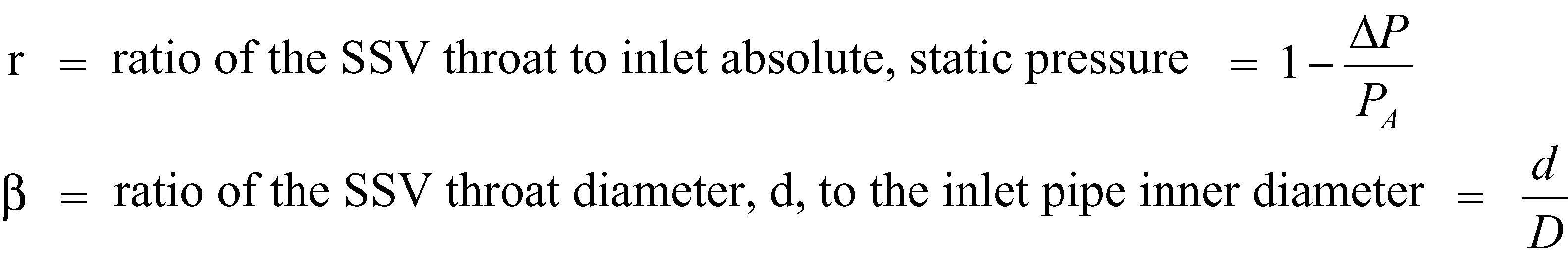

r

|

-

|

Ratio of the SSV throat to inlet absolute, static pressure

|

|

r

|

|

Ratio of cross sectional areas of isokinetic probe and exhaust pipe

|

|

Ra

|

%

|

Relative humidity of the intake air

|

|

Rd

|

%

|

Relative humidity of the dilution air

|

|

Re

|

-

|

Reynolds number

|

|

Rf

|

-

|

FID response factor

|

|

T

|

K

|

Absolute temperature

|

|

t

|

s

|

Measuring time

|

|

Ta

|

K

|

Absolute temperature of the intake air

|

|

TD

|

K

|

Absolute dew point temperature

|

|

Tref

|

K

|

Reference temperature of combustion air: (298 K)

|

|

Tsp

|

N·m

|

Demanded torque of the transient cycle

|

|

t10

|

s

|

Time between step input and 10 % of final reading

|

|

t50

|

s

|

Time between step input and 50 % of final reading

|

|

t90

|

s

|

Time between step input and 90 % of final reading

|

|

Δti

|

s

|

Time interval for instantaneous CFV flow

|

|

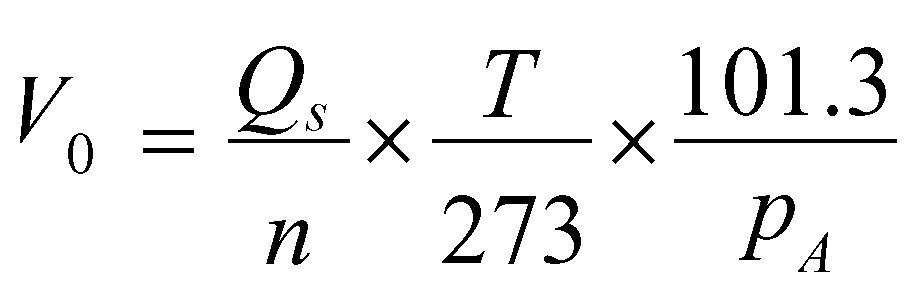

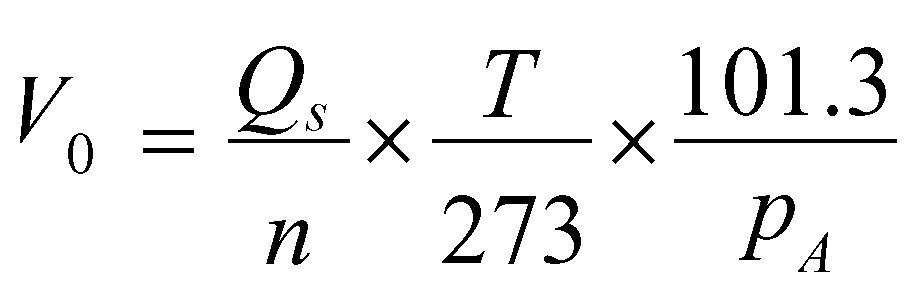

V0

|

m3/rev

|

PDP volume flow rate at actual conditions

|

|

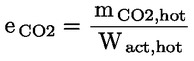

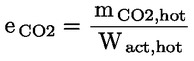

Wact

|

kWh

|

Actual cycle work of NRTC

|

|

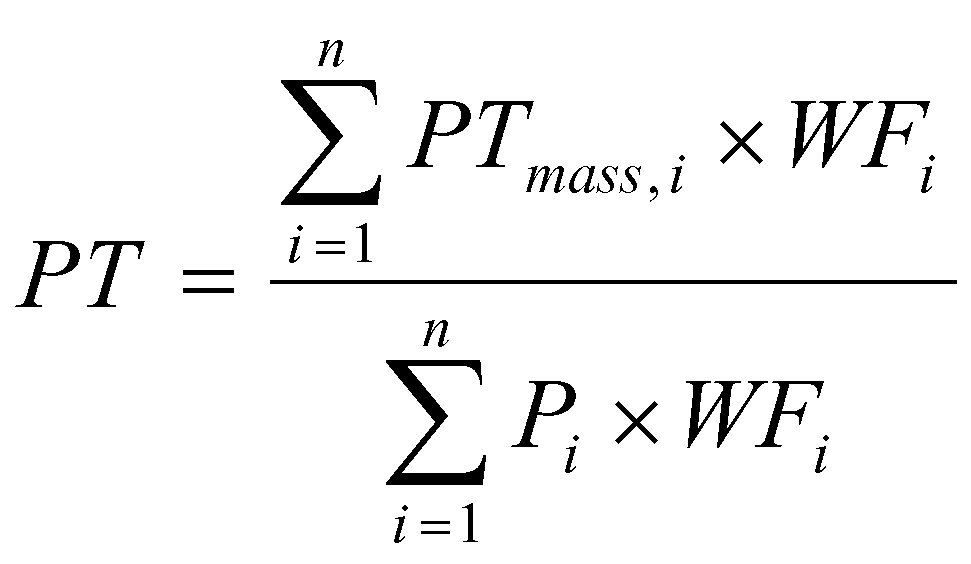

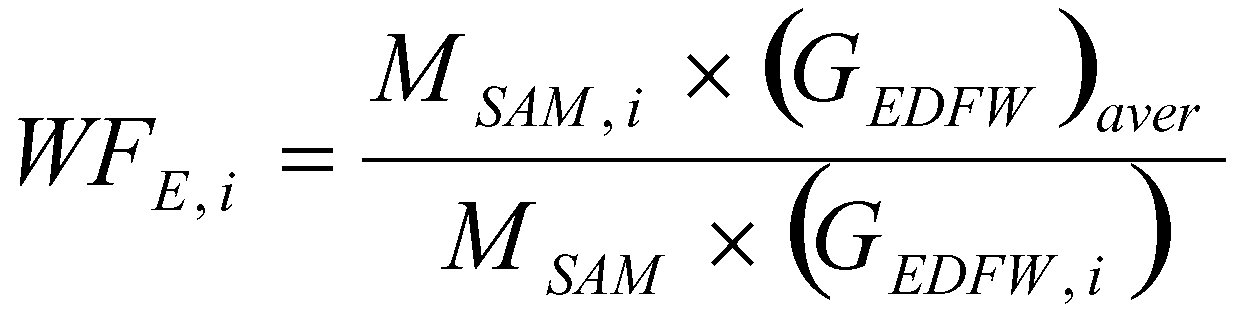

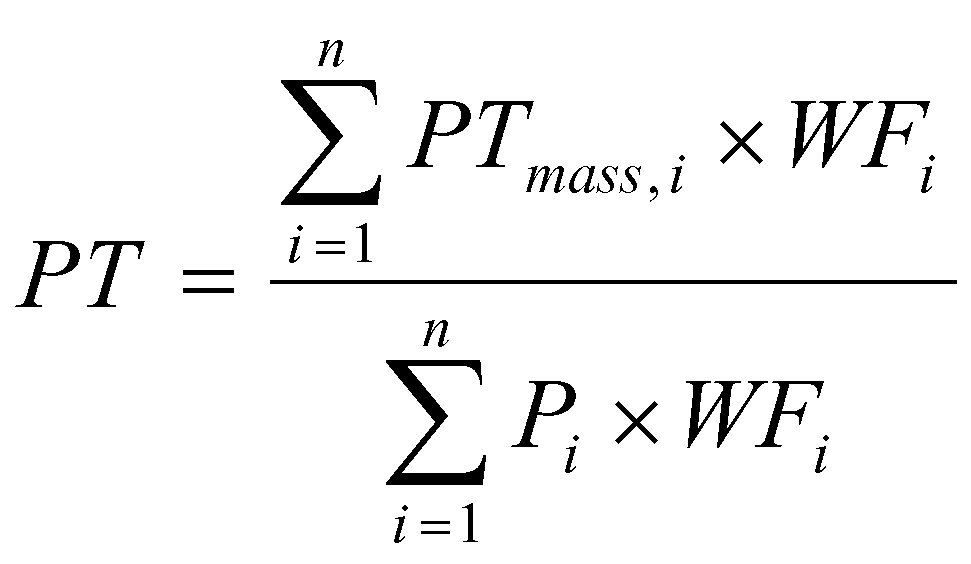

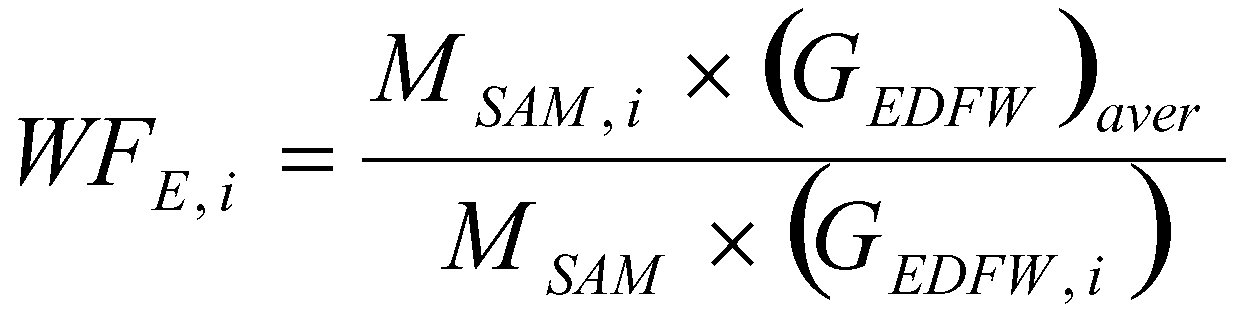

WF

|

-

|

Weighting factor

|

|

WFE

|

-

|

Effective weighting factor

|

|

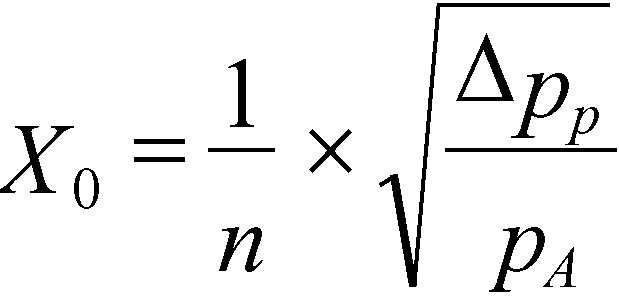

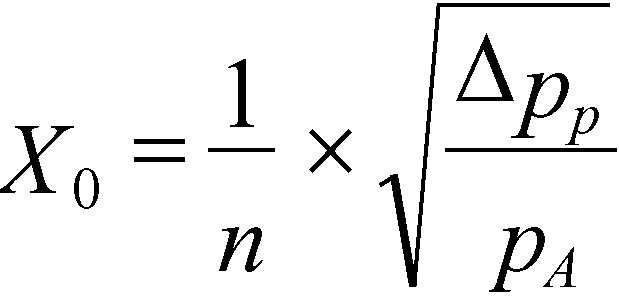

X0

|

m3/rev

|

Calibration function of PDP volume flow rate

|

|

ΘD

|

kg·m2

|

Rotational inertia of the eddy-current dynamometer

|

|

ß

|

-

|

Ratio of the SSV throat diameter, d, to the inlet pipe inner diameter

|

|

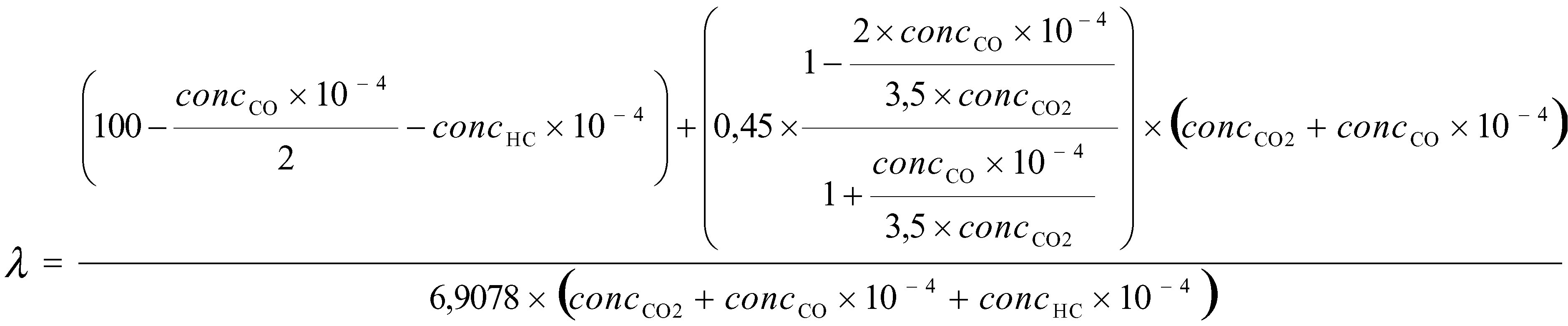

λ

|

-

|

Relative air/fuel ratio, actual A/F divided by stoichiometric A/F

|

|

ρEXH

|

kg/m3

|

Density of the exhaust gas

|

2.18.2. Symbols for chemical components

|

CH4

|

Methane

|

|

C3H8

|

Propane

|

|

C2H6

|

Ethane

|

|

CO

|

Carbon monoxide

|

|

CO2

|

Carbon dioxide

|

|

DOP

|

Di-octylphthalate

|

|

H2O

|

Water

|

|

HC

|

Hydrocarbons

|

|

NOx

|

Oxides of nitrogen

|

|

NO

|

Nitric oxide

|

|

NO2

|

Nitrogen dioxide

|

|

O2

|

Oxygen

|

|

PT

|

Particulates

|

|

PTFE

|

Polytetrafluoroethylene

|

2.18.3. Abbreviations

|

CFV

|

Critical flow venturi

|

|

CLD

|

Chemiluminescent detector

|

|

CI

|

Compression ignition

|

|

FID

|

Flame ionisation detector

|

|

FS

|

Full scale

|

|

HCLD

|

Heated chemiluminescent detector

|

|

HFID

|

Heated flame ionisation detector

|

|

NDIR

|

Non-dispersive infrared analyser

|

|

NG

|

Natural gas

|

|

NRSC

|

Non-road steady cycle

|

|

NRTC

|

Non-road transient cycle

|

|

PDP

|

Positive displacement pump

|

|

SI

|

Spark ignition

|

|

SSV

|

Subsonic venturi

|

|

▼B

3. ENGINE MARKINGS

▼M2

|

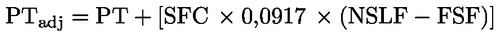

3.1.