|

(6)

|

the following Chapters C.31 to C.46 are added: ‘C.31. TERRESTRIAL PLANT TEST: SEEDLING EMERGENCE AND SEEDLING GROWTH TEST

INTRODUCTION

|

1.

|

This test method is equivalent to OECD Test Guideline (TG) 208 (2006). Test methods are periodically reviewed in the light of scientific progress and applicability to regulatory use. This updated test method is designed to assess potential effects of chemicals on seedling emergence and growth. As such it does not cover chronic effects or effects on reproduction (i.e. seed set, flower formation, fruit maturation). Conditions of exposure and properties of the chemical to be tested must be considered to ensure that appropriate test methods are used (e.g. when testing metals/metal compounds the effects of pH and associated counter ions should be considered) (1). This test method does not address plants exposed to vapours of chemicals. The test method is applicable to the testing of general chemicals, biocides and crop protection products (also known as plant protection products or pesticides). It has been developed on the basis of existing methods (2) (3) (4) (5) (6) (7). Other references pertinent to plant testing were also considered (8) (9) (10). Definitions used are given in Appendix 1.

|

PRINCIPLE OF THE TEST

|

2.

|

The test assesses effects on seedling emergence and early growth of higher plants following exposure to the test chemical in the soil (or other suitable soil matrix). Seeds are placed in contact with soil treated with the test chemical and evaluated for effects following usually 14 to 21 days after 50 % emergence of the seedlings in the control group. Endpoints measured are visual assessment of seedling emergence, dry shoot weight (alternatively fresh shoot weight) and in certain cases shoot height, as well as an assessment of visible detrimental effects on different parts of the plant. These measurements and observations are compared to those of untreated control plants.

|

|

3.

|

Depending on the expected route of exposure, the test chemical is either incorporated into the soil (or possibly into artificial soil matrix) or applied to the soil surface, which properly represents the potential route of exposure to the chemical. Soil incorporation is done by treating bulk soil. After the application the soil is transferred into pots, and then seeds of the given plant species are planted in the soil. Surface applications are made to potted soil in which the seeds have already been planted. The test units (controls and treated soils plus seeds) are then placed under appropriate conditions to support germination/growth of plants.

|

|

4.

|

The test can be conducted in order to determine the dose-response curve, or at a single concentration/rate as a limit test according to the aim of the study. If results from the single concentration/rate test exceed a certain toxicity level (e.g. whether effects greater than x % are observed), a range-finding test is carried out to determine upper and lower limits for toxicity followed by a multiple concentration/rate test to generate a dose-response curve. An appropriate statistical analysis is used to obtain effective concentration ECx or effective application rate ERx (e.g. EC25, ER25, EC50, ER50) for the most sensitive parameter(s) of interest. Also, the no observed effect concentration (NOEC) and lowest observed effect concentration (LOEC) can be calculated in this test.

|

INFORMATION ON THE TEST CHEMICAL

|

5.

|

The following information is useful for the identification of the expected route of exposure to the chemical and in designing the test: structural formula, purity, water solubility, solubility in organic solvents, 1-octanol/water partition coefficient, soil sorption behaviour, vapour pressure, chemical stability in water and light, and biodegradability.

|

VALIDITY OF THE TEST

|

6.

|

In order for the test to be considered valid, the following performance criteria must be met in the controls:

|

—

|

the seedling emergence is at least 70 %;

|

|

—

|

the seedlings do not exhibit visible phytotoxic effects (e.g. chlorosis, necrosis, wilting, leaf and stem deformations) and the plants exhibit only normal variation in growth and morphology for that particular species;

|

|

—

|

the mean survival of emerged control seedlings is at least 90 % for the duration of the study;

|

|

—

|

environmental conditions for a particular species are identical and growing media contain the same amount of soil matrix, support media, or substrate from the same source.

|

|

REFERENCE CHEMICAL

|

7.

|

A reference chemical may be tested at regular intervals, to verify that performance of the test and the response of the particular test plants and the test conditions have not changed significantly over time. Alternatively, historical biomass or growth measurement of controls could be used to evaluate the performance of the test system in particular laboratories, and can serve as an intra-laboratory quality control measure.

|

DESCRIPTION OF THE METHOD

Natural soil — Artificial substrate

|

8.

|

Plants may be grown in pots using a sandy loam, loamy sand, or sandy clay loam that contains up to 1,5 percent organic carbon (approx. 3 percent organic matter). Commercial potting soil or synthetic soil mix that contains up to 1,5 percent organic carbon may also be used. Clay soils should not be used if the test chemical is known to have a high affinity for clays. Field soil should be sieved to 2 mm particle size in order to homogenise it and remove coarse particles. The type and texture, % organic carbon, pH and salt content as electronic conductivity of the final prepared soil should be reported. The soil should be classified according to a standard classification scheme (11). The soil could be pasteurised or heat treated in order to reduce the effect of soil pathogens.

|

|

9.

|

Natural soil may complicate interpretation of results and increase variability due to varying physical/chemical properties and microbial populations. These variables in turn alter moisture-holding capacity, chemical-binding capacity, aeration, and nutrient and trace element content. In addition to the variations in these physical factors, there will also be variation in chemical properties such as pH and redox potential, which may affect the bioavailability of the test chemical (12) (13) (14).

|

|

10.

|

Artificial substrates are typically not used for testing of crop protection products, but they may be of use for the testing of general chemicals or where it is desired to minimize the variability of the natural soils and increase the comparability of the test results. Substrates used should be composed of inert materials that minimize interaction with the test chemical, the solvent carrier, or both. Acid washed quartz sand, mineral wool and glass beads (e.g. 0,35 to 0,85 mm in diameter) have been found to be suitable inert materials that minimally absorb the test chemical (15), ensuring that the chemical will be maximally available to the seedling via root uptake. Unsuitable substrates would include vermiculite, perlite or other highly absorptive materials. Nutrients for plant growth should be provided to ensure that plants are not stressed through nutrient deficiencies, and where possible this should be assessed via chemical analysis or by visual assessment of control plants.

|

Criteria for selection of test species

|

11.

|

The species selected should be reasonably broad, e.g., considering their taxonomic diversity in the plant kingdom, their distribution, abundance, species specific life-cycle characteristics and region of natural occurrence, to develop a range of responses (8) (10) (16) (17) (18) (19) (20). The following characteristics of the possible test species should be considered in the selection:

|

—

|

the species have uniform seeds that are readily available from reliable standard seed source(s) and that produce consistent, reliable and even germination, as well as uniform seedling growth;

|

|

—

|

plant is amenable to testing in the laboratory, and can give reliable and reproducible results within and across testing facilities;

|

|

—

|

the sensitivity of the species tested should be consistent with the responses of plants found in the environment exposed to the chemical;

|

|

—

|

they have been used to some extent in previous toxicity tests and their use in, for example, herbicide bioassays, heavy metal screening, salinity or mineral stress tests or allelopathy studies indicates sensitivity to a wide variety of stressors;

|

|

—

|

they are compatible with the growth conditions of the test method;

|

|

—

|

they meet the validity criteria of the test.

|

Some of the historically most used test species are listed in Appendix 2 and potential non-crop species in Appendix 3.

|

|

12.

|

The number of species to be tested is dependent on relevant regulatory requirements, therefore it is not specified in this test method.

|

Application of the test chemical

|

13.

|

The chemical should be applied in an appropriate carrier (e.g. water, acetone, ethanol, polyethylene glycol, gum Arabic, sand). Mixtures (formulated products or formulations) containing active ingredients and various adjuvants can be tested as well.

|

Incorporation into soil/artificial substrate

|

14.

|

Chemicals which are water soluble or suspended in water can be added to water, and then the solution is mixed with soil with an appropriate mixing device. This type of test may be appropriate if exposure to the chemical is through soil or soil pore-water and that there is concern for root uptake. The water-holding capacity of the soil should not be exceeded by the addition of the test chemical. The volume of water added should be the same for each test concentration, but should be limited to prevent soil agglomerate clumping.

|

|

15.

|

Chemicals with low water solubility should be dissolved in a suitable volatile solvent (e.g. acetone, ethanol) and mixed with sand. The solvent can then be removed from the sand using a stream of air while continuously mixing the sand. The treated sand is mixed with the experimental soil. A second control is established which receives only sand and solvent. Equal amounts of sand, with solvent mixed and removed, are added to all treatment levels and the second control. For solid, insoluble test chemicals, dry soil and the chemical are mixed in a suitable mixing device. Hereafter, the soil is added to the pots and seeds are sown immediately.

|

|

16.

|

When an artificial substrate is used instead of soil, chemicals that are soluble in water can be dissolved in the nutrient solution just prior to the beginning of the test. Chemicals that are insoluble in water, but which can be suspended in water by using a solvent carrier, should be added with the carrier, to the nutrient solution. Water-insoluble chemicals, for which there is no non-toxic water-soluble carrier available, should be dissolved in an appropriate volatile solvent. The solution is mixed with sand or glass beads, placed in a rotary vacuum apparatus, and evaporated, leaving a uniform coating of chemical on sand or beads. A weighed portion of beads should be extracted with the same organic solvent and the chemical assayed before the potting containers are filled.

|

Surface application

|

17.

|

For crop protection products, spraying the soil surface with the test solution is often used for application of the test chemical. All equipment used in conducting the tests, including equipment used to prepare and administer the test chemical, should be of such design and capacity that the tests involving this equipment can be conducted in an accurate way and it will give a reproducible coverage. The coverage should be uniform across the soil surfaces. Care should be taken to avoid the possibilities of chemicals being adsorbed to or reacting with the equipment (e.g. plastic tubing and lipophilic chemicals or steel parts and elements). The test chemical is sprayed onto the soil surface simulating typical spray tank applications. Generally, spray volumes should be in the range of normal agricultural practice and the volumes (amount of water etc. should be reported). Nozzle type should be selected to provide uniform coverage of the soil surface. If solvents and carriers are applied, a second group of control plants should be established receiving only the solvent/carrier. This is not necessary for crop protection products tested as formulations.

|

Verification of test chemical concentration/rate

|

18.

|

The concentrations/rates of application must be confirmed by an appropriate analytical verification. For soluble chemicals, verification of all test concentrations/rates can be confirmed by analysis of the highest concentration test solution used for the test with documentation on subsequent dilution and use of calibrated application equipment (e.g., calibrated analytical glassware, calibration of sprayer application equipment). For insoluble chemicals, verification of compound material must be provided with weights of the test chemical added to the soil. If demonstration of homogeneity is required, analysis of the soil may be necessary.

|

PROCEDURE

Test design

|

19.

|

Seeds of the same species are planted in pots. The number of seeds planted per pot will depend upon the species, pot size and test duration. The number of plants per pot should provide adequate growth conditions and avoid overcrowding for the duration of the test. The maximum plant density would be around 3 - 10 seeds per 100 cm2 depending to the size of the seeds. As an example, one to two corn, soybean, tomato, cucumber, or sugar beet plants per 15 cm container; three rape or pea plants per 15 cm container; and 5 to 10 onion, wheat, or other small seeds per 15 cm container are recommended. The number of seeds and replicate pots (the replicate is defined as a pot, therefore plants within the same pot do not constitute a replicate) should be adequate for optimal statistical analysis (21). It should be noted that variability will be greater for test species using fewer large seeds per pot (replicate), when compared to test species where it is possible to use greater numbers of small seeds per pot. By planting equal seed numbers in each pot this variability may be minimized.

|

|

20.

|

Control groups are used to assure that effects observed are associated with or attributed only to the test chemical exposure. The appropriate control group should be identical in every respect to the test group except for exposure to the test chemical. Within a given test, all test plants including the controls should be from the same source. To prevent bias, random assignment of test and control pots is required.

|

|

21.

|

Seeds coated with an insecticide or fungicide (i.e. “dressed” seeds) should be avoided. However, the use of certain non-systemic contact fungicides (e.g. captan, thiram) is permitted by some regulatory authorities (22). If seed-borne pathogens are a concern, the seeds may be soaked briefly in a weak 5 % hypochlorite solution, then rinsed extensively in running water and dried. No remedial treatment with other crop protection product is allowed.

|

Test conditions

|

22.

|

The test conditions should approximate those conditions necessary for normal growth for the species and varieties tested (Appendix 4 provides examples of test condition). The emerging plants should be maintained under good horticultural practices in controlled environment chambers, phytotrons, or greenhouses. When using growth facilities these practices usually include control and adequately frequent (e.g. daily) recording of temperature, humidity, carbon dioxide concentration, light (intensity, wave length, photosynthetically active radiation) and light period, means of watering, etc., to assure good plant growth as judged by the control plants of the selected species. Greenhouse temperatures should be controlled through venting, heating and/or cooling systems. The following conditions are generally recommended for greenhouse testing:

|

—

|

temperature: 22 °C ± 10 °C;

|

|

—

|

photoperiod: minimum 16 hour light;

|

|

—

|

light intensity: 350 ± 50 μE/m2/s. Additional lighting may be necessary if intensity decreases below 200 μE/m2/s, wavelength 400 - 700 nm except for certain species whose light requirements are less.

|

Environmental conditions should be monitored and reported during the course of the study. The plants should be grown in non-porous plastic or glazed pots with a tray or saucer under the pot. The pots may be repositioned periodically to minimize variability in growth of the plants (due to differences in test conditions within the growth facilities). The pots must be large enough to allow normal growth.

|

|

23.

|

Soil nutrients may be supplemented as needed to maintain good plant vigour. The need and timing of additional nutrients can be judged by observation of the control plants. Bottom watering of test containers (e.g. by using glass fiber wicks) is recommended. However, initial top watering can be used to stimulate seed germination and, for soil surface application it facilitates movement of the chemical into the soil.

|

|

24.

|

The specific growing conditions should be appropriate for the species tested and the test chemical under investigation. Control and treated plants must be kept under the same environmental conditions, however, adequate measures should be taken to prevent cross exposure (e.g. of volatile chemicals) among different treatments and of the controls to the test chemical.

|

Testing at a single concentration/rate

|

25.

|

In order to determine the appropriate concentration/rate of a chemical for conducting a single-concentration or rate (challenge/limit) test, a number of factors must be considered. For general chemicals, these include the physical/chemical properties of the chemical. For crop protection products, the physical/chemical properties and use pattern of the test chemical, its maximum concentration or application rate, the number of applications per season and/or the persistence of the test chemical need to be considered. To determine whether a general chemical possesses phytotoxic properties, it may be appropriate to test at a maximum level of 1 000 mg/kg dry soil.

|

Range-finding test

|

26.

|

When necessary a range-finding test could be performed to provide guidance on concentrations/rates to be tested in definitive dose-response study. For the range-finding test, the test concentrations/rates should be widely spaced (e.g. 0,1, 1,0, 10, 100 and 1 000 mg/kg dry soil). For crop protection products concentrations/rates could be based on the recommended or maximum concentration or application rate, e.g. 1/100, 1/10, 1/1 of the recommended/maximum concentration or application rate.

|

Testing at multiple concentrations/rates

|

27.

|

The purpose of the multiple concentration/rate test is to establish a dose-response relationship and to determine an ECx or ERx value for emergence, biomass and/or visual effects compared to un-exposed controls, as required by regulatory authorities.

|

|

28.

|

The number and spacing of the concentrations or rates should be sufficient to generate a reliable dose-response relationship and regression equation and give an estimate of the ECx. or ERx. The selected concentrations/rates should encompass the ECx or ERx values that are to be determined. For example, if an EC50 value is required it would be desirable to test at rates that produce a 20 to 80 % effect. The recommended number of test concentrations/rates to achieve this is at least five in a geometric series plus untreated control, and spaced by a factor not exceeding three. For each treatment and control group, the number of replicates should be at least four and the total number of seeds should be at least 20. More replicates of certain plants with low a germination rate or variable growth habits may be needed to increase the statistical power of the test. If a larger number of test concentrations/rates are used, the number of replicates may be reduced. If the NOEC is to be estimated, more replicates may be needed to obtain the desired statistical power (23).

|

Observations

|

29.

|

During the observation period, i.e. 14 to 21 days after 50 % of the control plants (also solvent controls if applicable) have emerged, the plants are observed frequently (at least weekly and if possible daily) for emergence and visual phytotoxicity and mortality. At the end of the test, measurement of percent emergence and biomass of surviving plants should be recorded, as well as visible detrimental effects on different parts of the plant. The latter include abnormalities in appearance of the emerged seedlings, stunted growth, chlorosis, discoloration, mortality, and effects on plant development. The final biomass can be measured using final average dry shoot weight of surviving plants, by harvesting the shoot at the soil surface and drying them to constant weight at 60 °C. Alternatively, the final biomass can be measured using fresh shoot weight. The height of the shoot may be another endpoint, if required by regulatory authorities. A uniform scoring system for visual injury should be used to evaluate the observable toxic responses. Examples for performing qualitative and quantitative visual ratings are provided in references (23) (24).

|

DATA AND REPORTING

Statistical analysis

Single concentration/rate test

|

30.

|

Data for each plant species should be analyzed using an appropriate statistical method (21). The level of effect at the test concentration/rate should be reported, or the lack of reaching a given effect at the test concentration/rate (e.g., < x % effect observed at y concentration or rate)

|

Multiple concentration/rate test

|

31.

|

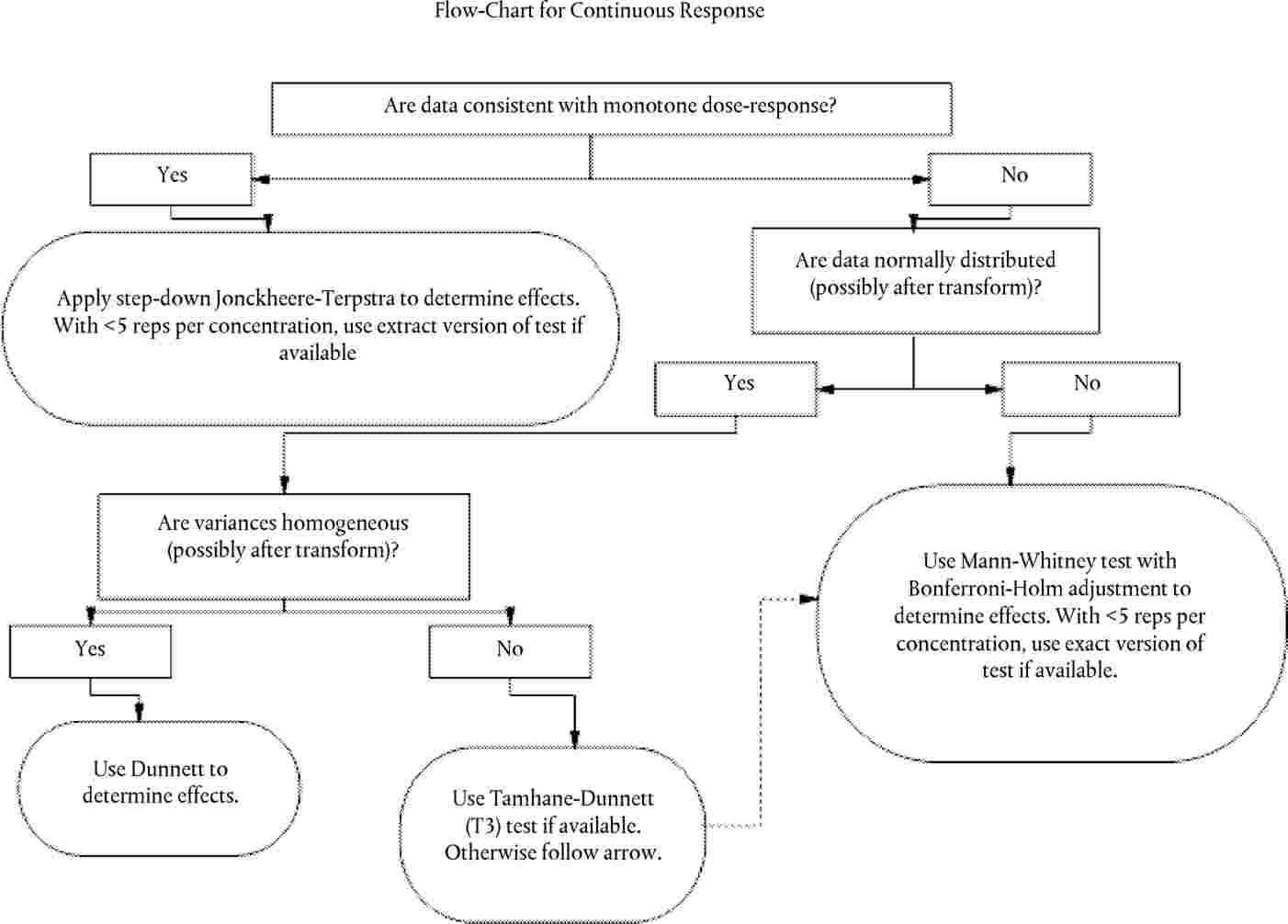

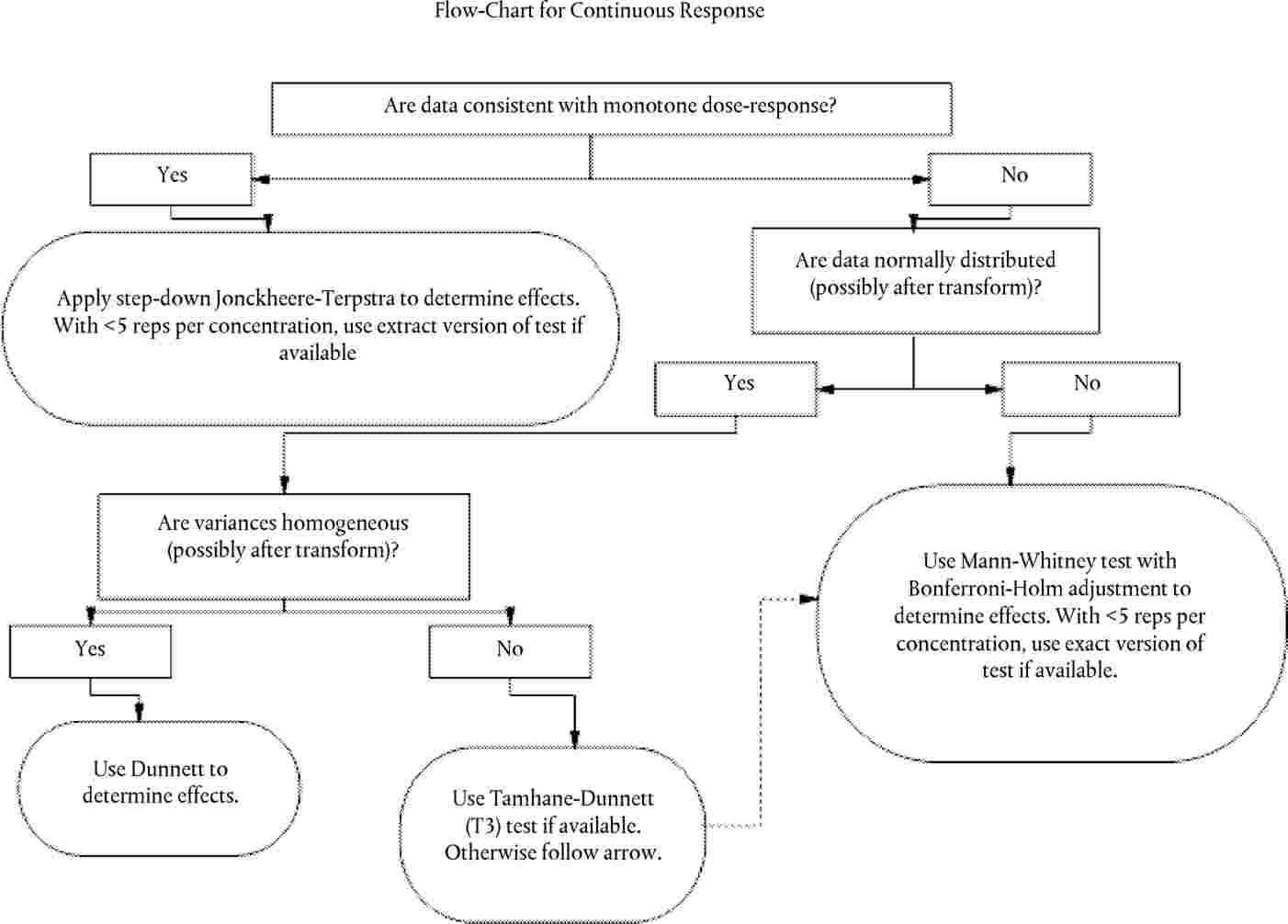

A dose-response relationship is established in terms of a regression equation. Different models can be used: for example, for estimating ECx or ERx (e.g. EC25, ER25, EC50, ER50) and its confidence limits for emergence as quantal data, logit, probit, Weibull, Spearman-Karber, trimmed Spearman-Karber methods, etc. could be appropriate. For the growth of the seedlings (weight and height) as continuous endpoints ECx or ERx and its confidence limits can be estimated by using appropriate regression analysis (e.g. Bruce-Versteeg non-linear regression analysis (25)). Wherever possible, the R2 should be 0,7 or higher for the most sensitive species and the test concentrations/rates used encompass 20 % to 80 % effects. If the NOEC is to be estimated, application of powerful statistical tests should be preferred and these should be selected on the basis of data distribution (21) (26).

|

Test report

|

32.

|

The test report should present results of the studies as well as a detailed description of test conditions, a thorough discussion of results, analysis of the data, and the conclusions drawn from the analysis. A tabular summary and abstract of results should be provided. The report must include the following:

|

|

Test chemical:

|

—

|

chemical identification data, relevant properties of the chemical tested (e.g. log Pow, water solubility, vapour pressure and information on environmental fate and behaviour, if available);

|

|

—

|

details on preparation of the test solution and verification of test concentrations as specified in paragraph 18.

|

|

|

|

Test species:

|

—

|

details of the test organism: species/variety, plant families, scientific and common names, source and history of the seed as detailed as possible (i.e. name of the supplier, percentage germination, seed size class, batch or lot number, seed year or growing season collected, date of germination rating), viability, etc.;

|

|

—

|

number of mono- and di-cotyledon species tested;

|

|

—

|

rationale for selecting the species;

|

|

—

|

description of seed storage, treatment and maintenance.

|

|

|

|

Test conditions:

|

—

|

testing facility (e.g. growth chamber, phytotron and greenhouse);

|

|

—

|

description of test system (e.g., pot dimensions, pot material and amounts of soil);

|

|

—

|

soil characteristics (texture or type of soil: soil particle distribution and classification, physical and chemical properties including % organic matter, % organic carbon and pH);

|

|

—

|

soil/substrate (e.g. soil, artificial soil, sand and others) preparation prior to test;

|

|

—

|

description of nutrient medium if used;

|

|

—

|

application of the test chemical: description of method of application, description of equipment, exposure rates and volumes including chemical verification, description of calibration method and description of environmental conditions during application;

|

|

—

|

growth conditions: light intensity (e.g. PAR, photosynthetically active radiation), photoperiod, max/min temperatures, watering schedule and method, fertilization;

|

|

—

|

number of seeds per pot, number of plants per dose, number of replicates (pots) per exposure rate;

|

|

—

|

type and number of controls (negative and/or positive controls, solvent control if used);

|

|

|

|

Results:

|

—

|

table of all endpoints for each replicate, test concentration/rate and species;

|

|

—

|

the number and percent emergence as compared to controls;

|

|

—

|

biomass measurements (shoot dry weight or fresh weight) of the plants as percentage of the controls;

|

|

—

|

shoot height of the plants as percentage of the controls, if measured;

|

|

—

|

percent visual injury and qualitative and quantitative description of visual injury (chlorosis, necrosis, wilting, leaf and stem deformation, as well as, any lack of effects) by the test chemical as compared to control plants;

|

|

—

|

description of the rating scale used to judge visual injury, if visual rating is provided;

|

|

—

|

for single rate studies, the percent injury should be reported;

|

|

—

|

ECx or ERx (e.g. EC50, ER50, EC25, ER25) values and related confidence limits. Where regression analysis is performed, provide the standard error for the regression equation, and the standard error for individual parameter estimate (e.g. slope, intercept);

|

|

—

|

NOEC (and LOEC) values if calculated;

|

|

—

|

description of the statistical procedures and assumptions used;

|

|

—

|

graphical display of these data and dose-response relationship of the species tested.

|

|

Deviations from the procedures described in this test method and any unusual occurrences during the test.

|

LITERATURE

|

(1)

|

Schrader G., Metge K., and Bahadir M. (1998). Importance of salt ions in ecotoxicological tests with soil arthropods. Applied Soil Ecology, 7, 189-193.

|

|

(2)

|

International Organisation of Standards. (1993). ISO 11269-1. Soil Quality -- Determination of the Effects of Pollutants on Soil Flora — Part 1: Method for the Measurement of Inhibition of Root Growth.

|

|

(3)

|

International Organisation of Standards. (1995). ISO 11269-2. Soil Quality -- Determination of the Effects of Pollutants on Soil Flora — Part 2: Effects of Chemicals on the Emergence and Growth of Higher Plants.

|

|

(4)

|

American Standard for Testing Material (ASTM). (2002). E 1963-98. Standard Guide for Conducting Terrestrial Plant Toxicity Tests.

|

|

(5)

|

U.S. EPA. (1982). FIFRA, 40CFR, Part 158.540. Subdivision J, Parts 122-1 and 123-1.

|

|

(6)

|

US EPA. (1996). OPPTS Harmonized Test Guidelines, Series 850. Ecological Effects Test Guidelines:

|

—

|

850.4000: Background — Non-target Plant Testing;

|

|

—

|

850.4025: Target Area Phytotoxicity;

|

|

—

|

850.4100: Terrestrial Plant Toxicity, Tier I (Seedling Emergence);

|

|

—

|

850.4200: Seed Germination/Root Elongation Toxicity Test;

|

|

—

|

850.4225: Seedling Emergence, Tier II;

|

|

—

|

850.4230: Early Seedling Growth Toxicity Test.

|

|

|

(7)

|

AFNOR, X31-201. (1982). Essai d'inhibition de la germination de semences par une substance. AFNOR X31-203/ISO 11269-1. (1993) Determination des effets des polluants sur la flore du sol: Méthode de mesurage de l'inhibition de la croissance des racines.

|

|

(8)

|

Boutin, C., Freemark, K.E. and Keddy, C.J. (1993). Proposed guidelines for registration of chemical pesticides: Non-target plant testing and evaluation. Technical Report Series No.145. Canadian Wildlife Service (Headquarters), Environment Canada, Hull, Québec, Canada.

|

|

(9)

|

Forster, R., Heimbach, U., Kula, C., and Zwerger, P. (1997). Effects of Plant Protection Products on Non-Target Organisms — A contribution to the Discussion of Risk Assessment and Risk Mitigation for Terrestrial Non-Target Organisms (Flora and Fauna). Nachrichtenbl. Deut. Pflanzenschutzd. No 48.

|

|

(10)

|

Hale, B., Hall, J.C., Solomon, K., and Stephenson, G. (1994). A Critical Review of the Proposed Guidelines for Registration of Chemical Pesticides; Non-Target Plant Testing and Evaluation, Centre for Toxicology, University of Guelph, Ontario Canada.

|

|

(11)

|

Soil Texture Classification (US and FAO systems): Weed Science, 33, Suppl. 1 (1985) and Soil Sc. Soc. Amer. Proc. 26:305 (1962).

|

|

(12)

|

Audus, L.J. (1964). Herbicide behaviour in the soil. In: Audus, L.J. ed. The Physiology and biochemistry of Herbicides, London, New York, Academic Press, NY, Chapter 5, pp. 163-206.

|

|

(13)

|

Beall, M.L., Jr. and Nash, R.G. (1969). Crop seedling uptake of DDT, dieldrin, endrin, and heptachlor from soil, J. Agro. 61:571-575.

|

|

(14)

|

Beetsman, G.D., Kenney, D.R. and Chesters, G. (1969). Dieldrin uptake by corn as affected by soil properties, J. Agro. 61:247-250.

|

|

(15)

|

U.S. Food and Drug Administration (FDA). (1987). Environmental Assessment Technical Handbook. Environmental Assessment Technical Assistance Document 4.07, Seedling Growth, 14 pp., FDA, Washington, DC.

|

|

(16)

|

McKelvey, R.A., Wright, J.P., Honegger, J.L. and Warren, L.W. (2002). A Comparison of Crop and Non-crop Plants as Sensitive Indicator Species for Regulatory Testing. Pest Management Science vol. 58:1161-1174

|

|

(17)

|

Boutin, C.; Elmegaard, N. and Kjær, C. (2004). Toxicity testing of fifteen non-crop plant species with six herbicides in a greenhouse experiment: Implications for risk assessment. Ecotoxicology vol. 13(4): 349-369.

|

|

(18)

|

Boutin, C., and Rogers, C.A. (2000). Patterns of sensitivity of plant species to various herbicides — An analysis with two databases. Ecotoxicology vol. 9(4): 255-271.

|

|

(19)

|

Boutin, C. and Harper, J.L. (1991). A comparative study of the population dynamics of five species of Veronica in natural habitats. J. Ecol. 9:155-271.

|

|

(20)

|

Boutin, C., Lee, H.-B., Peart, T.E., Batchelor, S.P. and Maguire, R.J.. (2000). Effects of the sulfonylurea herbicide metsulfuron methyl on growth and reproduction of five wetland and terrestrial plant species. Envir. Toxicol. Chem. 19 (10): 2532-2541.

|

|

(21)

|

OECD (2006). Guidance Document, Current Approaches in the Statistical Analysis of Ecotoxicity Data: A Guidance to Application. Series on Testing and Assessment No 54, Organisation for Economic Co-operation and Development, Paris.

|

|

(22)

|

Hatzios, K.K. and Penner, D. (1985). Interactions of herbicides with other agrochemicals in higher plants. Rev. Weed Sci. 1:1-63.

|

|

(23)

|

Hamill, P.B., Marriage, P.B. and G. Friesen. (1977). A method for assessing herbicide performance in small plot experiments. Weed Science 25:386-389.

|

|

(24)

|

Frans, R.E. and Talbert, R.E. (1992). Design of field experiments and the measurement and analysis of plant response. In: B. Truelove (Ed.) Research Methods in Weed Science, 2nd ed. Southern weed Science Society, Auburn, 15-23.

|

|

(25)

|

Bruce, R.D. and Versteeg, D. J.(1992). A Statistical Procedure for Modelling Continuous Toxicity Data. Environmental Toxicology and Chemistry 11, 1485-1492.

|

|

(26)

|

Chapter C.33 of this Annex: Earthworm Reproduction Test (Eisenia fetida/Eisenia andrei).

|

Appendix 1

Definitions

|

|

Active ingredient (a.i.) (or active substance (a.s.)) is a material designed to provide a specific biological effect (e.g., insect control, plant disease control, weed control in the treatment area), also known as technical grade active ingredient, active substance.

|

|

|

Chemical means a substance or a mixture.

|

|

|

Crop Protection Products (CPPs) or plant protection product (PPPs) or pesticides are materials with a specific biological activity used intentionally to protect crops from pests (e.g., fungal diseases, insects and competitive plants).

|

|

|

ECx. x % Effect Concentration or ERx. x % Effect Rate is the concentration or the rate that results in an undesirable change or alteration of x % in the test endpoint being measured relative to the control (e.g., 25 % or 50 % reduction in seedling emergence, shoot weight, final number of plants present, or increase in visual injury would constitute an EC25/ER25 or EC50/ER50 respectively).

|

|

|

Emergence is the appearance of the coleoptile or cotyledon above the soil surface.

|

|

|

Formulation is the commercial formulated product containing the active substance (active ingredient), also known as final preparation (8) or typical end-use product (TEP).

|

|

|

LOEC (Lowest Observed Effect Concentration) is the lowest concentration of the test chemical at which effect was observed. In this test, the concentration corresponding to the LOEC, has a statistically significant effect (p < 0,05) within a given exposure period when compared to the control, and is higher than the NOEC value.

|

|

|

Non-target plants: Those plants that are outside the target plant area. For crop protection products, this usually refers to plants outside the treatment area.

|

|

|

NOEC (No Observed Effect Concentration) is the highest concentration of the test chemical at which no effect was observed. In this test, the concentration corresponding to the NOEC, has no statistically significant effect (p < 0,05) within a given exposure period when compared with the control.

|

|

|

Phytotoxicity: Detrimental deviations (by measured and visual assessments) from the normal pattern of appearance and growth of plants in response to a given chemical.

|

|

|

Replicate is the experimental unit which represents the control group and/or treatment group. In these studies, the pot is defined as the replicate.

|

|

|

Visual assessment: Rating of visual damage based on observations of plant stand, vigour, malformation, chlorosis, necrosis, and overall appearance compared with a control.

|

|

|

Test Chemical: Any substance or mixture tested using this test method.

|

Appendix 2

List of species historically used in plant testing

|

Family

|

Species

|

Common names

|

|

DICOTYLEDONAE

|

|

Apiaceae (Umbelliferae)

|

Daucus carota

|

Carrot

|

|

Asteraceae (Compositae)

|

Helianthus annuus

|

Sunflower

|

|

Asteraceae (Compositae)

|

Lactuca sativa

|

Lettuce

|

|

Brassicaceae (Cruciferae)

|

Sinapis alba

|

White Mustard

|

|

Brassicaceae (Cruciferae)

|

Brassica campestris var. chinensis

|

Chinese cabbage

|

|

Brassicaceae (Cruciferae)

|

Brassica napus

|

Oilseed rape

|

|

Brassicaceae (Cruciferae)

|

Brassica oleracea var. capitata

|

Cabbage

|

|

Brassicaceae (Cruciferae)

|

Brassica rapa

|

Turnip

|

|

Brassicaceae (Cruciferae)

|

Lepidium sativum

|

Garden cress

|

|

Brassicaceae (Cruciferae)

|

Raphanus sativus

|

Radish

|

|

Chenopodiaceae

|

Beta vulgaris

|

Sugar beet

|

|

Cucurbitaceae

|

Cucumis sativus

|

Cucumber

|

|

Fabaceae (Leguminosae)

|

Glycine max (G. soja)

|

Soybean

|

|

Fabaceae (Leguminosae)

|

Phaseolus aureus

|

Mung bean

|

|

Fabaceae (Leguminosae)

|

Phaseolus vulgaris

|

Dwarf bean, French bean, Garden bean

|

|

Fabaceae (Leguminosae)

|

Pisum sativum

|

Pea

|

|

Fabaceae (Leguminosae)

|

Trigonella foenum-graecum

|

Fenugreek

|

|

Fabaceae (Leguminosae)

|

Lotus corniculatus

|

Birdsfoot trefoil

|

|

Fabaceae (Leguminosae)

|

Trifolium pratense

|

Red Clover

|

|

Fabaceae (Leguminosae)

|

Vicia sativa

|

Vetch

|

|

Linaceae

|

Linum usitatissimum

|

Flax

|

|

Polygonaceae

|

Fagopyrum esculentum

|

Buckwheat

|

|

Solanaceae

|

Solanum lycopersicon

|

Tomato

|

|

MONOCOTYLEDONAE

|

|

Liliaceae (Amarylladaceae)

|

Allium cepa

|

Onion

|

|

Poaceae (Gramineae)

|

Avena sativa

|

Oats

|

|

Poaceae (Gramineae)

|

Hordeum vulgare

|

Barley

|

|

Poaceae (Gramineae)

|

Lolium perenne

|

Perennial ryegrass

|

|

Poaceae (Gramineae)

|

Oryza sativa

|

Rice

|

|

Poaceae (Gramineae)

|

Secale cereale

|

Rye

|

|

Poaceae (Gramineae)

|

Sorghum bicolor

|

Grain sorghum, Shattercane

|

|

Poaceae (Gramineae)

|

Triticum aestivum

|

Wheat

|

|

Poaceae (Gramineae)

|

Zea mays

|

Corn

|

Appendix 3

List of potenatial non-crop species

OECD Potential Species for Plant Toxicity Testing

Note: The following table provides information for 52 non-crop species (references are given in brackets for each entry). Emergence rates provided are from published literature and are for general guidance only. Individual experience may vary depending upon seed source and other factors.

|

FAMILY Species Botanical Name

(English Common Name)

|

Lifespan (9) & Habitat

|

Seed Weight

(mg)

|

Photoperiod for germination or growth (10)

|

Planting Depth

(mm) (11)

|

Time to Germinate

(days) (12)

|

Special Treatments (13)

|

Toxicity Test (14)

|

Seed Suppliers (15)

|

Other References (16)

|

|

APIACEAE

Torilis japónica

(Japanese Hedge-parsley)

|

А, В disturbed areas, hedgerows, pastures (16, 19)

|

1,7-1,9 (14, 19)

|

L = D (14)

|

0

(1, 19)

|

5 (50 %) (19)

|

cold stratification (7, 14, 18, 19) maturation may be necessary (19) germination inhibited by darkness (1, 19) no special treatments (5)

|

POST (5)

|

|

|

|

ASTERACEAE

Bellis perennis

(English Daisy)

|

Ρ

grassland, arable fields, turf (16, 19)

|

0,09-0,17 (4, 19)

|

L = D (14)

|

0

(4)

|

3 (50 %) (19)

11 (100 %) (18)

|

germination not affected by irradiance (18, 19) no special treatments (4, 14)

|

POST (4)

|

A, D, F

|

7

|

|

Centaurea cyanus

(Cornflower)

|

A

fields, roadsides, open habitats (16)

|

4,1 -4,9 (4, 14)

|

L = D (14)

|

0-3 (2, 4, 14)

|

14-21 (100 %) (14)

|

no special treatments (2, 4)

|

POST (2,4)

|

A, D, E, F

|

7

|

|

Centaurea nigra

(Black Knapweed)

|

Ρ

fields, roadsides, open habitats (16, 19)

|

2,4-2,6 (14, 19)

|

L = D (14)

|

0 (19)

|

3 (50 %) (19)

4 (97 %) (18)

|

maturation may be necessary (18, 19) germination inhibited by darkness (19) no special treatments (5, 14, 26)

|

POST (5, 22, 26)

|

A

|

|

|

Inula helenium

Elecampane

|

Ρ

moist, disturbed sites

(16)

|

1-1,3 (4, 14, 29)

|

|

0

(4, 29)

|

|

no special treatments (4)

|

POST (4)

|

A, F

|

|

|

Leontodon hispidus

(Big Hawkbit)

|

Ρ

fields, roadsides, disturbed areas (16, 19)

|

0,85 -1,2 (14, 19)

|

L = D (14)

|

0 (19)

|

4 (50 %) (19)

7 (80 %) (18)

|

germination inhibited by darkness (17, 18, 19) no special treatments (5, 23)

|

POST (5, 22, 23)

|

|

|

|

Rudbeckia hirta

(Black-eyed Susan)

|

Β, Ρ disturbed

(16)

|

0,3 (4, 14)

|

L = D (14)

|

0

(4, 33)

|

< 10 (100 %) (33)

|

no special treatments

(4, 14, 33)

|

POST (4, 33)

|

C, D, E, F

|

|

|

Solidago canadensis

Canada Goldenrod

|

Ρ

pasture, open areas (16)

|

0,06-0,08 (4, 14)

|

L = D (11)

|

0

(4)

|

14-21

(11)

|

mix with equal part sand and soak in 500 ppm GA for 24 hrs (11) no special treatments (4)

|

POST (4)

|

E, F

|

|

|

Xanthium pensylvanicum

(Common Cocklebur)

|

A

fields, open habitats (16)

|

25-61 (14, 29)

|

|

0(1)

5(29)

|

|

germination may be inhibited by darkness (1) soak in warm water for 12 hrs (29)

|

PRE & POST (31)

|

A

|

|

|

Xanthium spinosum

(Spiny Cocklebur)

|

A

open habitats (16)

|

200 (14)

|

L = D (14)

L > D (6)

|

10

(6)

|

|

scarification (14) no special treatments (6)

|

PRE & POST (6)

|

A

|

|

|

Xanthium strumarium

(Italian Cocklebur)

|

A

fields, open habitats (16)

|

67,4 (14)

|

L = D (14)

|

10-20 (6, 21)

|

|

no special treatments

(6, 14, 21)

|

PRE & POST (6, 21, 28, 31)

|

A

|

|

|

BRASSICACEAE

Cardamine pratensis

(Cuckoo Flower)

|

Ρ

fields, roadsides, turf (16, 19)

|

0,6 (14, 19)

|

L = D (14)

|

0 (19)

|

5 (50 %) (19)

15 (98 %) (18)

|

germination inhibited by darkness (18, 19) no special treatments (5, 14, 22)

|

POST (5, 22)

|

F

|

|

|

CARYOPHYLLACEAE

Lychnis flos-cuculi

(Ragged Robin)

|

Ρ

(16)

|

0,21 (14)

|

L = D (14)

|

|

< 14 (100 %) (14, 25)

|

maturation may be necessary (18) no special treatments (5, 14, 15, 22-26)

|

POST (5, 15, 22-26)

|

F

|

|

|

CHENOPODIACEAE

Chenopodium album

(Lamb's Quarters)

|

A

field margins, disturbed areas (16, 19)

|

0,7- 1,5 (14, 19, 34)

|

L = D (14)

|

0

(1, 19)

|

2 (50 %) (19)

|

treatment differs depending on seed colour (19) dry storage dormancy (19) germination inhibited by darkness (1, 18, 19) cold stratification (18) no special treatments (14, 34)

|

PRE & POST (28, 31, 34)

|

A

|

32

|

|

CLUSIACEAE

Hypericum perforatum

(Common St. John's Wort)

|

Ρ

fields, arable land, open habitats (16, 19)

|

0,1 -0,23

(14, 19)

|

L= D

(14)

|

0

(1, 19)

|

3 (19)

11 (90 %) (18)

|

germination inhibited by darkness (1, 18, 19)

no special treatments (5, 14, 15, 25, 27)

|

POST

(5, 15, 25, 27)

|

A, E, F

|

|

|

CONVOLVULACEAE

Ipomoea hederacea

(Purple Morning Glory)

|

A

roadsides, open habitats, cornfields (16)

|

28,2

(14)

|

L > D

(6, 10)

|

10-20

(6, 10, 21)

|

4 (100 %)

(10)

|

germination not affected by irradiance (1)

no special treatments (6, 21)

|

PRE & POST

(6, 12, 21, 28)

|

A

|

|

|

CYPERACEAE

Cyperus rotundus

(Purple Nutsedge)

|

Ρ

arable land, pastures, roadsides (16, 30)

|

0,2

(14)

|

L= D

(14)

|

0 (1)

10-20 (6, 10)

|

12 (91 %)

(10)

|

germination inhibited by darkness (1)

no special treatments (6, 10, 14)

|

PRE & POST

(6, 28, 31)

|

B

|

7

|

|

FABACEAE

Lotus corniculatus

(Bird's-foot Trefoil)

|

Ρ

grassy areas, roadsides, open habitats (16, 19)

|

1-1,67

(14, 19)

|

L = D (14)

|

|

1 (50 %)

(19)

|

scarification (14, 19)

germination not affected by irradiance (18, 19) no special treatments (23, 25)

|

POST

(5, 23, 25)

|

A, D, E, F

|

|

|

Senna obtusifolia

(Cassia, Sicklepod)

|

A

moist woods (16)

|

23-28

(9)

|

L = D (14)

L > D (9)

|

10-20

(6,9)

|

|

soak seeds in water for 24 hours (9)

scarification (14) seed viability differs depending on colour (1) no special treatments (6)

|

POST

(6,9)

|

A

|

|

|

Sesbania exaltata

(Hemp)

|

A

alluvial soil (16)

|

11- 13

(9, 14)

|

L > D (9)

|

10-20

(9, 21)

|

|

soak seeds in water for 24 hours (9)

germination not affected by irradiance (1) no special treatments (21)

|

PRE & POST

(9, 21, 28, 31)

|

A

|

|

|

Trifolium pratense

(Red Clover)

|

Ρ

fields, roadsides, arable land (16, 19)

|

1,4- 1,7

(14, 19)

|

L= D (14)

|

|

1 (50 %)

(19)

|

scarification (14, 18)

may need maturation (19) germination not affected by irradiance (1, 19) no special treatments (5)

|

POST

(5)

|

A, E, F

|

|

|

LAM IAC E AE

Leonurus cardiaca

(Motherwort)

|

Ρ

open areas (16)

|

0,75 -1,0

(4, 14)

|

L= D (14)

|

0

(4)

|

|

no special treatments

(4, 14)

|

POST

(4)

|

F

|

|

|

Mentha spicata

(Spearmint)

|

Ρ

moist areas (16)

|

2,21

(4)

|

|

0

(4)

|

|

no special treatments

(4)

|

POST

(4)

|

F

|

|

|

Nepeta cataria

(Catnip)

|

Ρ

disturbed areas (16)

|

0,54

(4, 14)

|

L= D (14)

|

0

(4)

|

|

no special treatments

(2, 4, 14)

|

POST

(2,4)

|

F

|

|

|

Prunella vulgaris

(Self-heal)

|

Ρ

arable fields, grassy areas, disturbed sites (16, 19)

|

0,58 -1,2

(4, 14, 19)

|

L= D (14)

|

0

(4, 19)

|

5 (50 %) (19)

7 (91 %) (18)

|

germination inhibited by darkness (18, 19)

greater germination with larger seeds (1) no special treatments (4, 14, 22)

|

POST

(4, 22)

|

A, F

|

|

|

Stachys officinalis

(Hedge-nettle)

|

Ρ

grasslands, field margins (19)

|

14-18

(14, 19)

|

L= D (14)

|

|

7 (50 %)

(19)

|

no special treatments

(5, 14, 22)

|

POST

(5, 22)

|

F

|

|

|

MALVACEAE

Abutilón theophrasti

(Velvetleaf)

|

A

fields, open habitats (16)

|

8,8

(14)

|

L= D (14)

|

10-20

(6, 10, 21)

|

4 (84 %)

(10)

|

scarification (14)

no special treatments (5, 10, 21)

|

PRE & POST

(6, 22, 28, 31)

|

A, F

|

|

|

Sida spinosa

(Prickly Sida)

|

A

fields, roadsides (16)

|

3,8

(14)

|

L= D (14)

|

10-20

(6, 21)

|

|

scarification (14)

germination not affected by irradiance (1) no special treatments (6, 21)

|

PRE & POST

(6, 21, 28, 31)

|

A, F

|

|

|

PAPAVERACEAE

Papaver rhoeas

(Poppy)

|

A

fields, arable land, disturbed sites (16, 19)

|

0,1 -0,3

(4, 14, 19, 29)

|

L= D (14)

|

0

(4, 29)

|

4 (50 %)

(19)

|

cold stratification & scarification (1, 19, 32)

no special treatments (4, 14, 29)

|

POST

(4)

|

A, D, E, F, G

|

|

|

POACEAE

Agrostis tenuis

(Common Bentgrass)

|

lawns, pastures (16)

|

0,07 (14)

|

L > D (Ю)

|

20 (10)

|

10 (62 %) (10)

|

germination inhibited by darkness (1, 17-19) no special treatments (10)

|

POST (10)

|

A, E

|

|

|

Alopecurus myosuroides

(Foxtail)

|

A

fields, open habitats (16)

|

0,9-1,6

(29, 34)

|

L = D (14)

|

2

(29)

|

< 24 (30 %) (34)

|

scarification (14) treat with 101 mg/L KNO3 (14) warm stratification (1) germination inhibited by darkness (1) no special treatments (34)

|

PRE & POST

(28, 34)

|

A

|

32

|

|

Avena fatua

(Wild Oats)

|

A

cultivated areas, open habitats (16)

|

7-37,5 (14, 30)

|

L = D (14)

L > D (6)

|

10-20 (6, 10)

|

3 (70 %) (18)

|

scarification (7, 32) darkness inhibits germination (1)

cold stratification (1, 18) no special treatments (6, 10, 14)

|

PRE & POST (6, 10, 28, 31)

|

A

|

|

|

Bromus tectorum

(Downy Brome)

|

A

fields, roadsides, arable land (16)

|

0,45-2,28 (14, 29)

|

L = D (14)

|

3 (29)

|

|

maturation period (1, 7, 32) germination inhibited by light (1) no special treatments (14)

|

PRE & POST (28, 31)

|

A

|

|

|

Cynosurus cristatus

(Dog's-tail Grass)

|

P

fields, roadsides, open habitats (16, 19)

|

0,5-0,7 (14, 19, 29)

|

L = D (14)

|

0 (29)

|

3 (50 %) (19)

|

germination not affected by irradiance (19) no special treatments (14, 29)

|

POST (5)

|

A

|

|

|

Digitaria sanguinalis

(Crabgrass)

|

A

fields, turf, open habitats (16)

|

0,52-0,6 (14, 30)

|

L = D (14)

|

10-20 (21)

|

7 (75 %)

14 (94 %) (7)

|

scarification, cold stratification, & maturation (1, 7, 14, 32) treat with 101 mg/L KNO3 (14) germination inhibited by darkness (1) no special treatments (21)

|

PRE & POST (18, 25, 31)

|

A

|

|

|

Echinochloa crusgalli

(Barnyard Grass)

|

A

(16)

|

1,5 (14)

|

L = D (14)

L > D (3)

|

10-20 (7, 21)

|

|

scarification (7, 32) germination not affected by irradiance (1) no special treatments (3, 14, 21)

|

PRE & POST (3, 21, 28, 31)

|

A

|

|

|

Elymus canadensis

(Canada Wild Rye)

|

P

riparian, disturbed sites (16)

|

4-5 (14, 30)

|

L = D (11)

|

1

(11)

|

14-28

(11)

|

no special treatments

(2, 11)

|

POST (2)

|

C, D, E

|

|

|

Festuca pratensis

(Fescue)

|

P

fields, moist areas (16, 19)

|

1,53-2,2 (16, 19)

|

L = D (14)

L > D (10)

|

20 (10)

|

9 (74 %) (10)

2 (50 %) (19)

|

no special treatments

(10, 19)

|

POST (10)

|

A

|

7

|

|

Hordeum pusillum

(Little Barley)

|

A

pastures, roadsides, open habitats (16)

|

3,28 (14)

|

|

|

|

warm stratification (1) germination not affected by irradiance (1)

|

PRE (31)

|

|

7

|

|

Phieum pratense

(Timothy)

|

P

pastures, arable fields, disturbed sites (16, 19)

|

0,45 (14, 19)

|

L > D (10, 14)

|

0-10 (10, 19)

|

2 (74 %) (10)

8 (50 %) (19)

|

germination inhibited by darkness (19) germination not affected by irradiance (17) no special treatments (10, 14, 17, 19)

|

POST (10)

|

A, E

|

|

|

POLYGONACEAE

Polygonum convolvulus

(Black Bindweed)

|

A

open habitats, roadsides (16)

|

5-8 (4, 14, 29)

|

L = D (20)

|

0-2 (4, 29)

|

|

cold stratification for 4 — 8 weeks (1, 2, 4, 20, 29) germination not affected by irradiance (1)

|

PRE & POST 1, 2, 20, 28, 31

|

A

|

32

|

|

Polygonum lapathifolium

(Pale Persicaria)

|

A

moist soil (16)

|

1,8-2,5 (14)

|

L > D (6)

|

|

5 (94 %) (18)

|

germination not affected by irradiance (1) germination inhibited by darkness (18) cold stratification (1) no special treatments (5)

|

PRE & POST (6)

|

A, E

|

|

|

Polygonum pennsylvanicum

(Pennsylvania Smartweed)

|

A

fields, open habitats (16)

|

3,6-7 (14, 29)

|

|

2 (29)

|

|

cold stratification for 4 wks at 0 — 5oC (1, 29) germination inhibited by darkness (1)

|

PRE (31)

|

A, E

|

|

|

Polygonum periscaria

(Smartweed)

|

A

disturbed areas, arable land (16, 19)

|

2,1 -2,3 (14, 19)

|

L > D (13)

|

0 (19)

|

< 14 (13)

2 (50 %) (19)

|

scarification, cold stratification, GA treatment (14) cold stratification, maturation (17-19) germination inhibited by darkness (19) no special treatments (13)

|

POST (13)

|

A

|

32

|

|

Rumex crispus

(Curly Dock)

|

P

arable fields, roadsides open areas (16, 19)

|

1,3-1,5 (4, 14, 19)

|

L = D (14, 33)

|

0

(4, 19, 33)

|

3 (50 %) (19)

6 (100 %) (33)

|

germination inhibited by darkness (18, 19) maturation may be necessary (18) no special treatments (4, 14, 33)

|

POST (4, 33)

|

A, E

|

32

|

|

PRIMULACEAE

Anagallis arvensis

(Scarlett Pimpernel)

|

A

arable fields, open areas, disturbed sites (16, 19)

|

0,4-0,5 (4, 14, 19)

|

L = D (14)

|

|

1 (50 %) (19)

|

cold stratification, GA treatment (1,14, 18, 19, 32) light required for germination (1) no special treatments (2, 4)

|

POST (2,4)

|

A, F

|

|

|

RANUNCULACEAE

Ranunculus acris

(Common Buttercup)

|

Ρ

arable fields, roadsides, open areas (16, 19)

|

1,5-2 (14, 19, 29)

|

L = D (14)

|

1

(29)

|

41 -56 (19, 29)

|

no special treatments

(5, 14, 22, 24 -26)

|

POST (5, 22, 24-26)

|

|

32

|

|

ROSACEAE

Geum urbanum

(Yellow Avens)

|

Ρ

hedgerows, moist areas

(16, 19)

|

0,8 — 1,5 (14, 19)

|

L = D (14)

|

0 (19)

|

5 (50 %) (19)

16 (79 %) (18)

|

germination inhibited by darkness (18, 19) warm stratification (1) no special treatments (5, 14, 22, 25, 26)

|

POST (5, 22, 25, 26)

|

A

|

|

|

RUBIACEAE

Galium aparine

(Cleavers)

|

A

arable fields, moist areas, disturbed sites (16, 19)

|

7-9 (14, 19)

|

L = D (14)

|

|

5 (50 %) (19)

6 (100 %) (18)

|

cold stratification (1, 18, 19) germination not affected by irradiance (18, 19) light inhibits germination (1) no special treatments (6, 14)

|

PRE & POST (6, 28)

|

A

|

32

|

|

Galium mollugo

(Hedge Bedstraw)

|

Ρ

hedgebanks, open areas (8)

|

7

(29)

|

L = D (14)

|

2

(29)

|

|

no special treatments

(5, 14, 22, 24, 26, 29)

|

POST (5, 22, 24, 26)

|

A

|

|

|

SCROPHULARIACEAE

Digitalis purpurea

(Foxglove)

|

Β, Ρ hedgerows, open areas (16, 19)

|

0,1 -0,6 (4, 14, 19)

|

L = D (14)

|

0

(4, 19)

|

6 (50 %) (19)

8 (99 %) (18)

|

germination inhibited by darkness (1, 17-19) no special treatments (4, 22-26)

|

POST (4, 22 — 26)

|

D, G, F

|

|

|

Veronica persica

(Speedwell)

|

A

arable fields, open areas, disturbed sites (16, 19)

|

0,5-0,6 (14, 19)

|

L = D (14)

|

0 (19)

|

3(19)

5 (96 %) (18)

|

germination inhibited by darkness (18, 19) cold stratification (18) no special treatments (14)

|

PRE & POST (28)

|

A

|

32

|

Seed Suppliers Cited

|

Supplier ID

|

Supplier Information

|

|

A

|

|

Herbiseed

|

|

New Farm, Mire Lane, West End, Twyford RG10 0NJ ENGLAND +44 (0) 1189 349 464

|

|

www. herbiseed.com

|

|

|

B

|

|

Tropilab Inc.

|

|

8240 Ulmerton Road, Largo, FL 33771-3948 USA

|

|

(727) 344 - 4050

|

|

www.tropilab.com

|

|

|

C

|

|

Pterophylla — Native Plants & Seeds

|

|

#316 Regional Road 60, RR#1, Walsingham, ON N0E 1X0 CANADA (519) 586 - 3985

|

|

|

D

|

|

Applewood Seed Co.

|

|

5380 Vivian St., Arvada, CO 80002 USA (303) 431 - 7333

|

|

www.applewoodseed.com

|

|

|

E

|

|

Ernst Conservation Seeds

|

|

9006 Mercer Pike, Meadville, PA 16335 USA

|

|

(800) 873 - 3321

|

|

www.ernstseed.com

|

|

|

F

|

|

Chiltern Seeds

|

|

Bortree Stile, Ulverston, Cumbria LA12 7PB ENGLAND

|

|

+44 1229 581137

|

|

www.chiltemseeds.co.uk

|

|

|

G

|

|

Thompson & Morgan

|

|

P.O. Box 1051, Fort Erie, ON L2A 6C7 CANADA (800) 274 - 7333

|

|

www.thompson-morgan.com

|

|

REFERENCES CITED

|

(1)

|

Baskin, C.C. & Baskin, J.M. 1998. Seeds. Academic Press, Toronto

|

|

(2)

|

Blackburn, L.G. & Boutin, C. 2003. Subtle effects of herbicide use in the context of genetically modified crops: a case study with glyphosate (Round-Up®). Ecotoxicology, 12:271-285.

|

|

(3)

|

Boutin, C., Lee, H-B., Peart, T., Batchelor, P.S., & Maguire, R.J. 2000. Effects of the sulfonylurea herbicide metsulfuron methyl on growth and reproduction of five wetland and terrestrial plant species. Environmental Toxicology & Chemistry, 19(10):2532-2541.

|

|

(4)

|

Boutin, C., Elmegaard, N., & Kjaer, C. 2004. Toxicity testing of fifteen non-crop plant species with six herbicides in a greenhouse experiment: implications for risk assessment. Ecotoxicology, 13:349-369.

|

|

(5)

|

Breeze, V., Thomas, G., & Butler, R. 1992. Use of a model and toxicity data to predict the risks to some wild plant species from drift of four herbicides. Annals of Applied Biology, 121:669-677.

|

|

(6)

|

Brown, R.A., & Farmer, D. 1991. Track-sprayer and glasshouse techniques for terrestrial plant bioassays with pesticides. In: Plants for toxicity assessment: 2nd volume. ASTM STP 1115, J.W. Gorsuch, W.R. Lower, W. Wang, & M.A. Lewis, eds. American Society for Testing & Materials, Philadelphia. pp 197 - 208.

|

|

(7)

|

Buhler, D.D. & Hoffman, M.L. 1999. Anderson's guide to practical methods of propagating weeds and other plants. Weed Science Society of America, Lawrence, K.

|

|

(8)

|

Clapham, A.R., Tutin, T.G., & Warburg, E.F. 1981. Excursion flora of the British Isles, 3rd ed. Cambridge University Press, Cambridge

|

|

(9)

|

Clay, P.A. & Griffin, J.L. 2000. Weed seed production and seedling emergence response to late-season glyphosate applications. Weed Science, 48:481-486.

|

|

(10)

|

Cole, J.F.H. & Canning, L. 1993. Rationale for the choice of species in the regulatory testing of the effects of pesticides on terrestrial non-target plants. BCPC — Weeds. pp. 151 - 156.

|

|

(11)

|

Fiely, M. (Ernst Conservation Seeds). 2004. Personal communication. (www.ernstseed.com)

|

|

(12)

|

Fletcher, J.S., Johnson, F.L., & McFarlane, J.C. 1990. Influence of greenhouse versus field testing and taxonomic differences on plant sensitivity to chemical treatment. Environmental Toxicology & Chemistry, 9:769-776.

|

|

(13)

|

Fletcher, J.S., Pfleeger, T.G., Ratsch, H.C., & Hayes, R. 1996. Potential impact of low levels of chlorsulfuron and other herbicides on growth and yield of nontarget plants. Environmental Toxicology & Chemistry, 15(7):1189-1196.

|

|

(14)

|

Flynn, S., Turner, R.M., and Dickie, J.B. 2004. Seed Information Database (release 6.0, Oct 2004) Royal Botanic Gardens, Kew (www.rbgkew.org.uk/data/sid)

|

|

(15)

|

Franzaring, J., Kempenaar, C., & van der Eerden, L.J.M. 2001. Effects of vapours of chlorpropham and ethofumesate on wild plant species. Environmental Pollution, 114:21-28.

|

|

(16)

|

Gleason, H.A. & Cronquist, A. 1991. Manual of vascular plants of northeastern United States and adjacent Canada, 2nd ed. New York Botanical Garden, Bronx, NY

|

|

(17)

|

Grime, J.P. 1981. The role of seed dormancy in vegetation dynamics. Annals of Applied Biology, 98:555-558.

|

|

(18)

|

Grime, J.P., Mason, G., Curtis, A.V., Rodman, J., Band, S.R., Mowforth, M.A.G., Neal, A.M., & Shaw, S. 1981. A comparative study of germination characteristics in a local flora. Journal of Ecology, 69:1017-1059.

|

|

(19)

|

Grime, J.P., Hodgson, J.G., & Hunt, R. 1988. Comparative plant ecology: a functional approach to common British species. Unwin Hyman Ltd., London

|

|

(20)

|

Kjaer, C. 1994. Sublethal effects of chlorsulfuron on black bindweed (Polygonum convolvulus L.). Weed Research, 34:453-459.

|

|

(21)

|

Klingaman, T.E., King, C.A., & Oliver, L.R. 1992. Effect of application rate, weed species, and weed stage of growth on imazethapyr activity. Weed Science, 40:227-232.

|

|

(22)

|

Marrs, R.H., Williams, C.T., Frost, A.J., & Plant, R.A. 1989. Assessment of the effects of herbicide spray drift on a range of plant species of conservation interest. Environmental Pollution, 59:71-86.

|

|

(23)

|

Marrs, R.H., Frost, A.J., & Plant, R.A. 1991. Effects of herbicide spray drift on selected species of nature conservation interest: the effects of plant age and surrounding vegetation structure. Environmental Pollution, 69:223-235.

|

|

(24)

|

Marrs, R.H., Frost, A.J., & Plant, R.A. 1991. Effects of mecoprop drift on some plant species of conservation interest when grown in standardized mixtures in microcosms. Environmental Pollution, 73:25-42.

|

|

(25)

|

Marrs, R.H., Frost, A.J., Plant, R.A., & Lunnis, P. 1993. Determination of buffer zones to protect seedlings of non-target plants from the effects of glyphosate spray drift. Agriculture, Ecosystems, & Environment, 45:283-293.

|

|

(26)

|

Marrs, R.H. & Frost, A.J. 1997. A microcosm approach to detection of the effects of herbicide spray drift in plant communities. Journal of Environmental Management, 50:369-388.

|

|

(27)

|

Marshall, E.J.P. & Bernie, J.E. 1985. Herbicide effects on field margin flora. BCPC — Weeds. pp. 1021-1028.

|

|

(28)

|

McKelvey, R.A., Wright, J.P., & Honegger, J.L. 2002. A comparison of crop and non-crop plants as sensitive species for regulatory testing. Pest Management Science, 58:1161-1174.

|

|

(29)

|

Morton, S. (Herbiseed). 2004. Personal communication. (http://www.herbiseed.com)

|

|

(30)

|

USDA, NRCS. 2004. The Plants Database, version 3.5. (http://plants.usda.gov). National Plant Data Centre, Baton Rouge, LA 70874-4490 USA

|

|

(31)

|

USEPA. 1999. One-Liner Database. [U.S. E.P.A./Office of Pesticide Programs/Environmental Fate and Effects Division/Environmental Epidemiology Branch].

|

|

(32)

|

Webster, R.H. 1979. Technical Report No. 56: Growing weeds from seeds and other propagules for experimental purposes. Agricultural Research Council Weed Research Organization, Oxford.

|

|

(33)

|

White, A. L. & Boutin, C. (National Wildlife Research Centre, Environment Canada). 2004. Personal communication.

|

|

(34)

|

Zwerger, P. & Pestemer, W. 2000. Testing the phytotoxic effects of herbicides on higher terrestrial non-target plants using a plant life-cycle test. Z. PflKrankh. PflSchutz, Sonderh., 17:711-718.

|

Appendix 4

Examples for appropriate growth conditions for certain crop species

The following conditions have been found suitable for 10 crop species, and can be used as a guidance for tests in growth chambers with certain other species as well:

|

|

Carbon dioxide concentration: 350 ± 50 ppm;

|

|

|

Relative humidity: 70 ± 5 % during light periods and 90 ± 5 % during dark periods;

|

|

|

Temperature: 25 ± 3 °C during the day, 20 ± 3 °C during the night;

|

|

|

Photoperiod: 16 hour light/8 hour darkness, assuming an average wavelength of 400 to 700 nm;

|

|

|

Light: luminance of 350 ± 50 μE/m2/s, measured at the top of the canopy.

|

The crop species are:

|

—

|

tomato (Solanum lycopersicon);

|

|

—

|

cucumber (Cucumis sativus);

|

|

—

|

lettuce (Lactuca sativa);

|

|

—

|

cabbage (Brassica oleracea var. capitata);

|

|

—

|

carrot (Daucus carota);

|

|

—

|

perennial ryegrass (Lolium perenne);

|

C.32. ENCHYTRAEID REPRODUCTION TEST

INTRODUCTION

|

1.

|

This test method is equivalent to OECD test guideline (TG) 220 (2004). It is designed to be used for assessing the effects of chemicals on the reproductive output of the enchytraeid worm, Enchytraeus albidus Henle 1873, in soil. It is based principally on a method developed by the Umweltbundesamt, Germany (1) that has been ring-tested (2). Other methods for testing the toxicity of chemicals to Enchytraeidae and earthworms have also been considered (3)(4)(5)(6)(7)(8).

|

INITIAL CONSIDERATIONS

|

2.

|

Soil-dwelling annelids of the genus Enchytraeus are ecologically relevant species for ecotoxicological testing. Whilst enchytraeids are often found in soils containing earthworms it is also true that they are often abundant in many soils where earthworms are absent. Enchytraeids can be used in laboratory tests as well as in semi-field and field studies. From a practical point of view, many Enchytraeus species are easy to handle and breed, and their generation time is significantly shorter than that of earthworms. The duration for a reproduction test with enchytraeids is therefore only 4-6 weeks while for earthworms (Eisenia fetida) it is 8 weeks.

|

|

3.

|

Basic information on the ecology and ecotoxicology of enchytraeids in the terrestrial environment can be found in (9)(10)(11)(12).

|

PRINCIPLE OF THE TEST

|

4.

|

Adult enchytraeid worms are exposed to a range of concentrations of the test chemical mixed into an artificial soil. The test can be divided into two steps: (a) a range-finding test, in case no sufficient information is available, in which mortality is the main endpoint assessed after two weeks exposure and (b) a definitive reproduction test in which the total number of juveniles produced by parent animal and the survival of parent animals are assessed. The duration of the definitive test is six weeks. After the first three weeks, the adult worms are removed and morphological changes are recorded. After an additional three weeks, the number of offspring, hatched from the cocoons produced by the adults, is counted. The reproductive output of the animals exposed to the test chemical is compared to that of the control(s) in order to determine (i) the no observed effect concentration (NOEC) and/or (ii) ECx (e.g. EC10, EC50) by using a regression model to estimate the concentration that would cause a x % reduction in reproductive output. The test concentrations should bracket the ECx (e.g. EC10, EC50) so that the ECx then comes from interpolation rather than extrapolation.

|

INFORMATION ON THE TEST CHEMICAL

|

5.

|

The water solubility, the log Kow, the soil water partition coefficient (e.g. Chapter C.18 or C.19 of this Annex) and the vapour pressure of the test chemical should preferably be known. Additional information on the fate of the test chemical in soil, such as the rates of photolysis and hydrolysis is desirable.

|

|

6.

|

This test method can be used for water soluble or insoluble chemicals. However, the mode of application of the test chemical will differ accordingly. The test method is not applicable to volatile chemicals, i.e. chemicals for which the Henry's constant or the air/water partition coefficient is greater than one, or chemicals for which the vapour pressure exceeds 0,0133 Pa at 25 °C.

|

VALIDITY OF THE TEST

|

7.

|

For the test to be valid, the following performance criteria should be met in the controls:

|

—

|

adult mortality should not exceed 20 % at the end of the range-finding test and after the first three weeks of the reproduction test.

|

|

—

|

assuming that 10 adults per vessel were used in setting up the test, an average of at least 25 juveniles per vessel should have been produced at the end of the test.

|

|

—

|

the coefficient of variation around the mean number of juveniles should not be higher than 50 % at the end of the reproduction test.

|

Where a test fails to meet the above validity criteria the test should be terminated unless a justification for proceeding with the test can be provided. The justification should be included in the test report.

|

REFERENCE CHEMICAL

|

8.

|

A reference chemical should be tested either at regular intervals or possibly included in each test to verify that the response of the test organisms has not changed significantly over time. A suitable reference chemical is carbendazim, which has been shown to affect survival and reproduction of enchytraeids (13)(14), or other chemicals whose toxicity data are well known could be also used. A formulation of carbendazim known by the trade name of Derosal™ supplied by AgrEvo Company (Frankfurt, Germany) and containing 360 g/l (32,18 %) active ingredient was used in a ring-test (2). The EC50 for reproduction determined in the ring test was in the range of 1,2 ± 0,8 mg active ingredient (a.i) /kg dry mass (2). If a positive toxic standard is included in the test series, one concentration is used and the number of replicates should be the same as that in the controls. For carbendazim, the testing of 1,2 mg a.i./kg dry weight (tested as a liquid formulation) is recommended.

|

DESCRIPTION OF THE TEST

Equipment

|

9.

|